- home

- Differences between seamless pipe and electric welded pipe

Seamless pipe

- one-piece metal structure without types of joints. There are several ways to make such structures:

- forging;

- pressing;

- rolling;

- drawing.

The product has increased strength, which is why it is often used in complex structures exposed to different environments. Products without a welded seam are divided into 2 classes:

- hot rolled;

- cold rolled.

Both products are made from the same grades of steel. The difference is that cold rolling helps to achieve better metal surface quality, as well as accuracy in geometry parameters. Hot rolled steel has higher productivity and the price of the final product will be lower.

Due to the high reliability of seamless products, solid rolled metal can be used in complex areas and machine construction industries. In particular, hot-rolled pipes are used in industrial applications. This type of rental is used when the loads on the product greatly exceed the permissible level for the welded type.

Electric welded pipe

- a sample with one seam running along the entire length, made of rolled sheets or strips by molding or welding.

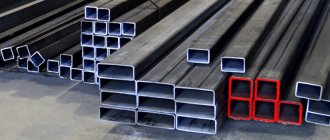

Rolled metal is divided into 4 types:

- straight-seam;

- spiral seam;

- water and gas pipeline;

- profile.

1. Straight seam type is made from metal strips welded at opposite ends, and formed by electric arc or high frequency welding.

2. Large diameter spiral weld type is produced by submerged arc welding.

3. In the production of water-gas electric-welded pipe samples, carbon steel is used as a raw material.

4. Profile products using the electric welding method are manufactured using various metals or alloys, as well as polymer materials.

The method of manufacturing electric-welded pipes is hot-rolled or cold-rolled.

This type has received a wide range of applications: construction, manufacturing of furniture, fences, cars, manufacturing of oil and gas pipelines, pipelines, and other economic/industrial areas.

Characteristics, scope of application of electric-welded pipes

The quality and reliability for which electric-welded pipes are especially valued determines the versatility of their use. This applies primarily to types with a round cross-section - they are used by construction organizations, industrial enterprises, used in the installation of pipelines, the production of furniture, various metal structures, and in the design of interiors of residential and commercial premises. Electric-welded pipes are also used as consumables in the manufacture of various types of products.

How popular the product is can be judged by the fact that it is found almost everywhere: in fencing areas and buildings, stair railings, canopies, canopies, stops, benches, etc. The quality is evidenced by the fact that they are widely used for the installation of pipelines through which aggressive liquids that are heated to high temperatures are transported.

Range and sizes

The assortment is determined by GOST 10704-91. For technical specifications, GOST 10705 is relevant. Steel grades 2PS or 3PS are used in production.

Dimensions established by GOST 10704-91

Compliance of a straight-seam pipe with GOST must be confirmed by a quality certificate.

Advantages and disadvantages

All the technological difficulties and costs in the production of straight- and spiral-seam types of products are incomparable with the efforts expended on the production of seamless ones. Hence the main advantage of electric welded products is cost.

Another undoubted advantage is its large diameter, which can even be 100 or more times the thickness of the walls. This makes it lighter and easier to transport.

The technology for manufacturing straight-seam pipes allows you to create both round and profile types of products (rectangular, square).

Some disadvantages are still present - according to GOST standards, welded pipes can withstand pressure much less than seamless ones. They also cannot be bent, and therefore, if you need to change the direction of a water or gas pipeline made from them, you cannot do without fittings.

Characteristics of seamless rolled metal according to GOST 8732-78

Used steel grades: st.20, 09g2s. The material is resistant to corrosion processes, has high strength and hardness, and is resistant to any climatic conditions.

- Length: from 4 to 12.5 m.

- Weight: up to 162 kg.

- Outer diameter: from 57 to 426 mm.

- Wall thickness: from 3 to 16 mm.

Thin-walled and thick-walled galvanized pipe samples were designed to work with increased loads, with environments of varying degrees of aggressiveness.

