Stainless steel is an alloy of iron and chromium. Its anti-corrosion properties are manifested due to the presence of a chromium oxide layer on the metal surface. This protective layer is very stable and even after mechanical or chemical damage it quickly regains its previous appearance, and the anti-corrosion qualities of the metal remain unchanged.

Features of stainless steel production

At steel foundries, when choosing the chemical composition of a corrosion-resistant alloy, they are guided by the rule that if a metal that forms a solid solution with it and is resistant to corrosion (for example, chromium) is added to a metal that is unstable to corrosion (for example, chromium), then a protective effect appears jumpwise with the introduction of 1/8, 2/8, 3/8... n/8 mole of the second metal. That is, corrosion resistance increases not in proportion to the amount of the alloying component, but in leaps and bounds. The main alloying element of stainless steel is chromium Cr (12-20%). In addition to chromium, stainless steel contains elements accompanying iron in its alloys (C, Si, Mn, S, P), as well as elements introduced into steel to give it the necessary physical and mechanical properties and corrosion resistance (Ni, Mn, Ti, Nb , Co, Mo).

The hardness and corrosion resistance of steel depends on the chromium content:

- 13% chromium and higher - alloys are stainless under normal conditions and in mildly aggressive environments.

- More than 17% chromium. Such steels are corrosion resistant in aggressive environments.

The following elements also affect the properties of steel:

- Titanium in the alloy increases strength and corrosion resistance.

- Nickel increases strength, ductility, and corrosion resistance.

- Manganese increases hardness, wear resistance, and resistance to shock loads.

- Molybdenum increases strength and resistance at high temperatures.

Main types of stainless steel sheets

Regardless of the chemical composition, the surface of a stainless steel sheet can have different finishing qualities. Provision is made for the production of perforated or expanded metal sheets for economical use in civil and industrial construction of complex alloys. Obtaining a matte, polished, mirror or polished surface requires the use of special technologies and materials, which increases the cost of building materials.

Additional grinding and polishing allows you to obtain a product with an excellent appearance, intended for finishing work, use in design and architecture. The user has the opportunity to use stainless steel sheets with different surface finishes. This significantly reduces the total cost of work without loss of quality and protective properties of the structure or equipment.

Stainless steel sheets with factory-applied corrugations deserve special attention. It is important that the thickness of the sheet in the order is indicated without taking into account the height of the pattern. The riffles give the sheets additional decorative properties, which allows them to be widely used in interior solutions. Also, corrugation significantly prevents slipping, which is necessary when creating platforms for technological equipment or steps of stairs for various purposes. Each enterprise has its own equipment for applying various corrugation patterns to the surface of stainless steel sheets.

Perforated and expanded metal sheets made of stainless alloys are widely used. They are mainly used to create various enclosing structures and stairs. Perforation reduces the weight of the part, providing sufficient structural rigidity, breathability and light transmission. PVL, with a mass equal to the original sheet, allows you to enclose an area several times larger. They are used as ventilation grilles, fences, and elements of staircase structures.

Application of stainless steel

The main applications of stainless steel include:

- Mechanical engineering.

- Chemical industry.

- Energy.

- Pulp and paper industry.

- Food industry.

- Medicine.

- Aerospace sector.

- Construction.

Due to its practicality and pleasant appearance, stainless steel has become widespread. The advantages also include a variety of stainless steel grades and surface types (ground, polished, matte, glossy and even colored surfaces). The appearance of stainless steel elements does not change for decades. Stainless steel also has higher heat-resistant properties than other steels.

In construction, stainless steel is used primarily as a material for the manufacture of finishing elements: railings, window and door openings, fire doors. It is also a good decorative material for equipping restaurants, offices, pubs, discos and metro stations. In everyday life, stainless steel in combination with glass or wood is found in furniture elements.

Special food grade steel is produced for the food industry. Such alloys are distinguished by a low amount of chemical additives and have the following markings: AISI 304, AISI 304L, AISI 316, AISI 316L, AISI 316Ti, AISI 321, AISI 430.

Medical stainless steel is needed for the manufacture of instruments, utensils and other devices. It is marked 12Х18Н10Т, and is distinguished by its high corrosion properties, absence of harmful substances, hardness and practicality.

There is a misconception that stainless steel is an expensive material. In fact, if you take into account the huge period of operation, the funds invested in it are fully recouped.

