- Composition of coolant (COTS)

- Additives in coolant for machine tools

- Main functions of coolant

- Coolant classification

- Cutting fluids for cutting operations

- How to properly use coolant for machine tools

When processing metals by cutting or plastic deformation, a large amount of heat is released. As a result of heating the working tool and the workpiece surface, the quality of processing deteriorates, the wear of expensive tools and equipment increases, and the structure of the surface layers of the workpiece metal changes. This, in turn, leads to a decrease in performance properties and quality of final products.

To prevent the listed manifestations and improve the quality of surface treatment of the workpiece, special cooling technical means are used - COTS.

According to their state of aggregation, COTS are divided into gaseous, liquid, and solid.

The most widely used liquid coolants are cutting fluids (cutting fluids).

Cutting fluid (coolant)

– a special substance used in the operation of metal processing machines. Each technological process of a turning or milling machine is accompanied by friction, which can lead to deformation of the workpiece, breakdown of an expensive machine or its part, and a change in the mechanical properties of the metal.

The main purpose of coolant for metalworking is to separate surfaces subject to friction and reduce the temperature of the tool. This fluid forms a lubricating film on the working surfaces, which reduces friction and the force required for cutting. The introduction of special additives into the composition of the product simplifies the cutting process - liquid molecules quickly penetrate microcracks on the metal surface and, as it were, drive a wedge between its particles.

Composition of coolant (COTS)

The composition of most metalworking coolants is approximately the same. In products of different manufacturers and names, only the concentration of a particular substance or additive needed by a specific process or metal changes.

Effective coolant for machine tools includes:

- Lubricants made from natural or synthetic oils

- Additives with various performance properties

- Substances that prevent the separation of cutting fluids into fractions

- Anti-corrosion and wear-reducing components

- Additives that reduce foaming and aggressiveness towards processed metals

How to purchase high-quality cutting fluids?

To purchase lubricants from the German manufacturer Zeller+Gmelin, contact the official representative of the company in our country, which is Divinoil Rus LLC. We will help you choose the optimal types of coolant. Please contact our experienced consultants with any questions you may have.

You can purchase lubricants at retail or wholesale. Prices are acceptable for all categories of buyers. Apply now. We will process it within 2 days and deliver the necessary German quality coolants to the specified address. Metalworking in this case will be effective and as cost-effective as possible.

Additives in coolant for machine tools

Additives are an important component of metalworking coolants. Having a very small concentration, they can significantly improve the quality and efficiency of working with metal.

Additives for various purposes perform several important functions:

- Increases the resistance of metals to corrosion

- Anti-wear by reducing wear on tool working surfaces

- do not allow scuff marks to form on the surface of the metal workpiece during processing,

- Prevents the formation of foam, which reduces the quality of the coolant, and the appearance of oil mist, which is harmful to the skin and respiratory organs of working personnel

The need to use high-quality cutting fluids

Only high quality cutting fluids can demonstrate the required performance. You cannot save on purchasing lubricants. The quality of the coolant determines the stable operation of the equipment, the absence of breakdowns and downtime, as well as the quality of the finished products. Accordingly, the products presented directly affect the profit margin of the enterprise.

To obtain a high economic effect from the use of special lubricants, it is necessary to purchase products from trusted manufacturers. Coolant and lubricants from the German brand Zeller+Gmelin are in great demand today. The company's technologists are constantly developing new compositions that not only meet all existing standards and requirements of metallurgical enterprises, but are also significantly ahead of them.

The presented manufacturer has developed many lines of various lubricants that can provide high quality in almost any area of metalworking. For any technological process it is necessary to select the appropriate composition of the product.

Main functions of coolant

Lubricating and cooling fluids for metal-cutting machines perform the following main functions:

- Cools cutting tools that get hot during operation and increases their service life

- Improving the quality of metal surface treatment

- Removing dust, dirt, metal shavings, etc. from working surfaces.

