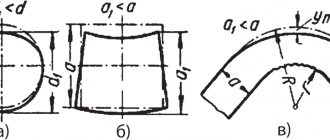

Bending of metal workpieces is presented as a technological process, during which the workpiece can be given a specific configuration by compressing the internal and stretching the outer layers of the workpiece. Bending metal involves stretching the outer layers and increasing their size; the inner layers, on the contrary, decrease in size due to compression. Only the layers located along the axis of the workpiece remain unchanged.

The service in question in metal production is quite in demand and is one of the areas of activity of our company. Sheet metal bending in Moscow involves the absence of welding seams, which allows for a stronger and more durable final product.

Sheet metal bending 6 meters

The capabilities of the technology largely depend on the length of the sheet and the potential of the equipment. Bending 6 meters of sheet metal without separating it is a complex process. But if the enterprise has the necessary capacities, its own production base, and its equipment has a high technical level for the production of rolled products, processing sheets of such length is not a problem. The potential of our bending production is very wide, and if you have six meters of sheet metal, the task will be completed.

| Monday, 01/17/2022, 10:01 Welcome Guest | RSS | ||

| Home | Registration | Entrance | ||

| Car maintenance and repair Find out everything about the car |

Metal bending

General information about bending

Bending of sheet and strip metal parts

Mechanization of bending works

Pipe bending

Types and causes of defects during bending

Occupational safety when bending

1. General information about bending

Bending is a method of processing metal by pressure, in which a workpiece or part thereof is given a curved shape.

Bench bending is performed with hammers (preferably with soft strikers) in a vice, on a plate or using special devices.

Thin sheet metal is bent with mallets, wire products with a diameter of up to 3 mm are bent with pliers or round nose pliers.

Only plastic material is subject to bending.

Bending parts is one of the most common metalworking operations.

The production of flexible parts is possible both manually using support tools and mandrels, and on bending machines (presses).

The essence of bending is that one part of the workpiece is bent relative to the other at a given angle.

This happens as follows:

A workpiece, freely lying on two supports, is subject to a bending force, which causes bending stresses in the workpiece, and if these stresses do not exceed the elastic limit of the material, the deformation obtained by the workpiece is elastic, and after the load is removed, the workpiece takes its original form (straightens).

However, when bending, it is necessary to ensure that the workpiece, after removing the load, retains its given shape, therefore the bending stresses must exceed the elastic limit and the deformation of the workpiece in this case will be plastic, while the inner layers of the workpiece are subjected to compression and shortened, the outer layers are subject to tension and their length increases .

At the same time, the middle layer of the workpiece - the neutral line - experiences neither compression nor stretching, and its length before and after bending remains constant. Therefore, determining the dimensions of profile blanks comes down to calculating the length of straight sections (flanges), the length of shortening of the blank within the radius or the length of the neutral line within the radius.

When bending parts at right angles without rounding on the inside, the bend allowance is taken from 0.5 to 0.8 of the thickness of the material.

By adding the length of the inner sides of the square or staple, we get the length of the workpiece.

Example 1.

Square dimensions: a = 30 mm, b = 70 mm, t = 6 mm.

Development length L = a + b + 0.5t = 30 + 70 + 3 = 103 mm.

Bracket dimensions: a = 70 mm, b = 80 mm, c = 60 mm, t = 4 mm.

The length of the development of the staple blank is L = 70 + 80 + 60 + 2 = 212 mm.

Example 2.

Calculate the length of the development of a square with an internal rounding.

We divide the square according to the drawing into sections.

We substitute their dimensions a = 50 mm, b = 30 mm, t = 6 mm, r = 4 mm into the formula L = a + b + π/2(r + t/2)

Then we get: L = 50 + 30 + 3.14/2(4 + 6/2) = 50 + 30 + 1.57⋅7 = 90.99 91 mm.

Example 3.

Calculate the length of the development of the rounded bracket blank.

We divide the bracket into sections, as shown in the drawing.

Their dimensions: a = 80 mm, h = 65 mm, c = 120 mm, t = 5 mm, r = 2.5 mm. L = a + h + c + π(r + t/2) = 80 + 65 + 120 + 3.14(2.5 + 5/2), therefore L = 265 4 + 15.75 = 280.75 mm.

Example 4.

