MesterulManole

9711 0 0

MesterulManole August 1, 2016Specialization: many years of experience in finishing works of residential and office premises, summer houses, country cottages, etc. Hobby: cycling in all its forms

In this article you will learn how to assemble equipment to bend pipes to such a radius

Hello. In this review, I’ll tell you about simple methods that you can use to make a machine for rolling profile pipes. There will be two methods, which means you can decide which one suits you best in terms of the materials used and the set of necessary tools.

Of course, in specialized stores you can buy or order ready-made equipment for correct deformation of the metal profile. But why buy ready-made equipment if the price of what you can assemble with your own hands will be many times more affordable.

Description of material

Profile pipe belongs to a special type of rolled product, with the help of which metal structures of various sizes and functions are assembled. Such rolled metal is distinguished by the presence of a multifaceted or oval profile in the cross section. Most often its shape is a square or rectangle. It goes without saying that pipelines and other transport communications are not made from such pipes.

This limitation is explained by weak resistance to internal pressure and insufficient throughput characteristics. The fact is that profile pipes are made from strip strips, which generally does not provide for the reliable formation of reliable connecting sections. As a result, if this material is used for the manufacture of pipelines, there is a high probability of ruptures.

Possible complications during work

The actual bending of such a pipe is the process of giving the element a curved-smooth configuration. This can only be done under pressure, since the part has high strength. To reduce the pressure force required for bending, you can use heating of the bent fragment.

Despite the apparent simplicity of the operation, bending does not always result in elements of the desired configuration. Problems arise quite often. The most common complications include three.

The first is that the inner side of the profile folds in peculiar folds that resemble corrugation. In the correct version, it contracts evenly.

The second difficulty is the rupture of the outer wall of the profile pipe. During bending it stretches. Sometimes the metal cannot withstand the force and bursts. The third problem is that the pipe, changing its shape, can lose the alignment of the elements.

This means that its fragments in a bent state will lie in different planes. And this is unacceptable. Practice shows that all difficulties occur due to the wrong choice of bending method.

To choose it correctly, you need to take into account the plastic capabilities of the profile pipe. They are determined by the size and shape of the section, as well as the thickness of the walls of the product. Based on these values, you can calculate the minimum possible radius of curvature. Trying to make a round with a smaller radius is strongly discouraged.

To determine the minimum radius, we need the height of the section. It is calculated as follows. The height of the profile is measured, and twice the wall thickness of the product is subtracted from it.

The resulting number will be the desired height, let's denote it h. For pipes with a cross-section in the shape of a rectangle and square, the following rule applies. If the profile height is above 20 mm, the part can withstand bending in a section whose minimum length is hx3.5.

Products with a profile below 20 mm can be bent over a length of hx2.5 or more. This rule applies to all pipes. However, the wall thickness of the part also affects bending limitations.

The thinner it is, the higher the likelihood of a rupture or crushing of the part. Experts strongly do not recommend trying to bend wide products with wall thickness less than 2 mm. In this case, it is optimal to use a welding machine.

One more thing to be aware of. Pipes made of low-alloy and carbon alloys are very elastic and, after bending, can seem to “spring”, trying to take their previous shape.

This involves additional work with the product, since it will have to be adjusted again according to a pre-made template. Therefore, it is recommended to find out the value of the plastic moment of resistance of a given profile pipe and carry out bending taking this indicator into account. The smaller it is, the less the part will “spring”.

What types of profile pipes are there?

When talking about profile pipes, we mainly mean square, oval or rectangular products. As for the production method, they can be suture or seamless, with or without tempering. Tempering is a special procedure that results in the removal of internal stresses after the profile has been formed.

In general, we can say that the range of profile pipes is so diverse that several GOSTs were required to standardize it. For example, square-type profile pipes are determined by GOST 8639-82.

