It is probably no secret to anyone that such an irreplaceable, multifunctional and universal device as a chainsaw is an integral part of the life of each of us. This especially applies to that part of our life when we carry out work of any nature in the agricultural field. But it is worth noting that buying a chainsaw model you like, and one that would fully meet your wishes and preferences, is, as they say, only part of the story. It is equally important to create conditions for this tool under which it would have the opportunity to serve you for more than one year, delighting you with its work and productivity. Therefore, like any equipment, a chainsaw needs care for its body , the main parts, and what can I say, even the smallest additions to the tool need repair or replacement. Therefore, this article will be dedicated specifically to the issue that will concern the processing and running of this device. Here you can find out why it is so important to carry out this kind of manipulation with the device and, in general, how it should be done correctly. But initially you need to decide on the model, and our rating of the best chainsaws will help you with this. So, let's begin to consider this topic.

Launch of a new chainsaw

The first launch of a new or repaired saw should be approached with the greatest responsibility, while at the same time observing the precise instructions in this step-by-step instructions. First, you need to prepare fuel. For chainsaws, and specifically for their two-stroke internal combustion engine, a special mixture consisting of gasoline and oil is prepared. The octane number of the fuel should not exceed 90; in exceptional cases, this value can be increased - this recommendation is described in the annotation for a particular saw model. With all this, the use of gasoline that has been stored for more than 2 months is prohibited, because with prolonged storage, natural prerequisites for tar formation may begin, which will inevitably lead to contamination of the combustion chamber with carbon deposits characteristic of this. The proportion is also regulated by the manufacturer and on average is about 1:40 or 1:50. This means that for 1 liter of gasoline you need to add about 0.20–0.30 grams of oil. Having prepared the fuel in this way, we fill the tank.

If the engine is after repair, it is also recommended to check and clean the special channels on the working tire of the chainsaw being started and additionally lubricate the driven sprocket.

The engine start itself is carried out as follows.

- Set the chain brake to the locked (non-operating) position. This is done by retracting the brake lever.

- Close the air supply damper.

- Turn on the ignition.

- If the chainsaw has a decompression valve, then it must be pressed to facilitate starting.

- After fixing the saw, take the starter handle with your free hand and pull it up until it engages with the drum mechanism, and only then does a sharp, confident jerk of the starter be made. Repeat this procedure a couple of times until the first flash occurs in the combustion chamber, and the saw starts up for a second or two and stalls. Only after that the damper is placed in the initial open position, and a restart is performed, which should be crowned with success.

- When the engine has started, press the handle or the speed increase (throttle) button to full throttle and release it for measured operation at idle.

Running in the saw set.

The saw set of a chainsaw, just like the engine, needs to be broken in

The main point to pay attention to is:

- Chain lubrication;

- Cutting blade tension.

The first step is to “soak” the saw chain in oil. To do this, take a clean container, place the cutting blade in it and fill it with the oil recommended by the manufacturer. Within a few hours, all moving and rubbing components will be completely saturated with lubricant.

At the next step of running in the saw set of the chainsaw, you need to tighten the chain so that it rotates freely by hand, and drive it at idle for 3...5 minutes. After this, the engine is stopped and its tension is checked. The cutting blade is tightened as needed. Test cut small branches without putting any load on the bar. Stop the tool and tighten the chain.

When stopping the engine, allow the chain to cool. And only then do you stretch it.

After running in the chainsaw, you will need to check and adjust the carburetor. It is best to create these manipulations in a service center. After the narrow option, you can use the equipment, observing safety precautions during the cutting process.

Preparing a fuel mixture for a chain saw.

Since the majority of chain saws available to consumers are equipped with two-stroke engines that do not provide separate lubrication of rubbing parts, it is very important to prepare the correct fuel mixture during break-in. It is prepared from gasoline and two-stroke motor oil in a certain proportion recommended by the chainsaw manufacturer.

What gasoline should I use for the fuel mixture?

The basis is gasoline with an octane rating of at least 90. For Russia, Belarus, Kazakhstan and other CIS countries, the optimal fuel option is AI-92. Avoid using questionable fuels, as well as using any additives that increase the octane number. Over time, additives lose their properties, and gasoline becomes of low quality.

Using fuel with a low octane number when running in and operating a chainsaw causes uneven engine operation and knocking. At the same time, there is an increase in engine temperature and an increase in the load on the main bearings. Imaginary savings most often lead to failure of the cylinder-piston group, requiring significant funds to restore it.

When running in a chainsaw, it is not allowed to use gasoline that has been stored for more than 2 months. During long-term storage in fuel, natural processes of polymerization and resin formation begin to occur, which leads to the formation of soot in the combustion chamber.

