Construction science is a complex relationship between physics and mathematics; it cannot be done without certain knowledge and the ability to calculate various values. For example, to properly organize transportation, it is important to know in advance the weight of the profile pipe, and not just its dimensions and dimensions, otherwise you may simply choose a vehicle for transportation or not fit all the pipes into one vehicle.

Let's figure out how to calculate the specific gravity of a certain type of pipe, what types of pipes there are, and the best way to transport them.

Types and sizes of pipes

Profile pipes are very popular today and are used in various construction activities, from laying paving slabs to welding work. In this regard, there are several types of metal profile pipes on the market:

- Rectangular;

- Square;

- Oval;

- Flat oval;

- Hexagonal;

- Triangular.

The most popular types of profiles are rectangular, square and oval pipes.

There is also a wide range of standard sizes of profile pipes. Standard professional pipes have a diameter from 15 to 300 millimeters, a wall thickness from 1 to 12 millimeters, but the weight is determined using a special mold - it directly depends on the shape of the pipe and what dimensions it has.

Conclusion

Profile pipes, including those with a cross-section of 60x40 mm, have a number of unique qualities, thanks to which they are used in a wide variety of applications. Most of the characteristics of these products are prescribed in the relevant GOSTs, however, in some cases it may be necessary to calculate the mass yourself.

As we found out, this is not difficult to do using a simple mathematical formula.

You can get some additional information on this topic from the video in this article.

Did you like the article? Subscribe to our Yandex.Zen channel

Tables of weight of steel pipes of various GOST and TU 1 meter

In order to calculate the specific gravity of a profile, a special table of the weight of a profile pipe is used, with which you can calculate the mass of a certain type of pipe by multiplying the length by the weight of a linear meter.

Using special tables, you can determine how many meters are in a ton of pipeline.

The characteristics of the best manufacturers and the standard sizes of their products are given in the tables below.