Calculate the length of a reamer from a steel strip 4 mm thick and 12 mm wide for a closed ring with an outer diameter of 120 mm.

By bending this strip into a circle, we obtain a cylindrical ring, with the outer part of the metal stretching somewhat and the inner part shrinking.

Consequently, the length of the workpiece will correspond to the length of the center line of the circle, passing in the middle between the outer and inner circles of the ring.

Workpiece length L = πD.

Knowing the diameter of the middle circle of the ring and substituting its numerical value into the formula, we find the length of the workpiece: L = πD = 3.14 108 = 339.12 mm.

As a result of preliminary calculations, it is possible to produce a part of the established dimensions.

During the bending process, significant stresses and deformations occur in the metal.

They are especially noticeable when the bending radius is small.

To prevent cracks from appearing in the outer layers, the bending radius should not be less than the minimum permissible radius, which is selected depending on the thickness and type of material being bent.

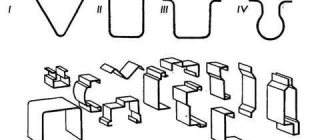

2. Bending of sheet and strip metal parts

Bending of a rectangular bracket made of strip steel is performed in the following order:

Determine the length of the workpiece development by adding the length of the sides of the staple with an allowance for one bend of 0.5 of the thickness of the strip.

I = 17.5 + 1 + 15 + 20 + 1 + 15 + 1 + 17.5 = 89 mm

mark the length with an additional allowance for processing the ends of 1 mm per side and cut off the workpiece with a chisel;

straighten the cut-out workpiece on the stove;

sawn to size according to the drawing;

cause bending risks; clamp the workpiece in a vice between the square jaws at the mark level and bend the end of the bracket with hammer blows (the first bend);

rearrange the workpiece in a vice, clamping it between a square and a mandrel bar longer than the end of the clamp;

bend the second end - the second bend;

remove the workpiece and take out the frame frame;

mark the length of the legs at the curved ends;

put a second square on the vice and, placing the same mandrel bar inside the bracket, but in a different position, clamp the bracket in the vice at the level of the marks;

bend the first and second legs, make the 4th and 5th bends of the first and second legs;

check and straighten the 4th and 5th bends using a square;

remove burrs on the edges of the staple and file the ends of the legs to size.

Bending of a double coal in a vice is carried out after marking, cutting out the workpiece, straightening on the plate and filing along the width to a given size.

The workpiece prepared in this way is clamped in a vice between the square jaws and the first shelf of the square is bent, and then one jaw is replaced with a lining block and the second shelf of the square is bent.

At the end of bending, the ends of the square are filed to size and the burrs are removed from the sharp edges.

The clamp is flexible.

After calculating the length of the workpiece and marking it at the bending points, clamp the mandrel in a vice in a vertical position.

The diameter of the mandrel must be equal to the diameter of the clamp hole.

Using two pliers, bend the clamp along the mandrel along the marking marks (two people work: one holds the pliers, and the second strikes).

The final shaping of the clamp is carried out using the same mandrel with a metal hammer, and then on a straight plate.

To avoid dents and nicks from impacts, a piece of iron strip is placed between the hammer and the part.

Bending the ear with round pliers.

An eyelet with a thin wire rod is made using pliers.

The length of the workpiece should be 10-15 mm longer than required according to the drawing.

Holding the workpiece by one end, bend the other, gradually moving the pliers at the bend points.

After the eyelet is bent according to the given dimensions, it is given the desired shape using pliers.

After this, the excess end of the rod is removed with pliers.

Bushing bending.

The sequence of transitions when bending a cylindrical bushing is described below.

Let's say you need to bend a cylindrical bushing from strip steel on round mandrels.

First, determine the length of the workpiece.

If the outer diameter of the sleeve is 20 mm, the inner diameter is 16 mm, then the average diameter will be 18 mm.

Then the total length of the workpiece is determined by the formula I = 3.14⋅18 = 56.5 mm.

Then the workpiece with the mandrel is clamped in a vice so that the bent part is above the level of the jaws of the vice and blows are applied to the protruding part through soft spacers with a hammer, bending the end of the strip on the mandrel so that the strip fits tightly to its surface.

Then the workpiece with the mandrel is rearranged with the reverse side and the second end is bent along the mandrel with blows of a hammer until both planes fit snugly into the mandrel at the joint.