New chainsaw owners often have a question about what kind of gasoline to pour into the tool tank: leaded or unleaded? Leaded fuel is used to start an engine without a catalyst. If your saw has a catalyst (green gas tank cap), then use unleaded fuel.

What oil should I use in the fuel mixture, and in what proportions?

Two-stroke engine oil is used both for break-in and for continuous operation of the chainsaw. If you don’t want to take risks and experiment, then purchase the lubricant recommended by the tool manufacturers. As a rule, large companies produce fuel and lubricants for them to order. This allows the manufacturer of chain saws and other gas-powered tools to guarantee proper starting and trouble-free operation of their products.

Since branded oils for chainsaws Husqvarna, Stihl, Partner, Oregon, Jonsered are bottled from the same barrel, you can break in the tool with any of the above. In this case, it is very important to take into account the recommendations both in the instructions for oils and the recommendations of chain saw manufacturers. When using branded fuels and lubricants, when preparing the fuel mixture, follow the operating instructions for the gas-powered tool.

| Recommended proportions of fuels and lubricants when preparing fuel | |||

| Break-in chainsaw | Proportion | Gasoline, (liters) | Oil, (liters) |

| Husqvarna up to 1.5 kW | 1:40 | 1 | 0,025 |

| Husqvarna over 1.5 kW | 1:50 | 1 | 0,020 |

| Stihl up to 1.5 kW | 1:40 | 1 | 0,025 |

| Stihl over 1.5 kW | 1:50 | 1 | 0,020 |

| Partner | 1:40 | 1 | 0,025 |

| Partner | 1:33 | 1 | 0,030 |

If branded oils are not available, you can break in a new chainsaw using third-party lubricants of the JASOFB or ISOEGB class. According to the instructions, the ratio of components is taken at the rate of 1:33. At the same time, the tool manufacturer does not recommend using four-stroke motor oils or two-stroke motor oils for water-cooled outboard engines, labeled as TCW.

To run in the Ural and Druzhba chainsaws, the fuel mixture is prepared at a rate of 1:15. That is, for 1 liter of gasoline you will need to add 66 ml of oil. After grinding in all the parts, the proportion is adjusted to 50 ml per 1 liter of fuel.

The fuel mixture for a chainsaw to be run in should be prepared in a clean container intended for storing fuel and lubricants.

- Pour half the required gasoline into the container;

- Add required amount of oil;

- Gently mix the ingredients;

- Pour in the remaining gasoline and stir.

Running in a chainsaw

After purchasing a new tool, every user asks the question: is it necessary to break in a chainsaw, and if so, how to break it in correctly. There are intense debates about this on forums, and you can read a variety of views in specialized publications. Some creators say that without running in, your chainsaw will break the next day, while other experts say that running in will do nothing but harm to your tool.

Let's try to understand more carefully - what running-in is, whether it is necessary, how to carry it out correctly, how long it takes. First, you need to understand that there is a difference between Chinese chainsaws and models from global brands. Companies such as Husqvarna, STIHL , taking care of their own consumers, create piston parts from durable steel using high-precision equipment. This eliminates roughness and bulges on the walls of the piston and cylinder. In addition, modern equipment makes it possible to produce parts with small tolerances, eliminating friction between moving units.

In the production of Chinese nonames, such equipment is not used, and the quality of the metal immediately leaves one wanting the best. These saws need to be run in using a different technology.

Stages of running in gas-powered chain tools.

After successfully starting the chainsaw, it’s time to start running it in. Let's start with the manufacturer's annotation. The procedure itself consists of two main steps, which allow the moving parts of the gasoline tool motor itself and the components of the saw set to become comfortable. Let's analyze all the actions more carefully.

Factory run-in

As we have already noted, well-known manufacturers of chainsaws prepare their products for work specifically at the factory. Preparation for operation consists of running in the piston group using a specially developed method. This process is carried out and monitored during industrial testing of the product.

Also, do not forget that most chainsaws from global brands are equipped with pistons with a shiny coating, which significantly improves their wear resistance. The question arises: should they be run in before use? Most well-known manufacturers consider running in their own chainsaws optional, but they advise running out several tanks of fuel (7 - 9) in a gentle mode, without overloading the chainsaw or overheating the engine.

Recommendations for the initial break-in stage

At the initial step of running in the chainsaw, adhere to the following rules:

- the bar and chain should always be lubricated with special saw lubricant;

- It is forbidden to run the saw completely at idle speed, since when the engine is running, oil must flow to the sawing parts of the chainsaw, but this does not happen in idle mode;

- when the first 5-7 hours have been worked, drain the remaining fuel mixture from the chainsaw and mix the freshest mixture;

- try not to overload the tool during the first 4-5 fuel fills, work in moderate mode, and also refrain from sawing logs larger than 40 cm in diameter.

