12/20/2019 In summer cottages, in private houses, when working in gardens and household plots, you often have to use special equipment, which requires the use of appropriate knowledge and skills on the part of the user.

Stihl chainsaws are garden tools with an engine that have a wide range of applications: collecting firewood, cutting down old trees, seasonal pruning of branches, etc. The equipment of the German company Stihl is known for such technical characteristics as:

- compactness and high power;

- special protection and safety system;

- quality parts and workmanship.

The unit belongs to traumatic types of equipment. Before using it, you must read the user manual and follow all safety precautions. An important and responsible step is to start the device correctly.

Tool launch features

To run the tool, several processes need to happen simultaneously:

- the fuel mixture must be supplied under the engine piston;

- it should shrink as much as possible;

- At this point, a spark must be supplied to ignite and start.

Each of these processes occurs the moment you pull the starter handle. When using a new chainsaw, you need to remember to break it in.

However, in reality everything is not so simple.

The fuel for starting the tool in hot and cold engine modes must differ in the quality of the air mixture . So, a hot engine can operate with a normal air level, which will ensure its stable operation and will maintain normal idle speed. However, a similar amount of air will be enough to drive a cold engine. Before starting the chainsaw, the starter will need to be pulled about 10 times and possibly more.

To reduce the amount of air and increase the fuel supply in the chainsaw carburetor, a special damper is installed, which is responsible for adjusting the amount of air when starting the engine . Starting the engine with a saw will be faster, so the duration of operation of the starter and the saw as a whole will be increased.

It is very dangerous to start the saw at a refueling site.

Fault detection algorithm

The cause of saw failure or deterioration in its performance may be:

- clogged fuel tank cap breather;

- air leakage from the carburetor due to the destruction of the gasket or loosening of the threaded fasteners;

- mechanical jamming of removable saw equipment and other minor defects.

Before you begin disassembly, you should make sure that more extensive repairs are necessary.

It will most likely not be possible to independently assemble a new chainsaw after repair with the original quality. The design of modern chainsaws often uses press fits of mating parts, which have minimal repairability.

Even partial disassembly of a chainsaw using improvised tools can lead to undesirable consequences. In most cases, to eliminate a malfunction, you can limit yourself to dismantling a separate unit or system.

This list includes:

- connecting rod and piston group;

- carburetor;

- clutch mechanism;

- saw chain drive sprocket.

Start according to instructions

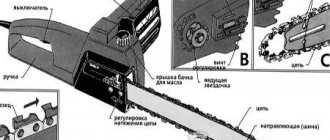

Different models of chainsaws have their own starting features and their own mechanisms. We will look at the device startup algorithm using the example of the popular Stihl MS 180 chainsaw model.

Before starting the startup process, it should be noted that the instructions for some chainsaw models state that

before starting the tool, you should apply the emergency stop brake to ensure additional safety. But with a fixed brake, starting will be more difficult .

Accordingly, it will be better to unfix it.

If you do everything correctly, then nothing will be difficult. If you are worried that without fixing the chainsaw at the moment of starting it will cause harm, then it is better not to take risks at all and not get to work. So, the algorithm for launching the Calm tool is as follows:

- Before starting to wind the tool, the damper adjustment lever should be moved to the lower position. Remember that it moves all the way down on the saw only when the gas button is pressed. Press the gas button and move the lever down. This will close the carburetor valve and lock the gas in the pressed position;

- Next, vigorously pull the starter handle until you hear the characteristic sound of an attempt to start the tool. It should stall immediately. Then the damper position adjustment lever is moved one step up;

- In this position, pull the starter handle again until the saw starts. And if it starts, then due to the fact that the gas handle is fixed pressed, the work will take place at high speeds;

- Then press and release the gas button once so that the throttle adjustment lever automatically assumes the operating position and the speed decreases;

- If it is necessary to put a heated chainsaw into operation, you need to put the lever in the working position and then start it;

- To stop the machine's engine, the throttle adjustment lever must be moved to the up position.

