In simple words: a block is a wheel with a groove on its circumference. The wheel can rotate around its axis, and a belt or rope can be placed in the groove.

For example, a bicycle wheel can be considered a block if the rubber tire is removed from it and instead of it, a rope, rope, etc. is placed in the groove. A load can be attached to one end of the rope, and a load can be attached to the other end, that is, a force can be applied to it .

If one wants to use a chain instead of a rope, then instead of a wheel with a groove, a wheel with protruding teeth is often used. This eliminates chain slippage and increases traction. Such structures are called asterisks. For example, a bicycle contains two sprockets - one driving, on the axle with pedals, the second - driven, on the axis of the rear wheel.

Blocks are used in various mechanisms, for example, for lifting loads.

Block system

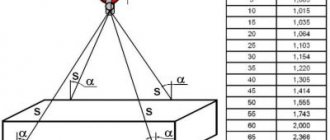

The use of a movable block gives a double gain in force, the use of a stationary block allows you to change the direction of the applied force.

In practice, combinations of movable and fixed blocks are used. Moreover, each moving block allows you to halve the applied force or double the speed of moving the load. Fixed blocks are used to connect movable blocks into a single system. Such a system of movable and fixed blocks is called a pulley block. A chain hoist is used in cases where it is necessary to lift or move a heavy load with minimal effort, provide tension, etc. The simplest pulley system consists of just one block and a rope, and at the same time it allows you to halve the traction force required to lift a load.

Figure 1. Each moving block in the pulley gives a double gain in strength or speed

Typically, lifting mechanisms use power pulleys to reduce the tension of the rope, the moment from the weight of the load on the drum and the gear ratio of the mechanism (hoist, winch). High-speed pulleys, which make it possible to obtain a gain in the speed of movement of the load at low speeds of the drive element, are used much less frequently. They are used in hydraulic or pneumatic lifts, loaders, and telescopic boom extension mechanisms of cranes.

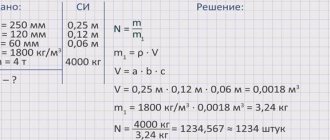

The main characteristic of the pulley is the multiplicity. This is the ratio of the number of branches of the flexible body on which the load is suspended to the number of branches wound on the drum (for power pulleys), or the ratio of the speed of the leading end of the flexible body to the driven end (for high-speed pulleys). Relatively speaking, the multiplicity is a theoretically calculated coefficient of gain in strength or speed when using a chain hoist. Changing the multiplicity of the pulley system occurs by introducing or removing additional blocks from the system, while the end of the rope with an even multiplicity is attached to a fixed structural element, and with an odd multiplicity - on the hook clip.

Figure 2. Rope fastening with even and odd multiplicity of pulley system

The gain in force when using a pulley with $n$ movable and $n$ fixed blocks is determined by the formula: $P=2Fn$, where $P$ is the weight of the load, $F$ is the force applied at the input of the pulley, $n$ - number of moving blocks.

Depending on the number of rope branches attached to the drum of the lifting mechanism, single (simple) and double chain hoists can be distinguished. In single pulley hoists, when winding or winding up a flexible element due to its movement along the axis of the drum, an undesirable change in the load on the drum supports is created. Also, if there are no free blocks in the system (the rope from the hook suspension block directly passes to the drum), the load moves not only in the vertical, but also in the horizontal plane.

Figure 3. Single and double pulleys

To ensure strictly vertical lifting of the load, double pulleys (consisting of two single ones) are used; in this case, both ends of the rope are fixed to the drum. To ensure the normal position of the hook suspension in case of uneven stretching of the flexible element of both pulleys, a balancer or equalizing blocks are used.

Figure 4. Methods to ensure vertical lifting of the load

High-speed pulleys differ from power pulleys in that in them the working force, usually developed by a hydraulic or pneumatic cylinder, is applied to a movable cage, and the load is suspended from the free end of a rope or chain. The gain in speed when using such a pulley is obtained as a result of increasing the height of the load.

When using pulleys, it should be taken into account that the elements used in the system are not absolutely flexible bodies, but have a certain rigidity, so the oncoming branch does not immediately fall into the stream of the block, and the running branch does not straighten out immediately. This is most noticeable when using steel ropes.