GOST 8639 82 – Square steel pipes

| Section square parameters | Weight of 1 linear meter |

| 15×15x1.0 | 0,479 |

| 15×15x1.2 | 0,501 |

| 15×15x1.5 | 0,605 |

| 20×20x1.2 | 0,689 |

| 20×20x1.5 | 0,841 |

| 20×20x2 | 1,08 |

| 25×25x1.2 | 0,877 |

| 25×25x1.5 | 1,07 |

| 25×25x2 | 1,39 |

| 30×30x1.5 | 1,31 |

| 30×30x2 | 1,70 |

| 40×40x1.5 | 1,78 |

| 40×40x2 | 2,33 |

| 40×40x2.5 | 2,85 |

| 40×40x3 | 3,36 |

| 40×40x4 | 4,30 |

| 50×50x2.5 | 3,64 |

| 50×50x3 | 4,31 |

| 50×50x3.5 | 4,94 |

| 50×50x4 | 5,56 |

| 60×60x2 | 3,59 |

| 60×60x2.5 | 4,43 |

| 60×60x3 | 5,25 |

| 60×60x3.5 | 6,04 |

| 60×60x4 | 6,82 |

| 80×80x3 | 7,13 |

| 80×80x4 | 9,33 |

| 80×80x5 | 11,44 |

| 80×80x6 | 13,46 |

| 100×100x3 | 9,02 |

| 100×100x4 | 11,84 |

| 100×100x5 | 14,58 |

| 100×100x6 | 17,22 |

| 100×100x7 | 17,3 |

| 100×100x8 | 22,25 |

| 120×120x4 | 14,35 |

| 120×120x5 | 17,72 |

| 120×120x6 | 20,99 |

| 120×120x8 | 27,27 |

| 140×140x5 | 20,86 |

| 140×140x6 | 24,76 |

| 150×150x5 | 22,43 |

| 150×150x6 | 26,64 |

| 150×150x8 | 34,81 |

| 160×160x4 | 19,38 |

| 160×160x5 | 24,00 |

| 160×160x6 | 28,53 |

| 160×160x8 | 37,32 |

| 180×180x5 | 27,14 |

| 180×180x6 | 32,30 |

| 180×180x8 | 42,34 |

| 180×180x10 | 52,03 |

| 200×200x6 | 36,06 |

| 200×200x8 | 47,37 |

| 200×200x10 | 58,31 |

| 200×200x12 | 68,89 |

| 250×250x6 | 45,48 |

| 250×250x8 | 59,93 |

| 250×250x10 | 74,01 |

| 250×250x12 | 87,73 |

| 300×300x6 | 54,90 |

| 300×300x8 | 72,49 |

| 300×300x10 | 89,71 |

| 300×300x12 | 106,6 |

GOST 8645 82 – Rectangular steel pipes

| Options | Weight of 1 linear meter |

| 20x10x1.2 | 0,501 |

| 20x10x1.5 | 0,605 |

| 25x10x1.5 | 0,723 |

| 28x25x1.2 | 0,934 |

| 28x25x1.5 | 1,15 |

| 28x25x2 | 1,48 |

| 30x15x1.5 | 0,959 |

| 30x20x1.5 | 1,08 |

| 30x20x2 | 1,39 |

| 40x20x1.5 | 1,31 |

| 40x20x2 | 1,70 |

| 40x25x1.5 | 1,43 |

| 40x25x2 | 1,86 |

| 40x25x2.5 | 2,27 |

| 50x25x1.5 | 1,67 |

| 50x20x2 | 2,02 |

| 50x25x2 | 2,17 |

| 50x30x2 | 2,32 |

| 50x30x2.5 | 2,86 |

| 50x40x2.0 | 2,65 |

| 50x40x2.5 | 3,25 |

| 50x40x3.5 | 4,39 |

| 60x30x2 | 2,65 |

| 60x30x2.5 | 3,25 |

| 60x30x3 | 3,83 |

| 60x40x2 | 2,96 |

| 60x40x3 | 4,30 |

| 60x40x3.5 | 4,94 |

| 60x40x4 | 5,56 |

| 80x40x2 | 3,59 |

| 80x40x2.5 | 4,43 |

| 80x40x3 | 5,25 |

| 80x40x4 | 6,82 |

| 80x60x3 | 6,19 |

| 80x60x4 | 8,07 |

| 100x50x3 | 6,66 |

| 100x50x4 | 8,70 |

| 100x50x5 | 10,65 |

| 100x60x3 | 7,13 |

| 100x60x4 | 9,33 |

| 100x60x5 | 11,44 |

| 100x80x4 | 10,59 |

| 100x80x5 | 13,01 |

| 120x60x3 | 8,07 |

| 120x60x4 | 10,59 |

| 120x60x5 | 13,00 |

| 120x80x4 | 11,84 |

| 120x80x5 | 13,01 |

| 120x80x6 | 17,22 |

| 140x60x4 | 11,84 |

| 140x60x5 | 14,58 |

| 140x100x4 | 14,35 |

| 140x100x5 | 17,72 |

| 140x100x6 | 20,99 |

| 150x100x5 | 18,50 |

| 150x100x6 | 21,93 |

| 150x100x8 | 28,53 |

| 160x80x5 | 17,72 |

| 160x120x5 | 20,86 |

| 160x120x6 | 24,76 |

| 180x100x6 | 24,76 |

| 180x100x8 | 32,29 |

| 200x120x5 | 24,00 |

| 200x120x6 | 28,53 |

| 200x160x5 | 27,14 |

| 200x160x6 | 32,30 |

| 230x160x8 | 46,11 |

Of course, for convenience, when purchasing a pipe, it can be cut into several parts, so take into account that the length can be from 3 to 12 meters, depending on the client’s wishes. There are also special sizes that differ from the standard ones; if necessary, they can be ordered on an individual basis. And now you can figure out how the weight of a linear meter of a profile pipe is calculated.

Characteristics

Among the key parameters, it is worth paying attention to the weight of the 40x20x2 mm profile pipe, as well as its length, markings, and manufacturing features. According to the existing state standard GOST 8645-68 for these products, the weight of one linear meter of material should be 1.7 kg. At the same time, increasing the length of the bar correspondingly increases the weight of the structure.

To calculate the weight of a 40x20x2 mm profile pipe, you can use a special rolled metal calculator, which will quickly convert the length into weight without the need for lengthy independent calculations. Other important indicators for a profile pipe include deviations in height and width, which should not exceed the boundary parameters as a percentage.

When the pipe height is less than one meter, a deviation of about one percent is allowed, more than a meter - 0.8%. In the cross section, the deviation from a right angle of ninety degrees should not be more than 1.3%. The standard profile length is 6-12 meters, although by agreement with the customer it can be produced two meters less and one meter more.

