In principle, you can sharpen the teeth on a circular saw using an ordinary file.

However, when choosing this very labor-intensive method of sharpening, difficulties arise that only a person with the appropriate experience can cope with. In particular, it is quite difficult to maintain the required degree of angles. It is much faster and more efficient to use special machines to sharpen circular saws.

How to know when it's time to sharpen a disc

Cutting discs used for processing wood and wood-based materials experience wear and tear over time, reducing their productivity. To restore the effectiveness of the cutting tool, you will need to sharpen the teeth. You can find out that the teeth on the disk need to be sharpened by the following factors:

- To cut wood, it is necessary to apply force to press the tool against the workpiece being cut.

- There is smoke coming from under the protective casing.

- The protective casing becomes overheated

- There are signs of a burning smell. This means that the teeth do not saw the wood, but cut it

Using a faulty attachment on a power tool leads to a decrease in work productivity, and also increases the likelihood of early failure of the power tool and the attachment itself. A decrease in performance increases the load on the electric motor, which eventually begins to overheat and fails.

This is interesting!

It is irrational to work with a dull disk, since in addition to increasing the load on the power tool, the work time for sawing workpieces increases.

Necessity of the procedure

Circular saws are needed both in private households and in production. When building a house, creating furniture, cutting boards, timber - a similar tool is required everywhere. Properly sharpening a circular saw requires practical skill and knowledge.

Circular saws compare favorably with other cutting tools:

- chain;

- saber;

- longitudinal.

Disc circular devices have significant productivity, and their service life is also much longer. Sharpening circular saws is an important necessary step; without it, the tool will not work fully. Thanks to various attachments with carbide tips, as well as pobedit coatings, cutting can be carried out with both wood and metals.

To sharpen discs with different attachments, special equipment is required. If the disk is treated “scientifically”, this will greatly extend its service life.

Timely sharpening of circular saws is carried out when there are several obvious signs.

- The engine begins to experience unnecessary loads. The reason is simple - the teeth are dull and additional resources are required to process the material. There is a danger: if the disk is damaged, if there is no engine shutdown relay, the machine may fail.

- If chips and chips form on the cut, and the cut itself becomes too wide, then this is a sure sign that the tool should be repaired.

- A foreign smell of burnt material appears, and dark spots are visible on the cut line.

- The time required to process a part increases.

What teeth are there on cutting attachments?

At the heart of any cutting device are teeth, the quality of their sharpening affects efficiency and productivity. The teeth on the attachments are made directly from carbide materials. To increase the service life, pobedit soldering is applied to the teeth, which allows you to extend the life of the working attachment by 5-6 times.

The number of cutting teeth on a wheel depends on its diameter. The teeth consist of a front and a back part, which differ in design, as well as a side part. Teeth according to their appearance (geometry) are classified into the following types:

- Straight - a type of teeth used for longitudinal cutting of sheet material

- Trapezoidal shape - the cutting links have a trapezoidal shape, which is an advantage - they need sharpening very rarely

- Bevel links are the most common type of teeth and are characterized by the presence of an angular bevel on the back or front. This design allows sawing not only wood, but also other types of materials such as fiberboard, chipboard, plywood and even plastic.

- Conical - they have the shape of a cone, but their main drawback is that they quickly become dull, so they need frequent sharpening. They are used not only for transverse, but also longitudinal cutting of sheet material

Manufacturers also produce circular saw blades with active and passive links. Depending on the type of teeth, the process of sharpening them differs. To properly sharpen the teeth on a circular saw, you will need to correctly determine the sharpening angle.

Do-it-yourself saw sharpening at home

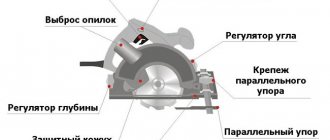

Figure 4. In order for sharpening to be correct and fast, the disc should be well secured.

