Plastic is a generalized name for a large group of polymers (synthetic). Plastics get their name due to their ability to become plastic when heated, harden and retain their shape when cooled. In terms of these properties, they are no different from the production of metals, many parts of which are also produced by casting. But this is the only similarity between the materials. So which is better: metal or plastic?

Advantages of plastics

Plastic appeared only in the mid-19th century. At first, natural polymers like rubber were used, but they were quickly replaced by synthetic materials. The main advantages of plastics:

- Light weight, ability to create foam materials. Compared to metal, polymers have a much lower specific gravity, they do not create a load on the base, and are easy to transport.

- Ease of processing and molding. Plastic can be given any fantasy shape. Many polymers are used to fill gaps, fill floors, create complex shapes, and are even suitable for 3D printing.

- Availability of coloring in any shade. In this parameter, plastic is ahead of metal. It is painted in bulk, so during further processing, for example, cutting, there is no need to tint the sections.

- No corrosion. Plastic is a material characterized by exceptional resistance to moisture and atmospheric factors. It can be used indoors and outdoors, in conditions of constant fog, and does not require a protective coating. Moreover, polymers are used for anti-corrosion protection of metal products on a par with galvanizing.

- High insulating properties. Polymers are dielectrics. They also dampen vibration, shock, absorb sound and do not allow heat to pass through. According to these characteristics, they are the exact opposite of steel.

- Low cost. This is one of the key factors due to which plastic is replacing metal. It is also worth noting that it is anti-vandal: no one steals plastic elements for recycling like parts made of non-ferrous metals.

- Plastic. Using certain types of polymers, it is possible to obtain plastic parts that can withstand bending, twisting, stretching and returning to their previous shape. Steel is not capable of this.

Plastic has many advantages, but there are also some disadvantages. Many polymers emit toxic compounds when burned, but this problem can be reduced by adding flame retardants to the composition - additives that reduce flammability. Not all polymers can be recycled.

More detailed information on the areas in which plastic is used can be found on the website https://artmalyar.ru !

Choosing glue to glue plastic and metal

To solve this problem, several types of adhesives are suitable: polyurethane, epoxy, contact. They form a strong connection with both metal surfaces and plastic. It is important to remember: for outdoor work you should take waterproof products so that they do not lose strength under the influence of atmospheric moisture.

Polyurethane glue

Polyurethane-based compositions have many useful qualities. They are resistant to high humidity, do not soften when heated, and are suitable for gluing a wide variety of materials, from paper to plastic and metal. An additional advantage is the absence of chlorine-containing solvents. An example is HOLZ-R PUR 501 adhesive, which is used for gluing non-absorbent surfaces. Polyurethane adhesive is used both indoors and outdoors.

Epoxy resins

Adhesives based on epoxy resins are good because they firmly bond almost any surface - metal, wood, plastic, glass, etc. However, using them is not very convenient, since epoxy resin acquires adhesive properties only after adding a hardener, which is stored separately and added immediately before use. After mixing, the composition must be used quickly before the chemical reaction ends, which results in irreversible hardening of the mixture. Avoid contact with skin and mucous membranes, as the mixture is quite toxic in a liquid state. The connection gains final strength within 24 hours. All this time it is necessary to keep the parts to be glued tightly pressed together.

Contact adhesives

The category of contact adhesives includes substances that have strong residual adhesion. This means that for high-quality gluing, the composition is first applied to both surfaces to be joined, slightly dried, and then pressed against each other with force. If the surfaces are too large and it is not possible to quickly treat them with glue, you can cover the glue layer with plastic film to maintain high adhesion. The most well-known contact adhesive for household use is “Moment”, but currently there are much more effective preparations.

When choosing which plastic to metal adhesive is best to use in your case, it is advisable to consider the type of plastic.

- For PVC and hard plastics such as ABS, use KLEYBERG 900I adhesive. This product is designed for the shoe industry and does an excellent job of gluing metal, rubber, leather, and fibrous materials.

- For HPL plastic, Kleiberit 152.0 24 adhesive, made on the basis of polychloroprene, is suitable.

- For plastic laminates, DUDIPREN 531S adhesive is used - a one-component composition based on polychloroprene.

To achieve the strongest possible connection, the surfaces with applied and dried glue should be pressed firmly against each other. Bonding occurs instantly, but it is advisable to ensure uniform pressure.

What's good about metal?

Compared with plastic, metal has its advantages:

- Strength. Where high loads are involved, few complex polymers can compete with steel. Although you have to pay for the strength with significant weight.

- UV resistance. Although steel does not like moisture, it is not afraid of sunlight, as well as temperature fluctuations in winter and summer. There is no such thing as aging for it, which is typical for plastic.

- Recyclable. You can melt down metal products as much as you like. In this sense, it is environmentally friendly. Plastic cannot boast of this. Only some of its types are suitable for reuse.

- Electrical conductivity and thermal conductivity. For some areas these qualities are important. Current-carrying conductors are made exclusively of metal; plastic has not yet been able to supplant it in this field.

