Cartouche pistol

Category

The capacity of the spray gun tank determines the time of continuous operation with it on one “refueling”.

The larger the tank volume, the longer you can work. Devices with a spacious tank are used mainly by professional painters who work with paint for a long time. For household, one-time work, a large tank is not necessary. \r\nThe weight of the spray gun depends on the material from which the device itself and the paint tank are made. If it is an alloy of non-ferrous metals and plastic, the weight is less, if it is steel, the weight is more. The weight of the spray gun affects fatigue when working with it; the greater the weight, the faster the hand gets tired. It should be taken into account that the working weight increases by the weight of the paint poured into the tank. ","sort":108,"additional":false>],"booleanFilters":[>,"id":NULL,"type":"is_packaging","label":"Buy in packaging","description": NULL,"sort":60,"additional":true>,>,"id":NULL,"type":"has_review","label":"Only with reviews","description":NULL,"sort" :80,”additional”:true>],”productCount”:2,”queryString”:””>” data-category-id=”198″ data-category-name=”Pneumatic spray guns” data-bowed-category-name =”in Kartushny pistol” data-rname=”pnevmaticheskie-kraskopulty” data-tag-page-id=”10616″ data-make-id=”0″ data-search-string=”” data-reset-link=” /instrument/pnevmoinstrument/pnevmaticheskie-kraskopulty/kartushnye-pistolety/#goods" data-is-search-page="" data-ab-is-expanded-filters="" >

Source

Nuances of use

The gun is easy to use. But when working with it for the first time, you should pay attention to the recommendations of professionals. The first of these is the need to use beacons. Otherwise, it will not be possible to create a flat surface.

Do not mix too much solution. This is especially true for gypsum mixtures. If it starts to harden, you just have to throw it away. And this is an unnecessary waste of effort, time and money. It is recommended to wear a clear face shield or goggles to protect your eyes.

Too low pressure in the apparatus leads to splashing of the solution and intermittent operation. Too high and it creates a foggy consistency that doesn’t adhere well to the wall. In addition, the hose may break out. The optimal distance to the wall is considered to be 30 cm. You should not bring it any closer.

The most controversial thing, even among professionals, is the thickness of the mixture. Some prefer liquid solutions, others prefer thick ones. Although the presence of nozzles of different diameters suggests the ability to work with any mixtures. It’s easier to start mastering the device using a medium-thick solution. It should be slightly thinner than for manual application.

Content:

Do you know the joke about Vovochka, who watches dad paint the ceiling? Mom says: “Look, son, and learn: when you grow up, you will help dad!” And the boy replies: “Won’t he finish the paint himself by then?”

It is likely that dad works with a brush or roller. But if he had chosen a spray gun, he would have done it faster himself and would have set an example for his son!

Do you also know the painful hours of working with a roller? How often do you have to dip it into a tray of paint, which tends to fall off the stepladder! The brush streaks and leaves lint. After work, you need no less time to clean your hands, clothes, and the tool itself. What about the car? Is it possible to paint it without a special apparatus?

A paint sprayer will help you avoid these troubles - a worthy replacement for brushes and rollers. This is a great companion in repairs, construction or when painting a car. It will help you achieve perfect coverage quickly and without much effort.

Compressor connection

To supply air from the compressor to the pneumatic bucket, you will need a hose with a cross-section of no more (and no less) 9 mm. A black or blue oxygen hose is suitable for this. Red hoses are not designed for high pressure, so they cannot be used.

, which produces a hopper-bucket for plaster, if buckets with several plugged nozzles or mini-buckets are used, recommends ordinary hoses with standard quick-release connectors for connection. This connection is also quite sufficient for mobile mixtures. But if a large air flow is required, such a connection is not suitable for thick solutions, because the cross-section of the adapter in the quick release and compressor adapter unit is 7 mm.

A prerequisite is the use of a shut-off device at the outlet of the receiver, for example, a ball valve. You can install it yourself. How to do this, watch the video. There you can also see how to increase the permeability of the quick release and adapter at the outlet of the pneumatic unit.

Why do you need a spray gun?

