There is no need to remind once again that the starter is one of the important components of the car.

Imagine that you are stuck in a traffic jam for many hours, where you have to start the car every 5 - 10 minutes in order to move 10 - 15 meters, and so on for 2 hours. Is this a familiar story? Definitely familiar to Muscovites.

And now imagine that the starter has stopped working. Definitely an unpleasant situation.

It is difficult to check and repair the device on the road, but in some cases it is possible.

The starter clicks intermittently but does not turn over

The battery is low

On modern cars, when the contact group brushes come out. When the ignition is turned on, the charging indicator lamp does not light up. When the engine is running, the indicator also does not light up. That is, when the ignition is turned on, the light should light up and go out while the engine is running. It's hard to pay attention to the fact that there is no generator malfunction signal. Because when you turn on the ignition, many warning lights come on.

You can only identify the charge indicator lamp if you accidentally pay attention to it. Therefore, there is still enough charge in the battery. The car starts and drives. This will last up to several days until the battery is completely discharged. As soon as this happens, the car will stall or the starter will not turn. Short knocking sounds will be heard from the starter solenoid relay.

The battery charge is enough to retract the armature of the solenoid relay. The windings will not be able to resist the spring. The anchor will be dropped. But since the key is at the start, the armature will be retracted and released. In this case, the battery will not have enough energy to crank the starter.

You can tell that the battery is dead because the lights in the lighting fixtures will dim when the starter is turned on.

There is no contact between the engine and the car body.

Or the starter mounting bolts are loose. The battery current is not enough to turn the starter due to poor contact. For this reason, the armature of the retractor relay is discarded. The force of the holding and retracting windings is not enough. To hold the armature spring in a compressed state. How the solenoid relay works is described in detail in this article. “How does the starter solenoid relay work - malfunction”

Lack of good contact is the first thing to check when such a problem occurs. That is, check the reliability and cleanliness of the contacts.

— Between the battery and the car body

— At the negative terminal of the battery.

— On the positive terminal of the battery

- between the engine and the body

— reliability of fastening of the starter bolts

— check the reliability of the connection of the positive wire going from the starter to the battery.

That is, check all connections going from the starter to the battery.

Winding

To monitor the integrity of the winding, a 220 Volt lamp or a flaw detector is used. The principle is this:

- we buy a light bulb with a power of up to 100 W;

- we connect it in series with the winding and the starter casing;

- We put one wire on the body, and the second on the plus.

If the light is on, this indicates a breakdown. If there is no lamp, you can use an ohmmeter and measure the resistance (optimal level 9-11 kOhm). The rotor winding is checked using the same principle. We supply 220 V to the lamp. Next, we place one terminal on the collector, and touch the second to the core. If the lamp is on, you will have to change the rotor or rewind the winding.

How to check the starter if it clicks but does not turn.

Reasons why the starter clicks but does not turn. Similar to those in which the solenoid relay is activated several times.

- The battery is discharged so much that its power is only enough to pull in the armature of the solenoid relay only once. The battery is completely discharged. Repeated retraction of the anchor does not occur. Accordingly, the starter will turn over, but it also cannot.

- Solenoid relay is faulty. It has two windings, a more powerful retractor and a holding one. Most often the pull-in winding fails. This is described in more detail in the article. How does the solenoid relay work?

The armature is pulled in only by the holding winding. His effort is only enough to retract the anchor halfway. Naturally, the nickel does not reach the terminals. No power is supplied to the motor. The starter does not rotate.

You can check why the starter clicks but does not turn as follows.

- When you turn the key to start. Check the voltage at the terminal to which the wire from the stator winding fits. It should be missing.

- Second way. Connect the terminal to which the positive wire from the battery comes and the terminal from which the wire goes to the stator windings. The voltage is transmitted through the jumper to the stator windings and the starter begins to rotate.

That is, the nickel inside the solenoid relay does not bridge the terminals.

The second malfunction in which voltage does not transfer between the terminals is that. Carbon deposits form on the coin and terminals at the contact points. Or contact burnout. As a result, one of the terminals becomes shorter and a nickel does not reach it. And even if the windings are working properly, due to the fact that there is no contact, the starter does not turn.

This can also be checked by bridging the contacts or measuring the voltage.

In case of such malfunctions, the car can still be started.

If the solenoid relay is working properly, then you can bridge the three positive terminals to the starter winding and the solenoid relay control terminal. The starter will begin to rotate and the engine will start. With this method of activating the starter, it is very important to first make sure that the car is in neutral gear with the handbrake. If the gear is engaged, the engine will start and the car will move. At best it will cause injury.