READ Do-it-yourself carburetor adjustment for Poulan 2150 chainsaw

Carburetor adjustment

STIHL brand chain saw plays one of the leading roles in the design of the model. During its operation, he is responsible for mixing the fuel mixture with air and feeding it into the engine cylinder.

Before adjusting the carburetor, you will need to remove the plastic body of the tool and clean the internal parts of the saw from dust and carbon deposits. There are 3 adjustment screws under the housing cover. The first 2 screws are marked with the letters H and L - they are needed to adjust the proportion of fuel and air, which is determined by the level of opening of the throttle valve.

The screw marked H is required to adjust the maximum engine speed. Screw L is responsible for adjusting the required minimum operating speed of the motor. The third screw, marked S, is needed to fine-tune the operating idle speed of the internal combustion engine of the STIHL MS 180 chainsaw.

Setting up the carburetor of a German brand saw consists of two stages. The first stage is the basic one, or, as it is also called, the factory stage. It can only be done when the engine of the garden tool is turned off. The second stage is the final one. To perform this, a warm engine must be turned on. To know how far to turn the adjustment bolts, you need to read the saw's instructions in advance.

During basic carburetor adjustment with the cold engine turned off, screws H and L must be slowly turned alternately in the direction of the clock hand until it stops. Then each of them needs to be turned 2 full turns in the opposite direction.

The final carburetor adjustment is performed in the following order:

- First you need to start the chainsaw engine and let it run for 5 minutes until it warms up completely;

- Next, you will need to start turning screw H alternately in different directions until the maximum engine speed at idle is found;

- Then the screw marked L must be turned 1/4 turn counterclockwise;

- If after these steps the chain on the bus begins to rotate, then screw S will need to be turned counterclockwise. You only need to finish manipulating the screws S when the saw chain comes to a complete stop;

- Next, you need to set the maximum engine speed using a manual tachometer connected to the engine.

After adjusting the carburetor, you will need to check the operation of the engine. To do this, with the instrument turned on, you must sharply press the gas trigger several times. If, when you quickly press the trigger, the engine sharply gains speed, and when it is released, it loses it, it means that the adjustment of the factory carburetor was performed correctly.

A full run-in of a new chainsaw involves properly setting up the fuel system. Standard factory carburetor adjustment is made on the basis of averaged data, therefore, depending on external factors, it needs to be adjusted.

A saw with an adjusted carburetor should quickly pick up speed, equally stable at operating mode and at idle speed. The proper quality of the air-fuel mixture is also indicated by the brown color of the spark plug insulator.

Sources:

https://proinstrument.com.ua/obkatka-benzopily-i-drugogo-instrumenta-STIHL/ https://vseopilah.ru/cepnye-pily/obkatka-benzopily-shtil/

Running in a chainsaw

After purchasing a new tool, every user asks the question: is it necessary to break in a chainsaw, and if so, how to break it in correctly. There are intense debates about this on forums, and you can read a variety of views in specialized publications. Some creators say that without running in, your chainsaw will break the next day, while other experts say that running in will do nothing but harm to your tool.

Let's try to understand more carefully - what running-in is, whether it is necessary, how to carry it out correctly, how long it takes. First, you need to understand that there is a difference between Chinese chainsaws and models from global brands. Companies such as Husqvarna, STIHL , taking care of their own consumers, create piston parts from durable steel using high-precision equipment. This eliminates roughness and bulges on the walls of the piston and cylinder. In addition, modern equipment makes it possible to produce parts with small tolerances, eliminating friction between moving units.

In the production of Chinese nonames, such equipment is not used, and the quality of the metal immediately leaves one wanting the best. These saws need to be run in using a different technology.

First launch

When everything is ready to launch, you can try to start the engine:

- The ignition switch is moved to the operating position.

- If there is a primer on the carburetor, press the button until the fuel mixture enters there.

- The saw is installed on a level platform so that the chain does not touch the ground.

- With your left hand, press the saw down by the handle.

- With your right foot, step on the inside of the protective shield of the working handle.

- The air damper is closed one hundred percent.

- Gently pull the starter handle up until the play in the ratchet mechanism is selected, and then jerk it sharply, turning the engine crankshaft.

- After signs of ignition occur (popping noises in the cylinder), the air damper is opened and the saw is tried to start.

The first start of the chainsaw may require some time to start with the air damper closed, especially in cool weather.

Carburetor, muffler and ignition coil

To remove the carburetor, you need to have a socket 8 and an extension, with which it is convenient to unscrew the nuts securing the carburetor and air filter. Before dismantling the carburetor, it is necessary to disconnect the ignition wire and choke rod from the engine control lever and remove the lever, only after this the air filter and carburetor are removed.

