Seamless stainless steel pipe, manufactured in accordance with GOST 9941-81 from steel grade 12Х18Н10Т, is one of the most popular types of products of this type. The high popularity of seamless stainless steel pipes of this brand is explained by the wide versatility of their characteristics.

Pipe 12Х18Н10Т is made from the most popular grade of stainless steel

Such pipes can be successfully used to solve a wide range of problems related to the need to transport liquid and gaseous media. Thanks to the properties of 12Х18Н10Т steel, products made from it can be successfully operated under conditions of constant exposure to high pressure and high temperature, as well as in contact with chemically aggressive substances for a long time, without losing their original characteristics.

You can familiarize yourself with the GOST requirements for seamless stainless pipes by downloading the document in pdf format from the link below.

GOST 9941-81 Cold- and heat-deformed seamless pipes made of corrosion-resistant steel. Specifications

Types of seamless pipes made of steel grade 12Х18Н10Т

The requirements of GOST 9941-81 cover not only 12Х18Н10Т pipes, but also seamless tubular products manufactured by cold and warm deformation methods from other grades of general-purpose stainless steels. According to the provisions of the specified GOST, the range of such pipes consists of products whose outer diameter is in the range of 5–273 mm, and the walls have a thickness from two tenths to twenty-two mm. The requirements of GOST 9941-81 concern not only the geometric parameters of seamless stainless steel pipes, but also the technical characteristics of such products.

The permissible length of stainless pipes transferred to warehouses or consumers, which is also specified by GOST, is determined by their outer diameter and wall thickness.

Length requirements for stainless steel pipes

In the standard version, this parameter can be in the range of 4–7 m, but GOST 9941-81 also allows that seamless stainless steel pipes can be supplied to consumers in the following lengths.

- Pipes, the wall thickness of which does not exceed half a millimeter, have an unmeasured length. In this case, the minimum length of such pipes cannot be less than 0.75 m, and the maximum should not exceed the largest standard value.

- Pipe products with a wall thickness in the range of 0.5–1 mm are made of unmeasured length, the value of which does not exceed 1 meter and the maximum standard value.

- Pipes with a wall thickness of more than 1 mm have an unmeasured length, the length of which is in the range of 1.5–12.5 m.

- They also produce stainless steel pipes of measured length, the minimum value of which does not exceed the lengths of unmeasured products, and the maximum value does not exceed the maximum length specified by GOST. For pipe products whose length corresponds to this category, the maximum maximum deviation of this parameter should not exceed 15 mm. The regulatory document allows that the length of measuring pipes may be greater than the parameters specified by the standard, but for the production of such products a preliminary agreement between the manufacturer and the consumer is necessary.

- There are pipes with a length that is a multiple of the measured length, and the smallest value of such a multiple, in accordance with the provisions of GOST 9941-81, is 300 mm. When producing such pipe products, it is allowed to leave an allowance on each side of the cut, the value of which should not exceed 5 mm. In addition, the standard stipulates the maximum deviation from the full length of such products, which should not exceed +15 mm.

- If the consumer needs stainless pipes whose length exceeds 12.5 m, GOST allows the possibility of their production, but this must also be previously agreed with the manufacturer.

- Tubular products, the outer diameter of which does not exceed 25 mm, by agreement between the customer of such products and its manufacturer, can be produced with a length of up to 16 m.

Stainless steel boiler pipe KVD 57x4, length 6.5 meters

GOST 9941-81 classifies pipes 12Х18Н10Т and products made from other steel grades, not only according to their lengths and other geometric parameters, but also according to their degree of accuracy. Thus, seamless pipes made of stainless steel alloys can meet normal, high and increased precision.

The geometric parameters of seamless pipe products are associated with the maximum deviations of their wall thickness, as well as their outer diameter. GOST 9941-81 also regulates the amount of permissible curvature of rolled pipes of the seamless category, which, if measured on a pipe section 1 meter long, cannot exceed:

- 1 mm – for pipes of any diameter, the wall thickness of which is half a millimeter or more;

- 2 mm - for pipes with a wall thickness of less than half a millimeter and an outer diameter exceeding 15 mm.