You can sharpen your saw at home. To do this, it is not necessary to have a specialized sharpening machine in your own workshop, which costs a lot of money and is rarely used for its intended purpose.

But simply holding the disc in your hands and sharpening the teeth on a grinding wheel while suspended is irrational. No amount of steady hand or excellent eye is enough to make the cutting element impeccably sharp and suitable for effective work. For this purpose, care should be taken to make the simplest fixing device (Fig. 4).

Its surface should coincide with the level of the grinding disc axis. The gear wheel itself is placed on the stand so that the planes of the teeth to be sharpened are perpendicular to the saw blade. To sharpen beveled teeth along the front and rear surfaces, this device is made with a movable hinge.

However, in this case it is difficult to maintain the same value of the front and rear sharpening angles. To eliminate this problem, the center of the saw wheel is rigidly fixed in the desired position in relation to the abrasive disc. This is done either using a groove for a mandrel, which is mounted on a stand to place the saw being sharpened on it, or by installing special stops on the stand that secure the saw blade at the required angle to the sharpening wheel.

If you meet all the requirements for the technology of sharpening carbide circular saws, then they will serve a person for a long time and effectively.

Sharpening circular saws is a mandatory activity during the operation of this equipment. Wood processing requires the master to have tools with appropriate cutting properties at his disposal. Just like sharpening chainsaws, circular saws require extra attention. If the shortcomings are not corrected in time, over time the tool will begin to become dull much faster.

Selecting the sharpening angle of the cutting teeth

The links on the cutting attachments have a working area, which has a corresponding sharpening angle. Depending on the type of teeth, the disc can be used in one or two cutting directions. When the links become dull on one part, the disk must be turned around and work continued in the opposite direction. However, this cannot be done with all circular discs; for example, circles with beveled links are not suitable for this.

If you sharpen a circular saw blade with your own hands, then you need to understand that depending on the direction of the cut, you need to take into account the sharpening angle.

- If you plan to saw wood in the longitudinal direction of the grain, then the sharpening angle on the links should be 15-25 degrees

- If the wood is sawn transversely, the sharpening angle is reduced to 5-10 degrees

- The universal sharpening angle is considered to be 15 degrees. With circles with such links you can saw not only across, but also along

When sharpening teeth on saw wheels and disks for circular saws, grinders and circular saws, one more important factor must be taken into account - the density of the material being cut. The lower the density, the higher the sharpness of the tooth should be. If a circular saw is used for sawing plastic or plastic, then the sharpening angle of the blade should be negative.

How to sharpen a blade on a circular saw with pobedit tips

Craftsmen often buy wheels that have increased wear resistance due to the presence of special pobedite soldering. These soldering extends the service life of the consumable, but does not make it last forever. The pobedite layer is applied to the links using a special solder. Due to soldering, the geometric shape of the tooth becomes more complicated, and therefore the sharpening process also becomes more difficult. Restoring the sharpness of the teeth must be carried out taking into account precise exposure.

To sharpen the teeth on a carbide-tipped blade, you will need to smooth the cutting edge to 0.3 mm. To perform high-quality sharpening of carbide-tipped teeth, experts recommend using special equipment for this, as well as diamond-coated grinding wheels. If you use an abrasive wheel, it will quickly wear off before the soldered disc can be sharpened.

When restoring the sharpness of links, the following factors are taken into account:

- Saw blades must be sharpened not only on the front, but also on the rear plane. You need to start directly from the front

- When sharpening, the pobedit tip should be in close contact with the diamond sharpening wheel.

- The contact time should be no more than 5 seconds. It is necessary to take into account the time in order to avoid overheating of the metal. If the metal overheats, it will harden and decrease in hardness.

When sharpening, you must also take into account that the thickness of the material being ground should not be more than 0.15 mm. If the procedure is carried out correctly, then at least 30 sharpenings are carried out until the disk with pobedit tips is completely worn out.

This is interesting!