Muffler Shtil

180 is fastened with two nuts, unscrewing which you need to pull it towards you, it can be easily removed.

The coil is secured with two screws; to remove it you just need to unscrew them.

Features of running in tools from different manufacturers

Chainsaws from different manufacturers differ from each other in design, motor power and other parameters. Accordingly, their running-in process also takes into account the specific features of the tool. It should be taken into account that the best manufacturers supply the market with tools that are fully prepared for work and do not require running-in. Information about operating modes, the need for break-in and other important points can be found in the annotation for this chainsaw.

Basically, running-in is required for Russian and Chinese chainsaws. It is done in accordance with the stated rules and specific techniques outlined in the annotation.

Let's look at the aspects of performing the procedure for the two favorite models of chainsaws:

- STIHL MS-180 (STIHL). German chainsaws, famous in the world. The carburetor of these tools goes on sale configured for the tool's break-in mode. The fuel-oil mixture is made up in a ratio of 1:50; for a complete break-in, more than 5 full tanks will be useful. Starting and leaving the saw idling is strictly prohibited! It has air cooling, which actually does not work in this mode.

For normal cooling, the flywheel needs to work, and this is only possible under load, even a small one. After the break-in is completed, you should contact a service center to reconfigure the carburetor to operating mode.

- Champion (Champion). Chinese instruments are difficult to repair, so they should be used very carefully. Champion chainsaws are run-in using a fuel-oil mixture with a ratio of 1:50. You need to use oil of the same brand - Champion JASO FD, since Chinese tools are sensitive to the quality of fuels and lubricants. The manufacturer asks to run-in until 6-8 full fuel tanks are used. There are no special requirements, apart from the usual criteria - a gentle operating mode without long loads at full engine speed.

Sketch 4 – Running in the “Champion” chainsaw

We repair most brands of power tools and petroleum equipment.

Any new (or after replacing the piston

group) a 2-stroke gasoline engine (which is equipped with your saw, trimmer, etc.) in the first hours of operation requires the so-called “break-in”, on which its further “life” depends. When preparing to start the chainsaw for the first time, you need to carefully read the instructions, taking into account all safety recommendations. The main component of the long service life of your gas-powered tool is oil. Now on the market there are more than a dozen different oils used for 2-stroke engines. The labels contain icons: saw, moped, boat engine. You should be very careful when choosing oil. As a rule, expensive oils are used for mopeds and motorcycles. It is not practical to use them for chainsaws due to their high cost. Some of the most common oils on our market are HUSQVARNA, STIHL, OREGON, PARTNER. These oils have additives that allow them to be used in any climatic conditions and, when mixed with gasoline, to ensure normal engine operation. Modern chainsaws and gas trimmers are designed for 92nd gasoline; it is better not to use 95th gasoline, because it contains too many additives. The operating instructions for 2-stroke gasoline engines indicate that oil and gasoline should be mixed in proportions of 1:50 (usually). This means that 1 liter of gasoline requires 20 grams of oil. It is permissible to mix the first fuel mixture in a 1-liter container with a different proportion (1 liter of gasoline and 25 grams of oil). This will allow for more enhanced lubrication of the engine mechanisms during the first hours of engine operation. In this case, smoke will be observed from the exhaust pipe. There is an opinion that in the first hours of operation the saw should operate at idle speed (i.e. without accelerating) for several hours and only then can it be used for cutting wood. We recommend that when you first start the saw, let it run for about five minutes and, observing safety rules, begin cutting small branches and trunks of about 100 mm, while working at medium speed. It is not recommended to overload the saw engine in the first minutes, allowing the chain to get stuck or the engine to stop. since under increased load, a new engine may experience “burrs” in the working cylinder, which ultimately leads to its failure. Advice: Never mix more gasoline with oil than you can produce within 2 weeks, as the properties of oil diluted with gasoline are lost. Tip: Do not use unknown oils. The label must state "Two-stroke engine oil." Advice: Do not transfer your gas-powered tool to another person without consulting him on safety precautions and rules for mixing oil “1 liter of gasoline. 20 grams of oil”

How to properly test new equipment - step-by-step instructions

After completing all the preliminary procedures, they move on to a specific run-in. Procedure:

- Disengage the brake of the cutting tool (pull its handle forward until it touches the front handle). This is an essential procedure; otherwise, strong heating will occur in the clutch area, which can lead to melting of the body and failure of tool parts. The condition of the chain is inspected by pulling it along the direction of travel. Gloves must be worn on hands.

- Close the choke and turn on the ignition. If there is a decompression valve, turn it on.

- Grab the starter handle, pull it a little until tight contact appears and jerk it a couple of times with a sharp movement until a flash of fuel occurs in the combustion chamber. The saw should start and stall after a second or two. After which the air damper is opened and the engine is started again.