Question: why do construction cranes have a hook that carries the load, not attached to the end of the cable, but to the holder of the moving block?

Answer: to ensure vertical lifting of the load.

referencenick.ru

How to make a lift with your own hands

In construction, during installation work, it is not always possible to fit a crane. Then the question arises of how to lift the load with a rope. And here a simple chain hoist finds its application. To make it and fully operate, you need to make calculations, drawings, and choose the right rope and blocks.

Preparation of the base - diagram and drawing

Before you start building a chain hoist with your own hands, you need to carefully study the drawings and choose a suitable scheme for yourself. You should rely on how it will be more convenient for you to place the structure, what blocks and cable are available.

It happens that the lifting capacity of the pulley blocks is not enough, and there is no time or opportunity to build a complex multiple lifting mechanism. Then double chain hoists are used, which are a combination of two single ones. This device can also lift the load so that it moves strictly vertically, without distortions.

How to choose a rope and block

The most important role in building a chain hoist with your own hands is played by the rope

It is important that it does not stretch. Such ropes are called static

Stretching and deformation of a flexible connection causes serious losses in work efficiency. For a homemade mechanism, a synthetic cable is suitable; the thickness depends on the weight of the load.

The material and quality of the blocks are indicators that will provide homemade lifting devices with the calculated load capacity. Depending on the bearings that are installed in the block, its efficiency changes and this is already taken into account in the calculations.

But how can you lift a load to a height with your own hands and not drop it? To protect the load from possible reverse movement, you can install a special locking block that allows the rope to move only in one direction - the desired direction.

Step-by-step instructions for lifting a load through a block

When the rope and blocks are ready, the diagram has been selected, and the calculations have been made, you can begin assembly. For a simple double pulley you will need:

- roller – 2 pcs.;

- bearings;

- bushing – 2 pcs.;

- clip for block – 2 pcs.;

- rope;

- hook for hanging cargo;

- slings - if they are needed for installation.

Step-by-step lifting of the load to a height is carried out as follows:

- Connect the rollers, bushing and bearings. They combine all this into a clip. Get a block.

- The rope is launched into the first block;

- The clip with this block is rigidly attached to a fixed support (reinforced concrete beam, pillar, wall, specially mounted extension, etc.);

- The end of the rope is then passed through the second block (movable).

- A hook is attached to the clip.

- The free end of the rope is fixed.

- They sling the lifted load and connect it to the chain hoist.

The homemade lifting mechanism is ready to use and will provide double the strength benefits. Now, to raise the load to a height, just pull the end of the rope. By bending around both rollers, the rope will lift the load without much effort.

Is it possible to combine a chain hoist and a winch?

If you attach an electric winch to the homemade mechanism that you build according to these instructions, you will get a real do-it-yourself crane. Now you don’t have to strain at all to lift the load; the winch will do everything for you.

Even a manual winch will make lifting the load more comfortable - you don’t need to rub your hands on the rope and worry about the rope slipping out of your hands. In any case, turning the winch handle is much easier.

In principle, even outside a construction site, the ability to build a basic pulley system for a winch in field conditions with a minimum of tools and materials is a very useful skill. It will be especially appreciated by motorists who are lucky enough to get their car stuck somewhere in an impassable place. A hastily made pulley will significantly increase the performance of the winch.

It is difficult to overestimate the importance of pulley hoists in the development of modern construction and mechanical engineering. Everyone should understand the principle of operation and visually imagine its design. Now you are not afraid of situations when you need to lift a load, but there is no special equipment. A few pulleys, a rope and ingenuity will allow you to do this without using a crane.

Pulley hoist. Purpose and device, types, diagram.

The crane drive has its limits. Or rather, the cost of the engine is growing much faster than the weight of the load it can lift. Of course, nothing prevents you from installing a very expensive engine, but there is a better way - using a chain hoist.

In fact, it was with the chain hoist that the development of hydraulic and mechanical engineering as complex mechanisms began. In its design, the pulley uses more ancient inventions, such as a block and a flexible joint. They did not immediately begin to use a rope instead of a lever.

Later, the chain hoist began to be used everywhere. Not a single sailing ship can do without such simple but irreplaceable rigging. Of course, the modern design of the pulley has changed greatly, but the essence remains the same.

