The starter does not turn (or turns slowly, jerkily). The situation is unfortunately not uncommon. Where to start troubleshooting?

Of course, we check the battery first. Have you made sure that it is charged normally, but the starter turns as if the battery is dead? There is no need to be afraid of such a malfunction and immediately send the car for service on a tow truck. The engine starting system is not the most complex part of the car.

Checking the battery starter

It is almost impossible to check a starter installed in its original place. You will not be sure of the true cause of the problem. Therefore, it would be better to remove it. Moreover, this is not at all difficult to do on any car.

Before dismantling, we check the integrity of the wiring and the cleanliness of the contacts. In some cases, simple cleaning and tightening of the terminals helps. To complete the experiment, check the supply wiring. The voltage at the contacts of the connecting cables must be the same as at the battery terminals.

Before you remove the entire assembly, check to see if the starter can drain the battery. To do this, it is not necessary to connect an ammeter and record the leakage current.

- Disconnect the power cables from the starter

- Connect the multimeter to the battery, record the voltage value (if possible, do not turn on any load: external lighting, multimedia, interior lights)

- Connect the power cables to the starter. If there are no leaks, the voltage on the battery will not change. If the value decreases, there is a problem in the starter circuit.

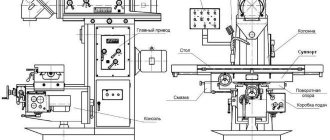

If you are not familiar with the starter design, carefully study the illustration. Then it will be easier to understand the principle of operation of the node.

Possible causes of battery failure. Details in this video.

Why can the starter take on a lot of current?

All possible causes of the presented malfunction, one way or another, consist of two factors:

Both are closely related. In other words, mechanical wear can lead to electrical failures. Electrical faults can cause mechanical damage.

Summarizing all of the above, we can say that the increased value of the starter inrush current occurs due to:

Jamming of the starter, and, as a result, increased current draw from the battery, can also be a consequence of early ignition.

How to properly test the starter on a battery

As can be seen in the illustration, the node consists of two separate components:

- The retractor relay - works on the principle of the clutch of a manual transmission - connects the Bendix gear to the engine flywheel to turn the crankshaft. After a successful start, the Bendix returns to the “parking” place so that the electric motor shaft does not rotate idle. A breakdown of the relay leads to the fact that a serviceable starter motor cannot crank the crankshaft, and the internal combustion engine does not start.

- Starter motor . The breakdowns are classic - the armature winding is burned out, the commutator is worn out, the brushes are worn out. The stator does not break because it has no winding.

There are also purely mechanical failures - for example, if the starter does not turn well when the battery is charged and the electrical part is in normal condition, it may be a matter of bearings or worn gears.

And if you removed the block from the engine, carry out preventative cleaning. The presence of dirt can make it difficult for the armature to rotate.

Let's look at checking electrical components. To do this, you need to directly connect the starter to the battery.

Checking the electric motor

Having securely secured the housing, we connect the negative terminal of the battery to the starter mounting eye (that is, we connect the negative terminal to the housing and ground). The cable must have a cross-section of at least 6 squares.

We connect the positive terminal to the engine power cable (a short piece of wire with a terminal that is attached to the contact of the solenoid relay).

The shaft should rotate vigorously. If the starter barely turns, we’ll deal with the engine. Check the condition of the brushes and commutator. The brush assembly is easily dismantled. Flexible wires must be without traces of melting, and the brushes themselves must have a margin of length. If there is visible damage, the elements must be replaced.

We inspect the rotor commutator (after removing the brush assembly, it is accessible from all sides). The rotor itself should rotate freely, and the copper lamellas should wear evenly. A short circuit between the contact plates is unacceptable (checked visually and with a multimeter).

There is another test - let the engine spin for 20-30 seconds. Then evaluate the heating of the housing and check for the absence of a burnt winding smell. The temperature should not be higher than 40-50°C.