Classification of electric welded products

Depending on the type of seam, products can be of two types:

- with a weld that runs parallel to their axis. The seams of the products are located in a straight line, which is why their name is appropriate - straight-seam steel pipes;

- with a weld made along a helical line. They are called spiral stitch.

Due to the ease of manufacture and low costs, the first type of product has become most widespread. And with the help of spiral welds, large diameter products are usually made.

Products with different types of seams are also classified according to the processing methods of the material used in their production. Depending on this parameter, products are distinguished:

- cold-deformed - made of sheet metal, which is produced by cold deformation;

- hot-deformed - for their production, metal sheets are used, which are additionally subjected to hot deformation.

Note that hot-deformed products have a higher cost, so their use in some cases is considered less profitable.

About ESV galvanized

Among rolled metal products, galvanization occupies a special place. The scope of its application is extensive due to its special strength and reliability.

ESV 76.1×3 Polished

The operating principle of the galvanizing process is based on the fact that zinc oxidizes much faster than steel alloy. This eliminates the very possibility of oxidative processes on the surface of the final product.

It will no longer be exposed to aggressive environmental influences, no matter where it is used. Such products are completely immune to high moisture, chemical environments and mechanical stress.

This product retains its properties in the most difficult conditions:

- under heavy wind load;

- when exposed to chemicals;

- at high humidity;

- under difficult climatic conditions.

An example of a heating system for a private house

The advantages of galvanized metal are a high degree of protection against ruptures and the longest service life.

Manufacturing technology

The technological process by which electric-welded pipes are manufactured includes a number of operations. It is complex, labor-intensive, and therefore time-consuming. In order for the electric-welded pipe to acquire a finished look, it is rolled from a strip, that is, a strip of alloy steel. It is pre-manufactured using either hot or cold deformation.

To produce reliable, durable products of different diameters, in most cases radio frequency welding is used, which allows metal to be joined at a fairly high speed. With this welding method, high voltage currents are passed through the rolled workpiece, which contribute to the rapid heating of the edges. In order to form a reliable seam in place of the heated and already melted edges, they are pressed against each other under high pressure. To make a workpiece of the required diameter from a steel strip (strip), special crimping machines are used.

The technology used to produce straight- and spiral-welded electric-welded pipes allows not only to obtain reliable products, but also to ensure their attractive appearance. The weld seam is almost invisible on the products.

Download GOST 10704-91 in PDF and what you need to know about it

The standard was developed in 1991, but it was not introduced into common practice until 1993. The changes made to it concerned mainly the assortment, dimensions and technical characteristics.

Electric-welded galvanized steel pipe DU65 is an extremely popular product. If it is used at any national economic facility, then all work will be focused on the content of GOST 10704.

Stainless steel

Perhaps some construction organization has already used this product several years ago. But emerging new technologies are immediately reflected in GOSTs.

Attention! You cannot start a new cycle of work without familiarizing yourself with the current amendments that have been added to the standard. You need to know about them “before” and not “after” the start of work.

As a rule, all technical nuances are grouped and released in the form of a separate application. But sometimes innovations are introduced directly into the text. In this case, the publication must be accompanied by special informative notes.

If you do not take into account all the amendments in time, then there is a high risk of working with information that has lost its relevance.

Why is the information reflected in GOST important? It contains basic data: a list of standard sizes, permitted deviations, and so on. The technical requirements for production are reflected in 10705-80 and 10706-76. These include: mechanical properties, steel grade used in manufacturing, etc.

Moreover, all technical requirements must necessarily correspond to the standards of standard 10704. Therefore, before starting any construction, installation or restoration work, a thorough study of all the above-mentioned GOSTs is necessary.

These three standards constantly reference each other. The fact is that the basic characteristics of the final product are often determined by what technical conditions are prescribed for its manufacture.