What to cling to (not to cling to) the winch

Most often you have to climb just behind the tree. Of course, stones and stumps, lying logs and artificial structures can serve well as anchors for the winch...

The best trees are birch and pine. It’s bad to winch for Christmas trees - their root system is weak for a winch and even trees twenty centimeters in diameter can be uprooted!

On stumps and stones you need to hang a bare cable (without bark protection) with a noose - it will hook more securely and will not jump off.

It is strictly forbidden to use power line supports for climbing. Both wooden and concrete pillars fall easily! In addition to the fact that the pole will severely damage the car, you can get an electric shock and problems with law enforcement agencies will arise: the power line is a strategic object!

In principle, you can reach for concrete foundations of large supports or iron structures and pillars... but I didn’t tell you that

Chain hoist diagram

Here is the simplest diagram of a chain hoist.

Circles are blocks. A large drive circle, or rather a drum, of a load-lifting crane. The end of the cable is not fixed to the crane hook, but to a surface that is stationary relative to the crane. Such a surface can be a crane boom or, if we talk about tower cranes, a carriage. The lower block is not fixed to the crane in any way and is movable relative to it. These are the two simplest schemes for constructing a chain hoist.

What loads arise in this case?

Calculation of the chain hoist

It would be more correct to ask how the load on the engine and on the rope itself will change. In our case, it will decrease by half. Of course, you can cite formulas and school examples known since the time of Archimedes, but you can take my word for it. But this is a relatively simple example. I will tell you how to calculate a more complex chain hoist in another article. Now let’s look at what types of chain hoists there are.

Screw

Screw . If we take an inclined plane and wrap it around a cylinder, we get a screw - a mechanism that is used to lower something, raise it, or usually just to hold two bodies together.

A typical jar or bottle cap is a prime example of a screw. But screwing in even a small screw is a time-consuming task, since screw mechanisms significantly increase the distance of application of force. To compare, you can take two screws and a piece of foam rubber: press one screw into it, screw the other into it. Now try to press the screw into the wall...

Design and types of pulleys

To begin with, it is worth noting that all chain hoists are divided into two types:

- power chain hoist

- high-speed chain hoist

Of course, as practitioners, we are more interested in the power pulley, but it’s worth understanding the structure of another type of pulley.

In the example above, the device of a power pulley is presented. In it, the effort is halved, but there is also a significant drawback. Look carefully at the drawing. The speed of change in the position of the load will be two times lower than the speed of “winding” the cable onto the motor reel.

The high-speed pulley is the opposite picture. Just imagine that the engine and hook are swapped. The speed relative to the basic blockless version will double. But the effort required to lift the load will also increase.

Multiplicity of chain hoist

Let's complicate the scheme. No one is stopping us from using not two blocks, but three, four or more.

The figure shows a double chain hoist. The load on the engine is reduced by approximately four times. “Approximately” because we lose part of the effort due to friction between the rope and the block. The unit efficiency is usually 0.97.

The multiplicity of the pulley is precisely the ratio of the forces of the cable on the drum and near the load. In the example above, the multiplicity of the pulley is four.

Purpose and use of the chain hoist

In modern construction, pulley blocks are used very widely. The crane hooks of a complex design with jaws are immediately designed for them.

The pulley design can be blocked if it is not necessary. The use of a chain hoist as an independent hydraulic lifting mechanism is limited by only one factor - the lack of a brake, which is vital in lifting machines.

Many specialized companies sell chain hoists. Before buying a chain hoist, make sure that the selected characteristics are correct for your needs and if in doubt, contact a professional.

Topic: Cranes

How rope affects work efficiency

You can avoid pinching and twisting of the rope if you use additional devices, for example, mounting plates, which allow you to space the rollers relative to each other. We categorically do not recommend using stretchable ropes in pulley hoists, since in comparison with conventional static products they seriously lose in efficiency. When assembling a block for lifting loads, specialists use both load and separate ropes, which are attached to the object independently of the lifting device.

There is some advantage to using separate ropes. The idea is that a separate rope provides the ability to pre-assemble or pre-assemble the entire structure. In addition, the passage of knots can be significantly facilitated, since the entire length of the rope is used. The only drawback is the inability to secure the load automatically. Cargo ropes can boast of just this feature, so if there is a need to automatically secure a load, use a cargo rope.