When sharpening discs, you need to take into account that the teeth can have a negative and positive angle.

If a tooth has a negative angle, it is more difficult to sharpen it at home than a positive one. You need to make your own decision about the rationality of restoring the sharpness of tipped discs, since the cost of a diamond-coated grinding wheel is sometimes more expensive than electrical drive equipment.

Introduction

Professional sharpening of circular saws is carried out on a specialized machine, according to a given program.

The entire technological process can be either automatic or semi-automatic from the beginning of sharpening to the end. The operator only prepares the workplace, places the discs in the washing machine and secures them on the machine bed. The robot manipulator performs the rest of the operations itself. Very convenient and efficient. After such repairs, the blade looks like new and continues to serve perfectly without losing its performance qualities during the sawing process. The question will follow - where to sharpen a circular saw with Pobedit tips, what workshops operate in the region? I do not provide any advertising, all information is provided solely for informational purposes and to help you. Please ask all questions via contact information or in private messages on the blog.

This is what a specialized workshop with equipment looks like.

Before the operator starts work, he must make a preliminary diagnosis of your disks, as well as check the wear and runout of the disk. Only after these measures have been carried out, a program for sharpening a circular saw with pobedit tips, if any, is selected.

How to sharpen a disc with a machine

To restore the integrity of cutting discs, two methods are used - manual and automated. Performing the procedure manually is not only difficult, but also time-consuming. That is why it makes sense to buy a sharpening machine for saw blades or make the device yourself.

A simple device for sharpening saw blades is considered to be a sharpener or an emery machine, on the shaft of which you need to attach a special wheel - diamond, CBN, or sputtered silicon carbide. The difficulty in implementing the process is that the equipment being sharpened must be fixed in a stationary position, so holding the disc in your hands while sharpening it is not recommended. This is not only dangerous, but also reduces the quality of sharpening.

This is interesting!

Before starting work, it is necessary to clean the surface of the equipment being sharpened from carbon deposits.

To do this, you can use kerosene, diesel fuel or industrial cleaners. If you do not clean it, the performance of the nozzle can be restored to 75% -80%. Instructions for properly sharpening cutting blades for circular saws:

- Each tooth that is sharpened must be perpendicular to the blade.

- The principle of sharpening is that each tooth of the disk must be brought to the rotating blade (diamond wheel).

- The amount of metal layer removed depends on the magnitude of the clamping force. The more wear or abrasion of the teeth, the more firmly the tool should be pressed against the blade.

- The procedure is performed in a similar way for each link

To sharpen circular saw blades, you do not need to buy special equipment. To a home sharpening machine you need to attach a stand, which consists of a fixed and movable part, as well as a mount. With this device you can easily and quickly sharpen at home.

The task becomes more complicated when it is necessary to maintain the appropriate sharpening angle. To modernize and expand the functionality of the installation, you will need to make a tilt regulator for the movable stand. Bolts and nuts are used as regulators, through which you can set the required angle of inclination of the stand.

The movable stand is a square frame, in the center of which there is a lock for installing the disk. The clamp has the same diameter as the sharpened equipment. A groove is made in the stand through which the required sharpening angle is maintained. It is not difficult to carry out sharpening work, therefore, if you frequently work with wood using a circular saw, it is necessary to make a sharpening machine.

This is interesting!

Carrying out sharpening work in an automated way is much faster and easier, but this will require special equipment. The manual method in this regard does not require any equipment other than a file.

Techniques and rules for turning saw blades on wood

To restore the condition of the saw teeth, it is necessary to sharpen their edges with high quality. In this case, it is necessary to take into account their uneven wear. Mostly the front part becomes dull because a lot of the load falls on it.

Before sharpening the cutting disc, you need to clean its surface from dust and dirt. Then you need to check it for chips and cracks. If these defects are identified, it is prohibited to continue using the damaged cutting tool.