If the solenoid relay is faulty. And the bendix, like an anchor, does not reach the flywheel crown. If the terminals of the positive and stator windings are shorted more than once. The Bendix will engage the flywheel. Because it is connected to the shaft using a threaded connection. When the starter shaft rotates, it will begin to twist forward. And can connect to the flywheel crown. This may not work the first time, but after repeated attempts it will happen and the car will start.

Bendix sticking on the starter shaft

The Bendix is connected to the solenoid relay armature. It moves freely along the shaft along a screw guide. A screw connection is necessary in order to. Protect the bendix and starter from destruction. The moment the engine starts. The flywheel speed becomes higher than the starter shaft speed. That is, the flywheel will start to lie to the Bendix. Due to the fact that the bendix is on a screw connection, it will begin to move inside the starter and disengage with the flywheel.

In our case, wear may occur between the bendix and the shaft. Bendix can jam. And do not reach the engagement with the flywheel. Accordingly, the anchor will also not reach the contact between the coin and the terminals. Therefore, a click will be heard but the starter will not turn over. This kind of thing rarely happens. You can make sure that the bendix is jammed on the shaft only by removing the starter.

Classification of faults

The starter is an electromechanical device, so faults can be classified as electrical or mechanical.

Electrical breakdowns

Such malfunctions often occur due to insufficient power supply. The reasons for inoperability may be:

- Dead battery.

- Damaged wiring.

- Winding short circuit.

- Oxidation and burning of contacts.

To determine this type of breakdown, you need to be able to check the starter using special instruments. Mechanical problems most often appear as a result of prolonged use and mechanical damage.

Mechanical damage may be caused by electrical problems. The parts of the starting device are subject to heavy loads, especially in severe frost, since the device must generate high power and pass high voltage.

The most vulnerable components are:

- Bushing and armature corrector.

- Brushes.

- Heels.

- Fork.

- Gear.

- Solenoid relay.

- Damper spring.

Extraneous noise, unpleasant odor and untimely activation of the starter can be evidence of mechanical failure.

Common Mechanical Failures

- Untimely switching on. The motor rotates, but during start-up a metallic grinding noise is heard. In this case, most likely the damper spring is faulty, the gear or bushings are unusable. The exact cause is determined visually after disassembly.

- The starting device works, but there is no rotation of the crankshaft and there are extraneous sounds. The cause may be a broken bushing.

- The starter does not work when trying to start. You need to tap the back of the starter with a mallet. If operation resumes upon impact, the brushes may be worn.

- After starting the engine, friction and metal grinding can be heard. The engine must be turned off immediately. Most likely the relay is stuck. The exact cause is determined during disassembly.

- The retractor relay clicks are heard, but the mechanism does not work. The battery may not be sufficiently charged. The voltage supplied to the mechanism is weak; there is enough current to operate the relay, but the terminals are not closed by the contact plate. You need to remove the battery and connect the charging unit. If such symptoms occur when the battery is charged, then the heels may burn or the power cable may malfunction.

- When the battery is charged, the starter rotates slowly. The bushings may be worn out or the electric drive may be dirty.

- When you try to start the engine, a burning smell may come from the device. The winding in the traction relay may have burned out. The anchor can also burn out, but this happens less often. In this case, the wires connected to the starter overheat.

- The retractor on the starter does not work. There is a fault in the electrical circuit. It is necessary to check the integrity of the wires and the operation of all components included in the electrical circuit.

The starter turns but does not turn the engine

Wear of bendx rollers

When you turn the ignition key to start, the starter turns, but the engine does not move. This happens due to a broken bendix.

Bendix consists of two parts.

- The first is connected to the starter shaft

- The second is a gear that meshes with the flywheel ring.

They are connected to each other using spring-loaded cylindrical rollers. The cavity in which these rollers are located is at an angle in the direction of rotation of the bendix. That is, the rollers do not create an obstacle in one direction of rotation. In the other direction, the rollers, due to the frictional force and the location of the movement of the rollers, become a wedge. Between two surfaces.

During operation, the rollers wear out and become thinner. The working surfaces also wear out. The rollers stop clamping. As a result, the bendix rotates and does not transmit rotation from the starter shaft to the flywheel.

If this happens on the road, there is a chance that the engine will still start. To do this, you need to drive the starter several times. Friction surfaces heat up. Thermal expansion of the bendix elements occurs. At some point it will work and the engine will start. As a rule, such a malfunction appears gradually. At first the Bendix slipped once. Then more and more often. It's better to replace it immediately. There will come a time when the Bendix completely fails.