Run-in

Many models of household and professional chainsaws are tested in the factory. However, experienced specialists advise operating the tool during the first refueling in gentle modes and on fuel with an increased content of engine oil.

Not all beginners, having picked up this tool for the first time, know how to start a chainsaw. Especially in special situations, for example in the winter season. In addition, even the best quality tools must be handled correctly to avoid breakage or accidents. Despite the wide range of different models, they all run about the same.

Tool Hold

To properly start the chainsaw into operation, you should hold it in the correct way at the moment of starting. The position of the saw is very important here. Holding at the moment of launch can be accomplished in two ways.

In the first case, the saw is placed on a flat surface, the left hand must be held straight and the tool should be held by the upper handle, the right foot should be placed on the protection for the second hand, and the tool itself should be pressed to the ground. In this position, it will be convenient to launch the tool, since your right hand is free, and the tool is fixed quite securely.

Regardless of the position in which you plan to start the saw, be sure to turn on the saw brake.

In the second option, you need to take a standing position and hold the upper handle of the instrument with your left hand, and hold the back handle between your legs. Thanks to this position, you can easily wind up a low-power tool, and it will be securely locked, thereby protecting yourself from an accident.

Possible causes of failure of a fuel cutter

Most often, a gas cutter is used in fairly dirty working conditions. Malfunctions of gas cutters are associated with clogging with dust and dirt. Our service center in Rostov-on-Don provides a wide range of services for troubleshooting gas cutters from various manufacturers.

The equipment may fail due to wear of INDIVIDUAL parts of the gas cutter after long-term use. But even new gas cutters break due to overloads or mechanical damage. Most often the following malfunctions and breakdowns of petrol cutters occur:

- clogging of the fuel system;

- starter breakdown; fuel cutter;

- clutch malfunction;

- belt rupture;

- clogged filters;

- wear of piston rings;

- piston group malfunctions;

- Gasoline engine malfunction. Petrol cutter.

To ensure that work does NOT stop at a construction site for a long time, it is necessary to carry out technical inspection of equipment on time. And if the gas cutter breaks down, you should quickly fix the problem.

Starting without a starter

Often, many home craftsmen are interested in whether it is possible to power a chainsaw without the help of a starter.

The answer is very simple: this cannot be done in principle. None of the manufacturers have provided other alternative starting methods. Therefore, even if you remove the starter and try to start the car in some other way, it still will not work, since disturbances will occur in the cooling system. This system contains a volute to transmit the flow of cold air from the flywheel impeller towards the cylinder. If it is not there, the engine will overheat and eventually seize.

What fuel cutter parts need to be replaced?

To troubleshoot a fuel cutter, it may be necessary to replace parts:

Petrol cutter Stihl TS 800

- oil, air and fuel filters;

- SEPARATE elements of a gasoline engine and fuel system;

- clutch;

- Belt drive;

- cutting disc.

If the engine of the fuel cutter does not start, the fuel cutter stalls, the fuel system or filters are clogged, the belt breaks, the settings are lost, the Alfa-Rost service center in Rostov-on-Don will repair the faulty fuel cutter at low prices.

During the construction of various objects and road repair work, a special tool with a gasoline engine is used - a gas cutter. It can be used to cut concrete, metal, and other strong and durable materials. Any work with a gas cutter requires strict adherence to safety regulations and professional skills.

Manufacturers produce various types of equipment designed to work with different materials. This category includes concrete cutters, wall cutters, wall cutters, rail cutters, and chrome-plated equipment. The functionality differs between tools for household, semi-professional and professional use. There are also models designed for dry and wet cutting.

When choosing a tool of a specific model, you need to focus on the amount of work, the type and characteristics of the material that you will have to work with. Among professionals, Makita, STIHL, and Echo equipment are very popular, which are characterized as reliable, productive and reliable.