These regulatory documents contain instructions on the parameters by which thin-walled and thick-walled profile pipes are manufactured. The upper overall feature for them is the size of 180x180 mm, with a wall thickness of 8-14 mm. The smallest profile pipe is a square product of millimeter thickness, with a side size of 10 mm. From these values, the technology by which this rolled product is subjected to longitudinal deformation was determined.

A hollow beam measuring 18x18 cm, where the wall thickness reaches 1.5 cm, can only be bent using special equipment.

Main stages of work

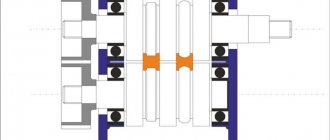

To make a homemade machine, you will also need four bearings and cages for them, cut from a metal pipe of a suitable diameter. You will also need four pieces of M12 studs with nuts.

It will also be necessary to cut two plates 118 mm wide and 142 mm long from a piece of metal 7-8 mm thick. You need to drill holes in them with a step drill with a diameter of 13 and 20 mm.

Next, you need to weld races for bearings to the plates, and install two bearings and a gear on the shafts. After this, you can begin assembling this device.

For details on how to assemble a homemade machine for strengthening a profile pipe, we recommend watching the video on the website.

Plastic Casing for PET Bottle Glass Jars

Next post

How to make a concrete mixer from a 200 liter barrel

Comments

Site headings

- Aviation

- Auto and motorcycle

- Army and Navy

- Archeology

- Animals

- Health

- Celebrities

- Games

- Interesting

- Internet and computers

- Story

- Space

- Crime

- Cooking

- Culture and art

- Fashion & Style

- Music

- Science and technology

- News

- Society

- Hunting and fishing

- Policy

- Nature

- Psychology

- Travel and leisure

- Entertainment

- Religion

- Rodnoverie

- Needlework

- Garden

- Homemade products

- Sport

- Construction and design

- Secrets and myths

- Economy

- Humor, jokes

- Sandbox

latest comments

When I play Topigr, I would like us to be completely free of problems, and not bess.

Now there is so much that is inexplicable in the world that mom, don’t worry.

Pindos, admit that you have not been to the moon and we will leave you behind.

Basque is the same banderlog as Rotaru! Basques, why aren’t you going to perform in Crimea and Donbass?

The so-called “truly great star” sponsored the genocide of Donbass! Let him speak.

Another pig returned to his pigsty. Donbass has become cleaner.

I agree 90% with the author’s opinion. Here is the opinion of a.filipovic. I still don’t understand who it is.

This is not a sandstorm. The sea receded with the wind and the wind raised the sand.

Gaining popularity

How to make a good wooden chair with your own hands

Manual sewing machine from unnecessary trash

How to fix a garland if one color doesn't light up

Electric nut cracker made of plywood and wiper motor

How to make a heated bath in your summer cottage

The information and entertainment site “Labuda” is daily, operational, relevant, interesting news and useful information from different spheres of life.

Full or partial copying of labuda.blog site materials is permitted only if an active and indexable hyperlink to the publication source is indicated.

legal information

Dear authors, remember that the publications you post must not violate the laws of the Russian Federation and the copyrights of third-party resources.

* Extremist and terrorist organizations banned in the Russian Federation and the Republics of Novorossiya: “Right Sector”, “Ukrainian Insurgent Army” (UPA), “ISIS”, “Jabhat Fatah al-Sham” (formerly “Jabhat al-Nusra”, “Jabhat al-Nusra"), National Bolshevik Party (NBP), Al-Qaeda, UNA-UNSO, Taliban, Majlis of the Crimean Tatar People, Jehovah's Witnesses, Misanthropic Division, Brotherhood "Korchinsky, "Art preparation", "Trident named after. Stepan Bandera", "NSO", "Slavic Union", "Format-18", "Hizb ut-Tahrir".

Features of rolling

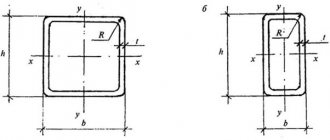

Longitudinal rolling of a profile pipe is based on rolling, which is very similar to a rolling mill. As a result, the profile pipe rolling machine was given a pyramid-shaped appearance.