Checking the solenoid relay

This element simultaneously closes the starter shaft with the internal combustion engine flywheel (via Bendix) and supplies power to the starter motor winding.

To check the starter solenoid relay from the battery, just connect the positive wire to the relay control terminal. It is easy to find - there is no threaded connection on the terminal, unlike power contacts.

When 12 volts are applied, a characteristic click should sound and the Bendix gear will take its working position.

You can check the closure of the power relay contacts that supply voltage to the starter motor. At the moment of operation, the resistance between them should be zero. If not, just clean the contacts (nickels).

If the relay does not operate , it should be replaced. This unit is purchased separately from the starter, is inexpensive, and can be easily changed. Restoring a burnt-out relay winding is impractical, although possible.

Having gained access to the “insides” of the starter, check the mechanical condition of the Bendix fork and gears. Wear may be present, but without tooth deformation. Play on the fork should not prevent reliable engagement of the Bendix gear.

After checking, the assembly is purged with compressed air and the bearings are lubricated. The contact junctions are treated with a special lubricant for contact groups.

How to check the starter on a battery video recommendations using the example of a VAZ 2110 car

The car battery is the primary source of current. Its main function is to supply energy to the starter, which starts the engine. Therefore, if the car battery is discharged, the reasons must be found immediately. Without this, the engine cannot be started. In addition to the main task, the battery powers devices, as well as on-board electrical devices.

Batteries installed on cars are divided into three types. They are available in maintenance-free, low-maintenance and maintenance-free versions. The most popular batteries are those that are easy to use.

They are in a sealed housing and do not require maintenance. Their passport service life is limited to 3 years, but this figure can be reduced if used incorrectly, or increased if the driver complies with the conditions and mode of operation of the device, i.e. prevents the battery from frequently entering a state of deep discharge.

Advice to a car owner

All external contacts of the starter should be cleaned before checking, since this is a fairly common malfunction and there is no need to remove it from the engine.

Even an initial check of the starter without removing it from the vehicle usually indicates a breakdown, reducing repair time, reducing costs and not taking much time.

- Posts: 3

October 31, 2012, 01:12 #1 123

In winter, at minus 20 and below, I could not start the engine. The starter turns for the first time, then sluggishly until the battery dies. I installed a new battery, same thing, but in the summer, no problem. They say the starter takes a lot of load. Tell.

- Posts: 24

- From: Saratov region

- Lada 2112 ZIL 5301 Bychok PO

October 31, 2012, 5:39 pm #2 123

What brand of car?

- Posts: 3

October 31, 2012, 10:19 pm #3 123

Opel Vectra 1990

- Posts: 3545

- From: Zaporozhye

- UAZ Patriot

November 1, 2012, 00:17 #4 123

If the starter “takes over”, it is repaired, and there may be an “anchor”, perhaps a stator, a gearbox (in some), bushings, etc., or maybe a mass for the motor. worthless

- Posts: 8523

- From: Russia, our Russia

- Ford Focus

November 1, 2012, 00:24 #5 123+ 1

Most likely it is a shoe, that is, the bushings on the rotor are broken and under load they cling to the stator. An autopsy will show!

- Posts: 3545

- From: Zaporozhye

- UAZ Patriot

November 1, 2012, 00:32 #6 123+ 1

Last Sunday, a relative in a Kamaz truck barely made it to Zaporozhye, didn’t turn off the car and got off the hill, there was a stator and bushings there. Kamaz, Opel, the starter principle is the same.

- Posts: 2605

- From: Saratov.

- Peugeot Partner Tepee

November 1, 2012, 00:49 #7 123

bogdannn, October 31, 2012, 10:19 pm, #3

Opel Vectra 1990

Prmchina - starter. In particular the bushings.