Visual inspection of the pipe surface is one of the stages of quality control

For stainless steel seamless pipes with an outer diameter of less than 15 mm, the wall thickness of which does not exceed half a millimeter, such a parameter as the amount of permissible curvature is not specified in the standard. The only requirement is that there should be no sharp kinks on their surface.

The ends of seamless pipes, according to GOST 9941-81, must be cut strictly at an angle of 90°, and after such cutting they must be cleaned of burrs. When cleaning, roughness and chamfer may form on the surface of the pipes, the presence of which is allowed by the standard. The consumer of pipes whose wall thickness exceeds 5 mm, if necessary, can specify that their cut ends must be specially chamfered for welding.

General information

As you know, pipes are needed to transmit gas and liquid. Depending on what will be transported, the composition of the alloy, the dimensions of the product, and its design are determined. For example, when interacting with chemically active liquids, corrosion may occur, followed by destruction of rolled metal. The product must be ready for this in order to meet its objectives and reliability requirements.

The pipe in question is made of a special grade of steel 12Х18Н10Т, which belongs to the austenitic class. The material withstands:

- aggressive environmental influences;

- strong temperature changes;

- significant pressure surges.

They are also manufactured in our country . There are two types of such pipes:

- profile, with a square or rectangular cross-section - the electric welding method is used for production;

- round - produced by electric welding or seamless method.

The absence of seams allows you to extend service life by increasing strength . To receive apply:

- drawing;

- forging;

- pressing;

- rolling.

The quality must meet the requirements of GOST 9941–81. The document was adopted even before the collapse of the Soviet Union, but is still in force in many of its former republics. The products meet not only Russian requirements. The products are suitable for the same purposes in some other foreign countries. Due to their quality, the scope of application of GOST stainless steel pipes is extensive. It includes many industries:

- petrochemical;

- construction;

- chemical;

- gas;

- shipbuilding;

- metallurgical, etc.

In addition, such pipes are always needed for those jobs where increased strength is required. These can be either special production sites or civil construction sites.

Pipes of this type are sometimes used for other purposes:

- as blanks for the production of various parts;

- as a support or barrier, etc.

On sale you can find sizes suitable for various needs: from 6 × 1.0 mm to 325 × 12.0 mm. Depending on the thickness, such pipes are divided into the following types:

- lungs;

- ordinary;

- reinforced.

This is interesting: Foundation made of fiberglass reinforcement: reinforcement rules

Formula for calculating mass

The provisions of GOST 9941-81 do not contain precise information about how much one linear meter of seamless stainless pipe weighs. This is explained by the fact that the requirements of this standard cover a range of seamless pipes, for the manufacture of which about 20 grades of general purpose stainless steel can be used.

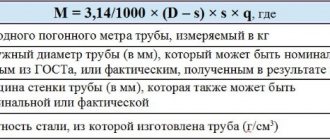

Meanwhile, this GOST presents a formula, using which you can easily determine the specific gravity of a pipe with certain geometric parameters.

Formula for calculating the mass of a linear meter of pipe

For convenience, GOST provides the density values of all steel grades from which pipes of this category are produced. In particular, for 12Х18Н10Т this parameter is 7.9 g/cm3. As an example, you can determine the weight of one linear meter of a seamless stainless steel pipe of a given grade:

M = 3.14/1000 × (50–4) × 4 × 7.9 = 4.56 kg.

Using the weight of one linear meter of stainless pipe, calculated using this formula, you can easily determine how much a product of a certain length will weigh. To do this, it is enough to multiply the resulting weight by the total length of the pipe.

Main characteristics

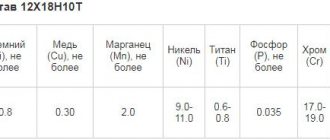

The chemical composition of the steel alloy 12Х18Н10Т, from which seamless pipes are made, is specified by the requirements of GOST number 5632. According to the provisions of this regulatory document, the composition of such steel (if it must have good weldability at the request of the customer) cannot contain more than 0.02% of such harmful impurities like sulfur. In accordance with the standard, the chemical composition of stainless steel of this grade may contain elements of the rare earth group in small quantities.