Reasons why the chainsaw does not start

The tool must be launched strictly according to the instructions. But if you have completed all of the above steps, and the saw still does not start, this means that there is something wrong with it. There are several reasons why it may not start:

- no spark;

- fuel is not supplied;

- air filter clogged.

So, what should you do to identify the real reason why the tool is not working?

Firstly, it must be said that if the tool does not start, the screws on the carburetor must under no circumstances be turned . And if you are not a professional in this field, then do not even try to adjust anything with your own hands or try to start the instrument .

The steps listed below, necessary for the tool to start working, must be performed in the strictly specified sequence. You need to start performing the next step only when the previous one did not work. The actions are:

General rules for using a chainsaw

The basic rules for operating the tool are the same for all brands - STIHL 180, Echo, Ural, and they are as follows:

- The dust must be held with both hands, clasping the handle with all fingers.

- The worker should not be directly with the chainsaw, but to the side of it.

- To cut material, use the upper or lower edge of the tool.

- If you need to go to another location, for safety reasons you should turn off the engine.

- You need to start sawing with the part of the bar that is located closer to the body.

- The worker must be dressed in special clothing, boots with protective inserts and use personal protective equipment - goggles, strong gloves, a helmet.

How to Start a Stihl MS 180 Chainsaw

All Calm chainsaws have two-stroke engines. Their cold start is carried out according to a similar algorithm. However, you can find models for sale that have accessories and you can start the saw without any effort. For this reason, the startup procedure may vary.

Installation algorithm for the Stihl 180 saw

If you have any questions about how to start a chainsaw, the process can be seen on the Model 180. For cold work, you need to turn the ignition on and set the engine control lever to the down position. The carburetor choke will block air from the filter and the throttle will be opened so that the fuel mixture will be richer.

The starter handle must be pressed several times until the first flash occurs. This indicates that the mixture has entered the cylinder and the equipment is ready for installation. Before starting the chainsaw, you must move the control lever up one position. In this case, the choke valve will open and the throttle valve will remain in the same position.

The starter must be removed and started. The tool will operate at higher speeds, the throttle will be open. To set the latter to idle, you need to fire the gas trigger and release it. In this case, the tool should start working normally. The described chainsaw model does not have any additional devices that would make starting easier.

Rules for drinking MS 180 C

This device, compared to the previous one, has some differences in the release mechanism. However, there will be no changes to the launch algorithm. In the embodiment described, the equipment is a system that uses a spring in the starter to reduce the resistance of the motor.

We are launching the saw brand MS 211 C-BE

You may also like

If you were also among those consumers who were thinking about how to start a Stil chainsaw, then we can consider another model as mentioned above as an example. The feed system is equipped with a hand pump, which facilitates the operation of the saw in the cold.

The instructions contain an additional paragraph indicating that fuel must be pumped into the carburetor before starting the pump. Then follow the principle described for model 180.

Dust formation after winter

Product reserve

The Stihl MS 180 C-BE 14 35 cm chainsaw is an improved version of the Stihl MS 180 saw - it has an ErgoStart ease-of-start system and tool-free lateral chain tension. The tool is suitable for collecting firewood, forming tree crowns, knots, erecting wooden structures, sawing tree trunks, as well as performing other simple household work. The Shtil chainsaw has high cutting capabilities, wide functionality and low weight. A high level of ergonomics ensures ease of use regardless of the complexity of the task. The device is equipped with a 14-inch tire (35 cm), providing the ability to work with trees with a diameter of up to 30 cm.

The STIHL MS 180 C-BE petrol saw has a modern vibration protection system. The anti-vibration system is located in the area of the saw handles and significantly dampens the vibration transmitted from the engine. The tool is equipped with a modern lubrication system that regulates the amount of lubricant supplied. The control button for cold and hot start, turning the tool on and off is represented by a separate lever. This makes handling the saw safe, since the operator's hand always remains on the handle.