- After start-up, apply gas until the engine reaches full speed, then leave the saw running at idle for 3-5 minutes. Read more about how to start a chainsaw.

- Cut small trunks or branches with a thickness of no more than 10 cm. The load is dosed - first small, then medium, and the transition to the maximum working load is made at the end of the running-in (after 5-6 full fuel tanks have been used up).

Important! There are often tips on the Internet about running in idle. Would-be experts advise starting the tool and leaving it running at minimum speed, “hanging the saw on the fence” - this is a popular expression. This advice is a direct path to engine overhaul, and under no circumstances should you follow it. The tool must work, albeit with a measured load.

After the break-in is completed, it is necessary to adjust the carburetor to operating mode.

Checking the lubrication

The lubrication should be checked not only during break-in. This is an ongoing procedure that must be performed throughout the life of the chainsaw. The following elements need to be checked:

- Oil level in the tank;

- Condition of the saw frame lubrication channels;

- The presence of lubricant on the drive sprocket, in particular on the needle bearing;

- Condition of the driven sprocket.

Based on the inspection results, the channels should be cleaned and lithol or grease should be applied to the driven sprocket.

READ How to spot a fake STIHL chainsaw

Manufacturer's warranty

A chainsaw is a rather complex device, and it is natural that malfunctions occur with it. If a breakdown occurs in the first two weeks after purchase, you have the right to return the product to the seller. However, here it is necessary to take into account a number of nuances.

Example of a warranty card

In order for a chainsaw to be accepted for warranty service, you must:

- When purchasing a tool, conduct a thorough visual inspection for external mechanical damage and correct completion of warranty documents;

- Keep the saw documents, sales receipt and packaging for the entire warranty period;

- Monitor the integrity of the warranty stickers (if there are any on your chainsaw);

- When running in and subsequent operation, use only high-quality fuel and lubricants;

Important: if the chainsaw breaks down during the warranty period, the seller can conduct an examination of the tool. If the study reveals the use of low-quality gasoline or oil, warranty service will be denied.

- If during the running-in process malfunctions are discovered that were caused by the manufacturer, you have the right to return the chainsaw if no more than 14 days have passed since its purchase. After this period, the buyer has the right to demand repair of the product;

After break-in, some chainsaw owners adjust the carburetor.

First carburetor adjustment:

- Start the saw and turn the high and low speed adjustment screws until they stop. Unscrew it back 1.5 turns;

- Warm up the saw for about 10 minutes. Set the idle speed using the idle speed screw. With the correct settings, the chain will not move along the bar at idle;

Carburetor adjustment screws - Check the saw for acceleration. When you press the accelerator, the speed should increase quickly. If this does not happen, use screw L, turning it counterclockwise no more than 1/8 of a turn;

Is it necessary to break in a chainsaw?

A new or overhauled chainsaw is not ready for full loads. It is necessary to operate it in a softer mode for some time so that all moving parts get used to each other properly. This applies not only to the piston group of the engine, but also to the elements of the cutting element and frame. The gentle mode allows you to prepare the mechanisms for full load, reduce or completely eliminate the risk of jamming of the pistons in the cylinder, and facilitate the movement of the chain without unnecessary friction and heat.

Chainsaw Shtil MS-180C run-in and review

The main problem with untested chainsaws is the lack of uniform transfer of thermal energy to the cylinder walls. It remains on the piston, which expands and creates the risk of wedging, which means engine failure and the need for major repairs. When all the smallest irregularities and roughness are smoothed out, good piston-cylinder contact appears, increasing compression and heat transfer. This evens out the operating mode and removes unnecessary friction loads. In addition, the noise level is reduced, which is also important for users who perform large volumes of work.

Important! Running in the chain and all connecting cams is equally important, since an excessively tight chain creates additional stress on the engine.

How to properly break in a chainsaw - detailed instructions and recommendations.

Any gas-powered tool requires proper operation, ensuring maximum performance in combination with optimal loads on the engine and other components of the tool. Chainsaw , as a cutting tool operating in difficult and dangerous conditions, needs to comply with operational requirements to the greatest extent. One of the most important conditions for proper operation is the creation of optimal working conditions in the first days of operation of the tool.

Running in a chainsaw is an important and responsible stage of operation, which requires an understanding of the meaning and purpose of all procedures performed. The issue is important and requires detailed coverage.

Production of fuel-oil mixture

The most suitable type of fuel for a given brand of tool is always indicated in the instructions. For break-in, you will need a mixture of gasoline and oil, prepared in the proportion determined by the manufacturer. As a rule, gasoline with a minimum octane number of 90 is used. For Russian types of fuel, grades A92 or AI92 are relevant. Higher values should not be chosen, as they are often counterfeited.