Unfortunately, you did not specify the modification. Approximately starter assembly from 7 tr. bushings from 30 RUR

- Posts: 3

November 1, 2012, 01:31 #8 123

Thanks, I'll try it

- Posts: 12128

- From: Vladimir

- Oka AvtoVAZ Oka

November 6, 2012, 11:56 pm #9 123

Z969, November 1, 2012, 00:17, #4

If the starter “takes over”, it is repaired, and there may be an “anchor”, perhaps a stator, a gearbox (in some), bushings, etc., or maybe a mass for the motor. worthless

Read also: Why does a furniture stapler bend staples?

My Oka (newly purchased) did not have a bushing. and the starter did not turn well exactly as the author of the topic indicated.

- Posts: 46

- From: Moscow

November 15, 2012, 16:59 #10 123

In addition to the problem with the starter itself, in winter, during rare or short trips, the battery charges worse. Hence the problem. But you need to deal with the starter, yes.

- Posts: 5

November 25, 2014, 12:16 #11 123

The battery drains when starting when the engine is cold! Bought a new starter and batteries! what could it be?

- Posts: 2195

- From: Samara

November 25, 2014, 1:18 pm #12 123+ 2

AJIEKCEEBKA, November 25, 2014, 12:16, #11

The battery drains when starting when the engine is cold! Bought a new starter and batteries! what could it be?

Buy normal oil for winter and you will be happy.

- Posts: 589

- From: Zhigulevsk

- Chevrolet Niva LC Vortex Estina

November 25, 2014, 1:36 pm #13 123

Measure the voltage on the batteries under load (when you turn the starter). It should not fall below 16V, if lower, perhaps 1 battery is weak, maybe both. If the voltage is normal, check the wire contacts: starter housing-frame, ground switch-frame, ground switch contacts.

I speak like an old mazist-kamazit.

- Posts: 5

November 26, 2014, 00:38 #14 123

actros, November 25, 2014, 13:18, #12

Buy normal oil for winter and you will be happy.

there was no frost yet -5 -10

- Posts: 5

November 26, 2014, 00:40 #15 123

I put the dead batteries in another car and it starts.

- Posts: 14551

- From: 66, Ekaterinburg

- UAZ Hunter 315195 ZIL 5301 Bull

November 26, 2014, 06:24 #16 123

AJIEKCEEBKA, November 26, 2014, 00:38, #14

there was no frost yet -5 -10

What kind of oil is in?

- Posts: 13

November 26, 2014, 07:42 #17 123

Check for current leakage! It seems like you remove the positive terminal from the battery, I don’t remember where to put the multimeter and measure it. In short, you need to google “check current leakage”. My alarm system was eating up the battery at night.

- Posts: 589

- From: Zhigulevsk

- Chevrolet Niva LC Vortex Estina

November 26, 2014, 09:41 #18 123

AJIEKCEEBKA, November 26, 2014, 00:40, #15

I put the dead batteries in another car and it starts.

Read my post above carefully. You have a weak connection somewhere. Clean all the contacts I indicated with a file. There, the currents are very high during startup, a voltage drop is possible, which is what the starter lacks.

- Posts: 11844

- Where:

November 26, 2014, 11:26 #19 123

bogdannn, October 31, 2012, 01:12, #1

In winter, at minus 20 and below, I could not start the engine. The starter turns for the first time, then sluggishly until the battery dies. I installed a new battery, same thing, but in the summer, no problem. They say the starter takes a lot of load. Tell.

Most likely the generator is not recharging the battery.

- Posts: 5

November 26, 2014, 5:51 pm #20 123

vadim20, November 26, 2014, 06:24, #16

What kind of oil is in?

- Posts: 5

November 26, 2014, 17:53 #21 123

RW4HJD, November 26, 2014, 09:41, #18

Read my post above carefully. You have a weak connection somewhere. Clean all the contacts I indicated with a file. There, the currents are very high during startup, a voltage drop is possible, which is what the starter lacks.

understandable, probably because of the mass.