- Fire resistance. If we talk about refractory metals, then they are able to withstand temperatures where the count is in the thousands. And they can withstand exposure to open fire better than plastic.

Conclusion. It is impossible to say unequivocally that plastic is better than metal in everything or vice versa. Due to its specific characteristics, steel cannot be replaced from all niches. Although, given the light weight, low price and the possibility of endless modifications of the composition, the future definitely belongs to polymers.

Rules for working with glue

Many adhesive compositions contain toxic or harmful compounds that are released during curing. Before gluing plastic to metal, you need to take care to follow safety rules so as not to harm yourself and others. To do this you should:

- ensure active ventilation of the room with removal of at least three times the volume of air outside within an hour;

- when working with glue, constantly wear a respirator of the appropriate protection class to protect the respiratory system;

- wear protective gloves to prevent glue from contacting the skin of your hands;

- Protect your eyes with goggles or a transparent mask;

- To store glue, choose a place inaccessible to children and pets.

By following simple recommendations, you will minimize the risk of poisoning from toxic components.

Another recipe for a solution for chemical metallization

You can prepare another recipe for chemical copper plating according to the order of dissolution sent by the user psychos from the RadioKot , where less reagents are taken and soda ash is not added. Potassium iron and thiocyanate and thiocyanate are also taken differently.

Solution composition:

CuS04*5H2O (copper sulfate) - 15 g. NiCL2*6H2O (nickel chloride) - 2 g. NaOH (sodium hydroxide, caustic soda) - 15 g. Trilon B - 30 gr. K3[Fe(CN)6] (potassium iron sulfide, red blood salt) - 0.01 g. (dilute 1 g of reagent in 100 ml of water, then take 1 ml of this solution with a syringe - this will be 0.01 g.) KNCS (potassium thiocyanate) - 0.01 g. (dilute 1 g of reagent in 100 ml of water, then take 1 ml of this solution with a syringe - this will be 0.01 g.) Formalin 20 ml/l. Distilled water - 1 l.

Dissolution order:

K3[Fe(CN)6] and KNCS in this video are not taken from the recipe above. Let me make a reservation, they can be added either according to the recipe or in the video.

Solution consumption

This solution also works well, the consumption is also 50 ml. per 1 dm.sq. boards, the stability of the solution after mixing with formaldehyde is 5..7 days. It works a little slower, but this does not affect the quality of the coating in any way.

Conclusion

Try both solutions and use whichever one you think is best for you.

This article also used the research of user mial on the topic of Metallization of holes from the Radiokot forum.

Happy metallized holes everyone.

Author of the article: Admin

If you liked the article, click on the button of the desired social network located below. With this action you will add an announcement of the article to your page. This will greatly help in the development of the site.

Copper plating solution for chemical plating

In this article I will tell you how to properly prepare a solution of chemical copper plating, which is one of the stages of metallization of holes in printed circuit boards.

Preparation of chemical metallization solution

To prepare the solution you will need inexpensive reagents. They can be bought in online stores, of which there are now many and they work with individuals. There should be no difficulties with the acquisition, if there is a desire.

The composition of the solution is as follows:

CuS04*5H2O (copper sulfate) - 30 g. NiCL2*6H2O (nickel chloride) - 4 g. NaOH (sodium hydroxide, caustic soda) - 50 g. Na2CO3 (sodium carbonate, soda ash) - 20 g. Trilon B - 85 gr. K3[Fe(CN)6] (potassium iron sulfide, red blood salt) - 0.1 g. KNCS (potassium thiocyanate) - 0.003 g. Formalin 20 ml/l. Distilled water - 1 l.

Order of mixing reagents

1. We weigh 30 grams. - copper sulfate and 4 g. - nickel chloride. Pour 0.4 liters of distilled water into a container and dissolve these reagents in it.

2. We weigh 50 grams. - caustic soda, 20 gr. - soda ash and 85 g. — trilona B.

3. Pour 0.4 liters of water into another container and dissolve the reagents in the following sequence.

First caustic soda, then soda ash and last Trilon B.

4. We mix these solutions by pouring a solution of copper sulfate with nickel into a solution with Trilon B, soda and caustic soda. Mix well and bring the volume of the solution to 1 liter with water. Let it stand for 5..10 minutes, if there is a slight sediment, then filter the solution.

5. Weigh 1 gram. potassium iron sulfide (red blood salt), dissolve it in 100 ml. distilled water. Then we take 10 cubes of this solution with a syringe - this will be 0.1 g. this reagent and add it to the just prepared chemical solution. copper plating

6. Weigh 1 gram. potassium rhodanate and dissolve it in 100 ml. distilled water. Then we take 0.3 cubes of this solution with a syringe - this will be 0.003 g. and also add it to the main solution.

Potassium iron sulfur and potassium radanium are toxic substances. When working with them, observe basic safety precautions. Do not smell, taste, etc. When stirring the solution, work with rubber gloves!!!