STAINLESS STEEL FINISH SYMBOLS (SHEET) AND THEIR DESCRIPTIONS

| EN | ASTM | DIN | Description | |

| N1 | c2 (IIa) | H/c | Hot rolled, heat treated, pickled | |

| 2B | 2B | n(IIIc) | Frosted mirror | Cold rolled, heat treated, pickled |

| 2R | B.A. | M(IIId) | Mirror | Cold rolled, fired in a vertical furnace using caustic ammonia |

| 2K | N4/N5/SB | P(V) | Sanded | |

| N8 | N8 | — | Super mirror | Wet abrasive processing + Polishing. (Quality like a glass mirror). |

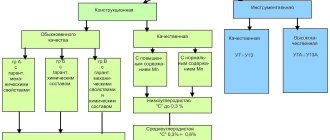

Types of stainless steels

Corrosion resistance is ensured by a film of chromium oxides that forms on the surface of the metal when it interacts with atmospheric oxygen and is capable of being restored after damage.

Stainless steels with a minimum chromium content of 11% (AISI 430, AISI 409, AISI 410) are called ferritic and are used only in slightly aggressive environments or for the manufacture of tableware and decor.

In addition to chromium, nickel, molybdenum and titanium are used in stainless alloys. Nickel provides the ductility and toughness of the alloy. Chromium-nickel steels containing at least 8% nickel and at least 17% chromium are called austenitic chromium-nickel steels . They have higher corrosion resistance at elevated operating temperatures (up to 450 °C). Chromium-nickel steels are used in the production of chimneys with mandatory restrictions on the maximum operating temperature and humidity conditions of the exhaust gases. Molybdenum and titanium increase corrosion resistance, inhibit the precipitation of chromium carbides, and increase scale resistance, including at high temperatures up to 800 ° C. Steels of this group (AISI 316L) are called austenitic chromium-nickel-molybdenum and are widely used in the production of chimneys.

Martensitic alloys are characterized by high strength and wear resistance (heat-resistant corrosion steel). Such steels contain a minimal amount of harmful substances that are not released when heated.

Methods for making stainless steel sheet

According to the production method, stainless steel sheets are divided into hot-rolled and cold-rolled. In the production of the hot rolled type of sheet, carbon steel is hot rolled. Cold rolling of coiled steel produces a cold-rolled sheet with a smooth, corrugated or grooved surface.

Depending on the type of surface treatment, stainless steel sheet has three main modifications:

- Matte;

- Polished;

- Mirror;

AISI marking of stainless steels

| steel grade | Characteristics of stainless steel | Chemical composition, % |

| AISI 201, AISI 202 (analogs: 12X15G9ND, 12X17G9AN4) | They belong to the austenitic group of alloys. They contain chromium, nickel, manganese, copper and nitrogen. They provide a high level of strength to the finished product, are perfectly deformable and change their shape, and are characterized by high anti-corrosion properties. They are used in the manufacture of household appliances, pipelines and building structures. | |

| AISI 301 (analogue: 15Х17Н7) | Refers to non-magnetic steels. It has a high level of strength and ductility. Most often, such stainless steel is used in the manufacture of parts for automobiles and railway transport, household equipment and medical equipment. | Cr from 16 to 18; Ni from 6 to 8; Mn 2; Si 1; C 0.15; N 0.1; P 0.045; S 0.03 |

| AISI 302 (analog: 12Х18Н9) | Characterized by high levels of strength and ductility. It is resistant to corrosion. | Cr 17-19; Ni 8-10; Mo 4-5; Si 2-3; Mn <2; C <0.15; N >0.1; P <0.045; S <0.03 |

| AISI 303 (analog: 12Х18Н9) | Refers to austenitic steels. Has a high sulfur content. This steel is non-magnetic and is optimally used in mechanical and moving components. | Cr 17-19; Ni 8-10; Mn <2; Si <1; P <0.2; S >0.15; C <0.15 |

| AISI 304 (analogue: 08Х18Н10) | This stainless steel is highly resistant to corrosion and can be used in aggressive environments. In addition to the food industry, it is used for pharmaceutical, petroleum, chemical and textile production. | Cr 18-20; Ni 8-10.5; Mn <2; C <0.08; P <0.045; S <0.03 |

| AISI 316 (analogues: 03Х17Н14М3 and 04Х17Н13М2) | The brand contains molybdenum, which increases the material’s resistance to corrosion. The alloy is resistant to elevated temperatures. | Cr 15-17; Ni 14-16; Mo 2.5-3; C up to 0.03 |