- Posts: 2195

- From: Samara

November 26, 2014, 5:58 pm #22 123

AJIEKCEEBKA, November 26, 2014, 17:53, #21

understandable, probably because of the mass.

It doesn’t take long to find out - one starts it and the other stands next to the batteries and watches. If there is a bad contact, you can notice it. If it’s not visible, then by touch, where it gets very hot - the battery terminals, fastening the wires to the main switch and from it to the frame and on the starter itself there is a positive one from the battery. If everything is cold, then the contact is good everywhere and there is no leakage to heating anywhere.

The starter began to drain the battery. The battery is new, even two! After you turn the starter, the positive terminal on the battery gets very hot (burns) as a result of the battery going to zero and the starter starts clicking. I took the starter apart and looked at it, cleaned all the terminals. It just started to heat up less the starter, but it still turns very sluggishly and won’t start, and the terminal still burns even though I cleaned it.

WHAT DO YOU RECOMMEND?

Factors affecting battery life

If the car battery is discharged due to exhausted service life, further diagnostics are not required - the battery needs to be replaced. In other cases, it makes sense to try to revive a dead car battery by washing it and replacing the electrolyte.

In order not to shorten its service life, the battery requires careful attention. Slow driving and sitting idle in traffic jams, during which it is advisable to turn off energy consumers such as heated seats and rear window, have a negative effect on it. It will not be possible to start the car if the battery is dead, but it can be started using auxiliary jumper cables or by lighting a cigarette from the battery of another car.

If the battery is frozen, which can happen at sub-zero temperatures, it must be defrosted in a warm room before connecting the auxiliary cable.

In addition to the reasons listed, after checking the battery capacity and detecting a deep discharge, the culprits may be: poor wiring insulation, malfunction of the generator, the battery itself, alarms and the connection of abnormal electrical equipment.

Why is the battery draining?

The reason for the rapid discharge, taking into account the above, may be due to natural wear and tear of the battery. If the energy leak is caused by the driver forgetting to turn off the interior lights or side lights, then nothing bad happened and the battery will easily restore its potential during the trip.

If the situation repeats, perhaps the reason is sulfation of the plates, which consists in the fact that they are covered with coarse metallic lead sulfate, reminiscent of a white coating. If the sulfation is small, you can try to revive a dead car battery. Well, when the process is running, the only way out is replacement.

Video: Why the battery drains quickly

How to check the starter's performance?

In second place is starter wear. This trouble cannot be measured by statistics and can even happen to a car that has just left the showroom.

As mentioned, the most common reasons for the malfunction of old batteries is sulfation of the plates. The capacity in this case sometimes drops to almost zero.

Therefore, when you get behind the wheel and turn the ignition key, don’t rush to blame the starter when you don’t hear the familiar rumbling. It has nothing to do with it when the current supplied to it is below 100 amperes.

To check whether the battery is acting up or the problem is in the starter, you can start it from another battery. Doubts will dissipate. Having measured the voltage on the battery, a lot will become clear: if it is 10V, but should be in the range of 13.6-15V, it will not be able to turn the starter. It is necessary to determine whether the wiring, the battery itself, or oxidized terminals are to blame.

It is impossible to restore a battery if the carbon plates are destroyed, as evidenced by the color of the electrolyte - almost black when charging.

The plates may have shorted in one of the sections. This is easy to determine: the section gets very hot, and the electrolyte boils away. It is very difficult to restore a battery with such a malfunction, but if you tinker and try to replace the plates, it will be more economical than buying a new one. To do this, you need to correctly remove the battery from the car.

There is no need to charge a battery with such a serious malfunction as shedding of plates or short circuit. This will not revive the car battery, but will only harm it. It is more correct to completely drain the electrolyte and remove all dirt by rinsing the battery with distilled water.

When the plates have not crumbled too much, this helps. You can combat plate sulfation using a special desulfatizing additive. Sometimes you can use a charger for these purposes (if it has such a mode).