Damage to bendix teeth and flywheel ring

There is one point in which a working starter does not rotate the engine. This happens due to the destruction of the bendix teeth and flywheel crown. That is, Bendis comes out completely. The contacts of the retractor relay are connected through a nickel. The starter is turning. But the engine does not turn over.

The Bendix feed was not initially adjusted. Or the bendix jammed on the starter shaft.

The contact patch of the Bendix gears and the flywheel crown is adjusted using the screw on which the Bendix fork is attached. The surface of the bolt is offset along its axis. Thanks to this, it is possible to adjust the bendix output up or down.

If the bendix teeth do not create a complete contact patch. Partially or half-engaged. Rotation occurs along the edge of the teeth. As a result, the teeth grind down or break off. It is difficult to check the starter as if the teeth are broken or the bendix is faulty.

Most likely, sounds that are not characteristic of the starter will appear. Grinding and sparking.

Bottom line

To summarize, we can say that to check the starter for serviceability, you do not need to have a professional understanding of electrical circuits and electrodynamics.

You need to know at least in general terms the principle of operation of the device, have the skills to work with an ohmmeter and a control unit.

After checking the starter and determining the reasons for its breakdown, complex repairs may not be possible for you, but you can clean the contacts, replace brushes and other main components.

And complex repairs of starters, such as winding rewinding, are done by specialists.

The starter does not turn when turning the key

- The first thing you need to check is how the starter works. To do this, make sure that the gearbox is in neutral and put the car on the handbrake. Using a jumper. Bridge the control terminal of the solenoid relay and the terminal that receives the positive from the battery. If the starter began to rotate the engine, and it started. This means the starter is OK. Most likely the problem is in the starter relay or ignition switch.

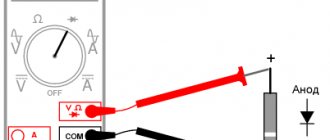

- Check the presence or absence of voltage at the control terminal. To do this, measure the voltage at the control terminal with a multimeter. Turn the key to start. If voltage does not appear, the starter relay is faulty.

- The starter relay is an electromagnetic coil that receives voltage from the ignition switch. As soon as voltage is applied to the coil. It attracts the plate with the contact. Which connects to another contact. As a result, voltage is transferred to the control terminal of the solenoid relay. A starter relay is used so that the current generated when the retractor relay is turned on cannot burn the ignition switch contacts.

Expert recommendations

If you have no experience in repair work, then you can contact a specialist who will tell you how to check the removed starter from the battery; the video can also help with this. If you carry out a comprehensive diagnosis and repair of the starting unit (replacing bushings, brushes, forks, bendix if necessary, cleaning internal surfaces), then it will last without repair for 3-4 years.

To extend the service life of the starter, you must adhere to the following rules:

- do not force the starter to operate continuously for 15 seconds,

- if extraneous noise is heard or the device periodically fails, you must immediately look for the cause of the malfunction and eliminate it,

- monitor the condition of the traction relay contacts; sparking and overheating of the contacts can destroy the part.

A working starter will ensure a comfortable trip and will not fail at the right time. It is better to correct minor problems in a timely manner than to make major repairs. The given tips on how to check the operation of a starter from a battery, the videos posted in the article will help to carry out a set of routine maintenance to restore the starter’s functionality.

The starter does not turn over due to a faulty starter relay

If you do not hear any knocking or clicking noises when you turn the starter key, there is most likely a problem with the starter relay. You need to find the deck on which the starter relay is installed. This can be done by following the indicators on the covers covering the fuse and relay boxes. And check the serviceability of the relay or determine whether the plus is suitable for it or whether there is an open circuit.

- On the block where pin No. 87 fits, check for voltage using a multimeter. If it is missing, check the integrity of the fuse through which the plus goes to the relay. This plus comes to the control terminal of the solenoid relay.

- If there is a plus. With the ignition on. You can briefly bridge the contacts on the block where relay contacts No. 87 and No. 30 are inserted. In this case, it is necessary to make sure. That the car's transmission is in neutral gear. If the car starts, there is a problem with the starter relay or ignition switch.

- When you turn the key to start, you should hear a click in the starter relay. This indicates that the coil is working properly. What if the starter doesn't turn? The problem is most likely with the contacts. They burned out or carbon deposits formed.

- If the click is not heard. The coil winding has burned out or the relay does not receive voltage from the ignition switch. You can check this by checking for the presence of voltage at the terminal of the block where relay contact No. 85 is inserted.