The optimal choice of oil is synthetic, it burns completely. Typically the oil content is 2% (1:50), but for some models of Chinese chainsaws this value varies (1:25), and for Partner tools it is 1:40. The prepared mixture should be used as early as possible, ideally on the same day, but not later than several weeks. During the running-in process, you will need to produce 5-6 full tanks of the mixture.

Carburetor adjustment

Most manufacturers pre-set the carburetor for break-in mode, so adjustments are only required to establish normal operating conditions at full load. The purpose of the procedure is:

- Setting the fuel supply in optimal mode;

- Stabilization of engine operation;

- Obtaining maximum engine power;

- Eliminates smoke and popping noises during tool operation.

Figure 3 – Carburetor settings

The carburetor has special adjustment screws, the location of which must be specified in the instructions. With their help, the idle speed, maximum and minimum engine speeds are adjusted. The adjustment is carried out with the chain installed, since during the process you will need to control the moment at which it begins to move. The setup process is not very difficult, but for the first time it is recommended to involve a competent and experienced specialist who can verify the correctness of the actions.

What threats exist and ways to overcome them

The main threat is blindly following various advice found on the Internet or from home-grown experts. The only source of recommendations can be the user manual, which outlines all the necessary actions that must be performed when running in the tool. It is important to understand that there is no universal way to grind working surfaces; all chainsaws are manufactured at different factories and require a separate approach.

Therefore, any information obtained from different sources should be clarified and compared with the requirements of the instructions. If in doubt, the right thing to do is contact the service center and get the appropriate advice there. In some cases, too much information is more harmful than its lack.

Running in a chainsaw is a necessary and responsible procedure, which is performed by using the tool in a gentle manner. The time required for break-in, as well as the specific requirements for this period, are set out in the user manual. Trying to break in the saw by simply starting it and idling it is prohibited, despite a lot of similar advice. Such actions can cause overheating and jamming of the pistons, which is tantamount to complete failure of the tool.

The saw should be used for its intended purpose, just do not cut thick and dense materials. The complete procedure requires the use of 5-8 tanks of fuel-oil mixture, the parameters of which must be specified in the instructions.

Preparing a new product

It is necessary to install the saw frame and chain on the tool. There are often tips online to make the first launches without load, but they are extremely harmful and will lead to the opposite result. Lack of load has a detrimental effect on the condition of the new engine:

- The fuel combustion mode changes;

- There is no possibility of uniform lubrication of all surfaces;

- The quality of heat removal decreases.

All these factors contribute to the appearance of carbon deposits and the formation of scuffing, which can lead to piston jamming. A major overhaul of the new chainsaw will be required, which could have been avoided by proper break-in.

Before starting actual work, some preparation will be required. It is no less important for obtaining a successful result, so let’s consider the process step by step:

Running in a chainsaw and other STIHL tools

The times of the first chainsaws (“Ural” and “Druzhba”) are over in our country. Gone are the days when questions like “How to break in a chainsaw” were relevant. STIHL does not require break-in. At all! No. Even if the guys at the market where you buy it to break

By the way, if you purchase a STIHL tool on the market, this means 99.99999% that you are not buying STIHL , but its Chinese replica. Firstly, this tool is sold only at official points of sale, through the manufacturer’s website and a few websites of certified partners. Secondly, not a single company manager will tell you that you need to cold start and run in a STIHL chainsaw. Why? Let's look a little more closely below.

How to break in STIHL gas tools

The chainsaw came off the assembly line and was taken to the workshop, where it was assembled, filled with oil and fuel mixture, checked, turned on and... secured in a special running-in chamber for gas-powered tools, which is located there, at the factory, next to the conveyor. During the regulated time, it undergoes a “hot” run-in until the components and mechanisms are completely ground into each other - in fact, this is the purpose of the run-in and the best way to run a STIHL chainsaw. Therefore, as soon as you purchase it, refuel and add oil - and immediately go into battle! Work for 10-15 minutes, rest for 5 minutes, then 15-30 minutes, and rest again. After 3-5 tanks of gasoline, it will gain maximum power, and it will be possible to operate for the time specified in the technical passport.

In addition, according to the analogy just described, you cannot break in either a STIHL STIHL hedge trimmer STIHL trimmer . Yes, other manufacturers may recommend such a run-in, but in this case, with STIHL, it will only be a waste of time and your resources (effort, fuel, oil).

If you want to break in a STIHL tool (be it running in a STIHL cutter, running in a STIHL asphalt cutter or something else), we can only recommend running in for grinding in parts that you have changed after a scheduled replacement or as a result of repairs. For example, in a lawn mower the following could be subject to such replacement:

- cutting attachments;

- frame;

- engine belt or wheel drive belt;

- a shaft on which the knives are attached;

- motor.