Possible reasons

Now let's look at the reasons why the starter can take on a lot of current. As with the symptoms, let’s list them, and then go through each item separately:

- poor contact;

- clogging or wear of bushings;

- brush wear;

- collector clogged;

- short circuit in the windings;

- shedding of magnets;

- It's not the starter that's at fault.

It’s probably worth starting with the last point, since it is special and does not apply to starter failures. The fact is that the starter can take on a lot of current, sag voltage, rotate “tightly” or not work at all, even in fully working condition. Therefore, before starting to diagnose it, it is worth ruling out other possible causes of the problem. Let's look at them.

First of all, this concerns the battery. If it is, as they say, tired, discharged, with shorted banks, and so on, then the starter will not turn vigorously. In this case, you can make sure that it is working properly by measuring the starting current using a current clamp. If the battery is “weak”, then the voltage drop will be noticeable, but you will not find an increased starting current. Rather, on the contrary, the current will be very small.

The second reason why a good starter takes a lot of current is the engine. It can create such mechanical resistance when starting that the starter simply “doesn’t have enough strength” to turn it normally. This happens if something gets stuck in the engine, the engine oil is too viscous, something gets stuck, and so on. It is quite difficult to identify such problems. However, they will have to be looked for if further testing of the starter shows its full suitability.

Now as for the starter itself. Let's go through the list. If there is poor contact in the starter wiring, it will not work fully. This problem should be looked for at the main terminals (on the battery), as well as at the starter terminals, which are located on the solenoid relay. Connections must be clean, free of oxides, rust and other dirt, and securely fastened. Poor contact leads to the fact that the electrical resistance in this area increases, and the current “not all reaches” the starter. It turns into heat on poor contacts, which can be seen by carbon deposits on the terminals.

The second common problem is bushings. There are two of them in the starter, and they act as plain bearings. If they are clogged or left without lubrication, their resistance will interfere with rotation. If the bushings are worn out, there may be strong lateral play, which also reduces rotation. The worst thing is when the bushings wear to the point that the starter rotor touches the stator. This leads to jamming, damage to the windings, and short circuits.

When the brushes wear out, the current flows poorly to the rotor, or does not reach there at all. If copper wires appear from the brush, then very noticeable sparking may be observed. This is due to the fact that the current strength in this area increases greatly, as the electrical resistance sharply decreases (according to Ohm’s law).

Collector clogged. Most often, graphite dust accumulates between its petals over time and separates from the brushes. Since this is a conductive material, the rotor windings either lose their normal resistance or even short-circuit to each other. As a result, the current increases, but no useful work is performed.

If there is a short circuit in the rotor windings, their electrical resistance is significantly reduced. According to the same Ohm's law, at relatively the same voltage, this leads to a sharp increase in the starting current. In this case, useful work is not performed, since the energy is spent not on rotation, but on overheating the starter. A short circuit in the windings can be judged by a characteristic smell or sparking on the brushes. It can also be detected by measuring the winding resistance using a multimeter in ohmmeter mode. This parameter should be approximately the same for all windings, and be more than 1 MOhm.

Shedding or destruction of the magnets, which act as a stator in the starter, leads to either a loss of effective power or even jamming. The problem is determined visually. The cause of magnet shedding may be vibrations or wear of the bushings, due to which the rotor “reached” the stator.

Generator failure

Next is a faulty generator drive. Belt tension leads to a drop in generator power (and as a result, rapid battery discharge), so it must be assessed. If the sagging of the belt when pressing on it with a finger exceeds 15mm, it needs to be tightened.

An equally common cause of a quickly discharging battery is considered to be a breakdown of the battery itself. To check the functionality of this unit, measure the voltage it produces at idle, turning on the low beam and the fan. If the voltage value does not fall within the range of 13.9-14.3 V, which characterizes a working device, then the reason has been found - the regulator is broken or there is a break in the wiring, the fuses in the mounting block are broken or the diode bridge is burned out, the starter winding is damaged or the generator brushes are worn out.