There are two lower and one upper cylinder: with the help of the lower elements, transportation is carried out, and the upper roller is used to deform the rolled product. The rolling machine for profile pipes has a very clear operating pattern: the pipe is placed on top of the lower pair of rollers, and then pressed to the upper cylinder.

Thanks to this pressing force transmitted to the upper cylinder, deflection of the pipe is achieved, with further deformation of the longitudinal profile. After turning on the “feed” (bottom drive), the deformation area spreads over the surface of the entire pipe being processed.

As a rule, with the help of one application a long profile cannot be particularly deformed. However, this operation can be repeated as many times as desired. This allows the formation of both arc-shaped and looped profiles.

Results

Thus, you can manually make an excellent machine for folding roofing sheets and other structures with minimal investment and labor, and you will never again need to rent sheet bending machines or any other metalworking equipment.

Real master jewelers have been working part-time for a long time, thus having a stable, profitable part-time job, or using their homemade equipment as the main source of income.

Republished by Blog Post Promoter

What types of rolling machines are there?

When assembling metal structures, you have to use a variety of blanks. To produce them, a wide variety of rolling units are used.

The currently most popular rolling machines are:

- Roller bending machines

. With their help, rolled sheets are deformed. Pipes cannot be processed in such machines due to the very small gap between the transporting and deforming elements. Roller benders are used where it is necessary to produce thin-walled shaped parts - ebbs, gutters, etc. - Three-roll machines

. Using such a device, you can deform both pipes and sheets. In addition, machines of this type make it possible to process rolled profiles (angles, etc.). The downforce generator determines the power and performance level of this equipment. On machines with a conventional clamp, to which a pressure roller is connected, productivity is below average: any mechanic can make such a rolling machine for a profile pipe with his own hands. When used instead of a hydraulic clamp, a machine of this type can even bend T-beams. - Four roller machines

. This equipment is considered the most powerful of all devices of this type. Using these pipe benders, you can produce not only arc profiles, but also ring profiles. Four-roll machines use exclusively a mechanical drive: in this respect, they differ from three-roll equipment, which can be either partially or completely manual. This involves rolling a profile pipe with your own hands, using the physical efforts of a worker. To increase the power of a machine, it is necessary to complicate its design and increase the level of energy consumption. This explains why in enterprises where profile pipes are produced on a mass scale, they mainly use a four-roll pipe bender: it is unlikely that you can make a profile bender of this type with your own hands.

Making a homemade pipe bender and profile bender with your own hands

There are many models of industrial pipe benders on the construction market, but it hardly makes sense to buy a professional tool to bend two or three pipes. But making this simple tool with your own hands and using it in the household is within the capabilities of every person who has certain technical skills.

Content

Application of pipe benders

Pipes were and are one of the most popular building materials, used both in households and in industry and construction. In addition to being used in the installation of water and gas pipelines, pipes are also used for the manufacture of fences, greenhouse structures, gazebos, canopies, garden furniture, etc. Thus, having a pipe bender in the household will never be superfluous.

Often, to produce various structures from pipes, it is necessary to bend profile pipes along a radius. For these purposes, a pipe bender is used, which allows bending pipes to an angle of 180 degrees. Pipe benders allow you to easily and accurately change the configuration of pipes made of various materials - aluminum, metal-plastic, stainless steel. The bend is made according to the required shape and dimensions.

Types and models of pipe benders

The industry produces various types of professional pipe benders. To bend pipes of small diameter, hand-powered tools are usually used, but pipes with a diameter of up to three inches are bent using pipe benders equipped with a hydraulic drive.

This type of tool is designed for large-scale work. Industrial pipe benders can be made in both stationary and mobile versions. The most convenient tool is one that connects to the mains.

Electromechanical pipe benders provide the most accurate bending angle and radius. In this case, changing the shape of the pipes does not entail any deformation of the internal profile.