A spray gun is a device for applying paint, varnish, enamel and other liquid solutions to a surface. Thanks to fine spraying, the layer is even and thin with a minimal likelihood of smudges. In addition, with the help of this tool you can easily and quickly work on a relief surface, hard-to-reach places and corners. For example, you can carefully paint the inside of the battery.

Previously, it was believed that a spray gun was an expensive and purely professional tool, and the average user had no need to spend money on it. But that's not true. First, there are inexpensive models for home use. Secondly, the device completely pays for itself. Thirdly, it is easy to use, which is why users love it. Many of them have already forgotten what brushes and rollers are - forget you too! Feel free to buy a paint sprayer for your purposes.

In addition to painting, the sprayer is suitable for:

whitewashing the ceiling; wall primers; applying varnish to a wooden surface; metal treatment with an anti-corrosion compound; spraying plants against pests; cleaning walls from old wallpaper.

The tool is in demand even among confectioners, who have adapted it for velor cakes.

It turns out that the device will be useful at all stages of renovation in an apartment or house, at all stages of car painting, as well as for implementing creative ideas. If by this point you have said to yourself: “I definitely need a spray gun!”, Let’s look into it in detail.

General information. Purpose and principle of operation

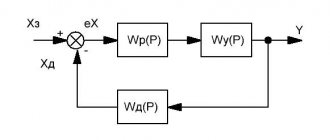

A cartouche gun is a pneumatic type tool, which is used primarily for applying various building mixtures to the surface; such a tool is usually used at the plastering and finishing, or more precisely, the finishing working stage. One of the main advantages of using such a tool, compared to manual methods of applying similar plaster, is the high operating speed, as well as productivity. It is also worth noting the ease of application, namely the spraying of solutions onto the treatment object, with different fraction sizes, and this will depend on the diameter of the nozzle used.

Such a gun will be useful if you need to spray the following coatings:

Heavy paint and varnish coatings that have increased viscosity, because classic spray guns simply do not push the thick mixture through the nozzle, and its multicolor, textured and mosaic variants.- Decorative types of mortar, and especially facade plaster, and we will be talking about a large area of coating.

- Primers, liquid wallpaper, concrete contact, liquid cork and even some types of marble chips.

The cartouche type gun is universal for finishing work, with which you can process up to 100 square meters during the day. meters of area, and with almost all ready-made mixtures, which have a layer up to 1 cm thick. As the work progresses, it will begin to eject solution from the nozzle at a certain angle, and for its operation it requires connection to an air compressor with the required technical characteristics.

Device structure

The liquid solution is poured into a special tank, which can be located on top, bottom and side of the sprayer. It is more convenient to paint vertical surfaces, such as walls and doors, with a gun with a lower tank. The upper container is ideal for painting ceilings and floors.

The tank can be of different sizes. For example, from 400 to 600 ml is suitable for short, small painting jobs - a chair or bench. Moreover, with such containers the hand does not get so tired. A tank of 700 to 1000 ml is needed for painting large objects, such as a house, garage, fence. The coloring speed directly depends on the volume of the tank. You don’t have to frequently add the composition to a large tank. You will be less likely to take time off from work, so you will get things done faster.

Plaster gun - and a suspension of plaster mixture flies into the wall

So what consistency should the plaster be before it can be applied with a mortar gun? Well, what thickness of the mass is usually applied to the wall - this is also the case with the unit, with the only condition that the solution flows (or slides) quite freely along the walls of the funnel down into the nozzle, where it will be picked up and thrown out by compressed air. For a thicker mixture we put on a wider nozzle, for a liquid solution - a narrower one, and monitor the stream, the main thing is that the plaster is distributed evenly over the wall.

As you work, you need to constantly update the mixture in the funnel, first cleaning out the old one. On average, a bag of plaster weighing 25 kilograms is enough for one and a half square meters of wall covering, taking into account a layer thickness of 10 mm. But the rate of consumption of the mixture is low, and even the fact that the plaster solution constantly settles in the tank does not mean that nothing will remain on the walls - everything will harden if it is not cleaned in a timely manner. Of course, applying plaster with a pistol is a fascinating process, somewhat similar to shooting at a shooting range and a Western in one bottle (only the pistols of shooters in the Wild West did not weigh more than 5 kilograms), but you should not forget.