Directory of rolled metal products

Steel pipes, electric welded

Straight-seam steel pipes 10704

Electric-welded pipes are widely used in mechanical engineering, in the construction of residential, public and industrial facilities, in furniture production and in the manufacture of sports equipment. The variety of configurations and sizes makes this material truly universal. One of the most important areas for using steel directly seam electric-welded pipes is the installation of heating pipelines, as well as structures intended for transporting oil, gas and other substances. Due to such advantages as affordable cost, durability and ease of installation, these products are widely used in various sectors of the economy.

In accordance with GOST, electric welded pipes can be conditionally divided into certain classes.

Class 1 includes standard rolled pipes intended for installation of heating systems, use as cable ducts or structural material.

Class 2 is represented by metal products for laying oil, water or gas pipelines, as well as for transporting various liquid and solid substances. This group is characterized by increased thermal resistance and the ability to maintain mechanical strength under conditions of high pressure.

Class 3 steel pipes are also resistant to high temperatures and pressure changes - such longitudinally welded products are used in various branches of industrial production, including nuclear power.

The scope of use of class 4 pipes is oil production and geological exploration.

Metal products belonging to class 5 are used for the needs of heavy mechanical engineering in the production of special equipment, carriage building, and as frame materials.

The last, 6th class of metal products is represented by a wide range of products intended for the manufacture of parts for pistons, pumps and other mechanisms.

Straight seam electric welded steel pipes

Electrically welded straight-seam steel pipes are produced from steel strips or rolled sheets by forming and welding a straight joint.

Manufactured to specifications in accordance with GOST 10705-80, with a diameter of 10-530 mm, from carbon and low-alloy steel. Electric-welded pipes are used to create pipelines, as well as structures for various purposes. At the same time, GOST 10704-91 establishes the dimensions and possible maximum deviations in dimensions.

Material for manufacturing according to quality indicator (GOST 10705-80):

A - with standardization of mechanical properties of steel St1, St2, St3, St4 according to GOST 380;

B - with standardization of the chemical composition of steel 20, 15, 10, 08 according to GOST 1050, steel St1, St2, St3, St4 according to GOST 380 and GOST 14637, steel 08Yu according to GOST 9045 and steel 22GYu;

B - with standardization of mechanical properties and composition of steel St1, St2, St3, St4 according to GOST 380, steel 20, 15, 10, 08 according to GOST 1050, steel 08Yu according to GOST 9045 and steel 22GYu;

D - with normalization of hydraulic pressure.

Electric-welded steel straight-seam profile pipes are manufactured by heat treatment, hot reduction or without treatment. They come in thin-walled and thick-walled.

Depending on the test pressure, electric-welded steel pipes are divided into 2 types: I and II.

Depending on the value equal to the ratio of the outer diameter to the wall thickness:

- less than 6 - especially thick-walled;

— 12.5-40 — thin-walled pipes;

- more than 40 - especially thin-walled pipes.

Thick-walled electric-welded steel pipes are produced by heat treatment. Without heat treatment, thin-walled electric-welded steel pipes are produced that work well in bending, with a ratio of outer diameter to wall thickness of at least 50. Thin-walled pipes are less durable, but have low weight.

Manufactured from steel with a chemical composition in accordance with GOST 380, GOST 1050, GOST 19281.

Varieties (by purpose):

· GOST 3262-75 - water and gas pipelines (VGP);

GOST 20295-85 - for main gas and oil pipelines:

1 - straight-seam welded with a diameter of 159-426 mm, manufactured by resistance welding with high-frequency currents;

2 - spiral welded with a diameter of 159-820 mm, made by electric arc welding;

3 - straight-seam welded with a diameter of 530-820 mm, made by electric arc welding.

Electric-welded pipes for highways are manufactured heat-treated (throughout the entire volume or along the welded joint) or without heat treatment, depending on the strength class: K34, K38, K42, K50, K52, K52, K55, K60. Their length is 10.6-11.6 m.

An example of the designation of an electric-welded round steel pipe , type 1, diameter 325 mm, wall thickness 7 mm, strength class K38, with volumetric heat treatment (T): Pipe type 1-T 325×7 - K38 GOST 20295-85.