Pipe benders are also divided according to the bending method:

- in crossbow pipe benders, a shape of a certain diameter is used as a bending element;

- manual spring tool is designed for bending metal-plastic pipes using special springs;

- in segmental pipe benders, bending is carried out by stretching the pipe around the segment; mandrel tools bend thin-walled pipes to a small radius using steel, plastic and brass mandrels.

When bending a pipe, one should take into account the permissible bending radii for pipes of different diameters and different wall thickness parameters. Permissible bending radii for products of various characteristics are presented in special reference books. If the radius is violated, the quality of the bend can be significantly reduced.

Let's start production

Despite the apparent simplicity of the process, bending pipes requires a rather serious approach, since with an incorrectly selected tool, various defects and deformations are possible, leading to a decrease in the throughput of pipes and a decrease in their strength characteristics.

Therefore, the selection of tools is carried out taking into account the compatibility of the characteristics of the pipe and the operating principle of the tool.

Pipes made of different materials, having different diameters and different wall thicknesses have a certain minimum bending radius. The following table is used to determine it:

Of course, it is possible to bend pipes with a smaller radius, but it should be taken into account that this will reduce the quality of their bending.

Now let's talk about making pipe benders ourselves and consider several designs of such tools.

The easiest way to bend a pipe is to use a special template. It should be noted that this method allows you to bend not only aluminum but also steel pipes.

To make a template, we will need wooden boards slightly thicker than the diameter of the pipe being bent. To ensure that the pipe does not slip out of the template during operation, the boards are cut with a certain slope.

The boards fastened together must be fixed on a table or other convenient base. In addition to the template, you should also attach a stop here at a certain distance to hold the pipe being bent. The simplest model of a pipe bender is ready.

The end of the bendable pipe is inserted into the space between the fixed template and the stop. Taking the pipe by the opposite end, you need to bend the product with smooth movements. To facilitate the process, you can use a lever by inserting a strong reinforcing rod into the pipe or put a larger diameter pipe on the product to be bent.

Trying to bend the pipe in the center of the template should be avoided, as this not only requires significant force, but may also cause the pipe to break.

A similar template can also be made from metal hooks attached to a sheet of plywood along the corresponding bend line. The advantage of this design is the ability to adjust the bending line by rearranging the hooks.

The simplest pipe benders allow you to bend not only thin-walled flexible pipes, but also thick-walled products. To do this, use a hand winch.

Using this design, even powerful profile pipes can be bent. However, for these purposes, when cutting out a wooden template, you should not make a bevel, and the pipe must be secured with several stops at once.

In various workshops you can often find pipe benders with a similar design:

You can make it yourself. In the process of manufacturing such a pipe bender, the most problematic is the selection or production of the necessary templates and rollers, since the quality of the bend depends on the girth of the pipe.

If the tool is designed to work with flexible pipes, steel rollers and templates can be replaced with similar parts made from hardwood.

The rollers can be turned on a lathe. Also, the roller can be cut with a jigsaw. To do this, circles of different diameters are cut out of hard plywood with an inclination in the required direction, which are then fastened into a single piece. Finally, the roller should be sanded. To give greater strength to the product, it should be reinforced with metal plates.

To obtain a large bending radius, it is optimal to use rolling pipe benders. These tools, like those described above, are not distinguished by their design complexity. In general, the level of complexity of the design of rolling pipe benders largely depends on the material of the pipes being bent.

If the tool is needed to work with flexible pipes, its working surfaces can be made of wood. Since wooden parts are quite simple to manufacture and do not require large expenses, they can be easily replaced when worn out.

If wooden parts prove to be ineffective, they can be replaced with metal ones. Let's look at several designs of homemade rolling pipe benders.

As you can see, this tool is made primarily of wooden parts. The rollers in this model are made of polyurethane, however, they can also be made of wood. T

Bearings can also be used as rollers. However, in this case, you will need to jam the pressure bearing so that it does not rotate.