Types of paint sprayers

Have you decided to buy a spray gun? But what to choose when the range is so wide and the prices are so different? We will help you understand the types of tools so that you buy the one that suits your ideas. After all, each type of sprayer is designed for a separate task in the domestic or professional sphere. We will divide them by drive type.

Mechanical

Such a device is also called a manual spray gun. The principle of operation is simple: when you press the lever, the tank is filled with air using a plunger pump, which pushes the paint through the spray nozzle. The device is designed to perform basic tasks such as whitewashing walls or spraying trees in the garden. The sprayer will not have enough power for painting, and the thick composition will clog the nozzle. The operating pressure of the unit is only 0.4 - 0.6 MPa. But such a paint sprayer does not need a compressor and does not depend on the electrical network. The device is suitable for those who often work in the garden or perform rough repair work where great care is not required.

Examples of models from our website

| Specifications | Name | ||

| Zitrek CO-20 V | KSOM KRDP-4 | ULIG 050-00 | |

| Weight, kg | 6,8 | 5,3 | 6,5 |

| Tank capacity, l | 2,5 | 2 | 2,2 |

| Capacity, l/min | 1,4 | 1,4 | 1,4 |

| Price, rub.* | 4890 | 4690 | 4390 |

*Prices are presented for the Moscow region as of March 1, 2019.

Mechanical spray guns differ slightly from each other both in operating parameters and in price. The sprayers are simply designed and rarely break, so they have a long service life.

Pneumatic

This type of sprayer is popular among professionals due to its high quality of work. The spray gun operates using a compressor with a receiver. When you press the trigger, air is pumped and paint is supplied to the nozzle. The nozzle turns a stream of paint into fine dust, which is shaped like a torch. Such devices cope with both liquid dispersion paints and thick materials, for example, viscous wood varnish.

Pneumatic spray guns are divided into three types based on spray technology.

HP (high pressure) is the most budget option among pneumatic spray guns. It has an outlet pressure of 1.2 - 1.5 atm. With this spray gun you can paint quickly and evenly. Another advantage is low cost. But the low percentage of paint transfer to the surface - only 35 - 50% - is the main disadvantage of the device. This option is good for painting walls, floors, ceilings in household and professional repairs.

HVLP (high volume, low pressure) are the most common spray guns among painters. What is the difference from the previous type? A pressure of about 1 atm is created in the nozzle. A clear torch at the output allows you to keep the device close to the surface. Professionals love the HVLP sprayer for its high transfer rate of paint materials to the surface - about 65%. However, there are also disadvantages: the spray gun requires a powerful, expensive compressor and well-purified air to operate, which can only be achieved in special conditions, for example, in a car repair shop. The tool is quite versatile - suitable for painting a car, for household and professional repairs.

LVLP (low volume, low pressure) - the transfer coefficient of this type is 80%. The device is more expensive than others, but this is justified by the fact that it has economical material consumption. Due to its high cost, such a spray gun is popular among professionals from various fields of activity - from auto painting to manufacturing.

Examples of models from our website

| Specifications | Name | ||

| QUATTRO ELEMENTI 770-810 | FUBAG MASTER G600/1.4 HVLP | HUBERTH R500 RP20500-14 | |

| Spray type | HP | HVLP | LVLP |

| Weight, kg | 0,6 | 1,15 | 0,8 |

| Tank capacity, l | 0,6 | 0,6 | 0,6 |

| Nozzle diameter, mm | 1,5 | 1,4 | 1,4 |

| Capacity, l/min | 200 | 180 | 110 |

| Working pressure, atm | 3-4 | 3,5 | 2,5-3 |

| Price, rub.* | 842 | 2290 | 3449 |

*Prices are presented for the Moscow region as of March 1, 2019.

Painters on construction sites, in auto repair shops, and in production love pneumatic spray guns for their power, accurate painting, performance and durability - the service life is more than 10 years. You can find a tool costing up to 1000 rubles, and there are models three or four times more expensive. But it is worth remembering that a pneumatic line will also require investment.