7. Mix the chemical solution well. copper plating, it is now ready for use.

Storing the solution and adding formalin

In this state, that is, without formalin, the solution is stored for a very long time; you can immediately stir 5 liters of solution, pour it into a canister and use it by pouring the required amount for copper plating, adding formalin to it.

As an example, I'll show you how this is done.

Take 20 ml. chemical copper plating solution. According to the recipe, we see that you need to add 20 ml per 1 liter of solution. formalin, let's do a little calculation.

Let's calculate how much formalin is needed per 1 ml. chemical copper plating solution.

20/1000 = 0.02 ml.

Since we took 20 ml. chemical solution copper plating, then..

20*0.02 = 0.4 ml. (0.4 cubes in a syringe) formalin must be added.

After adding formaldehyde, cover the container with a lid. Cover so as not to smell the smell of formaldehyde, take care of your health (formaldehyde is a carcinogen!)

This article was published on the website. The permanent link to this article is at this address

Read articles on the original site, do not support thieves.

Testing of electroless copper plating solution

To test how the chemical copper plating solution works, we take a dielectric activated by an activator (read this article on how to activate holes in printed circuit boards) and lower it into a container. Literally before our eyes, the textolite begins to darken and become covered with chemical copper.

The electroless copper plating process should take between 15 and 30 minutes, and this time depends on the result and the quality of the plating that you need to monitor. During the copper plating process, gas is released; the board must be constantly rocked and turned over to evenly distribute the solution over the surface.

20 minutes passed, the result of the solution was clear, the entire dielectric, including the holes, was covered with a thin layer of 1 micron. layer of copper and it is ready for the next stage - electroplating, this stage is described in detail in this article.

Non-foil PCB was taken as an example, some will think, in this way you can not buy foil PCB, but build up copper onto a bare dielectric and make boards in this way. I want to break you off right away: in order to build copper onto a dielectric, you need to prepare the surface well, which is very difficult to do at home. So don’t worry and make boards in the usual way, that is, activate the foil PCB.

Solution capacity for copper

In conclusion, I would also like to add that we take the consumption of this chemical copper plating solution at the rate of 50 ml. solution per 1 sq.m. printed circuit board. That is 50 ml. The solution is enough to copper a double-sided board measuring 10*10 cm.

After adding formalin, the solution will still live for about 5 days, then it will deteriorate.

I advise that if you are making critical boards, it is better to mix a fresh portion of the chemical copper plating solution with formaldehyde.

Technological features of metallization

Copper is most often used as an underlayer surface for electroplating. It is the copper layer that will play the role of a damper for the plastic, due to which the stress will be stabilized, which is inevitable with a significant difference in the thermal stress coefficient of such dissimilar materials. the sublayer will be additionally chromed or nickel plated, as described below.

Layer composition:

- Plastic.

- Matte copper layer.

- Copper layer with shine.

- Metal with a chemical type of deposition.

- Nickel shiny layer.

- Semi-shiny nickel finish.

- Nickel matte layer.

- Chrome layer with shine.

- Conversion layer.

- Shiny and matte metallic layer.

The structural components that are applied to the electrically conductive sublayer of the coating can vary greatly. We can talk about films of shiny, velor, bleached, blackened, patinated and other types.

The purpose of films is not simply to improve the appearance of products. For example, nickel plating will extend the life of the plastic. The fact is that nickel can compress plastic, greatly strengthening the material.

The features of the structural composition that will be applied to the electrically conductive coating layer can vary greatly. We will talk about films of bleached, shiny, blackened, velor, patinated and other types. The purpose of films is not only to improve the appearance of products. For example, nickel-plated coatings extend the service life of plastics. The fact is that nickel can inhabit plastic, significantly strengthening the material. To create a galvanic coating, an electrolyte is required.

There are different types of electrolytes used, including:

- Shiny copper plating.

- Electrolytes for nickel plating.

- Specialized compositions on the basis of which velor-type coatings or coatings interspersed with solid particles will be created.

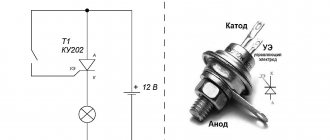

Other metals, such as zinc or tin, should also be used. But before applying these types of metals, passivation will be required, after which a film will appear on the surface (with or without color). These types of films will protect the material from rust or plaque. Chemical metallization of plastics is characterized by the fact that metal-type sublayers do not have high electrical conductivity. In any case, the conductivity will be much lower than in the case of an electrolyte.

For this reason, during electrochemical deposition, the current density used should be small - from 0.5 to 1 Ampere per square decimeter. If the density is higher, a bipolar effect will appear, which will lead to the dissolution of the coating near the place where there is contact with the conductive suspension. In certain cases, to avoid dissolution of the coating, nickel or copper will be applied to the chemically deposited metal layer. In this case, all this is done at a low electric current density, but further layers will be applied in the standard mode.