To obtain the exact values of the theoretical weight of steel pipes of round, rectangular, square cross-section, use the GOST pipe weight table.

To obtain the exact values of the theoretical weight of steel pipes of round, rectangular, square cross-section, use the GOST pipe weight table.

- GOST 8639-82 — Square steel pipes

- GOST 8645-82 — Rectangular steel pipes

- GOST 10704-91 — Electric-welded longitudinal pipes

Electric-welded pipes: classification of materials

Rolled steel pipes, depending on the shape, are presented in two versions:

- round;

- square.

Pipelines are classified according to such a criterion as purpose. They have the following purposes:

- Water and gas pipelines with high internal cross-sections.

- Electric welded. Their use is associated with the laying of main communications. This type of product is divided into straight-seam and spiral-shaped.

Pipes with straight seams appeared quite a long time ago, but have found their active use in the construction of pipelines.

Pipelines are used not only in the field of water and gas pipelines, but also in the field of furniture production, the construction industry for the installation of frame-shaped structures, and for the construction of fences.

Depending on the quality of the products, they are divided into 4 main criteria: A, B, C and D. Each group has corresponding characteristics. Pipes of group A are characterized only by control of the mechanical composition from which the product is made. Group B includes products that have a standardized chemical composition, and category B includes comprehensive control. The indicators of mechanical and chemical compounds are controlled, which allows us to obtain high-quality products. Products that belong to group D additionally undergo hydraulic tests.

When producing pipes, thickness deviations not exceeding 15% are allowed.

Pipelines are divided into 2 accuracy classes. They come in the following classes:

- First grade. Products undergo processing in which burrs are removed from the end parts.

- Second class. These products are not subject to deburring treatment.

The products in question are produced in various lengths, which range from 4 to 12.6 m. When calculating the weight of the products in question, one important factor is taken into account - this is the dependence of the weight of the product not only on the length, but also on the size of the walls.

Profile pipe weight

| Pipe size | Shelf dimensions A, mm | Shelf dimensions B, mm | Metal thickness S, mm | Weight m/p, kg | Number of meters in tons |

