How to unscrew a broken bolt using a drill with a left-hand spiral

In two stages:

- First you need to take a regular nozzle and center it.

- Then arm yourself with the one that rotates counterclockwise (let it be a little larger in diameter) and, using it, gradually remove the body.

You should be careful and control the direction of movement - then the edges of the working rod will catch the remaining hardware, pushing them upward, but without destroying the thread. If any damage occurs, it will be so minor that you can easily fix it with a tap. This method is effective when the fastening joint is not yet very rusty or stuck.

Types of breakdowns

There are three cases. Let's look at the simplest ones first.

If the bolt is broken but part of it is sticking out of the threaded hole, you're in luck! In this case, the broken bolt can be easily unscrewed in two simple ways.

- If the protruding part of the hardware is large, clamp it with pliers or an adjustable wrench. There shouldn't be any problems with unscrewing the bolt.

- If a piece of hardware cannot be clamped due to its small size, proceed this way.

- Make a cut along the diameter of the protruding part using a grinder.

- Unscrew the broken bolt with a screwdriver.

Most often, bolts break flush with the surfaces or, even worse, at the depth of the holes.

Unscrewing a broken bolt using another

This method is suitable if the diameter of the residues is relatively large.

Because you will have to drill a smaller threaded hole in the body, into which you will then install a fastener with a left notch and begin to tighten it, going deeper and deeper - it will push out the previously destroyed part. The only downside is that a drill is required to complete the task, but it is not always at hand, and you will have to spend one new hardware. Therefore, it makes sense to consider solutions that are easier to implement and universal in everyday life, and put this aside in reserve for the case when there is no other option.

Flush break

This type of failure is considered the most difficult to repair, since it is very difficult to determine the diameter of the hole, especially when cutting fasteners. Therefore, in order to drill out a broken bolt of a certain type, it is necessary to clean the surface. This will allow us to determine the gaps we need.

The following unpleasant situation often occurs: the breakage site has curved shapes that are very difficult to process and straighten. And it is categorically not recommended to drill a product in such a state, because there is a risk of completely ruining the structure. Therefore, you first need to use a core, which is used to prepare a place in the center of the drill.

The further procedure for drilling out a bolt that has broken in one way or another is similar to the option for a surface break. After creating the hole, the remaining threads are removed using a hook.

How to pull it out, drill it out and how to unscrew a broken bolt from a thread: the best methods

The choice of a specific method depends on the situation, but in practice, the fastening element we are considering most often turns out to be simply licked off (due to poor quality of workmanship). You can remove it without damaging the thread: to do this, just carefully sharpen the head so that its shape matches the size of the key. Well, if you want to minimize risks, you should additionally saturate the joint with lubricant - it will reduce the resistance to pulling.

Now let's pay attention to what to arm yourself with in the event of some kind of damage - due to rust, excessive pressure or for other reasons.

Flat head screwdriver and hammer

This is how to unscrew a broken bolt when the break occurs above the thread surface and the edge of the resulting surface is uneven. Here you need:

- Clean the contact area, examine it carefully and find the largest protrusion.

- Place the tool at the selected point, placing it at an angle; It is quite acceptable to deepen the uneven area with a core so that you can rest even more reliably.

- Try to turn the hardware using light blows; If it doesn’t work, increase the force of influence a little at a time until it works.

Of course, this method should be implemented with extreme caution so as not to accidentally damage adjacent elements or make the hole too deep.

Unscrew with a chisel

Another option for unscrewing is to drill out a broken bolt and remove the broken piece from a hole in a hard-to-reach place. It is carried out using the same technology as the previous one: they cleared the place, found a point of emphasis, and began to turn. Moreover, the remainder should be unscrewed quite easily and quickly, because the contact area of the tool in this case is larger than in the past.

Excellent for removing hardware with the top flying off.

Core and hammer

A suitable choice when the head has been torn off or if a defect is discovered at the very beginning of the thread, and there is no screwdriver at hand. Look, the tip of the marking tool is sharp and therefore excellent for deforming the cut. A few light blows, and the surface is no longer flat; you can grab onto it with pliers and pull out the stuck body.

Weld the nut by welding

Let's imagine that the head of a bolt is broken: how to unscrew the remaining part?

An original but effective solution is to attach something to it that you can pull on. A hollow fastener with a similar thread is an ideal option, but how to fix it? Using heat treatment with plastic deformation! To solve this, in addition to the element already mentioned, you need to take more wire cutters, and also connect a welding machine and:

- Take the nut with a holder and lean it against the fragment with a slight offset.

- Connect the body to the part using an arc.

Now it will not be difficult to remove the failed hardware and replace it.

Also, as an alternative, you can weld the pin - at an angle, and small. It will perfectly serve as a lever that can be pulled to remove the body.

When deciding how to remove and unscrew the remains of a bolt if it has broken off, many people prefer welding - because it has at least 3 advantages:

- You can start unscrewing almost without delay, since the same nut heats up strongly and quickly; and this does not harm the body of the part, because it continues to remain cold. Also, due to thermal expansion, decoking of the stuck contact is observed.