After releasing the workpiece, the quality of bending is checked with a measuring ruler.

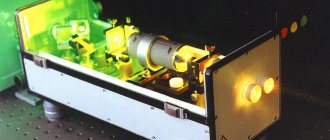

3. Mechanization of bending works

Profiles (strip, section metal) with different radii of curvature are bent on three-roller and four-roller machines.

When bending, remove accumulated dirt from the rollers and wipe them with clean rags.

The aluminum alloy profile blank is lubricated with thick oil during the bending process.

Profiles with a large bending radius are produced on a three-roller machine in several passes.

Profiles in the shape of circles, spirals or other curvatures are produced on four-roller machines.

1,

| Copyright avtomeh.ucoz.net © 2022 |

Sheet bending

The essence of sheet bending work is that they transform a flat product into a spatial one, “living” in three planes, and give it various shapes. Bending of a 6-meter sheet is usually performed without heating, in a cold way. Thermal exposure may be required only in cases where the rolled product has a large cross-section. Or when the raw material from which it is made has low ductility. The most difficult to process by bending are rolled titanium, duralumin and steel alloys with inclusions of manganese and silicon.

Bending metal of any complexity in Moscow and the Moscow region

Metal bending is possible using various methods, hot and cold. The most common method is the transformation of cold products on bending machines. The manual method is used quite rarely; it is used for bending thin sheet metal up to 0.6 mm thick. Automatic bending methods:

- On a hydraulic press

(universal air). A metal strip (up to 10 mm thick, up to 6 m long) is installed on the lower table with the matrix. The product of the desired shape is obtained due to the action of the punch directed from above to the required depth. - According to the matrix.

The technology is characterized by increased accuracy and is used when processing sheet metal up to 5 mm, deforming the workpiece at an angle of less than 90 degrees. - Using a rotating beam.

Used for bending sheets up to 1 mm to bend products in different directions. - Sliding processing.

When carrying out the procedure, a separate tool is used to prepare each thickness of workpiece.

Metal bending ensures a constant structure of the metal plate in the bend areas. The thickness of the sheet metal can reach 12 mm.

Bending sheet metal with a sheet metal bending machine

In an industrial way, sheet bending 6 m long is carried out on special devices - sheet bending machines. These devices differ significantly in functionality and the way they influence the workpiece. The main components of a rotary machine are rollers. They help the workpiece acquire a rounded shape. On the simplest machines, the rollers can be driven manually; in more complex machines, this process is carried out automatically. For simple types of bending, you can use a device with a simpler mechanism. It includes two plates - static and rotary - and a pressure beam. However, it is difficult to process long sheets on these devices. A simple bend, and again for small workpieces, can be performed by a press, the operation of which is based on pneumatic or hydraulic force. The bending of the sheet is carried out by two working parts - the matrix (fixed element) and the punch (movable). This machine method can process sheets of large thickness.

Step-by-step technological process

Our production allows us to produce a wide range of different rolled metal elements, and the bending technology itself is represented by the following stages.

- The preparatory stage requires deciding on the angles and bend points, dimensions of the final product and configuration.

- Before bending the metal, the sheet is cut by laser cutting.

- The sheet is clamped on a special bending machine with hydraulic cylinders, due to which the product is pressed.

- Metal bending with a press is carried out using hydraulic force.

- At each stage, we check the quality of the work performed and take control measurements before the subsequent submission of a full batch of workpieces.

Basic methods of sheet metal bending

We have already mentioned that bending 6 meters of metal is mainly performed without heating. However, in some cases, the second method is used - thermal. To prove the validity of this technique, the material is examined for:

- plasticity, that is, they determine its ability to deform;

- the ability to form an angle of the required size without cracking;

- ability to obtain a complex bending contour.

Knowing the characteristics of metals and alloys, a specialist can predict the result, relying only on theoretical calculations. However, most often the tests are carried out experimentally: in a workshop environment, using a sample for this purpose.

Advantages of Sheet Metal Bending

When ordering metal bending up to 6 meters or less, you get:

- still a monolithic product with no seams;

- if the work is performed correctly, it has no external or internal defects;

- a part whose appearance is not spoiled by any welds;

- as strong as before bending, and with no less service life.

It is noteworthy that most materials and alloys can be bent: steel, aluminum, copper. But not all of them can handle welding work. For the same aluminum, only a very experienced welder can make a high-quality weld without burnouts.