Pipe weight calculator

The formula for calculating the specific gravity of a profile is quite difficult to master; it takes into account the following indicators:

- Material density;

- The width and height of the profile section or its diameter;

- Wall thickness;

- Pipe length;

If you use stainless steel pipes, you can use the tables above for calculations, simply multiplying the pipe length in meters by the specific gravity of 1 linear meter, which is indicated in the table opposite the profile size.

If you decide to purchase a galvanized profile, aluminum profile or copper profile pipes, you can calculate the specific gravity using a special calculator. In it you can select materials, for example stainless steel, enter dimensions and calculate the weight of the pipe, whether it is thick-walled or thin-walled, you can also read the values from the reference book. Here you can calculate the density of the material.

Rolled metal calculator © metcalc.ru

Unfortunately, this calculator cannot calculate how much plastic pipes weigh; it can only indicate various metal materials and calculate their theoretical weight.

General information

So, a profile pipe 60 - 40 mm is an empty rod-shaped pipe with a rectangular cross-section.

The product can be made from the following materials:

- Carbon steel;

- Of stainless steel;

- Low alloy steel.

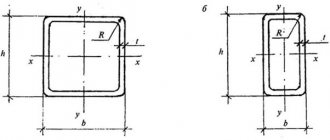

Rolled profile pipes

The production of these products is usually based on the deformation of an ordinary round pipe, as a result of which it acquires a rectangular shape. In addition, there is another technology, according to which a metal workpiece (strip) is subjected to deformation in a calibration mill, after which the seam is welded.

Electric welded pipes

What is the best way to transport corrugated pipe from the metal depot to your site?

Having found out the weight and size of a square pipe, you will have to think about how to transport a profile of this size. Of course, everything depends on the total number and dimensions of pipes.

Different modes of transport can accommodate different profiles. Let's figure out how you can transport pipes of one size or another.

8-12 meters

To transport profile pipes of this size, you will need a long vehicle with a total side length of 13.5 m. This range is the heaviest and at the same time the most capacious cargo carrier. The entry of such transport into many cities is prohibited, so the transportation route should be thought out in advance, and if possible, hire another transport and purchase a profile of shorter length.

6 meters (the most common option)

Most often, metal warehouses offer profile pipes 6 meters long; they are easier to transport, they have less weight, and most importantly, they meet the needs of most clients. If you need to transport 1-4 such profiles, then you can use an ordinary gazelle as a carrier - expensive and angry, not every driver will agree to such an undertaking, because the installation of the cargo will be “with a twist.”

You can hire a Chinese light truck - their body is elongated and is up to 5 meters long.

If there are more than 4 profile pipes, then it is better to hire a Kamaz or a truck - they will deliver the cargo safely and securely, and most importantly, there will be no problems on the way to the site.

3 meters

A three-meter profile can be taken away in almost any car, but according to the Administrative Code, it is best, of course, to carry out this procedure using a gazelle. You can fit several dozen products of this length in it.

In any case, it is better not to take risks and hire a car with a body longer than the dimensions of the profile products that you decide to transport, this way you will protect the driver from fines, and yourself from unnecessary hassle when delivering building materials.

( 3 ratings, average: 5.00 out of 5)

Application

The light weight of the 40x20x2 mm profile pipe makes it possible to widely use it in various fields of activity:

- construction of partitions, fences and fences;

- installation of construction pavilions, gazebos, places for trade;

- production of metal doors;

- creation of office furniture, school desks;

- sale of industrial equipment;

- manufacturing of transport equipment and much more.

Metal structures are distinguished by their endurance and strength, so they can last for many years without losing their original properties.

How to buy from us

Buying a profile pipe in our online store “ASTIM” will not be difficult. You can familiarize yourself with the range of products and calculate the weight of a 40x20x2 mm profile pipe. All you have to do over the phone is discuss the details with our manager and get answers to pressing questions.

Our price for profile pipes is affordable; at this price you get a quality product. Products are delivered to you directly from the factory without involving intermediaries in the transaction, which has a positive effect on the pricing policy.