| AISI 316Ti (analog: 10Х17Н13М2Т) | This stainless steel is enriched with titanium, which makes the material resistant to chlorine. Titanium also makes the alloy more durable and resistant to high temperatures. | Cr 15-17; Ni 14-16; Mo 2.5-3; C up to 0.03; Ti 1 |

| AISI 321 (analogue: 08Х18Н10Т) | The alloy is characterized by a high titanium content, is easily amenable to any type of processing, and is resistant to elevated temperatures, up to 800 degrees. It is used in the production of seamless pipes, in the manufacture of seam products and boilers, as well as in the construction of furnace systems. Also used in mechanical engineering, shipbuilding, and aviation. | Cr 17-19; Ni 9-11; Mn <2; Ti <1; Si <0.8; Cu <0.3 |

| AISI 403 (analog: 15Х12) | This alloy belongs to the martensitic-ferritic group. It is characterized by increased ductility and resistance to high temperatures. Products made from such steel can withstand loads in a slightly aggressive environment. | Fe 86; Cr 12.3; Mn 1; Si 0.5; C 0.15; P 0.04; S 0.03 |

| AISI 409 (analogue: 08Х13) | It is distinguished by its high chromium content and the addition of nickel, which allows it to be amenable to all types of processing. This stainless steel is used to make parts that will be subject to shock loads during operation: valves of presses and pumps, household items. The alloy is also used in the manufacture of products exposed to mildly aggressive environments: steam turbine blades, valves, bolts and pipes. | Fe ≈84; Cr 12-14; Mn up to 0.8; Si up to 0.8; Ni up to 0.6; C up to 0.08; P up to 0.03; S up to 0.025 |

| AISI 410 (analog: 12Х13) | This steel is characterized by ductility and strength. It withstands high temperatures and does not corrode in aggressive environments. | Cr 13.5; Mn 1.0; Si 1.0; Ni 0.6; C 0.15; P 0.045; Si 0.03 |

| AISI 416 | Belongs to the group of martensitic stainless steel, from which rolled sheets, metal profiles, and pipeline products are made. | Cr 12-14; Mn 1.25; Si 1; Se >0.15; C 0.15; P 0.06; S 0.06 |

| AISI 420 (analog: 40Х13) | This alloy is characterized by an increased level of heat resistance, wear and corrosion resistance. | Fe ≈84; Cr 12-14; Si up to 0.6; Mn up to 0.6; Ni up to 0.6; C 0.35-0.44; P up to 0.03; S up to 0.025 |

| AISI 430 (analog: 12Х17) | The grade belongs to the group of ferritic steels and has a balanced composition and good performance characteristics. | Fe ≈81; Cr 16-18; C up to 0.12; Si up to 0.8; Mn up to 0.8; P up to 0.035; S up to 0.025 |

| AISI 439 (analogue: 08Х17Т) | Stainless steel belonging to the ferritic group. Used in mechanical engineering, food industry, architecture and construction. | Fe ≈79; Cr 16-18; Si up to 0.8; Mn up to 0.8; Ti up to 0.8; Ni up to 0.6; Cu up to 0.3; C up to 0.08; P up to 0.035; S up to 0.025 |

| AISI 441 | Belongs to the group of ferritic alloys with a large amount of chromium. | Cr 16-18; Si up to 0.8; Mn up to 0.8; Ti up to 0.8; Ni up to 0.6; Cu up to 0.3; C up to 0.08; P up to 0.035; S up to 0.025 |

Thickness of rolled sheets made of corrosion-resistant and heat-resistant steel grades

Rolled stainless steel sheets come in thin and thick sheets.

Rolled thin sheets

made from alloy steel grades in accordance with technical specifications according to GOCT 5582-75. Standard range of sheet steel thicknesses:

- hot rolled from 1.5 to 3.9 mm in increments of 0.1; 0.2; 0.3 mm;

- cold rolled from 0.5 to 3.9 mm in increments of 0.05; 0.1; 0.2; 0.3 mm.

Thick stainless steel sheets

manufactured according to technical specifications according to GOCT - 7350-77. Standard range of thicknesses of thick alloy steel:

- hot rolled from 4 to 50 mm in increments of 0.5; 1; 2; 3 mm;

- cold rolled from 4 to 5 mm in increments of 0.2 and 0.3 mm.