The reverse motion is of great importance. This effect is inevitable, since at the moment of removal, as well as when intercepting the rope or stopping to rest, the load certainly moves in the opposite direction. How much the load goes back depends on the quality of the blocks used, as well as the entire device as a whole. This phenomenon can be prevented by purchasing special rollers that allow the rope to pass only in one direction.

Let's talk a little about how to properly attach a cargo rope to a lifting mechanism. Not always, even the most prudent master has a rope of the required length, which is required to attach the dynamic part of the block. Therefore, several methods of attaching the mechanism have been developed:

Using grasping knots. These knots are tied in five turns from cords, the cross-section of which does not exceed 8 mm. The use of such nodes is the most effective and, accordingly, widespread. According to experts, the units are very durable and reliable. Only a load over 13 kN can cause such a unit to slip

The important thing is that even when sliding, the knot does not deform the rope in any way, leaving it safe and sound. Application of general purpose clamps. These devices can be used even in difficult climatic conditions, for example, on wet or icy ropes

A load of 7 kN can cause the clamp to slip, which leads to damage to the rope, although not very severe. Personal clips. They are used only for small jobs, since a load over 4 kN leads to the clamp slipping and subsequent rope breakage.

Wedge

Klin . If you imagine two inclined planes converging at one point, you get what is called a wedge.

It helps hold objects in place, but more importantly, crack apart bodies or separate parts from them.

Knives, swords, axes and other cutting objects are classified as wedges according to the mechanics of their action. By the way, the airplane body also has them: airplane wedges help cut through the air as it moves, just like a kitchen knife cuts through a fresh cucumber.

Gearbox selection

The next problem is the choice of gearbox. Any 220 V electric winch with your own hands must contain a mechanism that will transmit rotation with a large traction force. There are the following types of gearboxes:

- Worm drives transmit rotation at an angle of 90 degrees and do not require braking devices, as they have good self-braking properties.

- They are not used for winches due to the complexity of the perpendicular arrangement of the main drive and secondary shafts.

- Cylindrical, are one or more pairs of gears in one plane, meshed. Rotation is transferred from the smaller wheel to the larger one. They have high reliability, but less tractive effort. Convenient for use when constructing homemade winches.

Planetary gearbox, the most common at the moment. It usually consists of 3 satellites, a sun gear, a ring gear and a carrier. They have an increased working life and transmitted power, but are complex in design.

The simplest solution when manufacturing a unit, an electric winch for 220 V, of course, you can always use a converter, especially since ready-made high-power devices are available for sale. An asynchronous motor can be used as a drive motor, but it is better to use a motor from a washing machine. Modern models are quite powerful and productive.

Kinematics of the Maltese mechanism

Before carrying out calculations, attention should be paid to the kinematic features of the device. A triangle with several vertices is used as a basis, as well as a lantern, which is formed when entering and exiting the groove

Using kinematics, the following calculations can be made:

Find the angles of rotation in the first and second phases. The angles and sides of a triangle are also considered important information. Angular velocity and angular acceleration.

When analyzing the rotation of the disk, attention is paid to the theorem of addition of velocities and acceleration of the center of the lantern when rotating at a uniform speed. The calculation algorithm involves the use of special tables

The principle of operation of the chain hoist

In essence, a chain hoist is a system of levers, the role of which is played by parts of the rope located between the blocks. As you know, the law of leverage states that while you gain in strength, you lose in distance, and therefore in speed, and vice versa. This means that to move a load 1 meter using a double-winning mechanism, you will have to choose 2 meters of rope, that is, spend 2 times more time. The applied force will be 2 times less than the mass of the load, however, the amount of energy expended will not change.

In the same way, the gain in distance is calculated if the attachment points of the pulley and the load are swapped.

Replacement Precautions

Replacing the valve on a gas cylinder must be carried out in compliance with certain safety measures, including the following:

Replacing the gas cylinder valve

- Remove any remaining gas from the vessel. It is permissible to release gas only in an open space. An exception can be made only for nitrogen, oxygen and a number of others.

- The workplace where work will be performed must be well ventilated.

- The flywheel must be unscrewed smoothly and at low speed.

- The valve can be replaced only after equalizing the pressure outside and in the cylinder.