| 15×10×1 | 15 | 10 | 1 | 0.348 | 2873.56 |

| 15×10×1.5 | 15 | 10 | 1.5 | 0.488 | 2049.18 |

| 15×10×2 | 15 | 10 | 2 | 0.605 | 1652.89 |

| 20×10×1 | 20 | 10 | 1 | 0.426 | 2347.42 |

| 20×10×1.5 | 20 | 10 | 1.5 | 0.605 | 1652.89 |

| 20×10×2 | 20 | 10 | 2 | 0.762 | 1312.34 |

| 20×15×1 | 20 | 15 | 1 | 0.505 | 1980.2 |

| 20×15×1.5 | 20 | 15 | 1.5 | 0.723 | 1383.13 |

| 20×15×2 | 20 | 15 | 2 | 0.919 | 1088.14 |

| 20×15×2.5 | 20 | 15 | 2.5 | 1.09 | 917.43 |

| 25×10×1 | 25 | 10 | 1 | 0.505 | 1980.2 |

| 25×10×1.5 | 25 | 10 | 1.5 | 0.723 | 1383.13 |

| 25×10×2 | 25 | 10 | 2 | 0.919 | 1088.14 |

| 25×10×2.5 | 25 | 10 | 2.5 | 1.09 | 917.43 |

| 25×15×1 | 25 | 15 | 1 | 0.583 | 1715.27 |

| 25×15×1.5 | 25 | 15 | 1.5 | 0.841 | 1189.06 |

| 25×15×2 | 25 | 15 | 2 | 1.08 | 925.93 |

| 25×15×2.5 | 25 | 15 | 2.5 | 1.29 | 775.19 |

| 28×25×1.5 | 28 | 25 | 1.5 | 1.15 | 869.57 |

| 28×25×2 | 28 | 25 | 2 | 1.49 | 671.14 |

| 28×25×2.5 | 28 | 25 | 2.5 | 1.8 | 555.56 |

| 30×10×1 | 30 | 10 | 1 | 0.583 | 1715.27 |

| 30×10×1.5 | 30 | 10 | 1.5 | 0.841 | 1189.06 |

| 30×10×2 | 30 | 10 | 2 | 1.08 | 925.93 |

| 30×10×2.5 | 30 | 10 | 2.5 | 1.29 | 775.19 |

| 30×10×3 | 30 | 10 | 3 | 1.48 | 675.68 |

| 30×15×1 | 30 | 15 | 1 | 0.661 | 1512.86 |

| 30×15×1.5 | 30 | 15 | 1.5 | 0.959 | 1042.75 |

| 30×15×2 | 30 | 15 | 2 | 1.23 | 813.01 |

| 30×15×2.5 | 30 | 15 | 2.5 | 1.48 | 675.68 |

| 30×15×3 | 30 | 15 | 3 | 1.71 | 584.8 |

| 30×20×1 | 30 | 20 | 1 | 0.74 | 1351.35 |

| 30×20×1.5 | 30 | 20 | 1.5 | 1.08 | 925.93 |

| 30×20×2 | 30 | 20 | 2 | 1.39 | 719.42 |

| 30×20×2.5 | 30 | 20 | 2.5 | 1.68 | 595.24 |

| 30×20×3 | 30 | 20 | 3 | 1.95 | 512.82 |

| 35×15×1.5 | 35 | 15 | 1.5 | 1.08 | 925.93 |

| 35×15×2 | 35 | 15 | 2 | 1.39 | 719.42 |

| 35×15×2.5 | 35 | 15 | 2.5 | 1.68 | 595.24 |

| 35×15×3 | 35 | 15 | 3 | 1.95 | 512.82 |

| 35×15×3.5 | 35 | 15 | 3.5 | 2.2 | 454.55 |

| 35×20×1.5 | 35 | 20 | 1.5 | 1.19 | 840.34 |

| 35×20×2 | 35 | 20 | 2 | 1.55 | 645.16 |

| 35×20×2.5 | 35 | 20 | 2.5 | 1.88 | 531.91 |

| 35×20×3 | 35 | 20 | 3 | 2.19 | 456.62 |

| 35×20×3.5 | 35 | 20 | 3.5 | 2.47 | 404.86 |

| 35×25×1.5 | 35 | 25 | 1.5 | 1.31 | 763.36 |

| 35×25×2 | 35 | 25 | 2 | 1.7 | 588.24 |

| 35×25×2.5 | 35 | 25 | 2.5 | 2.07 | 483.09 |

| 35×25×3 | 35 | 25 | 3 | 2.42 | 413.22 |

| 35×25×3.5 | 35 | 25 | 3.5 | 2.75 | 363.64 |

| 40×15×2 | 40 | 15 | 2 | 1.55 | 645.16 |

| 40×15×2.5 | 40 | 15 | 2.5 | 1.88 | 531.91 |

| 40×15×3 | 40 | 15 | 3 | 2.19 | 456.62 |

| 40×15×3.5 | 40 | 15 | 3.5 | 2.47 | 404.86 |