- Lubrication of the friction zone to increase the service life of cutters, reduce the coefficient of friction and heat generation

- Increasing machine productivity by increasing speed, improving quality and precision of processing

Which is better: homemade or factory coolant?

Many people wonder how to make coolant for a machine with their own hands. But at the same time they think little about the consequences. Experts say that the best option is to purchase a ready-made cooling lubricant.

Homemade products have many disadvantages:

- it is difficult to achieve stable fluid characteristics;

- alternative components do not always perform the stated functions;

- there is a high probability of damage to the coolant due to the development of fungus or rotting of individual components during storage.

If you prepare the liquid and coolant pump with your own hands, you will have to come into contact with chemically active components that can be dangerous to the skin and mucous membranes, and inhale toxic fumes. The result may be dizziness, nausea and other signs of poisoning, which should promptly consult a doctor. Therefore, it is better not to experiment, but to immediately purchase ready-made concentrated coolant for specific tasks.

Coolant classification

Each technological process requires a coolant, the properties of which will best meet the specifics of the material and the characteristics of the machine.

Typically, metalworking production uses several types of metalworking coolants:

- Oil coolants.

Their base is mineral or synthetic oil. To obtain special properties of the liquid, additives are added to the composition. Such coolants perfectly lubricate surfaces, but do not reduce temperatures well, so they are used for soft metals for simple work.

- Water-miscible coolants

– these liquids may contain alcohols, emulsifiers, oils, electrolytes, additives, etc. They cool tools and metals well, but have modest lubricating characteristics,

- Mineral cutting fluids

– produced from petroleum products, used primarily for the operation of milling and lathes for cutting steel,

- Synthetic and semi-synthetic coolants

– these types of cutting fluids are made on the basis of a mixture of water-soluble half-mirs with the addition of surfactants, inhibitors, biocides, etc.

- Coolant emulsions

– compositions with a higher concentration of dispersed components compared to water-miscible ones. Such fluids have excellent lubricating and anti-wear characteristics.

In addition to composition, cutting fluids can be classified according to other criteria, for example:

- Based on the method of preparation or composition of the working fluid, a distinction is made between emulsols - ready-made liquids that contain additives that prevent separation - and coolant concentrates, mixed with water before use to obtain coolant emulsions.

- By viscosity, flash point, acid number, etc. (oil coolants)

Control and maintenance of water-miscible coolants

Previously, we went through all the stages of preparing for the operation of water-miscible coolant, now it is poured into our machines and it’s time to learn how to care for it. This is where the fun begins, because water-miscible coolants are very capricious and require due attention. And the thing is that the basis of water-miscible coolants is water, and it is a natural environment for bacteria and fungi. In addition, you need to take into account the fact that water-miscible coolants are complex multicomponent systems that undergo physical and chemical changes during their operation:

— The first thing we notice during work is an increase or decrease in the concentration of the working solution, associated with the evaporation of water or the carryover of the oil phase with chips (has adhesive properties);

— Change in pH of the working solution due to the activity of bacteria and fungi; — Accumulation of foreign oil in the tank with the working solution, for example oil for guides;

— Accumulation of metal dust and shavings in the machine tank;

— Ingress of mechanical impurities into the working solution from the environment;

— Oxidation of oil and active additives upon contact with air;

— Foaming;

It is important to know how all these factors affect the emulsion, how to control them and what corrective actions need to be taken.

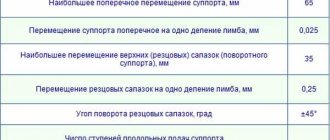

To monitor changes in the parameters of the working solution, it is recommended to keep a table in which the following measurements should be entered:

— Concentration (It is recommended to take measurements every day);

— pH (Recommended to do once a week);

— Volume of working solution in the tank;

— Smell (It is recommended to check every day);

— The presence of oil on the surface of the working solution in the tank (It is recommended to check every day);

— Bacteria/fungi (Recommended to be done as needed);

Concentration control

The most important and most frequent thing you will check is the concentration of the working solution. It is very important to maintain the concentration within the operating range recommended by the manufacturer. Because low concentrations promote bacterial growth, may cause corrosion of machine tools/workpieces and reduce metal processing efficiency. In turn, a high concentration can cause skin irritation, foaming, plus at high operating modes the cooling efficiency decreases.