- Using this method, it will not be difficult to remove even fragments of hardened hardware made of high-strength steel, drilling which is very time-consuming, difficult and impractical.

- A strong seam is created between the body and the lever (consumable), which allows you to pull out the worn element with pliers even with force.

Welding is also a convenient answer to the question of how to remove a broken bolt from a thread, because it allows you to unscrew any remaining hardware - protruding from the body, running flush, and even deeply recessed. In the first and second cases, you can attach a washer with a nut or a lever and pull, in the third - insert a metal tube and build it up - there are options, and each of them is quite simple to implement.

Unscrew the pin using an extractor

This is a specialized tool, and it is effective where available tools fail.

Previously, it was wedge-shaped (a cone with special edges) or rod-shaped, and both of these options were driven into holes. Its screw model, with a cut spiral, has also gained popularity. Today it is a whole set of devices, which includes bushings, drills and metal strips. So, you have a kink in the bolt, how to unscrew it using this device:

- Fill the contact area with lubricant or, if the connection is old and stuck, with a rust solvent.

- Make a hole (the same diameter as the damaged fastener), using one of the supplied tubes as a guide.

- Drive the rod to the wedging depth.

- Remove the tool element along with the remains of the body using a wrench.

After this, you just need to place the worn hardware on a hard surface and lightly hit it several times to loosen the contact force and remove it from the working part of the tool.

The method of how to unscrew a crimp with an extractor may differ slightly depending on where exactly the fastener managed to break off:

- Above/below the engine housing (or other functional unit) - you need to install a guide, drill a hole, hammer a rod into it, and remove the damaged element.

- Flush with the surface - you should also use a punch for centering; and when you mark the point for the location of the sleeve, all that remains is to repeat the above operations.

Universal sets are good because they can be used to remove not only hardware, but also screws and even thin studs. They are quite affordable in price, and when purchasing, it is better to give preference to extractors made of hardened or chrome vanadium steel - they are stronger.

How to properly drill out a broken bolt body in a hard-to-reach place

This is one of the most labor-intensive ways to remove a broken bolt from a thread, and it is worth using it in practice only when there are no other options. And not only because it takes time, it is important to maintain the accuracy of the work. The slightest mistake and the internal coils of the case will be damaged. In addition, to implement the method you will need a whole set of tools:

- Metal drill with a set of attachments.

- Screwdrivers with different blades.

- Triangular file

- Reliable pliers or, better yet, a wrench.

- Tap.

- Several needle files of various shapes and sizes.

WD-40 will also be useful: we remind you that it is worth pouring it into the work area 15 minutes before performing operations, it will dissolve some of the rust.

So, the bolt has broken off, how to unscrew the broken part from the thread using drilling:

- Put on the thinnest attachment, turn on the drill and make a recess exactly in the center of the hardware; try not to go aside, this is fraught with subsequent difficulties.

- Change drills, gradually increasing their cross-section, until the hole occupies 1/3 of the diameter of the body.

- Drive the file in, carefully but firmly, because if it does not hold well, you will not be able to remove the damaged element.

- Take pliers or a gas wrench, clamp the trihedron with them and begin to make circular movements, trying to pull out the fasteners.

It should work, but how to unscrew and remove the broken part, how to unscrew a broken bolt if it does not give in even after all these steps? It is necessary to widen the hole so that another hardware fits into it, but smaller and with the opposite thread (usually the left one). In this case, the second one will act as a cap after it is screwed into the first one.

If this doesn’t work, just continue to increase the diameter and length of the recess until the pressure on the remaining fastening element weakens, then they will begin to wobble and it will not be difficult to remove them using a suitable tap.

We remind you that this is a solution for extreme cases; in general, there are simpler, faster, more convenient options.

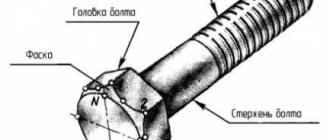

Reasons for tearing off edges

The desire to quickly replace failed parts secured with a threaded connection is not always feasible. Sometimes, when trying to unscrew a bolt from the unit body, the key begins to spin. This is due to the tearing of the edges on the head of the hardware when exposed to increased load. And the reason for this may be the following factors:

- sticking, which is caused by the diffusion of atoms during a long connection;

- displacement of the parts being connected relative to the axis of the holes, which leads to jamming of the screw;

- tugging during installation (increased load);

- using the wrong tool during assembly (for example, to tighten a bolt whose head size is 14 mm, a 17 mm wrench is used, and a screwdriver is inserted to eliminate the gap);

- corrosion that has eaten away the surface of the head.

How to remove a bolt if it is broken and nothing helps or the thread is already badly damaged

In such a difficult situation, you should drill a hole so that its width is sufficient for cutting new turns. Although the hardware may be hardened and difficult to give in. Then it must be subjected to heat - heated red-hot - and then left to cool. It is strictly forbidden to forcibly cool it with water - too sharp a temperature rise will only lead to the appearance of cracks.