Features and benefits of Stihl MS 180 C-BE 14 35 cm

- ErgoStart starting aid

- Side pressing of the chain without using a tool

- Light weight

- Convenience

- QuickStop chain brake

- Safety

- Quick chain tension

- Modern vibration protection system

- Modern lubrication system

Equipment

The QuickStop chain brake is a safety mechanism when working with chainsaws. The chain brake is activated by pressing the front palm rest and stops the saw chain in a matter of seconds. If the kickback is strong enough, the QuickStop chain brake engages automatically.

Strong vibration in the area of the handles can lead to chronic circulatory problems in the hands. That's why STIHL has developed a highly effective anti-vibration system (AS). For tools with AC, engine vibration transmitted to the handles is noticeably reduced.

The STIHL compensator - a regulating element in the carburetor - ensures almost constant engine power, exhaust quality and fuel consumption over a long period of time despite increasing contamination of the air filter. It is necessary to clean the air filter only when there is a noticeable drop in power. Long-term maintenance-free operation becomes possible.

The STIHL Ematic system consists of an Ematic guide bar, an Oilomatic saw chain and a variable-flow oil pump. The special design of the bar and chain ensures that every drop of oil reaches exactly where it is needed for lubrication. This allows you to reduce oil consumption by 50%.

The coil spring between the starter cable spool and the crankshaft compensates for peak forces, and now there is almost no shock felt on the cable. The result: STIHL ErgoStart reduces the force by half and the starting speed by approximately two-thirds compared to traditional jump starters.

Machine functions such as cold and hot start, operation and shutdown are controlled by a separate lever. This makes control especially convenient and safe, since the right palm remains on the handle.

The proprietary STIHL quick chain tensioning system (B) makes tensioning the saw chain child's play. You just need to loosen the nut securing the chain sprocket cover, and use the adjusting wheel to quickly and easily tighten the chain. No tool required for this.

If you find an error or inaccuracy in the text or product description, highlight it and press Shift+Enter.

Video: How to Start a Stihl MS 180 Chainsaw

Before storage, you must drain the fuel, then start the engine and burn the remaining fuel in the system. Preparation is necessary to prevent membranes from sticking during storage. This simple operation will allow you to start dusting after winter. If you still don't know how to start your Quiet 180 chainsaw, you should know that it will be easier if you add 2ml of fuel mixture to the cylinder before passing it through the spark plug hole. This can be done using a syringe.

Installing a saw with a decompression valve

Users sometimes ask how to start if the tool has a decompression valve. This is not the case with the 250. Once the first flash occurs, the valve will operate normally. The engine control lever will be set to the position where the choke is open. The launch will continue; the decompression valve must be pressed again. This does not make startup quick, but it makes the process easier and more comfortable since less effort is required from the operator to start it up.

If you are not entirely sure how to start your Calm 180 chainsaw, keep in mind that valve equipment, whether it has a hot or cold engine, must be started by a valve. This will make the engine easier to control. This way, you can extend the life of the starter and reduce the number of broken cords since these chainsaws have a larger cylinder capacity and compression ratio.

Review of the MC 180 chainsaw

You may also like

This model of equipment costs 11,490 rubles. This is a household tool that will help you cope with work in the country. Using the device, you can get rid of unnecessary branches and cut down small trees. Operation is carried out with one hand, and due to its light weight it is very convenient to work with the device.

The consumer should know not only how to get a Calm ms 180 chainsaw, but also the technical specifications. Among other things, there is a 35 cm tire and a 31.8 cm 3 engine. The oil tank capacity is 0.15 l. The weight of the equipment is 3.9 kg. The volume of the model is 2 liters. With. The fuel tank capacity is 0.25 l.

Calm 250 Chainsaw Review

You can buy the 250 model for RUB 29,532. This equipment is a semi-professional model with a 40 cm tire. Power. 3.1 l. With. or 2.3 kW. The fuel tank capacity is 0.47 liters.

Production of fuel mixture

To break in the tool, the fuel mixture is made in accordance with the proportion of 1:25, where 40 ml of oil is needed for 1 liter of gasoline. Be sure to follow the proportions; failure to comply can be fatal to the device.