Electric

Are you going to paint your house? Have you already called all your friends and relatives and prepared them for many hours of hard labor? Don't torture yourself or others! An electric paint sprayer is a solution for those who are tired of back and arm pain, and who no longer want to spend the whole weekend just painting. Better spend the remaining time on other useful things: update your garden furniture or fence.

The electric spray gun operates using a motor that creates pressure. The solution enters the nozzle and comes out as a coloring mist. The device is inferior in painting quality to a pneumatic spray gun, but has its advantages. Firstly, to operate an electrical device, you only need an outlet. There is no need to buy a compressor and make an air preparation unit. Secondly, this sprayer is easy to use - you can paint any surface the first time.

To work without smudges, you need to apply the paint evenly and try not to point the nozzle at the same place. By the way, the nozzle can periodically become contaminated with small debris flying outside. To clean it, use a small brush, a soft brush or a special needle. Avoid using hard objects such as wire, which may damage the nozzle. In addition, it is important to thin the paint to the correct consistency, otherwise there may not be enough power to spray dense compositions. How to do this is written in the instructions for the spray gun.

Electric sprayers are widely available on the market. There are so many models that it is easy to get confused in such variety. To make it easier for you to choose, we will tell you the principles by which such instruments are divided.

By design

By food type

| Mains - a paint sprayer that connects to an outlet. This is its main inconvenience: the device creates problems with movement, since the wire may not be long enough. And in rooms without power supply and on the street it can only be used with the help of a generator. On the plus side: a wide range of such spray guns allows you to choose a device of the required power. It is the network device that is most often purchased for homes, cottages and private renovations. |

| Rechargeable – suitable if you don’t want to bother with wires. It allows you to move over a large area. They are convenient for painting, for example, the roof of a house or a long fence. Again, there are disadvantages: continuous operation time, as a rule, is no more than 30 minutes, and the cost is an order of magnitude higher than that of network devices. In addition, the rechargeable type is heavier due to the built-in battery. |

Examples of models from our website

| Specifications | Name | ||

| Network | Rechargeable | ||

| Elitech CE 350P | Wagner W 450 | Ryobi ONE+ P620 | |

| Weight, kg | 1,7 | 2 | 1,93 |

| Tank capacity, l | 0,7 | 1,3 | 1 |

| Capacity, l/min | 0,7 | 0,23 | 0,34 |

| Power, W | 350 | 460 | 200 |

| Price, rub.* | 2550 | 8490 | 6990 |

*Prices are presented for the Moscow region as of March 1, 2019.

You have just become acquainted with the types of spray guns. Despite all the diversity, we hope that we have helped you and sorted everything out. Decide why you want to buy a spray gun and evaluate the conditions in which you will be working. Choose your sprayer wisely and you will see that the purchase is worth it.

Description

Using a gun, you can mechanize the main part of the operations. Manufacturers of such tools claim that their equipment is capable of working with solutions of any thickness. If you use a ladle, then voids may remain in the thickness of the plaster. When using a gun, the finish is dense, has no cavities and does not form cracks after drying. If we consider this tool using the example of the Western KP-10 model, we can note that the minimum compressor performance is 165 liters per minute. The maximum rate can be 250 liters per minute. The minimum pressure is 3 bars, and the weight of the equipment is only 1.4 kilograms. The tank is made of nylon and its volume is 5 liters.

The scope of use of such a device is wide. The gun can be used for applying mineral heavy paints, liquid wallpaper, putties and plasters. Unlike working by hand, the gun drives the mixture under high pressure, which ensures that there are no cavities or pores. Ultimately, it is possible to form a homogeneous and dense layer. The nozzles are made of stainless steel, which is resistant to minor damage and corrosion. The master can regulate the supply of material during work by installing nozzles of different diameters. This functionality allows you to create many textures. The body is made of aluminum alloy and has the ability to withstand heavy loads.

We answer common questions about choosing

What you need to know about power?