It is recommended to take samples to determine the coolant concentration directly in the working area of the equipment. Concentration can be determined in two ways:

Laboratory (titration method)

Portable (using a hand-held refractometer)

When using a refractometer, the following formula is used to obtain the actual concentration of the working emulsion:

Actual concentration = PR * PC

Where PR is the refractometer reading;

PC - correction factor for coolant (all coolants have a different coefficient, due to the composition), indicated in the technical description for the product;

Next, when we know the concentration in the equipment, we need to make the necessary adjustments to the working solution. We recommend calculating the amount of concentrate required for adjustment using the following formula:

V = Vworking solution * (Crequired - Ccurrent) / (PC - Crequired)

Where V is volume, liters

K - concentration, %

PC - correction calculation factor (need to increase concentration -

100; need to reduce concentration - 0)

pH control

Another equally significant parameter is pH or hydrogen index; we use it to monitor the acid-base balance in working coolant solutions. Once again, let's briefly recall the theory: The working pH range of coolant is from 8.7 to 10. A low pH in the working solution will create a favorable environment for microorganisms, this will start the process of biodestruction, which will affect the longevity of operation. High pH in the working solution can cause skin irritation (chemical burns).

Express pH analysis can be performed in two ways:

Electronic device pH meter

Using test strips (litmus paper)

Biodefeat

Let us focus on this topic, since this is the most important factor due to which water-miscible working coolant solutions become unusable. Bacteria are one of the first forms of life on earth and the most numerous, their biomass is greater than the biomass of plants and animals combined. Bacteria surround us everywhere, in soil, water, on every surface, be it a house, a table or a bed. They exist outside and inside us, so it is important to know how we can get along with them, but we will naturally speak only in the context of water-miscible cutting fluids.

So, bacteria surround us everywhere and naturally they are present in water-miscible cutting fluids. It is worth noting that from the point of view of coolant operation, bacteria can be divided into two types - harmless and harmful. Harmless bacteria live in an environment in which oxygen is present. Harmful bacteria begin to thrive in an environment lacking oxygen, and it is because of them that the coolant becomes unusable. Oxygen is a deterrent to the growth of harmful bacteria; the coolant must be constantly saturated with air. During operation, while the coolant circulates through the equipment system, the working solution is saturated with oxygen and this helps the “good” bacteria to gain the upper hand. If there is no oxygen supply to the coolant, for example, during prolonged downtime of the machine park (it is worth noting that foreign oil that completely covers the surface in the machine tank makes a significant contribution, since the access of air to the coolant tank is stopped), the environment becomes favorable for starting activity of harmful bacteria. Reproduction begins, bacteria feed on mineral oil, emulsifiers and inhibitors, reducing anti-corrosion protection and causing damage to working coolant solutions. All this is accompanied by the formation of deposits and the smell of a “rotten egg” of hydrogen sulfide, and the working solution may also change its color to blue-gray. We fix the main signs of biological damage:

— Unpleasant odor;

— Decrease in pH level below normal

— Changing the color of the working solution

— An indirect sign, in the presence of which it is necessary to take action, is foreign oil on the surface in the tank.

If one of these signs appears, it is necessary to urgently check the working solution for biological damage. For testing, special immersion slides (deepslides) are used. The slide plate is covered with a dense nutrient medium, on one side pale yellow TTX agar, which promotes the growth of bacteria, and on the other, pink Bengal agar, which promotes the growth of fungi and yeast. The slide is immersed in a sample of liquid, and after the excess has drained off, it is placed in a test tube. Next, keep in a dark place at room temperature for 3-5 days. After time, the appearance of the deep slide is compared with the standards.