READ STIHL saw does not start ms 180

How to break in a STIHL in this case? Give it gentle work for 30-60 minutes, get rid of particularly tough grass stems and debris, which usually lead to damage.

How to break in a STIHL blower

A leaf blower is also called a garden vacuum cleaner. This is a very convenient tool that in a matter of minutes can get rid of light debris and fallen leaves from a garden plot (usually 30-50 sq.m.). Like other STIHL , it undergoes the required running-in at the factory, and therefore there is no need to further break-in it. Only in the first days of work give him a reduced load; you cannot immediately put him “into battle” at 100%.

Running in the engine and its life after major overhaul

The main task of running in the engine is to grind in the installed parts. Since the engine is equipped with new spare parts (rings, pistons, camshafts, etc.), it is necessary to give it a little time so that all these components get used to each other, which is especially important when replacing rings that rub against the liner.

If you run-in the engine incorrectly, or neglect it altogether, the engine life will be reduced by at least 25%.

Also, two more important factors have a great influence on the resource of the restored power unit:

- Equipment and working conditions - any service station, even with the most modern equipment, is in no way able to compete with the manufacturer in terms of equipment and technical components. Consequently, the assembly accuracy is lower than at the factory;

- Engine mileage - the parameters of those components and parts that do not change during the overhaul can no longer correspond to the original ones, since during operation they were subject to a certain natural wear and tear.

If the running-in is incorrect, in addition to a noticeable reduction in engine life, it is quite possible that engine oil will get into the air cleaner, and fuel consumption (gasoline, gas, diesel fuel) may also significantly increase, and complications with starting are also possible.

Many car owners doubt the benefits of this measure and often neglect it, wanting to save money and relying on the quality of parts (which is not always the best, especially in cases with non-original spare parts). But it is worth remembering that properly carried out running-in will significantly extend the life of the engine.

Peculiarities

The modern STIHL MS 180 chainsaw has several design features that must be mentioned.

Anti-vibration system

The anti-vibration system circuit is implemented using rubber shock absorbers, which significantly reduce the vibration transmitted from the saw engine to the operator’s hands, which allows the chainsaw to be used without fear of harm to the operator’s health.

Compensator

The MS 180 compensator is a special valve in the saw’s carburetor, which allows the chainsaw to operate stably, even if the air filter is too dirty. This feature increases the operating life between scheduled maintenance of the chainsaw and allows you to wash or replace the filter only with a very noticeable loss of power.

Removing the handle

Direct disassembly of the Shtil 180 begins with removing the handle, which is attached to the chainsaw body using three rubber shock absorbers. To remove it, you need to remove the plastic plugs from the internal cavity of the shock absorbers, then using a powerful screwdriver, first press out the upper shock absorber, then the one closer to the rear handle.

At the rear of the handle there is a throttle trigger, which is connected to the carburetor through a wire rod; in order to disconnect the rod from the gas trigger, you need to unscrew two screws and disassemble the handle.

READ Stihl 180 Chainsaw Doesn't Work

When the handle remains on one shock absorber, you need to unscrew the chainsaw body from the inside of the handle and, bending it to the side, remove the body from the last rubber band.

What kind of gasoline should I use?

It is not recommended to use gasoline with more than 10% ethanol, because this causes problems with the carburetor. When using gasoline with up to 25% ethanol, engines with M-Tronic develop full power. There is no such system on 180 models.

What is M-Tronic? Whether you are starting up the chainsaw for a new job, working on it or starting it up after a break, the electronic STIHL M-Tronic system ensures the correct ignition timing and precise fuel dosing in any operating condition. External conditions are taken into account - temperature, altitude and fuel quality. This way, you can fully concentrate on the work at hand and achieve the most effective results. Source - official website of the STIHL in Russia.

Fuel consumption per hour

Regardless of the modification and installed tire, all STIHL MS 180 chainsaws are very economical and on average fuel consumption per hour is 0.7 liters. Consumption directly depends on the conditions and nature of the work performed and can vary from 0.5 to 1.2 l/hour.

Chainsaw Shtil MS 180 – technical specifications

The high efficiency of the Stihl model in the garden was achieved thanks to decent factory parameters.

Chainsaw features include:

- petrol engine power – 2 liters. s./1.5 kW;

- factory cylinder volume – 31.8 cm3;

- the permissible length of the tire used is 30–35 cm;

- fuel consumption – 200 ml/h;

- the pitch of the chain used is 3/8 “;

- weight including saw set – 4 kg.

The advantages of a chainsaw from the German brand Stihl include a low noise level, which, when the factory engine is running under maximum load, does not exceed 105 dB.