Characteristics of steel 12Х18Н10Т

Content of main chemical elements in alloy 12Х18Н10Т

Despite the fact that seamless rolled pipe must be subjected to heat treatment, GOST allows that it can be dispensed with, as well as without the surface lightening procedure. In such cases, it is necessary to additionally discuss with the consumer both the mechanical properties of the pipes and the permissible degree of curvature of their surface.

The high popularity of seamless pipes made of stainless steel alloy grade 12Х18Н10Т is explained by the fact that in terms of their mechanical properties and performance characteristics they are considered one of the best.

Technological features of steel

Mechanical properties, in particular, include the following parameters of a steel alloy of this grade:

- yield strength - at least 22 kgf/mm2 (216 MPa) (this parameter, very important for steels, characterizes the amount of stress upon reaching which the deformation processes occurring in the metal will continue to develop in it even without a subsequent increase in load);

- tensile strength – 56 kgf/mm2 (549 N/mm2);

- the relative elongation is at least 35%.

At customer's request, tensile tests on seamless stainless steel pipes can be carried out at 350°.

Physical properties of steel grade 12Х18Н10Т

Inside and outside of pipes made of stainless steel of the specified grade, there should be no defects such as cracks, films, flaws and sunsets. If they are discovered after inspection, then, according to the regulatory document, they can be eliminated using local stripping, turning and boring, local or continuous grinding. When performing such mechanical operations, it is important to ensure that the geometric parameters of the pipe, such as wall thickness and outer diameter, do not end up outside the deviations specified in GOST.

The provisions of the regulatory document also stipulate the color of seamless stainless steel pipes, which should be light. At the same time, individual pipe products of this category may have a matte surface, distinguished by a gray tint, which is due to the peculiarities of their production technology. The main part of pipes of this type is subjected to pickling in a vacuum or in a protective environment, which is carried out after heat treatment. This treatment (as mentioned above, optional) is performed in order to remove tarnish from the surface of the product.

Foreign analogues of steel grade 12Х18Н10Т

In accordance with the provisions of the regulatory document, seamless pipes made of steel alloy grade 12Х18Н10Т, at the request of consumers, can be subjected to additional tests for:

- flattening;

- distribution;

- ability to withstand hydraulic pressure.

In addition, a separate clause of the contract concluded between the manufacturer and the consumer may stipulate a requirement according to which the pipe material must be highly resistant to intergranular corrosion.

If seamless pipes made from a given steel alloy have not been subjected to heat treatment and have not been tested by flattening or expansion methods, then they are not tested for resistance to intergranular corrosion.

Alloying with other components

The steel of the presented grade, from which rolled pipes are produced, can be alloyed with other components. One of them is carbon. If it is determined in the structure of 0.1%, then upon heating from 900 ºС the structure becomes absolutely austenitic. When cooled, this component cannot have a significant effect on the material. Therefore, nickel and chromium provide austenitic qualities in this state.

Alloying with titanium eliminates the tendency for corrosion between crystals. This additive has strong carbide-forming properties. During crystallization, titanium bonds with carbon to form a strong carbide. This avoids the formation of chromium carbides. Otherwise, its amount in austenite would decrease.

Silicon is added to the alloy composition for the purpose of degassing it. Because of this, the steel becomes denser and stronger. Its yield threshold increases. But due to this additive, the elasticity of the material is somewhat reduced. This makes cold rolling more difficult.

The composition may include sulfur. It has limited solubility in solidified metal and unlimited in liquid. Along the contour of the grains in the solidifying metal, iron sulfides appear at the very end. They create a low-melting eutectic. In the presence of oxygen, the melt is produced at even lower temperatures.