| 40×15×4 | 40 | 15 | 4 | 2.73 | 366.3 |

| 40×20×2 | 40 | 20 | 2 | 1.7 | 588.24 |

| 40×20×2.5 | 40 | 20 | 2.5 | 2.07 | 483.09 |

| 40×20×3 | 40 | 20 | 3 | 2.42 | 413.22 |

| 40×20×3.5 | 40 | 20 | 3.5 | 2.75 | 363.64 |

| 40×20×4 | 40 | 20 | 4 | 3.05 | 327.87 |

| 40×25×1.5 | 40 | 25 | 1.5 | 1.43 | 699.3 |

| 40×25×2 | 40 | 25 | 2 | 1.86 | 537.63 |

| 40×25×2.5 | 40 | 25 | 2.5 | 2.27 | 440.53 |

| 40×25×3 | 40 | 25 | 3 | 2.66 | 375.94 |

| 40×25×3.5 | 40 | 25 | 3.5 | 3.02 | 331.13 |

| 40×25×4 | 40 | 25 | 4 | 3.36 | 297.62 |

| 40×28×2 | 40 | 28 | 2 | 1.95 | 512.82 |

| 40×28×2.5 | 40 | 28 | 2.5 | 2.39 | 418.41 |

| 40×30×2 | 40 | 30 | 2 | 2.02 | 495.05 |

| 40×30×2.5 | 40 | 30 | 2.5 | 2.47 | 404.86 |

| 40×30×3 | 40 | 30 | 3 | 2.89 | 346.02 |

| 40×30×3.5 | 40 | 30 | 3.5 | 3.3 | 303.03 |

| 40×30×4 | 40 | 30 | 4 | 3.68 | 271.74 |

| 42×20×2 | 42 | 20 | 2 | 1.77 | 564.97 |

| 42×20×2.5 | 42 | 20 | 2.5 | 2.15 | 465.12 |

| 42×20×3 | 42 | 20 | 3 | 2.52 | 396.83 |

| 42×20×3.5 | 42 | 20 | 3.5 | 2.86 | 349.65 |

| 42×20×4 | 42 | 20 | 4 | 3.17 | 315.46 |

| 42×30×2 | 42 | 30 | 2 | 2.08 | 480.77 |

| 42×30×2.5 | 42 | 30 | 2.5 | 2.54 | 393.7 |

| 42×30×3 | 42 | 30 | 3 | 2.99 | 334.45 |

| 42×30×3.5 | 42 | 30 | 3.5 | 3.41 | 293.26 |

| 42×30×4 | 42 | 30 | 4 | 3.8 | 263.16 |

| 45×20×2 | 45 | 20 | 2 | 1.86 | 537.63 |

| 45×20×2.5 | 45 | 20 | 2.5 | 2.27 | 440.53 |

| 45×20×3 | 45 | 20 | 3 | 2.66 | 375.94 |

| 45×20×3.5 | 45 | 20 | 3.5 | 3.02 | 331.13 |

| 45×20×4 | 45 | 20 | 4 | 3.36 | 297.62 |

| 45×30×2 | 45 | 30 | 2 | 2.17 | 460.83 |

| 45×30×2.5 | 45 | 30 | 2.5 | 2.66 | 375.94 |

| 45×30×3 | 45 | 30 | 3 | 3.13 | 319.49 |

| 45×30×3.5 | 45 | 30 | 3.5 | 3.57 | 280.11 |

| 45×30×4 | 45 | 30 | 4 | 3.99 | 250.63 |

| 50×25×2 | 50 | 25 | 2 | 2.17 | 460.83 |

| 50×25×2.5 | 50 | 25 | 2.5 | 2.66 | 375.94 |

| 50×25×3 | 50 | 25 | 3 | 3.13 | 319.49 |

| 50×25×3.5 | 50 | 25 | 3.5 | 3.57 | 280.11 |

| 50×25×4 | 50 | 25 | 4 | 3.99 | 250.63 |

| 50×30×2 | 50 | 30 | 2 | 2.32 | 431.03 |

| 50×30×2.5 | 50 | 30 | 2.5 | 2.86 | 349.65 |

| 50×30×3 | 50 | 30 | 3 | 3.36 | 297.62 |

| 50×30×3.5 | 50 | 30 | 3.5 | 3.85 | 259.74 |

| 50×30×4 | 50 | 30 | 4 | 4.3 | 232.56 |

| 50×35×2 | 50 | 35 | 2 | 2.49 | 401.61 |

| 50×35×2.5 | 50 | 35 | 2.5 | 3.09 | 323.62 |

| 50×35×3 | 50 | 35 | 3 | 3.6 | 277.78 |

| 50×35×3.5 | 50 | 35 | 3.5 | 4.12 | 242.72 |

| 50×35×4 | 50 | 35 | 4 | 4.62 | 216.45 |

| 50×40×2 | 50 | 40 | 2 | 2.65 | 377.36 |

| 50×40×2.5 | 50 | 40 | 2.5 | 3.25 | 307.69 |