Pipe 100x50x3

Home->Directory->Assortment of rolled metal products->Profile pipe->Rectangular pipe

Pipe 100x50x4 Pipe 80x60x4

Price of rectangular pipe 100x50x3

Profile pipe 100x50x3: weight, length, marking, packaging, warranty, technical and mechanical tolerances, acceptance

1. Theoretical weight according to GOST 30245-2003 of one 1 m/p - 6.60 kg

2. Deviations in the wall of a profile pipe can be identical to the deviation in the width of the workpiece according to GOST 19903. Deviations in thickness do not apply to the bending points of the profile (corners) 3. Deviations in the height and width of the profile pipe according to GOST 30245-2003 should be in percentage terms:

when pipe height up to 100 mm +/-1.0, not less than +/-0.5 mm;

over 100 mm +/- 0.8 4. In the cross section of the profile, deviations from an angle of 90 degrees should not exceed

+/- 1.30

5. The profile is manufactured in lengths

from 6.0 to 12.0 m

;

by agreement with the buyer, profile pipe 100x50x3 can be manufactured in lengths from 4.0 to 13.0 l/m

6. Twisting of the straight pipe should not be laid within

2.0 mm plus 0.5 mm for each 1 l/m

of the profile according to GOST 30245 7. The tensile strength of the longitudinal weld must be

at least 0.95

of the tensile strength of the base metal 8. Acceptance and conditions for monitoring the acceptance of products for straight pipes 100x50x3 cm. GOST 30245-2003 clause No. 5 9. Guaranteed shelf life of the profile pipe is 24 months from the moment of shipment by the manufacturer to the customer’s address 10. The profile is marked in accordance with GOST 7566, the marking must contain the company’s trademark, name. - dimensions of the pipe. — trunk numbers; — profile length; — number of profile; - weight and numbers of packs; - QC mark.

Rectangular pipe 100x50x3 6m St3ps5

The mass fractions of phosphorus and sulfur are within the limits established by GOST 27772-88; the customer can change the linear dimensions of the products, adapting them to their individual conditions. St3ps5 steel refers to structural steels with an average percentage of carbon and ordinary quality. The customer can change the grades of steel used; in this case, it is necessary to draw up a preliminary agreement indicating the desired parameters. The main technical parameters must meet the established state standards, the quality is checked at the manufacturer, the results are displayed in the certificate. The customer may require additional parameters to be tested in the laboratory; testing is performed on several square pipe samples from the batch. The selection is regulated by GOST. If there are quality deviations outside the tolerance limits, the test can be repeated, the number of samples is doubled. The results of repeated tests should be considered final. The chemical composition is controlled at the steelmaking plant, and selection is made from each smelting ladle. Finished rectangular pipes may have some surface defects; these can be removed mechanically. Visual inspection is carried out at the finished product receiving area.

Pipe 100x50x3 Pipe 100x50x4 Pipe 100x50x5 Pipe 100x60x4 Pipe 100x60x5 Pipe 100x80x4 Pipe 120x60x4 Pipe 120x60x5 Pipe 120x80x4 Pipe 120x80x5 Pipe 120x80x6 Pipe 140x100x4 Pipe 140x100x6 Pipe 140x120x5 Pipe 150x100x4 Pipe 160x120x5 Pipe 160x120x6 Pipe 160x120x8 Pipe 160x80x5 Pipe 180x100x6 Pipe 180x140x6 Pipe 180x14 0x8 09G2S Pipe 200x100x5 Pipe 200x100x6 Pipe 200x120x5 Pipe 200x120x6 Pipe 200x160x5 Pipe 200x160x6 Pipe 200x160x6 09G2S Pipe 200x160x8 Pipe 240x160x8 Pipe 250x150x6 Pipe 250x150x8 Pipe 300x200x1 0 Pipe 300x200x6 Pipe 300x200x8 Pipe 40x20x1.5 Pipe 40x20x2 Pipe 40x20x3 Pipe 40x25x1.5 Pipe 40x25x2 Pipe 40x25x3 Pipe 50x25x2 Pipe 50x25x3 Pipe 50x30x2 Pipe 60x 30x2 Pipe 60x30x3 Pipe 60x30x4 Pipe 60x40x1.5 Pipe 60x40x2 Pipe 60x40x3 Pipe 60x40x4 Pipe 80x40x2 Pipe 80x40x3 Pipe 80x40x4 Pipe 80x60x3 Pipe 80x60x4

Warranty and labeling

In accordance with regulatory standards, not only the weight of a 40x20x2 mm profile pipe is determined, but also other parameters. From the moment the product arrives to the customer, the guaranteed shelf life until use is two years. It is mandatory to mark the pipes: manufacturer's name, dimensions, heat number, length and number of profiles, weight and bundle numbers.

Structural low-carbon steel is used for production, which gives the low weight of the profile pipe 40x20x2 mm.