In the layers of phases between the grains, which are enriched with sulfur, softening occurs when the material is heated. In this case, the metal loses its original properties. The steel begins to break down. Therefore, the amount of sulfur in the composition is strictly standardized.

Phosphorus, which is present in the composition, negatively affects the mechanical properties of steel. During the crystallization process, a very strong primary liquation appears. Because of this, the plastic properties of the material are reduced. This is especially noticeable at low temperatures.

Requirements of GOST 9940-81

Stainless steel alloy grade 12Х18Н10Т is also used for the production of seamless pipes in accordance with GOST 9940-81. According to this regulatory document, seamless tubular products are manufactured by hot deformation, for which general purpose stainless steels are used.

Seamless pipes, which are produced in accordance with GOST 9940-81, can have diameters in the range of 57–325 mm and wall thicknesses of 3.5–32 mm. The standard length of such pipes, which can meet normal and high degrees of accuracy, can range from 3 to 8.5 meters. The provisions of GOST 9940-81 also stipulate the remaining geometric parameters of pipes of this category, the physical and mechanical properties of the material from which they are made, the maximum permissible deviations in the curvature of the surface of the products, their outer diameter and wall thickness.

Permissible deviations in the geometric dimensions of pipes depend on the manufacturing accuracy

In terms of the requirements for the chemical composition of the material for manufacturing seamless stainless steel pipes, GOST 9940-81 differs little from the provisions of the previous regulatory document. The mass of pipes can be determined using the same method presented above.

The state standard number 9940-81 stipulates that seamless pipes made of stainless steel, depending on the wishes of the customer, may or may not be subjected to heat treatment and meet additional requirements for their resistance to intergranular corrosion. In addition, consumers of pipes of this type can additionally negotiate with their manufacturer the testing methods for such products, which are carried out according to the methods specified by the provisions of GOST 9941-81.

Stainless steel seamless pipe is used most often for transporting various types of liquids and gases

A significant difference between GOST 9940-81 and the standard number 9941-81 is that its requirements do not provide for mandatory heat treatment of seamless stainless steel pipes. This is explained by the fact that pipes that meet this standard, as mentioned above, are produced by hot deformation, and this already implies that the material for their manufacture has been subjected to significant thermal effects. The latter is necessary to facilitate plastic deformation of the pipe material and at the same time gives it the required physical and mechanical properties.

It should be noted that the differences in the characteristics of seamless stainless pipes produced in accordance with GOSTs 9940-81 and 9941-81 are precisely explained by different manufacturing technologies. Thus, seamless stainless steel pipes produced by hot deformation are distinguished by good ductility and flexibility, but have less strength and resistance to mechanical stress than cold- and heat-deformed ones. For example, you can compare the following parameters of pipes made of stainless steel alloy grade 12Х18Н10Т, produced in accordance with GOSTs 9940-81 and 9941-81:

Comparison of stainless pipes produced using different technologies

Due to their increased strength, seamless stainless pipes manufactured by cold and warm deformation methods, regardless of their geometric parameters, must withstand the rated load specified by the requirements of the regulatory document. This is precisely why pipe rolls of this category can be produced with smaller outer diameters and wall thicknesses than products manufactured in accordance with GOST 9940-81. Thus, if we compare cold- and heat-deformed pipes with hot-rolled products of the same outer diameter (273 mm), made of stainless steel grade 12Х18Н10Т, then the former can be produced with a wall thickness of 3–14 mm, while for the latter this parameter should be 11–20 mm. Moreover, the yield limits of such products, since they are made of the same grade of steel, completely coincide and amount to 22 kgf/mm2 (216 MPa).

From all of the above, we can conclude that cold- and heat-deformed seamless pipes made from steel grade 12Х18Н10Т are more appropriate to use in cases where high strength with low weight of pipe structures is required, and hot-rolled products will be optimal when properties are especially important are the flexibility and ductility of the pipes used.

general description

Stainless steel pipe 12Х18Н10Т is a rolled product that is used for transporting liquid and gaseous substances, including under high pressure or at high temperatures. Products of the presented type have a round cross-section and are produced using seamless technology. The main parameters of the presented rolled products are regulated by GOST 9941-81. It also indicates the main requirements for the production of cold or warm formed stainless steel pipes.