When installing the valve in its original place in the cylinder, it is necessary to use fum tape and other types of sealants that ensure a reliable connection. It should be noted that seals of any type can create certain difficulties when removing the valve. To make this task easier, it is permissible to use a hair dryer.

It is permissible to heat the fittings installed on the cylinder only after emptying the contents of the container.

How do blocks work?

The block consists of one or more wheels (rollers) encircled by a chain, belt or cable. Just like a lever, a pulley reduces the force required to lift a load, but it can also change the direction of the force applied.

The gain in strength comes at the cost of distance: the less effort required to lift a load, the longer the distance that the point of application of this effort must travel. The pulley system increases the strength gain by using more load-carrying chains. Such power-saving devices have a very wide range of applications - from moving massive steel beams to the height of construction sites to raising flags.

As with other simple mechanisms, the inventors of the block are unknown. Although blocks may have existed before, the first mention of them in literature dates back to the fifth century BC and relates to the use of blocks by the ancient Greeks on ships and in theaters.

Moving pulley systems mounted on a suspended rail (picture above) are widely used on assembly lines because they greatly facilitate the movement of heavy parts. The applied force (F) is equal to the weight of the load (W) divided by the number of chains used to support it (n).

Single fixed blocks

This simplest type of pulley does not reduce the force required to lift the load, but it does change the direction of the force applied, as shown in the figures above and above right. A fixed block on the top of the flagpole makes it easier to lift the flag by allowing the cord to which the flag is attached to be pulled down.

Single moving blocks

The single pulley, which can be moved, reduces the force required to lift the load by half. However, halving the applied force means that the point of application must travel twice as far. In this case, the force is equal to half the weight (F=1/2W).

Block systems

When using a combination of a fixed block and a moving one, the applied force is a multiple of the total number of load-carrying chains. In this case, the force is equal to half the weight (F=1/2W).

A weight suspended vertically through the block allows horizontal electrical wires to be pulled taut.

The overhead lift (picture above) consists of a chain wrapped around one movable and two fixed blocks. Lifting a load requires a force that is only half of its weight.

A pulley, commonly used in large cranes (picture at right), consists of a set of moving pulleys from which a load is suspended, and a set of fixed pulleys attached to the crane's boom. By gaining strength from so many blocks, the crane can lift very heavy loads, such as steel beams. In this case, the force (F) is equal to the quotient of the weight of the load (W) divided by the number of supporting cables (n).

information-technology.ru

This is interesting: why do they say “they knock out a wedge with a wedge”?

The etymology of the phraseological unit is closely related to how massive logs were split in the old days.

A wedge alone could not cope with such a task: driven all the way, it only partially split the log.

You can’t get the wedge back, you can’t chop the wood. Therefore, next to the hammered wedge, they drove another one next to it - so that the second one would go deeper and knock out the first one. And so on, and so on, until the wooden block splits in half.

So it turns out that wedges are knocked out with wedges in the literal sense - one wedge is knocked out and the second. And where did the common speech error “knock it out with a wedge ” ?

Powerful block without DIY turning work

Hello, Today, with my own hands - a powerful block without the use of turning.

It was necessary to change the design of the suspension in greenhouses, where I used a block system to tension the 3 mm cable while bending it at 90°, so several blocks were needed.

Surely there are others, but for sale I found only one like the one in the photo, which didn’t quite inspire confidence in me, looks beautiful, but is completely unsatisfactory in terms of functionality, namely reliability, plus the price (8 pieces were needed).

I had to make my own version, and without the use of turning work, which I present to your attention.

The block described in this publication is designed for a cable Ø 3 - 4 mm and for the radius of its bend that I need, but using the same principle it is possible to make a block for a different cable diameter and maximum load, which will depend only on the choice of the rigging eyelet.

Of course, it is not designed for high rotation speeds, but for work in conditions where this is not required, it is quite suitable, the main thing is its power, and therefore reliability.

And if you make a pulley on a lathe, then the block will meet absolutely all the requirements necessary for it.

Components for making the block:

Earring (bracket) rigging 5 mm - 1 pc. The Omega type configuration is better, but I only found a straight one of this size.

Reinforced washer M8 - 2 pcs.