| 50×40×3 | 50 | 40 | 3 | 3.83 | 261.1 |

| 50×40×3.5 | 50 | 40 | 3.5 | 4.39 | 227.79 |

| 50×40×4 | 50 | 40 | 4 | 4.93 | 202.84 |

| 60×25×2.5 | 60 | 25 | 2.5 | 3.05 | 327.87 |

| 60×25×3 | 60 | 25 | 3 | 3.6 | 277.78 |

| 60×25×3.5 | 60 | 25 | 3.5 | 4.12 | 242.72 |

| 60×25×4 | 60 | 25 | 4 | 4.62 | 216.45 |

| 60×25×5 | 60 | 25 | 5 | 5.55 | 180.18 |

| 60×30×2.5 | 60 | 30 | 2.5 | 3.25 | 307.69 |

| 60×30×3 | 60 | 30 | 3 | 3.83 | 261.1 |

| 60×30×3.5 | 60 | 30 | 3.5 | 4.39 | 227.79 |

| 60×30×4 | 60 | 30 | 4 | 4.93 | 202.84 |

| 60×30×5 | 60 | 30 | 5 | 5.94 | 168.35 |

| 60×40×3 | 60 | 40 | 3 | 4.3 | 232.56 |

| 60×40×3.5 | 60 | 40 | 3.5 | 4.94 | 202.43 |

| 60×40×4 | 60 | 40 | 4 | 5.56 | 179.86 |

| 60×40×5 | 60 | 40 | 5 | 6.73 | 148.59 |

| 70×30×3 | 70 | 30 | 3 | 4.3 | 232.56 |

| 70×30×3.5 | 70 | 30 | 3.5 | 4.94 | 202.43 |

| 70×30×4 | 70 | 30 | 4 | 5.56 | 179.86 |

| 70×30×5 | 70 | 30 | 5 | 6.73 | 148.59 |

| 70×30×6 | 70 | 30 | 6 | 7.8 | 128.21 |

| 70×40×3 | 70 | 40 | 3 | 4.78 | 209.21 |

| 70×40×3.5 | 70 | 40 | 3.5 | 5.49 | 182.15 |

| 70×40×4 | 70 | 40 | 4 | 6.19 | 161.55 |

| 70×40×5 | 70 | 40 | 5 | 7.51 | 133.16 |

| 70×40×6 | 70 | 40 | 6 | 8.75 | 114.29 |

| 70×50×3 | 70 | 50 | 3 | 5.25 | 190.48 |

| 70×50×3.5 | 70 | 50 | 3.5 | 6.04 | 165.56 |

| 70×50×4 | 70 | 50 | 4 | 6.82 | 146.63 |

| 70×50×5 | 70 | 50 | 5 | 8.3 | 120.48 |

| 70×50×6 | 70 | 50 | 6 | 9.69 | 103.2 |

| 70×50×7 | 70 | 50 | 7 | 10.99 | 90.99 |

| 80×40×3 | 80 | 40 | 3 | 5.25 | 190.48 |

| 80×40×3.5 | 80 | 40 | 3.5 | 6.04 | 165.56 |

| 80×40×4 | 80 | 40 | 4 | 6.82 | 146.63 |

| 80×40×5 | 80 | 40 | 5 | 8.3 | 120.48 |

| 80×40×6 | 80 | 40 | 6 | 9.69 | 103.2 |

| 80×40×7 | 80 | 40 | 7 | 10.99 | 90.99 |

| 80×50×3 | 80 | 50 | 3 | 5.72 | 174.83 |

| 80×50×3.5 | 80 | 50 | 3.5 | 6.59 | 151.75 |

| 80×50×4 | 80 | 50 | 4 | 7.44 | 134.41 |

| 80×60×3.5 | 80 | 60 | 3.5 | 7.14 | 140.06 |

| 80×60×4 | 80 | 60 | 4 | 8.07 | 123.92 |

| 80×60×5 | 80 | 60 | 5 | 9.87 | 101.32 |

| 80×60×6 | 80 | 60 | 6 | 11.57 | 86.43 |

| 80×60×7 | 80 | 60 | 7 | 13.19 | 75.82 |

| 90×40×3.5 | 90 | 40 | 3.5 | 6.59 | 151.75 |

| 90×40×4 | 90 | 40 | 4 | 7.44 | 134.41 |

| 90×40×5 | 90 | 40 | 5 | 9.08 | 110.13 |

| 90×40×6 | 90 | 40 | 6 | 10.63 | 94.07 |

| 90×40×7 | 90 | 40 | 7 | 12.09 | 82.71 |

| 90×50×3 | 90 | 50 | 3 | 6.19 | 161.55 |

| 90×60×4 | 90 | 60 | 4 | 8.7 | 114.94 |

| 90×60×5 | 90 | 60 | 5 | 10.65 | 93.9 |

| 90×60×6 | 90 | 60 | 6 | 12.51 | 79.94 |

| 90×60×7 | 90 | 60 | 7 | 14.29 | 69.98 |