For electrical devices, performance directly depends on power. The higher the value, the greater the productivity, the faster the painting. This is the Enkor KE-700. Its power is 700 W. The tool is suitable for long-term repair work, when you need to paint the walls, put the ceiling in order, and renew the paint on the radiator. For weaker models, the power may be only 100 - 200 W, like the PATRIOT POBEDA KP-300. With such a tool you can perform decorative work: restoring furniture, painting on glass, finishing with a stencil.

What should the performance be?

This parameter determines the consumption of liters of paint per minute. The higher the value, the faster you will paint the surface. Users love SPEC BPO-350 for its speed. Its flow rate is 0.8 l/min. With it you can paint a fence of 20 m2 in 5 minutes.

Air or airless?

According to the type of spraying, all spray guns are divided into air and airless. The first include mechanical and pneumatic models. But among electric ones there are both options.

The air one has the same operating principle as a pneumatic spray gun. Electrical devices of this type have a solenoid or turbine motor. It can be located either inside the spray gun or placed outside it - then it can be hung on the shoulder or rolled behind you like a vacuum cleaner. Such sprayers create an air cloud with paint. Pros: smooth, high-quality coating, power adjustment to suit needs. The main disadvantage is the noise produced by the turbine engine.

An airless electric spray gun has a piston pump. It develops pressure and delivers paint to the nozzle, resulting in spraying onto the surface. In this case, the drops turn out to be quite large, so smudges are possible. The device works like a spray gun - it pushes paint out under pressure. It lays down in a thick layer, which cannot be called economical. With such a spray gun it is unlikely that you will be able to achieve perfect coverage. But it will help you quickly paint large objects, such as garage doors.

Do the weight and dimensions of the spray gun affect its performance?

You won't believe it, but even with a spray gun you can get tired. Holding a massive device in your hand for a long time is uncomfortable. Usually the weight does not exceed 2 kg. But there are heavy devices with portable pumps, such as the Bosch PFS 5000E. Their weight is about 5 kg. Lightweight spray guns weighing no more than 1.5 kg are well suited for women and will be convenient even when delicate, painstaking work is required. For example, when painting shaped picture frames, you often have to maneuver with your hand. With the Wagner W100 it will be easy.

What does the nozzle diameter affect?

The intensity of spraying depends on it. The larger the diameter, the more solution is supplied in a certain unit of time and the more viscous substances can be sprayed. Thick paint needs to be thinned, making it more liquid.

Nozzle with a diameter of 1.3 to 1.7 mm - for enamels, varnishes, liquid paints. For primer, putty and thick paints, a nozzle of 1.8 mm or higher, like the Sturm SG9641, is suitable. Need a multi-tool? Choose models with replaceable nozzles or with nozzle adjustment - the Wagner W 590 has this function.

What else to consider when choosing?

Are you a painter in a car repair shop or do airbrushing? Or maybe you are an artist who makes complex drawings? Then a comfortable handle, like the Zitrek FR 301, will probably be important to you. There are special models with recesses for fingers for a secure grip, like the SPEC BPO-300. It is convenient to work with such a tool while standing on a stepladder, when there is a risk of dropping it. More expensive models have a smart self-cleaning system. A few minutes - and the spray gun is clean. The Wagner W 990 Flexio has such a system. And if design is also important, you will be satisfied with Bosch and Wagner spray guns.

Which brands are worthy of attention?

There are manufacturers on the market that specialize in painting equipment, and there are those that produce tools and devices of different categories. Let's get to know them better.

Specialize in spray guns

If you want a high-quality, modern, technologically advanced device, go to Wagner. Professionals use the manufacturer's spray guns for any repair tasks, in auto repair shops, for complex and large-scale painting. Do you want a device for household use? There are others like that. Most Wagner spray guns feature Control Pro airless spray technology. The aerosol cloud is reduced by 55% thanks to the innovative nozzle design. The “soft” torch gives a perfect, streak-free result. The device pump is less loaded and wears out due to HEA technology, which leads to an increase in service life. And you will also be pleased with the 3-year warranty.

KSOM is a Belarusian brand of painting equipment. It was popular back in Soviet times, which is why many users still trust it. The manufacturer does not produce high-tech devices. Its range includes only mechanical spray guns. These are suitable for household use, especially for gardening and in preparation for renovations. For example, for wetting surfaces - removing old wallpaper and washing the ceiling. The manufacturer provides a 2-year warranty on its products.