Take a washed vessel and do everything according to the instructions:

- Pour half of the required gasoline into the container;

- Pour out all the oil;

- Stir the resulting substance;

- Add the remaining gasoline and mix.

The video shows how to make it, just don’t forget about the proportions. They differ depending on the chainsaw.

How to start a stihl 180 chainsaw

Chainsaw Husqvarna 395xp

- The model's power is 6.66 liters. With;

- chain size – 60 cm;

- containers for lubricant and fuel - 500 ml and 900 ml, respectively;

- saw weight – 8.1 kg.

Chainsaw Husqvarna 61

- The power in the tool is 3.9 liters. With;

- chain size – 45 cm;

- oil tank – 400 ml;

- fuel tank – 750 ml;

- weight – 6.6 kg.

How to start a Shtil chainsaw

All Stihl chainsaws are equipped with two-stroke engines, the cold start of which has a similar algorithm. But there are models that have additional equipment installed that allows you to start the saw without excessive effort. For this reason, their start algorithm may be slightly different.

Let's look at how to start a regular saw and how the process differs from starting a modified model.

Repair and diagnostics of gas cutters in Rostov-on-Don

The petrol cutter has a rather complex design. The design of most gas cutters is based on a powerful two-stroke engine and a massive clutch. The rotation of the cutting disc is ensured by a belt drive.

Our experienced specialists, thanks to the availability of original components and professional equipment, will repair vibration equipment of any complexity in the shortest possible time.

When a client contacts our Alfa-Rost service center in Rostov-on-Don, the technicians diagnose the malfunction of the fuel cutter to determine the cause of the breakdown. We repair gas cutters at affordable prices.

Starting Shtil 180

In order to start the Shtil 180 chainsaw when cold, you must follow the algorithm specified by the manufacturer in the instructions for the Shtil 180 chainsaw, namely:

- Turn on the ignition and set the engine control lever to the lowest position (in this position, the air damper of the Stihl 180 carburetor blocks the access of air from the air filter, and the throttle is fully open, thus enriching the fuel mixture);

- Pull the starter handle several times until the first flash passes (the flash indicates that the fuel mixture has entered the cylinder and the saw is ready to start);

- Set the control lever one position up from fully lowered (in this position the air damper opens and the throttle remains in the same position as before);

- Pull the starter and start. The saw will start and operate at higher speeds, due to the fact that the throttle valve is maximally open. To set the throttle to idle mode, you need to press the gas trigger and immediately release it, the tool will immediately normalize the speed.

The Stihl MS 180 chainsaw does not come standard with any additional devices that can make starting easier.

Below you can see how to start a calm 180. The video reflects in detail all the main points, and the author’s comments allow you to understand the whole process down to the smallest detail.

If you can’t turn on and start the chainsaw

When all actions are performed according to the established order, but the chainsaw does not start working, it means there is a malfunction in its mechanism. Typically, this phenomenon is caused by common and easily fixable problems, such as lack of spark, shutoff of the fuel supply, or clogged air filter. In order to start a chainsaw, you will have to find the cause and take the necessary actions to eliminate it.

Gotta follow the rules

Only the right actions should be taken . If a person does not know what to do, there is no need to commit rash acts. It is prohibited to disassemble the device; be especially careful when handling the carburetor. You cannot unscrew any screws on it, because if its device caused a breakdown, then it is impossible to repair the chainsaw without professional equipment.

Actions that must be performed in strict order are listed. Only when moving from one event to another can you determine the exact cause of the malfunction and quickly eliminate it without damaging other parts. Algorithm of actions performed in case of failures in starting a chainsaw:

- First, just let the device rest. This is especially true for saws that have been in use recently. It is enough to wait no more than 10 minutes, since during this time the mechanism will cool down and, in the absence of other breakdowns, will easily start. Sometimes it happens that during the installation the candle near the device is filled with water. If this unpleasant behavior occurs, then it is enough to wait a very short pause and repeat all the steps again to start the engine.