Water and gas pipes in accordance with GOST 3262-75 can be galvanized or non-galvanized, with cut or rolled cylindrical threads or without threads.

They are used for water and gas pipelines, heating systems, as well as for parts of water and gas pipeline structures. Round VGP pipes are manufactured in lengths of 4-12 m.

For more detailed information on the sale of steel pipes and cost, go to the “Water and Gas Pipe (WGP)” section of the website or contact our specialists.

Boiler pipes

Produced according to TU 14-3-460-75. Designed for steam boilers and pipelines made of rolled, forged, machined and drilled billets with high and supercritical steam parameters. They are produced cold-deformed or hot-deformed from carbon and alloy steel 10, 15GS, 15ХМ, 12Х1МФ, 15Х1М1Ф, 12Х2МФР, 12Х11В2МФ, 12Х18Н12Т. They have an outer diameter of 42-219 mm with a wall thickness of 0.5-18 mm and a length of 3-9 m for cold-formed, 4-11 m for hot-formed. Highly qualified employees of our company will help you buy the entire range of profile steel pipes from the price list at a low price per meter, any types and sizes: round, oval, rectangular, square, boiler.

Round steel pipes GOST-10704

This group includes steel electric-welded straight-seam pipes with a diameter from 10 to 530 mm according to GOST 10705-91; from 478 to 1420 mm according to GOST 10706-76.

According to the length of the pipe, they are made: of unmeasured length from 2 to 12 m; measured length from 5 to 12 m;

Theoretical weight of a linear meter of steel pipes, kg

Advantages of electrically welded pipes

Electric welded pipe occupies a leading position among pipes, having a number of advantages.

Firstly, it is produced by welding using the electric welding method. This seam is very durable. After subsequent heat treatment, such a pipe can be coated with a wide variety of compounds and materials.

The second advantage is versatility. Electric welded pipe is used in a wide variety of technological processes - for transporting media, for the manufacture of metal structures and other industrial production systems.

Thirdly, having high strength indicators, it is used for laying gas pipelines and pipelines.

How are electric-welded pipes different from seamless pipes?

Let's move on to the answer to the question posed at the very beginning. The main differences between seamless and electric welded pipes can be grouped into several categories.

Appearance

Seamless products are made from steel billets or cylindrical ingots. Increased demands are placed on the quality of workpieces, because external defects cannot be eliminated in the future during hot rolling. It is possible to reduce the wall thickness, but this can only partially offset the shortcomings of the raw material.

For the production of electric welded pipes, cold- or hot-rolled sheets are used. Due to this, the appearance of the surface will be better than that of seamless analogues.

Production technology

A seamless pipe can only be formed once by rolling. To produce welded pipe products, several technological processes are used at once - bending, cold or hot rolling, welding. This versatility allows you to significantly expand the range of technical characteristics of the finished product.

Performance

Due to the absence of vulnerable areas, seamless pipes can withstand higher pressures. They have high resistance, therefore they are widely in demand in the heating industry and other industries that use high-pressure boilers.

Welded analogues are more vulnerable to high pressure (the maximum permissible level is 20% lower). The main areas of use are the aerospace industry and automobile production.

Range of sizes

The maximum outer diameter of a seamless pipe is 508 mm. Many manufacturers take into account the features of the equipment and do not exceed 400 mm: products with larger diameters are produced on an individual basis. As for electric-welded analogues, the range of sizes is very wide: from 48 to 2540 mm.

Price

We noted earlier that seamless products are more expensive than electric welded ones. This is explained by manufacturing technology, more stringent requirements for raw materials and equipment features. In general, the price of pipes is very susceptible to fluctuations in the rolled metal market, so it is realistic to purchase seamless products even cheaper than welded ones.