Then you need to study in detail the manufacturer’s instructions for operating the machine. It is important to first prepare it (install it on a flat surface, connect and configure it correctly). Then you can move on to turning the discs, and the technology will depend on the type of teeth and the area being sharpened.

Sharpening a straight tooth along the front plane

The front part of the teeth of the saw blades is sharpened in this way:

- The disc to be sharpened is placed on the mandrel, after which it is clamped with a conical sleeve and nut.

- Then it is adjusted horizontally using a pendulum protractor. In this case, the bevel angle of the front plane should be equal to 0°.

- By rotating the screw, the mandrel with the wheel moves horizontally to precisely adjust the front sharpening angle, as a result, the front part of the tooth should be pressed tightly against the grinding wheel.

- The first tooth to be sharpened is marked with a marker.

- The electric motor is turned on, after which the front part of the tooth is sharpened - to do this, it is pressed against the abrasive wheel several times with translational movements and released. Moreover, due to the pressing force, the thickness of the metal removed from the tooth is regulated.

- After sharpening one tooth, the saw blade is removed from the grinding wheel, then it is rotated along the axis by one tooth for further sharpening.

- This procedure is repeated until the disc being sharpened rotates to the location previously marked with a marker.

Sharpening a front beveled tooth

To do this, the disk must be installed at an angle - at the bevel angle of the front part of the teeth. Most often it is +8°. Then the 1st tooth is also marked with a marker and every 2nd tooth is sharpened sequentially. Next, the position of the disk is changed and a negative sharpening angle of -8° is set. Then every second tooth of the disc is sharpened again.

During turning, it is necessary to maintain a uniform bevel for each cutting segment. If there is a large error, it is necessary to reinstall the disc being sharpened so that the teeth on it are of the same shape. In this case, it is necessary to periodically make control measurements.

Sharpening teeth on the back plane

One of the important stages of turning circular saw blades is processing the back of the teeth. To do this, they are installed so that the back of the teeth is located in the same plane with the working surface of the grinding wheel and is in normal contact with it.

It is also necessary to take into account the rotation speed of the working tool. On equipment with manual adjustment, it is necessary to eliminate the possible overheating of the edges of the teeth being sharpened. In addition, you need to make sure that the circle does not remove a lot of metal from the teeth. Changing the shape of one or more cutting elements will negatively affect the quality of wood processing.

Important! Regardless of the part of the teeth being sharpened, it is necessary to follow the dressing technology so that the saw cuts wood quickly and efficiently.

How to sharpen a disc by hand with a file

If an emery machine is not available, the procedure can be performed manually. The principle of sharpening is that the disc being sharpened should be fixed in a stationary position. A vice or clamp is used for this. When the equipment is fixed, all that remains is to pick up a marker and mark the starting point of the work. Next, sharpening work is carried out using a file.

- It is recommended to use a flat file, but a triangular file will also work. The main requirement for a file is that it fits freely between the teeth.

- There is a lot of wear on the front and top of the tooth, so this wear should be restored

- At the initial stage, the back surface of the teeth is restored, and then the front

- When sharpening, you need to apply the same force. In addition, the size of the teeth, or rather their size, must be the same

Carrying out sharpening work by hand is much more difficult and takes longer, so this method is rational only in one case, if you do not have to work with a circular saw often. If work with a tool is carried out frequently, then it is rational to buy an emery machine and make equipment from it for sharpening circular saw blades.

