Method number 2 – Let’s do without instruments

A less qualitative way to check the functionality of a capacitive element is using a homemade dialer in the form of a light bulb and two wires. In this way you can only check the capacitor for a short circuit. As in the case of a screwdriver, we first charge the part, after which we touch the legs with the probe leads. If the condenser is working, a spark will occur, which will instantly discharge it. We also talked about how to make an electrician's warning lamp.

Check procedure

Touching contacts with probes

A multimeter can identify causes of malfunction such as breakdown, which entails the destruction of the dielectric separating the plates, and the current flows directly, while the capacitor itself, in fact, becomes a simple conductor. Or it does this partially, losing its capacity, becoming an additional active resistance in the electrical circuit.

The capacitor itself, due to its operating principle, passes only alternating current , and in no case direct current, therefore its resistance, measured between the terminals, is quite large and is limited by a very small leakage current through the dielectric separating its working plates, which accumulate charge.

In non-polar capacitors, the role of dielectric of which is played by mica, ceramics, paper, glass, air, the leakage current is infinitely small, and the resistance is very large and when measured between the terminals with a digital multimeter, the device will show infinity in the form of 1 on the digital display. Therefore, in the event of a breakdown, its resistance, measured at the terminals, is quite small - up to several tens of ohms.

Possible causes of failure

Failure to comply with basic operating parameters, such as:

- Rated voltage. When the rated voltage increases, a breakdown occurs due to the electrical characteristics of the dielectric that insulates the capacitor plates.

- Design capacity. A discrepancy between the capacity (lower than the calculated one) entails an overestimation of the rated voltage on the element in question, therefore, when replacing it, if there is no analogue, an element with a larger capacity is installed.

- Polarity in some cases . Polarity is a mandatory parameter for electrolytic and tantalum capacitors due to the design features.

The operating temperature directly depends on compliance with the above parameters. An exception is aging that occurs in the electrolytic type and the location of the element on the printed circuit board, as a result of which its operating temperature may be higher than the critical temperature due to the placement of other units of the electrical circuit that have a higher temperature regime.

This is the reason for the failure of an oxide semiconductor element, since it itself is an explosive: it contains tantalum, which is flammable, and the oxidizing agent is manganese dioxide.

Each component is a powder and it is all mixed together. Isn't it an explosive mixture? That is why an increase in temperature due to breakdown or non-compliance with polarity can lead to an explosion that can destroy not only neighboring elements, but also the entire board.

Checking the capacitor at home using a multimeter + video

The process of checking a capacitor with a multimeter

To test capacitors, special devices are often used - multimeters.

First you need to measure the resistance of the device, for this:

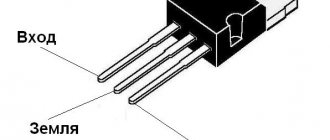

- Disconnect the capacitor barrel from the circuit;

- Touch the probes of the device to the legs of the capacitor, without reversing the polarities. The “minus” on the capacitor is indicated by a white stripe along the entire length of the device;

Visual image of a light stripe on a capacitor - Look at the device display. The readings should immediately begin to increase, because the multimeter will begin to charge the capacitor;

- After some time, the value will stop increasing. If the multimeter immediately shows the number “1”, the capacitor is faulty and must be replaced. If the resistance is okay, you need to check the capacitance, for this:

- Switch the multimeter to capacitance measurement mode;

- Touch the legs of the capacitor with the probes of the device. The multimeter display will show the capacitance value. If it is far from the nominal value, the capacitor is faulty. The next step is to measure the voltage:

- To do this, you will need a current source whose voltage is less than the capacitor, for example, a battery. You need to connect it to the legs of the capacitor;

- After the capacitor is charged, you need to switch the multimeter to voltage measurement mode. If the display does not immediately show a value close to the nominal value, the capacitor is faulty.

The following video will describe the process of checking the capacitor in more detail.