Its technical characteristics depend on the distance between the rollers of a pipe bender. The greater the distance between the rollers, the less effort will be required to bend and run the pipe. However, in this case, a minimum bending radius is ensured, and a significant section of the pipe is not subject to bending at all.

In order to produce a more versatile tool, the possibility of installing side rollers in different positions should be provided at the design stage. It is necessary to fasten steel clamps on the sides to hold the pipe in a certain position perpendicular to the axes of the rollers. Otherwise, the pipe will begin to bend in a spiral.

The pressure roller of the pipe bender should be tightened from below using a metal strip with a thread of the required diameter cut in the center.

By smoothly tightening the pressure roller of the device, the bent pipe is rolled through the pipe bender. When rolling, for every half turn of the fixing metal strip, a pipe is run through.

When bending a small radius, you will need to make from 50 to 100 runs. To ensure that the bending circle does not undergo deformation, it is necessary to roll the pipe at the same speed. If there is a weld on the surface of the pipe, it is necessary to ensure that the seam is always on one side during rolling.

Homemade pipe bender for profile pipe

The author's story of creating a homemade profile pipe bender.

Spring is coming, rooks are coming, and the greenhouse has been unfinished for many years now). From the very beginning I decided to make a normal greenhouse from a normal profile. To do this you need to bend the frame. You can, of course, look for where it is bent or even buy a ready-made one, but we are not looking for easy ways. We will bend it ourselves, and for this we need to make a pipe bender. It will come in handy more than once on the farm...

So, having rummaged through the search for drawings or diagrams for making a pipe bender with my own hands, I collected a small collection of photos. So let's start this manufacturing process with drawings and photographs.

The pipe bender itself:

A little manufacturing process:

Well, when we already have an idea of the design, the drawings themselves:

The most important thing is to grind the rollers and races for the bearings. We select the shaft sizes based on our bearings and sprockets. You can avoid sprockets altogether by making the drive from a single roller, but according to reviews, this can cause the structure to slip.

You can also replace the clamping screw with a jack. In any case, the main shafts.

Well, let's start selecting materials and adjusting drawings? In the meantime, you can look at an even more advanced option. The shafts are machined to fit a couple of diameters of round pipes and a regular profile pipe.

To begin with, I bought bearings. I didn’t buy simple ones, but bought self-centering ones with supports that cost a ruble more. Since the bevel bender will be made of a “premium class”, the gears and chain for it must be premium). In my case, Mercedes ones.

The turner's task was formulated on a piece of wallpaper and he successfully completed the task.

Well, the first fitting

The gears will be secured through a key. You also need to drill holes in the rings and cut threads to secure them.

I drill holes and make grooves for the key to attach the gear.

I drill holes in the restrictive rings and cut threads for clamping bolts. I sawed off a piece of channel to mount the pressure shaft. One shelf was cut off so as not to interfere with the installation of the jack. Holes are drilled and threaded for mounting the bearings.

Now you can proceed to welding work. I lay out the parts on the “welding table”. I assemble the structure and weld the legs.

We fasten the pressure shaft. We touch it and weld the nuts for the springs.

I hang the platform on springs. By the way, the upper stop is bolted on, just in case you suddenly have to remove the pressure shaft.

Well, then I drill and screw the lower support shafts.

I'm making a chain tensioner. Use a magnetic corner as a holder. Great stuff!

I screw the sprockets on, not forgetting to insert the dowels. The dowels were made by cutting with an engraver. I tighten the tensioner.

The next part is the handle for rotation. Don't forget to make a handle with a rotating tube so as not to rub calluses. And we install the jack, weld a couple of bolts and fix it on the site.

Result

It's time for bench testing! What can I say about the quality of the bend... the bend itself turned out just wonderful. There is a slight crease at the extreme points. There is no way without it. But thanks to the collar on the central shaft, there is no jam along the arc.

In principle, I am more than satisfied with the result. The machine turned out just right. It turns easily, bends well. All that's left is to give it a little presentation... paint is used.

gredx.ru