- The housing cover is unscrewed from the device to remove the air filter . The process of starting the device is carried out in its absence. Sometimes the reason for no ignition is that the filter is dirty. If ignition occurs without it, then this is the reason. To eliminate these troubles, just wash the filter under running, warm water and soap, then dry it. You can also replace the old element with a new one.

- The spark plug is removed. The spark is checked. If it does not appear, you need to replace the old spark plug with a new one. Usually this helps and a spark appears, but in some cases there is no spark even when replacing the mixture.

This means that the ignition unit is damaged and the chainsaw needs professional repair. Sometimes there is a malfunction of the ignition unit even if there is a spark, so this criterion cannot be used to eliminate the likelihood of a breakdown.

When a spark appears and you cannot get the device to work, you must continue to follow the steps below.

- There are times when a spark appears, but the spark plug itself is wet. This is possible if gasoline gets on it. To get rid of it, just turn the device over so that the cylinder is facing downwards. Then all the excess liquid will pour out. Next, you should check the combustion chamber, for which you need to pull the starter more than 10 times. You can try to replace a candle damaged by moisture and then check the effectiveness of its operation. If it becomes faulty, you can replace this element with a new one. After these steps, you need to try to activate the device again.

- Sometimes the candle remains dry . In this case, it is necessary to fill the syringe with gasoline mixture and pass it into the cylinder. After this, you should immediately try to start the device. If the reason for a long lack of response to attempts to turn on is debris that has gotten into the carburetor, then when it is removed there should be no interference with the flow of fuel into the combustion chamber. The mechanism for successful garbage collection is determined by the flow of liquid when pouring the gasoline mixture, so you need to pour fuel with force, and then almost immediately try to start the device.

- The muffler is removed. To do this, it is unscrewed and carefully removed so as not to deform the gasket separating it from the engine. You should try to start the mechanism without using an air filter and muffler, which helps to prevent damage to these structural elements.

If there is any damage to the cylinder walls, we can conclude that it will have to be repaired professionally or replaced with a new one. Typically, such malfunctions are caused by insufficient oil concentration in the fuel.

Starting the Stihl MS 211 C-BE

The fuel supply system in the Stihl MS 211 C-BE chainsaw is additionally equipped with a manual fuel pump, which makes it easier to start the chainsaw when cold.

The instructions for starting this Calm chainsaw model contain one additional point, which is that before starting the chainsaw when cold, you need to pump fuel into the carburetor using a pump. Further, the instructions are no different from launching calm 180 and follow the same algorithm.

What happens when the primer pumps fuel, and how does this help start the saw more efficiently?

At the moment of starting the saw without a primer, several movements of the starter are carried out only so that the fuel pump, under the influence of an impulse from the saw crankcase, pumps fuel into the carburetor.

A pump installed in the fuel line allows you to manually pump gasoline into the carburetor without unnecessary movements of the starter. The effect of this action is obvious; the saw will start much faster.

Many owners of gas-powered tools mistakenly believe that using a hand pump can over-pump fuel into the carburetor and for this reason the spark plug will flood. This is fundamentally wrong, since the system is capable of circulating in a circle. Excess gasoline from the carburetor will be directed through a special hose designed for this purpose back into the tank.

There is no need to use a primer on a hot chainsaw, since the fuel in the carburetor is sufficient for starting.

Business interruptions

To restore the operation of the saw, no matter the Ural or Shtil brand, you need to know the location of the breakdown. First we check and change the unsuitable fuel mixture

If the saw still does not start, then we check further point by point

First, we check and change the unsuitable fuel mixture. If the saw still does not start, then we check further point by point.

The problem is in the candle - we pull it out and dry it. Under no circumstances should you pierce it, as this will lead to a malfunction of the part. Fills a spark plug on a chainsaw: what to do? 30 minutes after drying, you can insert the spark plug back, first checking to see if there is any fuel left in its place.