Troubleshooting

Quite often, a breakdown of a radio element can be detected as a result of a visual inspection, by characteristic swelling, darkening, cracks or other violations of the integrity of the housing. As an example, the photograph shows such signs.

Breakdown of ceramic and electrolytic capacitors

Unfortunately, it is not always possible to visually detect a non-working radio element; a completely normal-looking part, the whole body of which does not have pronounced defects, may be inoperative due to an internal short circuit.

Before you start checking a non-polar film, ceramic, electrolytic, smd or sbb capacitor with a multimeter, you should remove it from the board, since it is practically impossible to test without soldering the radio component.

To be fair, it should be noted that there are several ways not to resort to a soldering iron, one of them is to measure the circuit resistance on the board, but this will require a resistance map, moreover, for the specific model of the broken device, and this is not always available even in official service centers.

Capacitance measurement

It should be noted that this type of test can not be carried out by all models of multimeters. You will need to have a professional or semi-professional device on hand that has a capacity testing function.

The work order is as follows:

- the part is discharged by closing its contacts;

- observing polarity (if it is a polar type), the probes of the device are applied to the contact terminals of the capacitor;

- The obtained capacitance value is compared with the nominal value.

If the obtained capacity value and the nominal value differ by 20% or more, then the part must be replaced.

More about the multimeter

This is a compact device that allows you to measure the basic parameters of both an electrical circuit and its individual elements for testing and troubleshooting.

There are 2 types:

Analog

Consists of the following elements:

- Pointer magnetoelectric indicator.

- Additional resistors for taking voltage readings,

- Shunts for measuring current.

Digital

A more complex and accurate device (the most common are multimeters with an accuracy of 1%), consisting of a set of chips and a digital indicator, which is usually liquid crystal.

Some of the characteristics measured by a multimeter:

- Voltage (AC and DC).

- Current strength (AC and DC).

- Resistance (with beep if less than 50 ohms).

- Capacity.

- Checking semiconductors for integrity and polarity.

- Temperature.

Malfunctions and causes of their occurrence

Regardless of what type of capacitor is paper or high-voltage, it can fail as a result of the following faults:

- reduction in nominal capacity as a result of drying out;

- the leakage current exceeds a certain value;

- increase in active losses in the circuit;

- short circuit of the plates (insulator breakdown);

- loss of contact between the plate and the lead of the part (break).

The malfunctions described above can occur as a result of temperature violations, exceeding the permissible voltage threshold, mechanical damage, etc.

Note that by lowering the operating temperature you can significantly extend the service life of almost any radio element. It is overheating that in most cases becomes the main cause of failure of radio components.

As practice shows, most often a capacitor malfunction is caused by a short circuit of the plates, that is, a breakdown. We will tell you in detail how to make a diagnosis in this case.

Results and practical recommendations

There is little point in buying complex and expensive equipment in order to test capacitors. It is quite possible to use a regular multimeter with a suitable range for this purpose. The most important thing is to use its capabilities wisely and correctly.

Although the multimeter is not a highly specialized device and its capabilities are limited, it is quite enough for diagnostic activities and repair of a huge number of popular radio-electronic devices.

Please add your comments to the block below, post photos and ask questions of any complexity on the proposed topic of the article. Tell us about your experience, how you diagnosed capacitors for efficiency and performance. Share recommendations and useful information that may be useful to site users.

You may also be wondering how to connect the wires to each other.

Features of testing different types of capacitors

There are many types of radio components that differ in the material of the dielectric, plates, and type of electrolyte, so they have different methods for diagnosing the operating condition.

To check the suitability of a ceramic capacitor, set the highest measurement limit of the ohmmeter. A sign of serviceability will be a measured resistance of at least 2 MOhm. For other values, the part is changed.

To test a tantalum capacitor, select the largest measurement limit in ohms. If the resistance is 0, change it. Before testing a high-capacity, high-voltage electrolytic capacitor, maximum discharge is necessary. Residual voltage will damage the device.