M8 washer - 2 pcs. Attention! They should be the same, given that the washers come in different diameters and thicknesses. I selected washers with a total thickness of 4 mm, which is what I needed

I selected washers with a total thickness of 4 mm, which is what I needed.

Screw M8 × 25 — 1 pc. Attention! For convenience, when drilling an axial hole, it is advisable to choose the screw shown in the photo. Through nut M8 - 1 pc.

Through nut M8 - 1 pc.

Manufacturing:

Making several blocks at once takes very little time if you perform each individual operation for all the workpieces at once.

Assemble the prepared components together.

To do this, hold the screw head in a vice and tighten the nut tightly.

Clamp the workpiece with the threaded part in the drill chuck using a Ø 4.8 mm drill. make an axial hole.

Using a grinder and a cutting wheel 1 mm thick, cut off the screw head and nut to a thickness of 1.5 ÷ 2 mm from the plane of the outer washers.

Attention! This option for manufacturing a block provides for the possibility of not using a welding machine, but it would be better if, before or after cutting, electric welding (two or three points) is used to attach the screw head and nut to the outermost wide washers. Using a suitable tool, with a diameter slightly larger than the thickness of the manufactured pulley, slightly spread the “horns” of the earring (I used a Ø 12 mm drill as a tool)

Using a suitable tool, with a diameter slightly larger than the thickness of the manufactured pulley, slightly spread the “horns” of the earring (I used a Ø 12 mm drill as a tool).

Using light blows of a hammer, with the device inserted, bring the “horns” of the earring together to the desired size, thus fitting the rigging bracket to the manufactured pulley.

Place the pulley in place.

Attention! Everything is manufactured without turning, so adjustments are indispensable for free rotation of the pulley. Powerful block for cable 3 ÷ 4 mm, made without turning, ready

A powerful block for a cable 3 ÷ 4 mm, made without turning, is ready.

That's all. Good luck!

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

We make a chain hoist from paper cups and gears

The devices used in construction are very complex, which is logical, because it requires lifting large loads to a fairly large height. Understanding their design features can be very problematic. The same cannot be said about household chain hoists that are used in everyday life. They are so simple and understandable that anyone can build a chain hoist with their own hands. For this we need the following devices:

- several paper glasses;

- scissors;

- lace or strong thread acting as a rope;

- plasticine;

- plastic hangers.

First of all, you will need to make a basket in which the cargo will move. For these purposes we will use paper cups through which we thread a rope. We assemble the chain hoist from hangers. We fix the rope or thread on the top of the hanger, and then wind it around the crossbar several times. The basket obtained from the glasses should be hung on the lower hanger by the hook. In principle, at this point the collection of the chain hoist can be considered complete. To lift loads, you just need to use the mechanism correctly. To do this, you will need to pull the free end of the thread, which will lead to the connection of the hangers. Now you can try to lift heavy objects to a height.

There is another way to make a chain hoist with your own hands, which is somewhat more complicated, but is more efficient and reliable in design. Here we need bearings, a gear, a hook, cables with blocks, and a threaded rod. First, we attach the bearings to the stud, after which we install the gear on the end of the stud to make it more convenient and easier to use a homemade pulley. All that remains is to throw the cable over the gears and secure it; the free end will be equipped with a hook, which is necessary for lifting objects.

Finally, let us remind you that when working with any chain hoists, purchased in a store or made at home, you should definitely remember safety precautions. It is necessary to carefully check the structure for strength and integrity

The loads themselves should be lifted smoothly and carefully, without being located under a suspended object at this time

Carrying out calculations

In order to make a crane beam in the garage with your own hands, you need to calculate the dimensions of the structure and the grade of rolled metal according to the load capacity. Such calculations are performed using special online calculators, which allow you to select the necessary materials with sufficient accuracy for handicraft production. These calculators require you to enter the dimensions of the structure and the maximum allowable weight that is expected to be lifted and moved. Then you need to make a working drawing and you can start working.

It is best to make the working beam of the mechanism from equal-flange I-roll, because when using welded corners it is very difficult to achieve uniformity of the rolling surface. Uneven rolling surfaces will lead to underloading of some bearings and overloading of others. The working beam slide can be made from a section of channel, the length of which will be equal to the width of the I-beam flange of the working beam. The size should allow it to slide freely along the span beam supports.

Here the bolts are used as racks for fastening the support bearings.