| 100×40×4 | 100 | 40 | 4 | 8.07 | 123.92 |

| 100×40×5 | 100 | 40 | 5 | 9.87 | 101.32 |

| 100×40×6 | 100 | 40 | 6 | 11.57 | 86.43 |

| 100×40×7 | 100 | 40 | 7 | 13.19 | 75.82 |

| 100×50×4 | 100 | 50 | 4 | 8.7 | 114.94 |

| 100×50×5 | 100 | 50 | 5 | 10.65 | 93.9 |

| 100×50×6 | 100 | 50 | 6 | 12.51 | 79.94 |

| 100×50×7 | 100 | 50 | 7 | 14.29 | 69.98 |

| 100×70×4 | 100 | 70 | 4 | 9.96 | 100.4 |

| 100×70×5 | 100 | 70 | 5 | 12.22 | 81.83 |

| 100×70×6 | 100 | 70 | 6 | 14.4 | 69.44 |

| 100×70×7 | 100 | 70 | 7 | 16.48 | 60.68 |

| 110×40×4 | 110 | 40 | 4 | 8.7 | 114.94 |

| 110×40×5 | 110 | 40 | 5 | 10.65 | 93.9 |

| 110×40×6 | 110 | 40 | 6 | 12.51 | 79.94 |

| 110×40×7 | 110 | 40 | 7 | 14.29 | 69.98 |

| 110×50×4 | 110 | 50 | 4 | 9.33 | 107.18 |

| 110×50×5 | 110 | 50 | 5 | 11.44 | 87.41 |

| 110×50×6 | 110 | 50 | 6 | 13.46 | 74.29 |

| 110×50×7 | 110 | 50 | 7 | 15.38 | 65.02 |

| 110×60×4 | 110 | 60 | 4 | 9.96 | 100.4 |

| 110×60×5 | 110 | 60 | 5 | 12.22 | 81.83 |

| 110×60×6 | 110 | 60 | 6 | 14.4 | 69.44 |

| 110×60×7 | 110 | 60 | 7 | 16.48 | 60.68 |

| 120×40×5 | 120 | 40 | 5 | 11.44 | 87.41 |

| 120×40×6 | 120 | 40 | 6 | 13.46 | 74.29 |

| 120×40×7 | 120 | 40 | 7 | 15.38 | 65.02 |

| 120×40×8 | 120 | 40 | 8 | 17.22 | 58.07 |

| 120×60×5 | 120 | 60 | 5 | 13 | 76.92 |

| 120×60×6 | 120 | 60 | 6 | 15.34 | 65.19 |

| 120×60×7 | 120 | 60 | 7 | 17.58 | 56.88 |

| 120×60×8 | 120 | 60 | 8 | 19.73 | 50.68 |

| 120×80×5 | 120 | 80 | 5 | 14.58 | 68.59 |

| 120×80×6 | 120 | 80 | 6 | 17.22 | 58.07 |

| 120×80×7 | 120 | 80 | 7 | 19.78 | 50.56 |

| 120×80×8 | 120 | 80 | 8 | 22.25 | 44.94 |

| 140×60×3 | 140 | 60 | 3 | 9.02 | 110.86 |

| 140×60×5 | 140 | 60 | 5 | 14.58 | 68.59 |

| 140×60×6 | 140 | 60 | 6 | 17.22 | 58.07 |

| 140×60×7 | 140 | 60 | 7 | 19.78 | 50.56 |

| 140×60×8 | 140 | 60 | 8 | 22.25 | 44.94 |

| 140×80×5 | 140 | 80 | 5 | 16.15 | 61.92 |

| 140×80×6 | 140 | 80 | 6 | 19.11 | 52.33 |

| 140×80×7 | 140 | 80 | 7 | 21.98 | 45.5 |

| 140×80×8 | 140 | 80 | 8 | 24.76 | 40.39 |

| 140×120×6 | 140 | 120 | 6 | 22.88 | 43.71 |

| 140×120×7 | 140 | 120 | 7 | 26.37 | 37.92 |

| 140×120×8 | 140 | 120 | 8 | 29.78 | 33.58 |

| 140×120×9 | 140 | 120 | 9 | 33.1 | 30.21 |

| 150×60×7 | 150 | 60 | 7 | 20.88 | 47.89 |

| 150×80×6 | 150 | 80 | 6 | 20.05 | 49.88 |

| 150×80×7 | 150 | 80 | 7 | 23.08 | 43.33 |

| 150×80×8 | 150 | 80 | 8 | 26.01 | 38.45 |

| 150×80×9 | 150 | 80 | 9 | 28.86 | 34.65 |

| 150×80×10 | 150 | 80 | 10 | 31.62 | 31.63 |

| 150×100×6 | 150 | 100 | 6 | 21.93 | 45.6 |