Fortunately, the breakdown is not critical - you need to replace the generator with a new one and continue driving.

How does battery wear depend on storage conditions?

Finally, the cause of rapid discharge can be the driver’s simple inattention: he left energy-consuming devices turned on for an extended period:

- dimensions;

- lighting in the cabin, trunk or glove compartment;

- heated mirrors, windows, seats;

- low beam

Violation of storage conditions is also a prerequisite for the “loss” of the battery. Even a battery that is not completely discharged and stored in severe frost has its plates destroyed and its casing cracked. As a result, multiple short circuits of the plates occur. It is impossible to restore it. Therefore, you need to store the device in a warmer place (from +10 to +15 degrees).

Malfunction of electrical components

It is not immediately possible to detect an electrical fault, which leads to rapid battery discharge. Usually you have to contact auto repair shop specialists who will carry out diagnostics using a computer. If it turns out to be powerless, they will be able to identify the breakdown visually, relying on their wealth of experience.

Another factor that negatively affects the normal operation of the battery, leading to its rapid discharge, is a fairly large leakage current, divided into external and internal. Moreover, the value of the first currents is much higher.

To find out the reason for the rapid discharge, you need to check the current value by completely turning off electrical appliances and closing the doors. This parameter depends directly on the energy consumers integrated into the on-board electrical network.

The current should be up to 50mA. If the reading is higher than this value, try removing fuses one at a time. The moment when the current drops, remember - you need to look for a leak in this circuit.

Leakage current

When the power supply is operating normally, the slight decrease in capacity caused by current leakage is compensated by recharging the battery from the generator. When the battery cannot maintain its nominal parameters, loss of current becomes a problem leading to rapid discharge.

Practice has shown that the cause of the leak is improper connection of additional equipment: electronic alarm systems, powerful speaker systems, additional optics (daytime running lights, fog lights, etc.). A satellite alarm greatly drains the battery of an unused car in just two weeks. An improperly installed alarm system can create problems. In this case, it is dismantled and the electrical circuit is checked, determining where the current leak occurs.

Overloading the on-board network also leads to battery discharge, i.e. installation of additional devices not provided by the manufacturer: energy-intensive low and high beam lamps, audio and video equipment, etc.

Video: Finding a current leak in a car

Non-original speaker systems

With rare exceptions, when tuning car audio, drivers do not think about the colossal load that acoustics place on electrical components. The energy generated by the generator is not enough, which is why the battery discharges. Therefore, when installing acoustics, it is advisable to first consult with an auto electrician, who will calculate what load is permissible for the generator.

Late battery maintenance also causes battery drain.

The battery contacts must always be carefully tightened and the terminals and surface of the battery clean. The wires should not dangle. You can clean terminals coated with oxide using sandpaper.

You need to remember one more thing - traveling short distances (especially in the city, where you often get stuck in traffic jams) also cannot have a positive effect on the condition of the battery. It simply does not have time to charge, since many generators charge the battery when the engine speed reaches 1.5 thousand.

Starter problem. (sits the battery HARD)

Starter problem. (sits the battery HARD)

Message by Maxon » 02 Feb 2010 21:08

Message by ikaz » 02 Feb 2010 21:35

Post by fast » 02 Feb 2010 22:00

Post by Little_CJIOH » 02 Feb 2010 22:14

mmmm. Try after parking, when it should be difficult to start, remove the spark plugs and turn them over. Just put a candle on the central wire and lean it with a skirt against the mass; it would also be good to cover the spark plug holes with a clean, dry rag, just cover, not plug.