- If the voltage from the ignition switch does not reach the starter relay block, then there is a malfunction either in the ignition switch, or it is necessary to check the integrity of the wiring.

In all cases, you can check how the starter works. Start the car and drive. Or by briefly bridging the control terminal with the battery positive terminal. Or also briefly while starting the engine by bridging the contacts on the starter relay block. The most extreme case is a tug, of course, if the gearbox is not automatic.

Anchor

To monitor the serviceability of the armature, a voltage of 12 Volts from the battery is required. Power is supplied directly to the starter. If the device works, we can say that it is working properly. In case of failure, there is a problem with the brushes or the device itself. To understand the reasons, you need to disassemble the assembly and check each element with a multimeter.

The main faults of the armature include a breakdown in the winding, a short circuit between the turns or soldering of the leads. To check, use a multimeter, PCP or conventional inspection, respectively. A short circuit can be easily identified visually by a number of symptoms - the appearance of metal shavings and burning of lamellas. If nothing is done, more serious consequences are possible - damage to the brushes and starter malfunction. The depth between the grooves should be 0.5 mm and below.

On a MAZ car the starter relay clicks but the starter does not turn

As an example, on a MAZ car with a YaMZ 236 engine, the starter stopped turning. When you turn the ignition key, you can hear the starter relay click, but the starter does not rotate. The starter relay is located under the fuse panel. It is located opposite the passenger seat.

If the starter relay clicks, the starter relay is receiving power from the ignition switch. It is possible that the plus from the starter relay does not reach the solenoid relay. To do this, you need to check the power on the gray wire. Which goes from the starter relay to the solenoid relay.

This can be done using a voltmeter or a regular light bulb. It is possible that due to carbon deposits on the relay contacts, voltage does not transfer. In our case, on the terminal to which the gray wire is connected. When you turn the ignition key, the plus appears. Now you need to check the plus on the solenoid relay, where the gray wire comes. Plus is also present. It is also necessary to measure the voltage at the terminal of the solenoid relay to which the wire coming from the battery positive is screwed.

Plus is also present. This means there is a malfunction in the solenoid relay. You can check this in the same way as mentioned above, by bridging the terminal with the wire from the battery and the terminal to which the gray wire comes. But it’s inconvenient to do this on a masa. And starting a car while under it is very dangerous. The starter can work and start the engine. And if the gearbox is not in neutral, the car will drive. And the handbrake may not hold the MAZ engine at idle speed. They say that an unloaded gun fires once a year. So it’s better to limit yourself to dialing. And if there are objective reasons for the malfunction, remove the starter. And check it in the removed state. What was and was done.

Removing the starter from the YaMZ engine.

- Before removing the starter from the YaMZ engine, it is necessary to disconnect the positive terminal of the battery. This will certainly avoid future short circuits.

- Disconnect all wires at the solenoid relay. There are three of them. The positive wire from the battery, the gray wire coming from the starter relay, and the red wire to the generator

- Then the clamp unwinds. Which holds the starter in place. After this, the starter easily comes out of its place. Although the word easy is not at all applicable to the MAZ car. The starter is very heavy. And you have to make an effort to remove it. It is especially difficult to install. There is only one good thing: the clamp bolt is conveniently located and easy to unscrew.

Installing a starter on a YaMZ engine

When installing the starter, it must be installed in its place. Completely unscrew the clamp bolt. Insert half of the clamp between the starter and the solenoid relay. And by some miracle try to hook the inner end of the clamp onto the protrusion on the reverse side. This is perhaps the most unpleasant operation when installing a starter. Next, the second half of the clamp is installed and tightened with a coupling bolt.

Checking the MAZ starter for functionality.

The negative terminal from the charger is connected to the starter housing. When the positive terminal is connected to the positive contact of the starter, the armature begins to rotate. This indicates that the starter windings are in good condition.

But when connecting the positive terminal from the charger to the positive of the solenoid relay. Where the gray wire was screwed. The relay armature does not retract. That is, the nickel does not connect the contacts with the wire from the battery and the contact of the starter winding. That is, the starter will not rotate. Malfunction in the solenoid relay.