| 150×100×7 | 150 | 100 | 7 | 25.28 | 39.56 |

| 150×100×8 | 150 | 100 | 8 | 28.53 | 35.05 |

| 150×100×9 | 150 | 100 | 9 | 31.69 | 31.56 |

| 150×100×10 | 150 | 100 | 10 | 34.76 | 28.77 |

| 160×130×8 | 160 | 130 | 8 | 33.55 | 29.81 |

| 180×80×7 | 180 | 80 | 7 | 26.37 | 37.92 |

| 180×80×8 | 180 | 80 | 8 | 29.78 | 33.58 |

| 180×80×9 | 180 | 80 | 9 | 33.1 | 30.21 |

| 180×80×10 | 180 | 80 | 10 | 36.33 | 27.53 |

| 180×80×12 | 180 | 80 | 12 | 42.52 | 23.52 |

| 180×100×8 | 180 | 100 | 8 | 32.29 | 30.97 |

| 180×100×9 | 180 | 100 | 9 | 35.93 | 27.83 |

| 180×100×10 | 180 | 100 | 10 | 39.47 | 25.34 |

| 180×100×12 | 180 | 100 | 12 | 46.29 | 42907 |

| 180×145×20 | 180 | 145 | 20 | 84.1 | 32813 |

| 180×150×8 | 180 | 150 | 8 | 38.57 | 25.93 |

| 180×150×9 | 180 | 150 | 9 | 42.99 | 23.26 |

| 180×150×10 | 180 | 150 | 10 | 47.32 | 21.13 |

| 180×150×12 | 180 | 150 | 12 | 55.71 | 17.95 |

| 190×120×12 | 190 | 120 | 12 | 51.94 | 19.25 |

| 196×170×18 | 196 | 170 | 18 | 88.99 | 45597 |

| 200×120×8 | 200 | 120 | 8 | 37.32 | 42973 |

| 230×100×8 | 230 | 100 | 8 | 38.57 | 25.93 |

Cast iron pipes and their features

When laying a water pipeline, it is important to take into account criteria such as the service life of the material, its strength, as well as weight and diameter. Cast iron pipelines have been used for laying water pipes for a long time, and today their main competitor is plastic. If we compare plastic and cast iron, the first option has more advantages, but is still inferior to the second in terms of strength, durability and reliability.

Unlike steel welding products, cast iron materials have much greater weight, which is due to the thickness of the walls of these products. To improve the quality of cast iron material, a mixture of spheroidal graphite is added to its composition. This made it possible to increase the strength, ductility and resistance of the material to cracking under the influence of negative aggressive environments.

The popularity of cast iron is due to the variety of its diameters, but even this factor does not help reduce the large weight of the material. To reduce weight, manufacturers reduce the length of pipes, causing the inconvenience of creating a large number of connections. However, this simplifies the installation process.

The main advantages of cast iron products include:

- Long service life of more than 100 years.

- Low accident rates.

- Resistance to physical and mechanical stress.

- Resistant to temperature changes.