Types and types of bending

Any metal bending can be done either with your own hands or using special professional equipment designed for these purposes.

It should be noted that when performing this technological operation with your own hands, you will have to expend some physical effort and time.

Video:

In this case, bending is carried out using pliers and a hammer; in some individual cases, a special device is used.

It should be noted that bending a thin metal sheet, as well as aluminum, with your own hands is done using a mallet.

At industrial enterprises, they try to automate this process in every possible way and use manual or hydraulic rollers, as well as special roller units, directly for bending.

For example, to give a product a cylindrical shape, metal is bent using rollers. This is how pipes, chimneys, gutters and much more are produced.

Most often in industrial enterprises, metal bending is performed on special press brakes.

IMPORTANT TO KNOW: Aluminum milling technology with and without CNC

Depending on the functionality, such presses can have different designs and, accordingly, sizes.

It should be noted that modern equipment makes it possible to perform high-tech operations with metal.

Thus, new industrial machines make it possible to simultaneously bend a sheet along several lines in one working cycle, which makes it possible to produce parts of any complexity.

As a rule, such equipment is quite easy to operate.

You can reconfigure it to work with other materials quite quickly.

This operation requires special attention if it is necessary to bend aluminum sheets.

This is due, first of all, to the fact that sheet aluminum has slightly different strength and elasticity parameters than other types of metals.

Types of metal bending techniques

The simplest bending techniques involve the formation of one or two corners on a sheet (one-corner or two-corner bending). Based on their profile shape, they are also called V-shaped and U-shaped. To obtain more angles, multi-angle bending is required. And finally, to form not corners, but rounded shapes, radial bending, or rolling, is used. According to the nature of the force that is applied to the sheet, bending of 6-meter sheet metal can be free and with a calibrating blow. It also differs in the number of transitions, that is, the efforts made to complete one fold. For ductile metals a single force is enough, for non-plastic ones two or even three are required, in especially difficult cases - with heating.

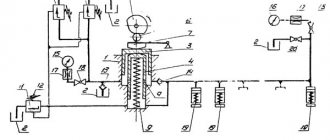

Basic techniques for bending pipe parts

Bending of pipe parts is carried out in cold and hot states by manual and mechanized methods, with and without fillers.

Fillers are used to prevent the formation of folds and flattening of pipe walls. Dried fine sand or synthetic granules are used as fillers.

For each pipe, depending on its diameter and material, the minimum permissible bending radius is established. With a smaller radius, bending is unacceptable (Table 1).

Table 1. Values of the minimum permissible bending radii of pipes in a cold state, mm

| Pipe outer diameter, mm | Pipe material | Pipe outer diameter, mm | Pipe material | ||||||

| Steel 45 | Steel 35 | Steel 20 | Steel 10 | Steel 45 | Steel 35 | Steel 20 | Steel 10 | ||

| 18 | 74 | 62 | 56 | 43 | 105 | 450 | 344 | 282 | 240 |

| 24 | 95 | 79 | 65 | 55 | 110 | 510 | 377 | 310 | 264 |

| 32 | 115 | 96 | 79 | 67 | 130 | 536 | 450 | 370 | 315 |

| 38 | 156 | 131 | 107 | 91 | 145 | 578 | 484 | 398 | 339 |

| 50 | 197 | 165 | 136 | 115 | 155 | 620 | 522 | 430 | 360 |

| 60 | 238 | 199 | 165 | 139 | 181 | 720 | 600 | 498 | 425 |

| 75 | 280 | 260 | 194 | 173 | 194 | 752 | 630 | 516 | 444 |

| 80 | 324 | 270 | 224 | 190 | 206 | 835 | 702 | 575 | 488 |

| 90 | 362 | 302 | 250 | 213 | 220 | 920 | 770 | 635 | 540 |

When cold bending pipes with a diameter of up to 25 mm, hand tools are used.

In Fig. 4, a shows a manual machine designed for bending pipes with a diameter of 12 to 20 mm. The machine has an axis 1 and a base plate 2, with which it is bolted to the workbench. The working parts of the machine are a fixed roller 4 with a clamp 5, mounted on axis 1, and a movable roller 3, mounted on a bracket 6 with a handle 7. The end of the bent pipe is placed in the clamp between the rollers, then the bracket with the movable roller is rotated around the axis of the fixed roller until the required bend, after which the bracket is returned to its original position and the pipe is removed.