Advantages and disadvantages

High product quality is ensured through strict adherence to industry standards, which involve the production of both measured and non-measured pipes. The first includes rolled metal up to 2 m long with a cross-section of up to 30 mm, up to 3 m with a diameter of 30-70 mm, up to 4 m with a diameter of 70-152 mm, up to 5 m with a diameter of more than 152 mm. In the case of the production of measured products, a different classification is used: 5-9 meters with a diameter of up to 70 mm, 6-9 m with a diameter of 70-219 mm, 10-12 m with a diameter of 219-426 mm. Other sizes are also possible, but upon individual order. In this case, it is important to take into account the convenience of transportation, because the length of vehicles is limited.

Product Features:

- the maximum pressure characteristics of welded pipes are lower than seamless ones, which is important to take into account when designing water supply, heating, and main lines;

- state standards recommend the use of low-alloy carbon steel grades that are suitable for welding;

- high-quality protection from aggressive environments requires additional processing;

- installation of gas and water pipes with bends requires the use of fittings, since seamed pipes are not suitable for bending.

Electric pipes

Electrical pipe (electric welded) is a product made from strips or rolled sheets by molding and subsequent electric welding. After this, the pipe is subjected to heat treatment. The welded pipe can also be coated with cement, bitumen and paint.

Electric welded steel pipe has a significant advantage over many other types of pipes. These pipes have a fairly long service life and can withstand high loads.

Electric welded steel pipe is considered a universal pipe due to its diverse uses:

- transportation of various media (gas, oil, petroleum products and other materials);

- element of television and radio supports;

- use in the construction industry.

- for laying main pipelines.

Electric-welded pipes are made of carbon and low-alloy steel. Electric-welded pipes can be classified depending on the manufacturing technology and methods of their subsequent processing.

- Straight-seam (manufactured by welding a straight joint parallel to the axis)

- Hot-deformed straight-seam (subjected to hot deformation after welding)

- Cold-deformed straight-seam (subjected to cold deformation after welding)

- Cold rolled straight seam

- Cold drawn straight seam

- Spiral seam (made from strips or rolled sheets by spiral molding and continuous welding of the joint with a spiral seam)

Straight or spiral?

Oddly enough, welded pipes are a rather “young” type of metal product. The first samples of welded (more precisely, forged) pipes appeared less than 200 years ago - in 1824. And only at the beginning of the 20th century did they begin to use the so-called. “furnace” welding, in which the hot edges of the pipe are held together by compressing them with rollers.

It was only with the advent of electric welding that seam pipes were divided into straight-seam and spiral-seam.

The name “straight seam” speaks for itself: this method of making pipes is due to the fact that a steel strip - strip - is heated until the metal becomes plastic and passed through two rows of rolls that roll the metal “into a tube” - so that all that remains is to connect its edges electric welding.

This is a fairly simple and cheap technology, but some problems arise when using it, namely:

— for the manufacture of pipes of different diameters, blank strips of different widths will be needed.

— the transition to the production of pipes of a different diameter will require re-equipping the entire production line with new parts (primarily rolls).

— when the workpiece cools, stresses will arise in the weld, which will significantly reduce its strength.

- if such a pipe still cannot withstand the pressure supplied through it, then its rupture will occur precisely along the seam and along the entire length of the pipe section, which will create additional problems when eliminating the accident.

Another option for producing welded pipes is to join steel strips using a spiral weld. With this technological option, the seam itself turns out to be much longer than with a straight-seam connection, but a number of advantages appear:

— when manufacturing a spiral-welded pipe, there is no need to use blank strips of clearly defined sizes; the pipe can be welded from metal strip of any width

— changing the diameter of the produced pipes can be done using a simple readjustment of the production line; It will be enough to simply change the feed angle of the tape.

— when welding a pipe from a metal strip, it is not necessary to strongly heat the entire metal strip; this reduces the possibility of changes in the properties of the metal during heating and cooling and reduces the possibility of internal stress in it.

— during spiral welding, the resulting seam itself becomes an element that gives additional strength to the structure

- if such a seam still does not hold up and diverges, then it diverges not “alongwise”, but “obliquely”, which reduces the size of the section of pipe that will have to be replaced.