Equipment

As standard with a saw, there must be a 35 centimeter (14 inch) bar and a chain suitable for this bar length (50 links).

The manufacturer cares about the safety of customers and already offers customers a protective cover for the tool tire as standard.

Also included in the kit is a universal screwdriver key for unscrewing the spark plug, unscrewing the side cover and tensioning the chain, and an adjusting screwdriver for adjusting the idle speed. We also recommend reading a useful article about adjusting the carburetor on a STIHL

Any saw is required to be supplied with an instruction manual, which describes in detail how to use the STIHL 180 chainsaw, as well as how to carry out diagnostics and maintenance. download the instructions for the STIHL 180 chainsaw in our catalog of manuals.

conclusions

Today, there are many models of chainsaws and manufacturers represented by different countries (see the ranking of the best). And each of these devices requires its own individual approach, even though they all consist of almost the same parts. How to properly start a calm 180 video. But even the slightest additions affect the operation of the chainsaw itself , as well as its maintenance.

Therefore, it is very important to be as attentive as possible to the instructions in the operating instructions established by one or another manufacturer (for example, read the instructions for the Husqvarna chainsaw). Take care of your tool, give it due attention and it will undoubtedly serve you for many years without breakdowns and provide you with good performance.

The Stihl MS 180 gasoline saw for household purposes is one of the most popular models on the modern market. Among its main factory advantages, gardeners highlight increased reliability, vibration resistance, flexible traction parameters and efficiency. Relatively small physical dimensions and fairly light weight allow the saw to be easily used in very limited spaces without the risk of damaging decorative plantings or the body of the tool.

Device

chainsaw has a fairly simple design, intended for use by users without specific experience. The saw carburetor is designed in such a way that it is not possible to adjust it to the maximum number of engine speeds. The only available adjustment screw is responsible for stable idle operation.

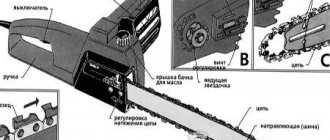

The saw consists of the following structural elements:

- engine;

- starter;

- flywheel, also known as cooling fan;

- ignition module;

- clutch;

- saw chain brake mechanism;

- carburetor;

- air filter with replaceable filter element;

- oil and fuel tanks;

- muffler;

- side cover with chain tension adjustment mechanism;

- control handle and saw handle.

Let's look at the structure of a chainsaw and how the main elements work in more detail.

To start the STIHL chainsaw, you need to pull the starter cord.

The starter transmits force through the flywheel to the crankshaft and drives the piston. At this moment, under the influence of an air pulse from the engine crankcase, transmitted through special channels to the carburetor, the fuel pump begins supplying gasoline and oil to the carburetor, where a fuel-air mixture is formed and supplied under the piston.

Running in the Shtil 180,170#ViktorPolev chainsaw

At the same time, when the piston is at TDC (top dead center), an electrical discharge is supplied from the ignition coil to the spark plug, which ignites the fuel mixture under the piston in the cylinder and forces the piston to move down, thereby making a power stroke.

After a successful start-up, the saw cyclically repeats all work processes and works stably.

To avoid fire, start-up must be carried out at a safe distance from the refueling site.

Let's consider how the force from the engine is transmitted to the drive sprocket and causes it to rotate the saw chain. For this purpose, a gasoline saw has a centrifugal clutch, which is installed inside the drive sprocket and is rigidly fixed to the engine crankshaft.

As the engine speed increases, the clutch opens and, resting against the sprocket body, transfers force from the engine crankshaft to it, forcing it to rotate the chain mechanism.

The next element is the saw chain brake. The brake device is quite simple and consists of a control lever and a metal plate that wraps around the drive sprocket and is installed in the saw body. In the working position, the chain brake plate securely holds the drum sprocket.

When the saw chain brake is set to the working position, it is forbidden to increase the engine speed, as this will lead to disturbances in the clutch mechanism.

Sources:

https://2lzz.ru/ruchnoj-instrument/benzopila/obkatka https://proinstrument.com.ua/obkatka-benzopily-i-drugogo-instrumenta-STIHL/ https://benzopilok.ru/brend/STIHL/ms -180-ustroistvo-i-harakteristiki-benzopily.html

Removing and disassembling the engine

The engine is held in place by 4 screws installed on the bottom of the Shtil

180. To remove it, you need to unscrew them, and then carefully remove the engine from the seat and the rubber carburetor pipe.

To disassemble the engine, 4 crankcase screws are unscrewed and it is removed, then you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings were pressed onto the shaft with force, then a special puller will be needed for dismantling.

To remove the piston from the connecting rod, you will need to remove the retaining ring from the seat using a thin screwdriver, then press out the piston pin from the opposite side, after which the piston is removed to the side.