Principle of operation

The operating principle on which the operation of this radio element is based is that when used in electrical circuits, it is capable of accumulating an electrical charge.

This property is only possible with alternating electric current - therefore it is used in circuits where it is necessary to separate two current components - direct and alternating. But in circuits with constant electric current, the capacitor will act as a dielectric, since under such conditions it is not able to accumulate charge.

Useful tips

Useful tips from experts:

- The voltage in a charged storage device with a large capacity can be checked by closing the contacts using a screwdriver with an insulated handle - a powerful spark should flash through.

- Before starting research, it is advisable to install a fresh battery in the multimeter or other device you are using.

- It is better to desolder or disconnect the part being tested from the circuit.

- You should not touch the contacts with your hands during the examination, as they may be under dangerous voltage or the device readings will be distorted.

Non-polar and polar varieties

Among the variety of capacitors, two main types should be distinguished: polar or electrolytic, and non-polar. The dielectrics used in these devices are glass, paper and air.

Specifics of polar capacitors

The name itself clearly indicates that they have polarity, therefore they are electrolytic. It will be necessary to faithfully and accurately follow the diagram when they are connected - “minus” to “minus”, and “plus” to “plus”. If you do not follow this rule, the element will not only lose its functionality, but is quite capable of exploding. Electrolyte occurs in both solid and liquid states.

The devices use paper impregnated with electrolyte as a dielectric. The capacity varies from 0.1 thousand to 100 thousand microfarads.

Reference! Polar capacitors are designed to equalize the electrofiltration of incoming signals. The “+” mark is longer. The mark “-” is indicated on the body itself.

When the plates close, heat is released. Under its influence, the electrolyte evaporates, followed by an explosion.

On top of modern capacitors there is a cross and a slight indentation. The thickness of the depressed part is slightly less than the rest of the surface. If an explosion occurs, then the upper section opens like a rose. Therefore, when observing a damaged element, you can notice swelling on the body.

Distinctive features of non-polar capacitors

Film non-polar parts use a dielectric made of ceramics and also glass. When compared with electrolytic capacitors, they have less self-charging. This can be explained by the fact that ceramic has a higher resistance than paper.

What is a capacitor used for?

The industrial sector produces a wide variety of capacitors, which are then used in many fields. They are required in the following industries:

- automotive industry;

- radio engineering;

- electronics;

- electrical appliances;

- instrument making.

Capacitors can be called "vessels" for storing energy. They release energy during short power failures. In addition to the above, a special type of these components separates the necessary signals and determines the frequency of the devices that generate the signals. The capacitor has a fast charge-discharge period.

Reference ! This electrical element (capacitor) contains a pair of conductors - these are conductive plates. When passing direct current through a circuit, it is prohibited to turn it on, as this will be tantamount to breaking the circuit.

In an alternating current circuit, the capacitor plates are alternately charged at the frequency of the passing current. This can be explained by the following: the terminals of a given current source are subject to voltage changes from time to time. Next, an alternating current appears in the circuit.

Like a coil and also a resistor, a capacitor provides resistance to alternating current. It should be taken into account that for currents of different frequencies it will be different. For example, while exhibiting good throughput for high-frequency currents, it will provide insulating properties for low-frequency currents.

The resistance of an electrical component is related to the frequency as well as the current capacity.

Repair of household appliances

Failure of capacitors leads to the fact that household appliances cease to function. The testing technique described above will allow you to identify the faulty part. Once it is detected, it is enough to replace the faulty element to restore the functionality of the TV, microwave oven or vacuum cleaner.

Knowing how to test a capacitor with a multimeter, you can check how efficient the starting element in a car generator is or determine whether the distributor is faulty.

Attention! Before you begin repairing any electrical appliances, you must make sure that they are disconnected from the power supply. Handling live devices may result in electric shock.