Steel 12Х18Н10Т is an austenitic type alloy containing titanium. For this material, the optimal processing mode is heating to 1050-1080ºС. Water is used during production. The steel undergoes a hardening procedure, which maximizes its toughness and elasticity. After this treatment, the material acquires strength and hardness.

Stainless steel pipe 12Х18Н10Т has two main advantages:

- high plasticity rates;

- significant level of impact strength.

The material can be alloyed with different metals. This gives the product certain performance properties. The main qualities of this material are relative elongation and tensile strength. They are installed with the required degree of approximation. It is worth noting that the reference information does not take into account data on the hardening of each type of alloy, as well as on pre-treatment.

From the presented variety of pipes, objects are made that are intended for use in environments containing dilute solutions of acetic, phosphoric, nitric acid, as well as alkalis or salts. In this case, the internal environment can be supplied under pressure and at temperatures up to 600 ºС.

Reasons for the popularity of 12Х18Н10Т pipes

Seamless pipes made from steel grade 12Х18Н10Т are in high demand. They are widely used in mechanical engineering, fuel, energy, food, chemical and other industries. The main reasons for this popularity lie in the physical and mechanical properties of this alloy, determined primarily by its chemical composition.

Stainless alloy grade 12Х18Н10Т is a material with an austenitic structure that belongs to the chromium-nickel steel category. According to the provisions of GOST, it is intended for operation in conditions of constant exposure to chemically aggressive environments and elevated temperatures.

Pipe 12Х18Н10Т has the best properties of stainless steel: easy to weld, non-magnetic and resistant to corrosion

If you decipher the markings of this steel alloy, it will become clear that it contains the following chemical elements: carbon - 0.12%, chromium - 17-19%, nickel - 9-11%, titanium - 5%. In addition, this grade of stainless steel also contains silicon (0.8%) and manganese (2%). Thanks to this balanced chemical composition, the steel alloy of this grade is distinguished not only by its high corrosion resistance, but also by its heat resistance and heat resistance.

In addition, the advantages of this grade of steel, from which seamless pipes are produced using various technologies, are:

- good weldability;

- the ability to perform processing using both hot and cold deformation methods.

Application area

The special chemical composition determines the scope of application of 12Х18Н10Т pipes. The steel alloy from which various communications are made has high resistance to intercrystalline corrosion. The material is not affected by salts, alkalis, acids, as well as atmospheric humidity and soil.

Pipes made from the presented alloy are resistant to aggressive environments, for example:

- nitric acid solution (65%) with a temperature of up to 85 ºС;

- sulfuric acid (100%) with temperatures up to 65 ºС;

- nitric acid solution (80%), heated to 65 ºС;

- composition of sulfuric (70%) and nitric (25%) acid with a temperature of up to 70 ºС;

- phosphoric acid solution (40%) heated to 100 ºС;

- strong alkalis;

- solutions of acetic, formic, citric and other organic acids.

It is possible to weld 12Х18Н10Т pipes, which allows them to be used in oil refining, chemical, food and other industries.

If gas is transported through a pipe made of the presented alloy, the temperature of the internal working environment should not exceed 550 ºС. In this case, the load on the system should be minimal. Often this type of pipe is used to create a homemade heat exchanger for a stove in a bathhouse or fireplace.

When the temperature of the internal environment increases to the maximum limit (800 ºС), a steel product of the presented type can be used for up to 10,000 hours. If the ambient temperature rises to 85 ºС or higher, scale will begin to form on the surface of the product. Most often, this type of pipe is used for:

- heat exchangers;

- elements of furnace fittings;

- retort;

- exhaust system manifolds and pipes;

- muffles;

- electrodes for spark spark plugs.

By maintaining certain operating conditions at a given level, it is possible to extend the service life of pipelines to 50-100 thousand operating hours.