Cause of malfunction

- Solenoid relay removed from starter

- The cover with contacts is unscrewed. And you can see how the contact of the wire coming from the coil of the solenoid relay has burnt out. This is just the wire from the pull-in winding. The contact was pressed with a coin to the terminal. And over time, he simply burned out. Because the nickel did not touch the terminal itself. And the sweat hit the contact of the wire. Apparently during the repair the contact was not installed correctly. Or drivers practice repairs without removing the starter. Without thinking about the consequences. Namely. When carbon deposits form on a nickel. The nickel stops letting tension pass through itself. Some craftsmen unscrew the nuts of the terminals with which the coin comes into contact. And they turn them ninety degrees. As if removing the contact point on the terminal where the contact was formed. Of course, a similar repair method can be used. Especially if you are on the road and the engine does not start. But there is no need to turn the terminals. It is enough to simply move them or hit them on a penny. The carbon deposits will be removed and the terminals can be tightened.

In this example, the pull-in winding wire has broken. This is the reason why the starter relay clicks but the starter does not turn. This prevents contact between the positive wires in the solenoid relay. It was decided to replace the solenoid relay completely with a new one. Since connecting the contact to the winding wire using a makeshift method cannot last long.

How to check the starter if the malfunction cannot be detected by external signs is described in detail in the article The starter turns poorly when the battery is charged

Where should repair work begin?

To start repairs and carry out diagnostics without a stand for testing generators, you need to prepare:

- a set of keys;

- screwdrivers;

- special pullers;

- tester;

- control light;

- old rags.

Before checking the starter, it must first be removed and cleaned of dirt. Disassembly requires special tools. To make a thorough diagnosis, the device must be completely disassembled, down to the smallest parts. Then each part needs to be washed and dried.

Machine starter device

Diagnostics without a stand for generators consists of a sequence of actions:

- First of all, you should check that the device is functioning correctly.

- Check the solenoid relay.

- Perform brush and armature diagnostics.

- Call the power grid.

- Carry out a Bendix diagnostic, thanks to which the engine starts silently.

After performing the diagnostics, you should replace or repair the faulty parts.

We will open Priora in Moscow and Moscow Region

Promptly, carefully and professionally, experienced technicians from the LOCKSERVICE emergency service will provide assistance with the problem of how to open a Priora without a key. We have been working in the emergency car opening market for more than 12 years and know how to open a Lada Priora or open a car of any other brand without any damage. In what other situations may you need to call LOCKSERVICE specialists?

- The doors locked spontaneously, the keys remained in the cabin;

- The battery is dead;

- The lock cylinders are faulty or dirty;

- Locks froze in the cold due to moisture that accumulated on the seals;

- The key is lost or broken;

- The alarm went off from the inside and the driver was locked inside the car;

- The car stalled in a traffic jam, the central locking was blocked;

- The key fob is discharged, the car does not open;

- The lock in the glove compartment is broken;

- The trunk does not open;

- The key broke in half in the door keyhole;

- The gas tank cap does not come off;

- The lock of the tank filler cap is broken.

There are many ways to open any car without a key. We offer you those that can be used in any conditions, while remembering that the best way to open a car is to entrust it to professionals.

Turning on the starter directly from the battery

To make a direct contact with your own hands, you just need to get a piece of copper cable, a connector and an alligator clip. These three components are used to solder a device that will run the starter directly from the battery.

- Under the hood of the car, near the right headlight, there is a red wire with a plug that needs to be disconnected and the prepared cable with a connector inserted into it;

- The car is idled;

- The ignition is turned on;

- The crocodile connects neatly to the positive side of the battery.

These manipulations are often enough to start the starter if it is working and has no other problems. After the car starts, the crocodile needs to be thrown off the plus side.

It is recommended to always keep such a homemade device with a connector and a crocodile in the trunk as a last resort. After using it, it is simply pulled out, and the previously removed plug is put back in place. Everything is easy and simple, except for one thing - you need to work carefully so as not to get burned or short circuit something else.

Disadvantages of the method

The main disadvantage of this method of starting the starter is that you can easily burn the ignition coil. That is why experts recommend carrying out this action only once. But sometimes the engine does not start using this method, so the reason lies much deeper.

It is also worth considering that in those places where the screwdriver comes into contact with the terminal, a current of up to 50 A is issued. It can easily become stuck, and it will also kick back into your hand; it can be quickly removed using an open-end wrench.

Method two - towing

No less efficient and even more reliable, but you need another machine more powerful than your car. It will be enough to tow the vehicle for a short distance, and then start the engine in the same manner as described above. In this case, I would like to give a couple of practical tips:

- Do not turn off the car after it has started and then go straight to the service center;

- Do not forget that after starting the car, it will pick up speed if it is in second gear and you press the accelerator pedal;

- Don’t forget that after starting, the car towing you will stop. Therefore, you will need to have time to slow down.

Each of the listed options can be used to get to your home or service station. It is highly not recommended to use them every day.