The operation of slowly changing the temperature regime must be carried out several times. Due to this, the metal will be tempered and slightly softened, and the damaged element will become easier to drill out. But if the body of the part (unit, functional unit) is made of aluminum, special care should be taken to ensure that the surface in the heating zone does not warp.

> Buy as a gift or order a unique item

- More about the author

- 15 recent entries

About alexlevchenko

- ATTENTION! Need Brain Help! – 08.11.2017

- Ideal for a Halloween party – 10/31/2017

- Limited Edition: Black Lemonade – 10/31/2017

- Isaac Clarke's budget helmet from the Dead Space universe – 10/29/2017

- Dinner Party at Bruce Wayne's Estate – 10/28/2017

- Who is hiding behind the carnival mask? – 10/27/2017

- A smile makes a gloomy day brighter... – 10/26/2017

- How to overcome fear of strangers? – 10/25/2017

- Get the most out of your drilling machine – 10/24/2017

- Becoming a knight is absolutely easy! – 10/23/2017

- A fantastic story about the crown of the elf queen – 10/21/2017

- 45 profitable ideas for home production business part 2 – 10/19/2017

- 10 professional woodworking tricks – 10/18/2017

- Homemade products for Halloween (MozgoChins 2017) – 10.17.2017

- 45 profitable ideas for a home production business part 1 – 10/17/2017

The cap has come off, the hardware protrudes above the surface

This problem is the easiest to solve. There are several options for this. To begin with, we again generously treat the bolt and its connection points with the part with diesel fuel or a special compound. Next, we try to pick up the bolt with wire cutters or a gas wrench (it has greater clamping force).

Of course, the situation is unpleasant, but not fatal, everything can be solved PHOTO: drive2.ru

Another good method will require a hacksaw or hand engraver. Using the tool, you need to make a notch across the circumference of the piece of hardware, and then try to unscrew it using a powerful slotted screwdriver. A percussion instrument is well suited for such purposes. But in this case, you should not make a deep cut. If you hit the back of the screwdriver, the bolt may simply break. If you cannot unscrew the hardware, you need to move on to more radical measures.

You can file a broken bolt, and then try to unscrew it using a screwdriver PHOTO: drive2.ru

Many experts recommend a method using a welding machine. To perform it, you will need a piece of steel bar (you can use reinforcement, but the strip is more reliable). In it, in the middle, a hole is drilled, with a diameter slightly larger than the bolt. The tire is placed on the part so that the hardware fits into the hole, after which the elements are welded together. This method allows you not only to weld the lever to the broken bolt, but also to heat up the hardware, as a result of which various dirt burns out, and the corrosive coating ceases to “hold” the thread so tightly. After complete cooling, all that remains is to turn the welded lever counterclockwise and remove the broken hardware, replacing it with a new one.

Welding can be used to unscrew a broken bolt.

4 Replies to “5 ways to remove a screw with a broken slot with your own hands”

Of all the ones presented, the extractor is the most universal; it is ideal for metal. It's always easier with wood.

Quite clear and intelligible for wooden structures. Rubber bands and extractors can additionally be used on plastic materials. But what to do if the threads on the bike bolts are broken? For example, a hex anchor on the steering wheel?

Bgg, my handlebars came off, right on the stem mount. I thought for a long time about cutting a new thread or welding a nut or two, but then I realized that if the metal is bad to begin with, then all this is bullshit against the backdrop of the possible consequences in case of loss of control right on the road in traffic. So I stupidly bought a new stem for 500 rubles, made of good metal.

knock knock-turn, knock knock-turn)

Add a comment Cancel reply

Simple option

The first thing to do is not to panic. At all. A broken bolt can almost always be removed, the main thing is to do it correctly.

Secondly, inspect the “scene of the incident.” If it breaks when unscrewing it, fill it with WD40, brilliant green or brake fluid - it is required that the broken piece is slid along the threads. You can try to anneal the threads with a blowtorch - you need to look at the circumstances. Let's see where it broke. When a broken piece sticks out above the part, you are very lucky - you can try to unscrew it. If this is possible, screw on two nuts, fixing the lower one with the upper one. We unscrew it by the bottom nut - if the broken bolt left the thread intact, it should come out. There is not enough space for two nuts - we try to unscrew them by the thread with pliers. Another way is to make a slot in the middle with a grinder. As a result, we get a screw that you can try to unscrew with a screwdriver. If it works, the problem is solved. But more often the bolt breaks either flush with the part or inside it.

Removing a Broken Bolt

If it is broken at the part level, try unscrewing it with your finger. In fact, when a broken bolt is inside the hole along the thread, it is clean, and the screw simply broke due to metal fatigue or because it was pulled earlier - it can simply come from a finger. Or we pay attention to the chip - when a piece breaks off, a edge always forms on the fracture plane - we substitute a chisel, a screwdriver - we try to unscrew it with light blows.

Such cases often occur when a non-threaded part is attached with a pin or bolt - for example, a manifold to a cylinder block.