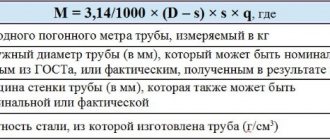

Knowing the characteristics of the two options for metal pipes, you need to understand the issue of measuring the weight of 1 meter of the product.

Specific gravity and features of its determination

Before you find out how much 1 meter of pipe weighs, you need to find out what specific gravity is. Specific gravity is the mass value of a pipe 1 linear meter long. This designation is convenient, as it makes it possible to calculate the weight of a round pipe or even entire batches.

To carry out the calculation, you will need to resort to finding out the following information:

- Determination of indicators of the external section of products.

- Product wall size.

- Length, which is an important parameter when determining weight.

- Steel grade. Knowing the steel grade, you can perform the most accurate weight calculation. For comparison, it is worth noting that cast iron products will weigh more than steel ones.

The above information is found in the accompanying documentation attached to the products, and is also obtained through independent measurements. To find out the total weight of the pipe, you first need to determine the specific gravity, after which the resulting value is multiplied by the length of the product. As a result, we have the total mass of the pipe. Below is a table showing the parameters of electric welded pipes and their specific gravity.

Determining the weight of an electric-welded pipe is an important event carried out during transportation, accounting and manufacturing of products. The weight of the seamless pipe is determined in order to determine the optimal transportation method. Knowing the weight of steel water and gas pipes, you can calculate the required number of connecting and fastening elements, supports and hangers.

Specific gravity. What is it and how to determine this indicator?

Specific gravity is an indicator that indicates the mass of one linear meter of pipe. This value is very convenient, as it allows you to very quickly determine the total mass of a part or an entire batch of pipes.

For calculations you will need the following information:

- indicator of the external cross-section of pipes;

- wall thickness;

- length;

- steel grade (for more accurate calculations).

To calculate the weight of one meter of pipe you need to know its outer diameter

All this data can be found in the relevant documentation that comes with the pipes, and you can also take measurements yourself. Each standard size has its own specific weight. This value is derived through certain calculations, after which it is multiplied by the length of the pipe and the total mass of the product is obtained.

Table 1

| Type of electric welded pipe (DN/wall thickness) | Theoretical specific gravity, kg |

| 630x10 | 152,9 |

| 426x10 | 102,6 |

| 89x5 | 10,36 |

| 159x6 | 22,64 |

| 530x7 | 90,29 |

| 57x3 | 4,0 |

| 114x3.5 | 9,54 |

| 325x10 | 77,68 |

| 102x4 | 9,67 |

| 630x8 | 122,7 |

| 159x4 | 15,29 |

| 377x6 | 54,9 |

| 377x7 | 63,87 |

| 325x6 | 47,2 |

| 127x4 | 12,13 |

| 426x9 | 92,56 |

| 219x8 | 41,63 |

| 159x5 | 18,99 |

| 426x6 | 82,46 |

| 76x4 | 7,1 |

| 273x8 | 52,28 |

| 114x5 | 13,44 |

| 325x5 | 39,46 |

| 108x4 | 10,26 |

| 426x7 | 72,3 |

| 89x3.5 | 7,38 |

The total mass of rolled metal is a very important characteristic that allows you to determine such points as:

- the amount of raw materials that must be spent on producing a batch;

- accounting and transportation.

When transporting pipes, it is necessary to know their weight, and the weight of the products appears in all accompanying documentation (accounting, warehouse, etc.). Therefore, determining the weight of 1 meter of electric welded pipe is a necessary measure.

Pipe weight is an important indicator for calculating transportation and installation costs

The total weight of rolled metal is necessary in order to determine how the products will be transported. In addition, this indicator is needed when buying and selling rolled metal products.

Features of identifying the specific gravity of steel pipes

A simple way to determine the weight of 1 m of pipe is to use an online calculator. However, there is not always a computer at hand in which automatic calculations can be made. The second option for determining the weight of a metal structure is to weigh it. Weighing a pipe is a labor-intensive process, so the third option remains - calculating the mass of the pipe using the formula.

The weight of the products in question depends not only on 1 meter of material, but also on geometric data. The length of the device taken during calculations is 1 meter. The density of steel pipes is a constant value of 7850 kg/m3.