Marking of stainless steels GOST

| steel grade | Characteristic | Chemical composition, % |

| 06ХН28МДТ (analogue: AISI 904L) | Stainless steel is used for the manufacture of welded chemical equipment operating at temperatures up to 80 degrees in highly aggressive environments. | Ni 26-29; Cr 22-25; Cu 2.5-3.5; Mo 2.5-3; Si ≤0.8; Mn ≤0.8; Ti 0.5-0.9; C ≤0.06; P ≤0.035; S ≤0.02; Fe rest. |

| 08Х17Н13М2Т (analogue: AISI 316Ti) | Stainless steel of this grade is characterized by high ductility, is easily molded and does not have magnetic properties. | C up to 0.08; Si up to 0.8; Mn up to 2; Ni 12-14; S up to 0.02; P up to 0.035; Cr 16-18; Mo 2-3; Cu up to 0.3; (5 C-0.7) Ti ; Fe ≈61 |

| 08Х18Н9 | Austenitic stainless steel with high chromium content. It is used in the production of steel seams, fittings, and heat exchange equipment. | Cr 17-19; Ni 8-10; C 0.8; Si 0.8; Ti 0.5; Cu 0.3; Mn 0.2; P 0.035; S 0.02 |

| 08Х18Н10 (analogue: AISI 304) | This stainless steel is characterized by increased strength, ductility and resistance to ultra-high temperatures. The alloy has no magnetic properties. | Cr 17-19; Ni 9-11; C 0.8; Si 0.8; Ti 0.5; Cu 0.3; Mn 0.2; P 0.035; S 0.02 |

| 08Х18Н10Т (analogue: AISI 321) | Characterized by high heat resistance. There are no magnetic properties. It is used for the manufacture of folds, heat exchange equipment, and parts of furnace fittings. | Cr 17-19; Ni 9-11; Mn up to 2; Si up to 0.8; Ti 0.4-0.7; Cu up to 0.3; S up to 0.2; C up to 0.08; P up to 0.035; Fe ≈69 |

| 08Х22Н6Т | Belongs to the austenitic-ferritic group of alloys. Does not lose its properties even when used in an aggressive environment. | Cr 21-23; Si up to 0.8; Mn up to 0.8; Ni up to 0.8; Cu up to 0.3; C up to 0.08; P up to 0.035; S up to 0.025; (5 C - 0.65) Ti ; the rest is Fe |

| 10Х17Н13М2Т (analogue: AISI 316Ti) | Stainless steel retains its physical properties and characteristics even at high temperatures (up to 600 degrees). | Cr 16-18; Ni 12-14; Mo 2-3; Mn no more than 2; Si no more than 0.8; Ti 0.5-0.7; Cu not more than 0.3; P not more than 0.035; S no more than 0.02 |

| 10Х18Н10Т | Heat-resistant stainless steel is used for the manufacture of parts for welded equipment operating in aggressive environments. Suitable for the production of furnace equipment, heat exchangers and pipes. | Cr 17-19; Ni 10-11; Mn 1-2; Si up to 0.8; C up to 0.1; P up to 0.035; S up to 0.02; 5(C - 0.02) < Ti < 0.6 |

| 10Х23Н18 (analogue: AISI 310S) | High-alloy, high-temperature resistant stainless steel belongs to the austenitic group of alloys. | Cr 22-25; Ni 17-20; Mn up to 2; Si up to 1; Cu 0.035; Ti 0.3; C up to 0.1; S up to 0.02; P up to 0.02 |

| 12Х18Н9 (analogues: AISI 301, 302, 303, S30200) | Belongs to the group of austenitic alloys. It is used in the manufacture of parts that subsequently undergo a hardening stage: parts of furnace fittings, heat exchangers, rotors, couplings. | Cr 17-19; Ni 8-10; Mn ≤ 2; Si ≤ 0.8; Ti ≤0.5; Mo ≤0.5; Cu ≤0.3; C ≤ 0.12; P ≤0.035; S ≤0.02; Fe about 70 |

| 12Х18Н10Т (analogues: AISI 321, 321H) | Austenitic grade stainless steel. It is used in the food, pharmaceutical and chemical industries, petrochemical industry, mechanical engineering, and energy. | Cr 17-19; Ni 9-11; Mn no more than 2; Si no more than 0.8; Ti 0.6-0.8; Cu not more than 0.3; P not more than 0.035; S no more than 0.02 |

