Plexiglas and polycarbonate lend themselves well to thermal molding. One of the most popular thermoforming operations is string bending. The technology is applicable for sheets of small thickness (up to 8-10 mm). Bending is carried out in a straight line, with a small bending radius at any angle.

The main tool for bending acrylic and polycarbonate sheets is a tightly stretched nichrome string connected to a power source. The string becomes heated and locally heats the material in a straight line. In the local heating area, the workpiece becomes plastic and the sheet bends. After cooling, the curved sheet retains its shape and regains its original strength. The nichrome string performs two functions: it serves as a heating source and as a guide for the bending line.

Homemade machine for bending plexiglass

Authorization on the site

How to make a simple machine for bending plexiglass with your own hands.

To make my own homemade products, I have long been planning to assemble a small machine for bending plexiglass and plastic.

A case helped: they asked me to make a stand for a paper sheet of A4 size.

When making products from plexiglass, acrylic or plastic, nichrome thread is used. So I assembled a small machine and used an electric spiral. tiles

Manufacturing

First, planks were made: two short (200 mm) and two long (400 mm).

At the end of one of the boards I attached an aluminum profile, which will serve as a heat reflector from the nichrome thread.

I didn’t have the required profile length, so I assembled it from two halves.

On the reverse side of the same board, a longitudinal groove was made for laying the power wire.

Using loops, I connected two long boards.

Two short boards served as a backing and were attached to the sides of a long board with a profile.

From a terminal block and a spring I assembled a simple tensioner for a nichrome thread.

Since the machine was assembled from what was at hand, and the required nichrome thread with a large diameter was not available, I had to twist two threads together. The downside of this solution was the constant tightening of the thread after each use.

All that remains is to connect the power from the transformer. The thread will be replaced as soon as possible, but even with this option it heats well.

When warmed up, the spring tightens the thread like a string.

Working with the machine

We heat the workpiece on both sides for about one minute (the heating time is selected experimentally depending on the thickness of the material).

Next, we lift one of the halves (the moving part) and give the desired angle to the workpiece, put it aside and fix it until it cools.

I also attached a leg to the back of the holder.

The paper stand is ready!

After assembling the holder, there were scraps of plexiglass left, from which I also made a jig for drilling holes and driving nails.

Using this machine I plan to make more than one useful homemade product.

There are already a couple of ideas where it can be used!

Source

Techniques

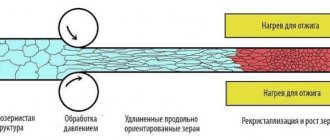

There are several ways to bend plexiglass. When choosing a method, you need to focus on the size of the sheet and the desired type of bend.

String

This method is used to obtain products with straight lines: price tags, stands, display cases, etc.

In this case, the sheet is bent using a nichrome string connected to a power source, at a rate of about 1 kW per 1.2 m of wire. When the heating element is heated, a sheet is brought to it at the place where it will be folded. The material heats up and quickly acquires plasticity, after which it is bent at the desired angle and fixed with a support and weight until it cools.

This method has a number of disadvantages:

Temperature

Thermal bending is the heating of a specific area of material, not necessarily in the form of a line. For this purpose, both special machines and improvised means are used. The latter are more suitable for small sheets. The following methods are popular:

By radius

This method is used for large sheets. The curves are smooth.

The work is carried out as follows: a large metal pipe is securely fixed and heated to 90–100 °C. A sheet of plexiglass is treated with soda, secured to the pipe using clamps and carefully wrapped around it. The workpiece cools down there.

Uses a metal pipe as a device to create smooth bends of plexiglass

Note! The metal must be clean and unpainted.

Acrylic bending machine in 20 minutes

I won’t write anything about the power supply; it was left over from the previous machine, which I decided to replace. There is a lot of information on the Internet.

In the workshop I found the remains of a profile for a compartment door and a U-shaped profile made of painted tin.

Connecting them with rivets, we get:

I attach the bars so that there is a flat surface.

Now you need to tighten the nichrome thread (or whatever it’s called). Sold in household goods and twisted into a spring.

After looking at a bunch of fasteners for this thread, I didn't like anything. I didn't want to increase the size of the machine. Therefore, I secured the tension springs perpendicular to the direction of the thread.