Produce a wide range of tools

Probably everyone has heard about the Bosch brand. And for good reason. The German brand has over 130 years of experience. The manufacturer produces tools and other equipment for professionals and amateurs. The patented ALLPaint technology for working with any paintwork material and the ConstantFeed function for a constant supply of paint without additional adjustment are advantages that almost every Bosch paint machine has. With the help of these spray guns you can achieve an even, high-quality coating, so they are suitable for any household work and for professional repairs. The warranty on them is 3 years.

Patriot is an American manufacturer of power tools, gardening, construction and power equipment. The company produces inexpensive household paint sprayers - up to 4,500 rubles.

The Japanese company Ryobi produces high-quality power tools, machine tools, climate control equipment and much more. A large selection, high quality, many years of experience and the latest developments are the reasons why users choose brand products. Spray guns and painting stations are suitable for any household purposes, as well as for private construction teams. A 3 to 5 year warranty is another plus!

SPEC is a Russian brand of power tools. The assortment includes more than 100 items. There is a small line of electric spray guns. All of them have good reviews with ratings above 4 stars. The price is also pleasing - you can buy the device for up to 3,000 rubles. The devices are not suitable for professional use, but for domestic purposes they are just right.

The Russian company Kalibr produces affordable tools. Users love them for their price-quality ratio. Spray guns of this brand are inexpensive devices for home use.

Sturm brand products are manufactured in China. A wide range, extensive experience - thanks to this, buyers often pay attention to the brand. Electric spray guns are inexpensive and cope with any household tasks adequately.

Produce pneumatic tools and power equipment

Foxweld is an Italian brand that specializes in pneumatic tools, power equipment and construction equipment. All products on our website have high customer ratings, including spray guns. The devices are suitable for priming and painting cars, so they are used in car repair shops.

The manufacturer HUBERTH also has a product range mainly of pneumatic tools. Professional, high-quality devices are suitable for complex work that requires precision, for example, applying airbrushing to a car body.

It's worth taking care of

Have you chosen a spray gun? Great! But don't forget about the important little things.

Equipment. Special clothing will help prevent harmful vapors from reaching the skin and mucous membranes. The suit will keep your clothes clean, glasses will protect your eyes, a respirator will protect your respiratory tract, and gloves will protect your hands.

Care. The long life of the spray gun depends not only on the manufacturer, but also on you. Clean it immediately after use with solvent or water. To do this, pour liquid into the tank and spray. Then dry the device thoroughly.

Storage and carrying. May you need a spray gun on different objects? Are you going to often take the device to the dacha? Then a box is needed for the sprayer. The tool will be convenient to store and carry with you.

Equipment. The sprayers may come with additional accessories included in the kit. Thus, heavy devices often come with a carrying strap. Many manufacturers include a measuring cup for dispensing and determining the viscosity of paint, needles or even entire sets for cleaning nozzles, nozzles and tips for different paintwork materials and types of spraying.

Spare materials. Tanks, nozzles, valves, springs are consumables. For your convenience, many manufacturers equip their spray guns with them. If you choose a machine that comes with spare parts, you won't have to buy them separately when the need arises. After all, one small broken spring can ruin your painting plans! Therefore, it is better to take care of consumables in advance.

What solutions are suitable

Construction mixtures for plastering and finishing work are produced in a large assortment.

They come ready for application, or dry, which you need to mix yourself. The basis of the solution is gypsum or cement; various natural or synthetic additives are needed to improve the strength and ductility of the coating. Gypsum mixtures provide elasticity and viscosity of the solution, but harden quite quickly. They are used for interior decoration of rooms with normal or low humidity levels. Cement mortars are widely used due to their moisture resistance; they are suitable for any finishing work - facades, interior openings, swimming pools, bathrooms and other objects.

The cartouche gun can be filled with almost any type of solution, the main thing is that the consistency of the mixture allows the solution to flow smoothly down the walls of the bucket. Professionals conventionally designate a suitable structure as “thick sour cream.” Solutions with synthetic additives, marble chips or adhesive mixtures can be poured into the device.