Rice. 4. Bending using hand tools

To bend copper tubes of different diameters when assembling machines, a multi-strand pipe bender (5.66, b) is used. In this case, the tube is passed between rollers 1 and 2 until it comes into contact with the stop, then when the fork 3 is turned, the movable roller 2 rolls around the stationary one, bending the tube along a radius equal to the radius of roller 1.

Using a manual lever pipe bender (5.66, c), you can bend steel gas pipes with a diameter of 1/2, 3/4 and 1" in a cold state without filler.

For manual bending of steel pipes with a diameter of up to 50 mm at an angle of 180° without filler in a cold state, a special head with a manual drive can be used.

Price list for sheet metal bending

Unlike many other sites that work only at negotiated prices and do not indicate exact amounts in their price lists, we publish specific prices for this service.

However, let us clarify that these are average amounts. If you entrust us with an order of increased complexity or very urgent work, the cost of the project may increase. When completing large volumes within a comfortable time frame, we can please you with a discount. Features of sheet metal bending

The most difficult task, even for a specialist bending a 6-meter sheet, is to “feel” the balance of stress and deformation in a specific sheet of a specific thickness, made of a specific metal. In the process of bending - no matter whether manually or machine-made - two influences are alternately exerted on the sheet: first elastic, and then plastic. Thus, the inner layers are compressed in the sheet and the outer layers are stretched. The border, or neutral, layer becomes the “golden mean between them. The ability to find it is a “pass” to bending that is harmless to metal.

Defects and difficulties when bending

During the deformation of metals, defects may appear. The most common are oblique bends, mechanical damage to the surface. This phenomenon occurs due to errors when marking or securing workpieces above/below the marking line. A common mistake when bending is also considered to be rupture (crack) of the metal. It occurs due to insufficient plasticity of the material. Bending of thin sheet metal is most often susceptible to this type of defect, which is why it often has to be done manually. Another common bending defect is dimensional irregularities. It manifests itself when there is a shortage or excess of sheet at the ends of the part, which occurs when the calculation of the length of the workpieces is incorrect.

Examples of work on bending workpieces

You will see that our craftsmen can easily bend 6-meter sheets if you look at samples of bent steel and products made from it in the “Examples of Work” section. Our gallery is regularly updated with new samples. After evaluating the photos and videos for the article, you will see from a live example that it is better to bend it several times than to weld it a couple of times.

Sheet metal bending in Moscow

Bending metal 6 meters is of particular importance for the capital, where all types of industry are actively developing - from heavy to light. Moscow production places higher demands on bent products: they need high-quality rolled products that completely match the proportions with the drawings. This problem can only be solved using automatic equipment. Our machines are distinguished not only by accuracy, but also by high productivity.

The result of punching and bending sheet metal

Bending metal up to 6 meters is not the only operation that can be performed for such large-sized products. In addition to it, there are punching, cutting, and cutting. And bending itself can be different: for example, combined with stretching (usually used to produce products with a large radius). The result of all these actions is no longer a blank, but an almost completed part that can be used in installation or assembly.

Laser cutting and bending of galvanized steel and powder-coated sheets

Galvanized metal, as well as powder-painted metal, has its own processing nuances. The zinc and polymer layers have sufficient impact strength and resistance to deformation of the coating, but can be damaged during mechanical cutting. Therefore, for such products they usually choose cutting with a laser beam, which is almost “painless” for coated metal.

METAL PROCESSING BEFORE BENDING

The process of processing metal blanks before bending is divided into three types:

- Panoramic deformation. In this case, the metal is deformed by the translational movement of the machine, tensioning it with the upper traverse. Panning machines and bending machines are used to carry out the work.

- Perm. Programmable machine equipment advances the upper bending beam with a special type of panoramic stroke. Such equipment not only guides the traverse, but also sets the required radius.

- Stamping. The name speaks for itself. The process uses pressing devices: two-track horizontal, vertical with reinforced, or simple drive.

Our specialists adhere to the following technology for preparing metal bending:

- At the initial stage, specialists determine the bending points and angles, the size and complexity of the required metal product;

- Based on the required dimensions, the metal sheet is laser cut before bending;

- Then the sheet is clamped;

- At the last stage, the bending itself takes place;