I cut the spacers (blue ones in the photo) from aluminum composite. You can use textolite. The main thing is to maintain the temperature and not damage the thread. Their main task is to adjust the position of the heated thread (lower, raise). I cut out a corner at the top so that the thread would not fly off. I secured all this to a wooden block for the sake of electrical isolation.

The result was a light, smooth machine. The wires from the power supply are attached with “crocodiles” directly to the thread. You can easily remove it from the wall, bend a few pockets and put it away so it doesn’t get in the way.

Review

Now let's look at professional machines for bending plexiglass.

S-Master 1000

The main advantage is the ability to install additional heating lines, and each of them can be configured separately. It is possible to heat the sheet on both sides.

The device is connected to a 220 V network and consumes only up to 0.8 kW.

There are several types of configuration:

If the standard width of one mini-table is not enough for comfortable work, it can be equipped with additional ones, obtaining a working surface of up to 40 cm. The working surface and stop can be adjusted, fixed in the desired position using screw clamps.

It is possible to operate in a gentle mode: the strings heat up less, which extends their service life.

This is how you work with this device:

Before processing, practice on an unnecessary piece so as not to spoil an expensive part. Adjust heating time or other parameters as necessary.

With this device you can bend not only plexiglass, but also polycarbonate, polystyrene and other types of plastic with a thickness of 1 to 8 mm. The device is suitable for making relatively small objects, but with many complex bends.

The HRT machine is great for creating plexiglass parts with many complex curves

Power up to 1 kW per line.

The package includes 2 threads with separate adjustment. Installed in a reflective profile, which eliminates the need for water cooling. The number of threads can be increased to 4.

The height of the lines can be adjusted. They are secured in the required position with a limit bar.

There is no timer. Recommendations for calculating heating time are in the instructions.

The process of working with the device is as follows:

The HR model range is compact, easy to assemble and use devices. An excellent choice for a private workshop. Even the simplest of devices provides high bending accuracy. Softening of the material occurs strictly in the treated area.

The thickness of the sheets can be from 1 to 6 mm. Some models have a special option for processing thinner sheets.

Power depends on the model and can range from 225 to 1000 W. The food is standard, from a 220 V network. The length of the tables is from 0.5 to 3 m.

The standard kit includes 1 filament located in the reflector, with adjustable temperature and height. There is usually no possibility of additional staffing.

A series of semi-automatic devices designed for double-sided heating. Allows you to process sheets up to 20 mm.

The HRK machine is capable of processing plexiglass sheets with a thickness of 20mm

The power of models with 4 heating lines is 1000 W, 8 lines are 3200 W. The length of the tables ranges from 0.65 to 1.25 mm. The threads are installed in reflective profiles.

All devices have a timer. Thanks to the modular design, they are easy to disassemble and assemble. Additional equipment is possible.

The temperature of each thread can be adjusted separately. The heaters are easily adjustable in height. They can be moved in both the lower and upper planes.

The upper frame is controlled using a pneumatic drive.

Warming up is carried out according to the standard scheme. The upper part is additionally adjusted using a special pedal.

The upper frame of plexiglass processing machines is controlled by a pneumatic drive

Night light made of LED strip and plexiglass

I continue the theme of my crafts.

This time we will make a night light from LED strip and plexiglass.

My daughter does gymnastics, and I decided to please her. My daughter’s team is called “Kubanushka” (Kavkazskaya station, Krasnodar region). And what could be better than a night light with the name of the team?

I prepared these boards with spacers and cut out the base of the lamp from 4 mm plexiglass.

I wanted thicker plexiglass, but 4 mm is the maximum thickness that we found. So we will make from what we have. Also, we will need a set of LED strip 1.5 m 6 W 160 Lm/m 3000 K

which I bought in Leroy. The set contains a switch; in principle, you can buy it with a remote control if you want to repeat it. This will probably be even better, but it will also be more expensive.

We make a drawing in a vector editor and mirror it:

The reflection is needed so that you can glue the reflected image from the inside to the plexiglass and engrave it, then after all the work is done and when turned over, we will get a normal picture. The drawing itself will be on the back of the night light.

Well, then we engrave with Dremel. My wife carefully helped me out