The chainsaw is no longer considered an innovative technique intended exclusively for professionals. Nowadays, many summer residents and owners of personal plots have a similar universal unit in their arsenal. After all, modern manufacturers offer customers a wide selection of types and models of units of this kind.

If equipment of this type is provided with proper use and maintenance, spark plugs for Stihl chainsaws rarely become unusable. But if one day the chainsaw does not start, you need to figure out the problem in order:

A spark plug for a chainsaw is an important part for units of this kind. If problems arise with it (for example, it floods), they can lead to breakdown of all equipment; If, upon inspection, the chainsaw spark plug feels completely dry to the touch, this indicates a lack of fuel supply. Why is this happening? The salt of the problem is concentrated in the carburetor. Be sure to clean the fuel filter and turn the engine back on. Nothing happens? Then the carburetor needs to be disassembled and examined, but it is better to entrust this matter to specialists from the service center; If the unit does not start, then this may indicate a problem with the spark plugs of a different nature - it is flooded. Your chainsaw is calm: the spark plug is flooded and the engine of the unit does not start? To fix the problem, remove the flooded spark plug and dry it thoroughly. At the same time, it does not need to be heated. It is enough to drain the fuel mixture from the spark plug hole and leave the part to dry for half an hour. Next, put it back in place and start the engine.

In addition, it is important to inspect the contact between the tip of the spark plug and the high-voltage wire; It is important to ensure that the chainsaw spark plug gap is adjusted correctly.

Why does the spark plug on the chainsaw become calm? The answer is simple: this happens when the unit is started by an inexperienced user who does not follow the correct sequence of starting the equipment when cold.

Because of this, the spark plug tip may fail. To verify the presence of such a problem, unscrew the spark plug and insert it into the tip. Then place the part on the block and pull the trigger cord several times. If there is a spark, you don’t have to worry about the electrics and the condition of the spark plug.

Be sure to check that the chainsaw's spark plug gap is adjusted correctly.

A spark plug for a chainsaw is an important part for units of this kind. Why the spark plug on a chainsaw floods: reasons and. If problems arise with it (for example, it floods), they can lead to breakdown of all equipment; If, upon inspection, the chainsaw spark plug feels completely dry to the touch, this indicates a lack of fuel supply. Why is this happening? The salt of the problem is concentrated in the carburetor. These days your chainsaw is calm: it fills the spark plug and why does it fill the spark plug on the chainsaw. Be sure to clean the fuel filter and turn the engine back on. Nothing happens? Then the carburetor needs to be disassembled and examined, but it is better to entrust this matter to specialists from the service center; If the unit does not start, then this may indicate a problem with the spark plugs of a different nature - it is flooded. Let's figure out why the spark plug on a chainsaw floods, how to prevent it and how to deal with it. Your chainsaw is calm: the spark plug is flooded and the engine of the unit does not start? To fix the problem, remove the flooded spark plug and dry it thoroughly. At the same time, it does not need to be heated. It is enough to drain the fuel mixture from the spark plug hole and leave the part to dry for half an hour. Next, put it back in place and start the engine.

In addition, it is important to inspect the contact between the tip of the spark plug and the high-voltage wire; It is important to ensure that the chainsaw spark plug gap is adjusted correctly.

How to start chainsaws with a decompression valve

Before you start a Stihl chainsaw on which a decompression valve is installed, you must turn it on. I would like to note that the Shtil 250 saw does not have a decompression valve.

After the first flash has passed, the valve will return to normal operation; therefore, after the engine control lever is set to the open choke position and starting continues, the decompression valve must be pressed again.

The operation of the valve is shown schematically in the figure below.

In fact, the valve does not make starting faster, it just simplifies the process and makes it more comfortable, because During launch, a person will have to apply significantly less force.

A saw with a decompression valve, regardless of whether the engine is cold or hot, must be started using the valve to facilitate the cranking force of the engine. This will significantly increase the service life of the starter and reduce the number of broken laces, since it is installed on chainsaws with a large cylinder volume and, accordingly, compression.