| 12Х18Н12Т | High-alloy steel is used in the manufacture of parts operating at elevated temperatures. Use in aggressive environments is allowed. | Cr 17-19; Ni 11 - 13; Mn up to 2; Si up to 0.8; Cu up to 0.3; C up to 0.12; P up to 0.035; S up to 0.02; (5 C - 0.7) Ti ; the rest is Fe |

| 14Х17Н2 (analogue: AISI 431) | Belongs to the martensitic-ferritic group of alloys. This stainless steel is difficult to weld and is prone to temper brittleness. | Cr 16-18; Ni 1.5-2.5; Si 0.8; Mn 0.8; Cu 0.3; C 0.11-0.17; P 0.03; Ti 0.2 |

| 20Х23Н18 (analogue: AISI 310) | High-alloy heat-resistant steel. Used for the production of individual combustion chambers, clamps, suspensions, and fastening parts. Seamless pipes are also made from steel of this grade, which will be used at high temperatures. | Cr 22-25; Ni 17-20; Mn no more than 2; Si no more than 1; Cu not more than 0.3; Ti no more than 0.2; P not more than 0.035; S no more than 0.02 |

| 08Х13 (analogues: AISI 403, 409, 410S, 429) | Belongs to the group of ferritic alloys. Steel has good corrosion resistance and can withstand high temperatures. | Cr 12-14; Si 0.8; Mn 0.8; Ni 0.6; C 0.08; P 0.03; S 0.025 |

| 08Х17 (analogue: AISI 430) | Characterized by a high chromium content. Used in mechanical engineering, food and chemical industries. | Cr 16-18; Si 0.8; Mn 0.8; Ni 0.6; C 0.08; P 0.03; S 0.025 |

| 12Х13 (analogue: AISI 410) | Brittle steel that is difficult to weld. Belongs to the martensitic-ferritic class. | Cr 12-14; Si 0.8; Mn 0.8; Ni 0.6; C 0.1; P 0.03; S 0.025 |

| 12Х17 (analogue: AISI 430) | Belongs to the ferritic group. Does not lose its properties, even when exposed to acids and salt solutions. | Cr 16-18; Si 0.8; Mn 0.8; C 0.12; P 0.035; S 0.025 |

| 20Х13 (analogue: AISI 420) | It belongs to the martensitic class of alloys and is intended for the manufacture of power engineering parts, furnace equipment, various fasteners and fittings. This stainless steel is difficult to weld and is prone to temper brittleness. | Cr 12-14; Si 0.6; Mn 0.6; Ni 0.6; C 0.2; P 0.033; S 0.025 |

| 30Х13 (analogues: AISI 420S, 420F) | This steel is not suitable for welding. It is used for the manufacture of springs, compressor parts and other devices. | Cr 12-14; Si 0.8; Mn 0.8; Ni 0.6; C 0.3; Cu 0.3; Ti 0.2; P 0.03; S 0.025 |

| 40Х13 (analogue: AISI 420) | Stainless steel made from this alloy is distinguished by its high level of wear resistance and heat resistance. It is used for the manufacture of cutting and measuring tools, as well as compressor parts that operate at high temperatures. | Cr 12-14; Si 0.6; Mn 0.6; C 0.4; P 0.03; S 0.025 |

Stainless steel grade for chimney

Steel 430 is a heat-resistant budget grade. Household hoods, casings, and protective screens made of 430 steel are used everywhere. Some articles recommend 430 steel as an inexpensive stainless steel for chimneys. But 430 differs from other brands in its relatively low corrosion resistance.

In the chimney of an outdoor stove, moisture and combustion products form acids. Stainless steel for the chimney must be resistant to nitric, carbon and sulfuric acid. In metallurgists' reference books, AISI 430 is recommended for gas boilers with low intensity of operation. The chimney of an outdoor stove made of steel of this brand gradually rusts.

304 steel is considered universal. Stoves and chimneys are made from this stainless steel for baths. They can withstand temperature changes and high humidity. Surfaces retain their shine for a long time. This is what the owners of commercial bathhouses with high traffic were convinced of.

Important. It is easy to distinguish between AISI 304 and AISI 430. 304 steel is not magnetic. Steel 430 belongs to the ferromagnetic class. A magnet sticks to its surface.

AISI 304 steel is more suitable for the manufacture of sauna vats and stoves. It is more expensive due to chromium and nickel. It is used wherever reliable welds are needed. This is its main advantage.