Calculations of the specific gravity of the product in question are determined by performing the following manipulations:

- View the weight of 1 meter of steel tube according to the table. This parameter is already pre-calculated according to GOST.

- Use mathematical values and determine the value of 1 linear meter of pipe using mathematical formulas.

Both methods provide only an approximate answer to the question. After all, to get the most accurate answer you will need the following important information:

- Exact steel grade. All types of brands differ from each other in density (from the normalized standard), so errors arise.

- Pipe shape and uniformity of thickness along the entire length. There is a thickening on the weld seam, the value of which is almost impossible to determine.

- Rounding. When making calculations, it is often necessary to use values that are rounded. Ultimately, this negatively affects the final result.

Tables for identifying the specific gravity of welded pipes are popular. Complex mathematical formulations are used to determine them. Often maximum accuracy is not needed, so table values are sufficient.

It often happens that even in a large tabular list there is no data for a specific product. If this happens, it is recommended to use the value closest to the available rolled metal parameters.

Alternative calculation

In order to calculate the weight of a steel pipe, we must calculate its volume and multiply the result by the specific density of the metal - 7800 kilograms/cubic meter. Moreover, only three methods can be used in the calculation process.

Calculation of weight based on volume difference

If you want to calculate the specific gravity of a steel round pipe without reference books, then you will have to use the method of calculating the difference in volumes.

It is implemented in the following way:

- At the first stage, we determine the volume of the cylinder inscribed within the external dimensions of the pipe. Simply put, we calculate the volume of an all-metal rod, the dimensions of which are equal to the external dimensions of the pipe. To do this, you need to calculate the area of a circle with a diameter equal to the outer diameter of the pipe and multiply it by the length of the measured segment of the product.

- At the second stage, we do essentially the same calculations. Our only goal will be to determine the volume of the hollow part of the pipe. To do this, you need to calculate the area of a circle with a diameter equal to the internal diameter of the pipe and multiply it by the length of the measured segment of the product.

- In the final, we subtract from the first result (the volume of the solid metal rod) the second result (the volume of the hollow part). The result of the calculations will be the volume of the pipe.

Calculation of pipe weight by outer and inner diameter

The weight of the product is determined by multiplying the volume of the pipe by the specific density of the steel.

The weight of a pipe with a profile section is calculated using the same formula. Only instead of the area of a circle, we calculate the area of a rectangle (all-metal and hollow).

Calculation of weight by calculating the volume of pipe development

In order to find out the specific gravity of a pipe - steel, cast iron or copper - it does not matter, you can use the calculation method based on the volume of the product. After all, any product is unfolded into a steel sheet, the volume of which is calculated even easier than the volume of the finished product. To do this, you simply need to multiply the perimeter (circumference) by the wall thickness and the length of the measured segment.

In practice, this method looks like this:

- The diameter or circumference of a pipe is measured.

- At the next stage, the wall thickness and length of the pipe section are measured

- Next, we multiply the diameter, thickness and length of the pipe. As a result, we get the volume of the sheet scan.

To calculate the weight of the pipe, we need to multiply the volume of the reamer by 7800 kg/m3 - the specific gravity of steel.

This option is good because you don’t need to spend a lot of time and effort on its implementation. After all, the volume of the development is calculated in one action, while the volume of the product is calculated in at least two actions. In addition, in the case of round pipes, this method will be preferable, because the circumference can be measured much more accurately than its diameter.

Weight calculation on a calculator

If such calculations cause difficulties, then in the process of searching for the result you can use a ready-made program - a calculator for calculating the weight of a linear meter of pipe. This software product is downloaded from the Internet, installed on a computer, launched, and by entering the geometric parameters, the weight of the measured segment of the product is obtained.

Moreover, to obtain the result, you need to enter into the program not only the diameter of the product, but also the thickness of the pipe wall. And in the case of determining the weight of a meter of rolled profiles, the computer can request the dimensions of each face: width/height and wall thickness.

Further calculations do not differ from the method in which the steel pipe weight table is used. After all, the calculator calculates the weight of a linear meter, which must be multiplied by the length of the measured segment and the result is in our pocket.