Results

Starting a calm chainsaw almost always follows the same algorithm, except for those cases when a decompression valve and a fuel primer are additionally installed on the chainsaw. These devices are designed to facilitate the startup process and perform their functions perfectly.

Beginner sawmills who do not have the skills to work with chainsaw equipment have to develop the skills to service it on their own. How to prepare the fuel mixture and how to start the chainsaw is described in detail in the instructions supplied with the tool.

At the initial stage of preparation for the first start, the new chainsaw is freed from preservative lubricant, after which you should make sure that it is fully equipped, that the threaded fasteners are securely tightened, especially in the area where the headset is attached, and that the saw chain is correctly tensioned.

How to start a saw after a long period of inactivity

I can’t start the chainsaw after a long period of inactivity. Such comments can be found on forums dedicated to the repair and operation of saws. Let's figure out how to start a chainsaw after a long period of inactivity.

The fact is that successful startup after downtime must be taken care of in advance and the saw properly prepared for storage. According to the manufacturer's instructions, before storing it, it is necessary to drain the fuel from the tank, then start the engine and burn out the fuel in the fuel system.

Preparation is necessary to ensure that the carburetor membranes do not stick together during storage. Performing this simple operation will allow you to successfully start the saw after long-term storage.

It is much easier to start a chainsaw six months after being idle if, immediately before starting, through the spark plug hole, add 1 - 2 ml of the fuel mixture to the cylinder. This can be done using a syringe.

Preparation and refueling of the combustible mixture

All modern chainsaws, with rare exceptions, are equipped with compact two-stroke internal combustion engines running on high-octane gasoline. A measured amount of special motor oil is added to the fuel composition in a ratio of 40:1 or 50:1.

There are few requirements for the quality of gasoline - these are:

- minimum storage time;

- octane number not less than 92;

- absence of water and foreign impurities.

How does a gas cutter work?

During the construction of various objects and road repair work, a special tool with a gasoline engine is used - a gas cutter. It can be used to cut concrete, metal, and other strong and durable materials. Any work with a gas cutter requires strict adherence to safety regulations and professional skills.

Manufacturers produce various types of equipment designed to work with different materials. This category includes concrete cutters, wall cutters, wall cutters, rail cutters, and chrome-plated equipment. The functionality differs between tools for household, semi-professional and professional use. There are also models designed for dry and wet cutting.

When choosing a tool of a specific model, you need to focus on the amount of work, the type and characteristics of the material that you will have to work with. STIHL , Echo, which is characterized as reliable, productive and reliable, is very popular among professionals

The principle of operation of a gas cutter for cutting metal

Concrete and steel structures are the main objects that are processed using a gasoline cutter. Working with metal structures does not require the use of powerful models, as when cutting concrete. A popular option for cutting steel elements is gas cutter ; other models with a power of up to 4200 W can also be used.

Stihl TS 400 manual

When processing metal structures, the following rules must be observed:

- to perform vertical cutting, the tool must be held at an angle of 90 degrees to the surface;

- the position of the protective casing should be such that sparks fly in the opposite direction from the worker;

- at the moment the disk touches the steel surface, the engine should operate at medium speed, and after creating a guide groove, the speed can be increased to the maximum;

- In order for the cutting area to be of high quality, smooth and without jagged edges, the tool should be moved smoothly, without jerking;

- thin sheet material, small diameter pipes can be immediately cut with a vertical cut;

- steel corners and beams are cut into segments, being especially careful where parts join at an angle.

It should be remembered that the metal gets very hot in the places where it is cut, so to avoid burns, you should touch the cut fragments after some time.

Sources:

https://ingener-pto.ru/2019/12/12/kak-zavoditsja-benzopila-shtil/ https://crast.ru/instrumenty/kak-zavodit-benzorez-shtil https://www.mosstroyprokat.ru /benzorezy/kak_rabotayet_benzorez/