The number of CFU/ml 102 is considered insignificant and does not require special corrective actions; it is enough to increase the concentration of the working solution to suppress the growth of bacteria. The number of CFU/ml 104 is considered significant and requires the introduction of special bactericidal compounds (biocides or fungicides) into the working solution; we suggest using the “BACCID” biocide. The number of CFU/ml above 104 is considered critical and correction is not advisable. A complete replacement of the working solution is required after thorough cleaning of contaminants and residues of old coolant, washing and disinfection of the coolant supply system with a washing-disinfecting solution. For these purposes, we suggest using the EKOS-D coolant supply system cleaner.

Cutting fluids for cutting operations

Let us note which cutting fluids are most common when carrying out various cutting operations on lathes:

- One and a half percent solution of soda ash in boiled water (for rough grinding)

- Water, trisodium phosphate and sodium trinitrate – increases anti-corrosion resistance

- Water, emulsol and soda - ensures high quality grinding

- Oil (industrial and linseed) and kerosene - for high-precision work with expensive cutters

- Sulfofresol and kerosene - for deep metal drilling

- Kerosene – when working with aluminum and its alloys

Metal forming also requires the use of metalworking coolants, but such materials must have special properties. Metal forming is characterized by significant forces and low sliding speed between the workpiece and the tool, therefore the coolant must be sufficiently viscous and resistant to delamination at high temperatures. Often, such fluids contain fine-flaked graphite, which minimizes friction in the plastic deformation zone.

Special lubricants and cooling materials are also used when working with aluminum and its alloys. This metal tends to stick to the surfaces of the cutting tool with which it comes into contact. For this reason, cutting fluids for aluminum must provide high quality finishing of the workpiece. When working with aluminum, emulsions of coolant based on fatty acids and substances with ethylene glycol or glycerin are usually used.

Lubricants for metal forming operations

The pressure exerted on the workpiece requires high mechanical forces from the working tool. The coolants used in this case are characterized by a high viscosity. This reduces slippage of rubbing surfaces.

New compositions make it possible to avoid metal destruction when using high pressure. The material does not delaminate and cracks do not form on the surface. For the presented processing processes, water-graphite lubricants are used. They consist of an oil suspension. The composition includes fine particles of graphite.

Features of the use of coolant from the German company Zeller+Gmelin

The use of coolant is a mandatory component of the modern process of processing metals and composite alloys. The effectiveness of the production cycle depends on the choice of a quality product.

Therefore, you should give preference only to proven, reliable manufacturers. One of the best brands in this area is the German company Zeller+Gmelin, which has been operating in the lubricants market for more than 150 years.

Many special compositions have been developed for various branches of manufacturing and engineering production. Our coolants have a certain set of qualities.

These include actions:

- lubricating;

- cooling;

- dispersant;

- detergent

When processing metals and alloys, high temperatures and pressures are observed. To prevent destruction of the cutting tool and the surface of the workpiece, the lubricant envelops them with a hard film. Coolant reduces friction and removes heat and chips from the cutting zone. This allows you to significantly extend the life of the equipment, reduce the number of malfunctions and downtime. Metal processing is carried out with specified precision.

Areas of application of different coolants

The main functions of coolant are to cool and lubricate. Modern products from this category often do much more, but first we will talk about their main purpose.

How and where to use oil coolants

They have proven themselves in difficult operating conditions on metal-cutting equipment, where increased depth of cut at moderate speeds is required. They are often used for honing, reaming and drilling. Experts recommend using them where it is not technically possible to work with water-miscible compounds. Oil-based products are used to lubricate the surfaces of metal workpieces made of bronze, copper and brass, when working with carbon steels and cast iron.

Differences in the use of water-soluble cutting fluids

Cooling properties determine the use of water-based coolants. They have proven themselves where the tool operates at high speed, gets hot and requires effective cooling. The same liquid in different concentrations can be used in different operating modes: in low concentration during roughing, and in high concentration during finishing. The minimum setting is suitable for most sanding operations. Exact recommendations can be found in the technical specifications developed by the manufacturer.