Option 1 - making a simple sharpening machine from a sharpener

The first option for manufacturing the simplest sharpening equipment has the following form:

- On the workbench there is an emery machine, on the shaft of which there is a diamond-coated circle

- A fixed base is made from chipboard. This base simultaneously acts as a guide along which the moving frame will move

- At the next stage, a movable frame is made from chipboard or plywood, the walls of which should be directed downwards and act as a moving mechanism

- A disc clamp of the appropriate diameter is placed on the outside of the movable frame, and a groove is also made

- The result is a finished sharpening machine for saw blades

The manufacture of such a device requires a minimum of time and costs, and the effectiveness of its use is 100%. Details in the video:

Main characteristics

Devices for sharpening circular saws on wood are usually equipped with wheels. These circles can differ significantly from each other in several characteristics:

- by diameter (varies from 12 to 250 mm);

- the material from which the abrasive wheels are made (this could be, for example, CBN or silicon carbide, in some cases diamond coating is also used);

- thickness (it can range from 16 to 40 millimeters);

- sizes of mounting holes (standard diameters of such holes today are 16, 20 and 32 mm).

Almost all modern sharpening machines have an electric drive. The sharpening performance will directly depend on its power. Low-power household models can function uninterruptedly for up to 20 minutes, then they must be turned off so that they can rest and cool down. But professional sharpening units can work up to eight hours with two short breaks of half an hour. Moreover, here the main working element may not be the abrasive wheel, but the so-called sanding belt.

Option 2 - how to make a sharpening machine from a grinder and a drill

In addition to an emery machine, you can use a grinder or angle grinder to make a contactor. An appropriate diamond-coated sharpening disc is installed in the spindle of this tool, and the power tool itself is fixedly attached to the base. The principle of manufacturing the conductor is as follows:

- Take a frame made of chipboard or fiberboard measuring 50x80 cm. The components will be located on this frame

- Initially, you should fix the angle grinder motionless using clamps. The tool spindle should be positioned at right angles to the frame

- A movable frame is made and placed at the end of the tool, on which discs for sharpening will be installed.

- Frame mobility is achieved through the use of furniture slides

- A bracket is made on the frame to secure the sharpened equipment

The finished product is shown in the photo below.

How to use, as well as the features of working on a homemade machine for sharpening the equipment of circular saws, is shown in the video.

The result of the work done is the following - restoration of the integrity of the disk with teeth, which allows you to continue working with power tools when processing wood. The methods discussed in the material are suitable for sharpening saw blades of tools such as grinders, circular saws and stationary circular saws. If the principle of performing the work is clear, then there will be no difficulties with the manufacture of a special machine and its operation.

Types of saws

If the disk is properly sharpened and the teeth are set according to the pattern, then it can process the workpiece in any direction relative to the wood fibers.

There are these types of tools:

- saw with carbide blades;

- discs made of solid metal;

- discs with teeth treated with hard material;

- discs with heavy-duty soldered teeth.

Hardwoods are processed with discs that have special grooves. Technological breaks prevent tool deformation and prevent it from overheating during the production cycle. Vibration and background noise are also significantly reduced, and the quality of the line formed by the cut is improved. The saw has teeth that are machined at a certain angle, each tooth has several cutting edges.

There is a main edge, additional ones are mated to it, and intersecting planes are formed:

- A;

- IN;

- WITH.

The planes themselves also vary in different mates.

The teeth can be straight, they are usually used for preliminary cutting of material. These teeth provide a low level cut. However, the productivity of such teeth is quite high.

Beveled teeth provide a more precise line and are suitable for cutting materials such as:

- plywood;

- PVC sheets;

- chipboard;

- Fiberboard.

The teeth ensure an even cut without the material crumbling.

There are also discs in which there is a bevel at the leading edge of the cutter, and there is also a bevel with the trailing edge. Options for alternating different teeth with different bevels are possible. Such tricks ensure a clean cut, but you should remember: the denser the material, the faster such teeth become dull.

Trapezoidal tooth – this tooth configuration ensures long tool life. Often a complex design is used, when trapezoidal and straight teeth alternate. The latter make the primary cut, which allows straight-shaped teeth to “polish” the cut.

Cone-shaped tooth - these teeth are auxiliary and are designed to work with materials that have a laminated surface. They ensure correct cutting without the formation of any chips.

Sickle-shaped tooth - in this case, the teeth are bent, which makes it possible to accurately cut the material across the wood fibers.