See if it spins well, if so, look at what flew out of the cylinders onto the rag

Post by Mike » 02 Feb 2010 23:23

Post by Maxon » 02 Feb 2010 23:30

Post by Maxon » 02 Feb 2010 23:35

Post by DimaM20 » 02 Feb 2010 23:52

Post by Konst » 03 Feb 2010 01:11

Post by Little_CJIOH » 03 Feb 2010 10:04

If one terminal gets hot - 100% bad contact. Without spark plugs, of course, it will be easy to turn if it doesn’t jam somewhere else. But the fact is that when cold, the starter cannot crank the engine, but if you start it with a pushrod and turn it off, then it starts normally. Regarding this, I only have one thought - there is some kind of liquid in the cylinders, that’s why I suggested turning it around, bringing the spark plugs and a rag. And for some reason I associate the white coating on the spark plugs with antifreeze in the cylinders.

PS: Change the terminal, and try to get a known good battery from someone.

Source

How to check if a dead car battery is working with a multimeter

Over time, any battery loses its properties - it runs out. To understand whether it needs to be replaced or whether it can be restored, you need to check the charge. To do this, use a special device called a multimeter. It allows you to check the capacity of any type of battery.

To use it to check the battery capacity, turn on the device, prepare it for operation in direct current mode (reposition the probe or move the switch), and set the range to 10-20A. Then the probes are connected to the battery terminals, strictly controlling the polarity. The charge indicators will be displayed on the device screen.

Measurements will be correct if taken after overnight parking and before the vehicle is started.

You turn the ignition key, but instead of the vigorous rhythm of the running engine, you hear that the starter is turning the engine, as if the battery is dead. Another attempt to start the engine. And further. Stop: until the battery really requires charging, and the car is not sent on a tow truck for service, it is worth remembering how to check the starter without removing it from the car, and even fix the breakdown. To identify the malfunction, you will have to remember the operating principle and design of the starter.

Why do you need a starter?

Today, this device is used to remotely start the engine, eliminating the need for drivers to get out of the car and turn the starting handle. One can only imagine how unpleasant it is to do this at a time when it is freezing outside or pouring rain. Now you don't have to be afraid of this.

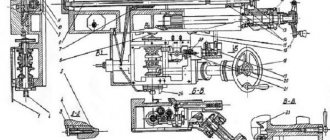

The engine starter is an electric DC motor, which, consuming current from the battery, rotates the crankshaft of the car engine. Its design contains devices such as a retractor relay and an overrunning clutch. Without their installation, the electric motor does not become a starter, so these devices also require proper care and maintenance.

Units and design details

The function of the starter is to start the car engine by spinning its flywheel with an electric motor, creating temporary contact between the gears. Subsequently, the electric motor is turned off and physical contact with the flywheel gear is broken. The starter is located on the engine body closer to the battery and the cab.

Structurally, the device can be divided into two functional blocks:

- Solenoid relay. When 12 volts are applied directly to the control contact, the electromagnet pulls in the core. The core pushes the bendix through a lever to engage the gear with the flywheel teeth. At the final point of retraction, the armature, with a contact plate through the rod, closes the contact of the nickels, providing a direct connection of the electric motor to the “+” of the battery.

- Electric motor. When voltage is applied, it begins to rotate, spinning the flywheel through the Bendix to the operating speed of the car engine.

After starting the engine, the key is returned from the ignition position, de-energizing the relay. The relay opens the contacts, the spring returns the bendix to its original state. When starting, the electric motor requires several tens of amperes of current from the battery. After starting the car engine, the generator restores the battery charge.

The starter may have malfunctions, determined by the nature of the manifestation, visible signs, and tester readings.

For what reasons can problems begin with the engine starting device?

Despite the fact that the starter is used for a short time, its components and mechanisms are subject to mechanical and electrical wear.

This problem can be caused by various reasons.

Among them are:

A voltage drop in the starter circuit makes itself felt when voltage is applied to the solenoid relay when the key is turned to the “st” position. It is expressed in the fact that the running lights and instrument lighting are dim. This means that the starter takes up most of the car's battery charge.

Often, the cause of this phenomenon is the connecting elements of the starter circuit. To ensure their serviceability, a complete inspection of all terminals and terminals should be carried out. Even if outwardly they look quite functional, you should not make hasty conclusions. The operating conditions of such elements involve heavy loads, which can cause them to burn, especially with weak contact.

The starter motor armature, due to design features, rotates inside copper-graphite bushings. It is worth noting that the greatest wear occurs on the front bushing - the one facing the flywheel. As wear increases, the alignment of the armature is disrupted and it will inevitably touch the insulated “shoes” of the stator winding. The insulating layer of the windings will be damaged.

It would seem, why not replace the copper bushings with much more wear-resistant bearings. They are not used in this case, due to the fact that their working elements will experience serious electromechanical loads. In addition, the question arises about additional insulation of the starter armature.

Signs indicating such a misunderstanding are expressed in increased noise from the starter when the engine starts. It is worth noting that before the anchor begins his wild life, he will long and persistently remind you of his illness. Therefore, as soon as the first symptoms of armature runout appear, the bushings need to be replaced.

In addition, banal jamming of the freewheel often occurs, which can be caused by increased wear of the working surface or contamination.

Another accompanying factor is high mechanical resistance. This term implies that due to some unfavorable circumstances, there is difficulty in rotating the crankshaft of the car.

Most often, this problem can occur in the winter season if the engine lubricant is of mineral origin. The option is also not excluded when a would-be mechanic, during the assembly of the crank mechanism, took and tightened the liners, believing that this was more reliable. To make sure of this, just turn the crankshaft through the ratchet. If the shaft stands rooted to the spot, this is probably the case.

Don't forget about the brush assembly. Carbon-graphite brushes deteriorate over time, which in turn has a detrimental effect on the service life of the electric motor commutator.

To carry out diagnostic measures to identify voltage drops at the starter, you will need a multimeter and a test lamp.

To ensure the integrity of the starter winding, you need to use an ordinary 220V household light bulb. We fix one end of the lamp on the starter body, and connect the other one in turn to the terminals of the stator winding. If any winding is broken, the lamp will certainly light up.

The brushes are checked according to the same scheme, only using a 12V light bulb.

Possible faults

The starter consists of more than 20 parts. The electric motor consumes hundreds of kW of power from the battery, converts it into rotational motion of the flywheel, overcoming the resistance of a car engine frozen on a winter night. In this mode, there is something and why to break. How to check if the starter is working - there is a method for finding out the location of the breakdown in order of complexity of the work - from diagnostics without removing the starter to its complete disassembly.

Low on-board voltage

A sign of a malfunction - the engine started and the car drove 5-10 kilometers. When trying to start, the starter turns weakly, the battery is charged before the trip. When you turn on the high beams, the headlights shine dimly. You can verify that the voltage is low by measuring it at the battery terminals with a tester with the key in the ignition switch and without it.

Probable reasons:

- the generator does not work;

- battery discharge due to a faulty on-board electrical appliance, including the starter.

Can the alarm drain the battery?

A standard alarm consumes 0.08 amp/hour. Complex alarms with remote notification spend 30% more. This is not much; a 60 Amp/hour battery will discharge after about a month of inactivity.

The alarm works like this: when armed, it goes into “sleep” mode. Current consumption is minimal. When a contact in the sensor circuit is closed, the unit is triggered, sending a signal to the headlights and siren, as well as an alert to the key fob. Modern alarms are able to respond to loud sounds, vibrations and even excessive proximity to the car. Such systems consume more current because they use the radar principle or photocells.

Reasons why alarms consume more current.

Attention! Install and repair alarms in a specialized workshop from an experienced auto electrician. Incorrect connections or exposed wires may cause fire or serious damage.

It is quite difficult to check the serviceability of the alarm, since the discharge can be short in time and impossible to track. The test is simple: