How to saw off chipboard smoothly without chips and lint?

Today we will tell you what affects the quality of sawing, how to saw off chipboard evenly and cleanly, and also how you can saw with a guide and without a guide with a regular circular saw.

We will show it using a hand-held circular saw as an example, but this does not affect the sawing techniques in any way, the difference is only in minor details. You can get similar quality cuts with a cheaper tool if you follow our advice.

Sawing with undercut

You will need a large ruler (tire), which is fixed to the workpiece with clamps. The first cut is made to trim the laminate along the marking mowing line. The tire must be installed on the mowing line, and the cut must be made to a depth of 6-10 mm - there will be no chips.

The second cut is made through. There will be no chips on the mowing line where the teeth enter the slab, but at the exit point the laminate has already been cut off, so they simply cannot happen.

Correct sawing of laminated chipboard: sawing chipboard without chipping, do-it-yourself machine

Chipboard (chipboard), and nowadays mainly laminated chipboard ( chipboard ) is one of the main materials for making affordable furniture in the home workshop. This board is made from coniferous and deciduous wood materials, therefore it has such qualities as strength and ease of processing. But if cut incorrectly, this material may chip. Therefore, before making furniture, you should find out how to properly cut laminated chipboard .

For this purpose, you can even assemble industrial equipment yourself - a cutting machine.

- Sawing rules

- What not to saw

- Methods for cutting laminated chipboard without chipping

- Scratch

- Jigsaw

- A circular saw

- Sawing with undercut

- Fraser

- Sawing with a format saw

- Design

- How to make a machine with your own hands

- Required tools and materials

- Manufacturing

- Video about cutting laminated chipboard without chipping

READ Can You Cut Metal With a Miter Saw?

What not to saw

Chipboard cannot be sawed using an angle grinder, which is also called a grinder. When working with this tool, there is a high risk of injury, especially when using large diameter discs. Injury can also occur when the tool guard is removed from the tool.

Do-it-yourself sawing

Not everyone has stores or workshops with the necessary equipment within close proximity. Some people use old disassembled furniture as a source material. There may be other reasons why you have to do everything yourself, having only a hand tool and a jigsaw. Knowing some secrets, you can also use them to solve the problem of how to saw off chipboard evenly.

Hacksaw

Chipboards are a very difficult material to cut due to the high content of hardened glue in them, which binds small particles of wood. Cutting it with a hacksaw is difficult and time-consuming, but if there is no other choice, then it is possible. And quite high quality. To do this, you need a hacksaw with slightly set, hardened teeth.

Source onlinetrade.ru

Instructions on how to cut laminated chipboard without chipping with a hand saw:

- make markings;

- Using a sharp knife, cut through the decorative laminated layer using a ruler or rule;

- glue masking tape on top and transfer the markings to it;

- we cut the workpiece with smooth movements, holding the blade at an angle of about 30 degrees to the surface;

- remove the tape and process the defects first with a file, then with fine-grained sandpaper, moving from the edges of the cut inward.

Jigsaw

Before cutting chipboard with a jigsaw, it is advisable to install a bimetallic laminate file with teeth pointed inward. It gives the cleanest cut.

Source abc.ru

You can even cut complex radius parts with a jigsaw, but it is difficult to avoid the formation of chips. However, there are a few tricks that can help you deal with this problem.

- Using masking tape.

The adhesive tape glued to the cutting line will hold the laminated layer when the saw moves in the opposite direction.

- Cutting between two notches.

On both sides of the markings, you need to cut the laminate with a sharp knife so that between these notches you get a distance slightly larger than the thickness of the file. Then the chips will break off along these lines and will not go further.

- Sawing through the overlay.

Chips on the surface are formed primarily due to poor pressing of the edges of the cut. When moving, the sole of the jigsaw is not able to reliably hold the top layer, which is destroyed during the return movement of the cutting blade. Therefore, before sawing laminated chipboard, you need to make an overlay on the sole of the jigsaw from thin plastic or cut the workpiece through a thin sheet of fiberboard or MDF, holding it with clamps.

All methods for cutting chipboard, plywood, and laminate with a jigsaw without chipping are shown in the video:

If you make a stop and guide the jigsaw along it, the cut will be even cleaner.

Sawing with a format saw

To cut with a machine, the workpiece is placed on the left fixed table up to the adjustable stop. The required length is measured. The saw unit starts. When the disk reaches the required speed, the table moves forward.

The workpiece, together with the table, is fed onto the disk for sawing off the desired piece.

- workpiece position;

- depth of cut;

- cutting angle.

- light (designed for a workload of five hours);

- medium (8-10 hours);

- heavy (16-20 hours).

Scratch

Using a ruler, scratch the marking line with an awl or nail to the thickness of the laminated coating. Saw along this mowing line, making sure that the edges of the saw teeth fall exactly into the scratch. You can cut with a jigsaw or a hand saw.

Design

The most popular models are Mj 45kb-2, JTS-315SP SM, Woodtec ps 45, Altendorf F 45. Despite their different features, they have a common design.

Required components of a cutting machine:

- The bed is the base on which all mechanisms are attached. Heavy beds eliminate vibrations and vibrations, which is extremely important for precise cutting.

- A saw unit consisting of two disks. The first disk is located in front of the unit and is used for preliminary filing of the workpiece. The second is for completely sawing the slab.

- Three desktops. The first one is stationary; a node is located on it. The second, format, is movable; it feeds the slab onto the disk . The third supports the parts to be sawed off.

- The carriage is a part that allows the format table to move.

- Stops and rulers that secure the workpiece in the required position.

Depending on the model, price and cutting features, machines may have different design nuances.

- a pipe that removes shavings and sawdust and connects a dust removal system;

- clamps for securely securing the workpiece to the table;

- a rotating ruler and corner stops, with the help of which the cut is made at the desired angle and without markings;

- frame with a stop leg for cutting long workpieces;

- ball and roller carriages.

The first formatting machine with a moving carriage was assembled in 1906 by the German carpenter Wilhelm Altendorf.

What tools can you use?

Hacksaw

This tool is used for the good old scratch method. It must be said that it is difficult to achieve good quality cuts with a hacksaw.

The algorithm of actions is as follows:

- First, we scratch or cut the measurement line along the material with some kind of sharp-cutting tool (for example, a knife) and glue tape along it. It is needed in order not to damage the laminated coating.

- We direct the hacksaw to the material at an angle of 30 degrees and smoothly move it back and forth. In this case, chips from it will definitely remain.

- If damage from the hacksaw remains, then we go over it with a file (from the edge to the center).

- The final stage is to sand the laminated chipboard sections so that there are no rough edges left.

The main advantage of a hacksaw is its accessibility and ease of use, but at the same time it does not perform the function we need to prevent chipping, so we do not recommend using it.

Jigsaw

A jigsaw is the most popular solution at home, since the tool itself does not cost exorbitant amounts of money, and therefore is accessible to the average consumer.

Files for cutting tabletops using a jigsaw should be chosen of small length (not exceeding 75 cm) with teeth of classes A or B, suitable specifically for laminated chipboards.

When cutting with a jigsaw, you need to make smooth movements with the tool without pressure at a speed slightly above average. Most likely, chips will appear on the opposite side of the slab from the one into which the jigsaw teeth enter.

Chips during the process appear on the back side of the slab and spoil the appearance of the part. They can only be removed with a milling cutter, which means an additional amount of work and waste of material. Therefore, this tool is not suitable for us.

A circular saw

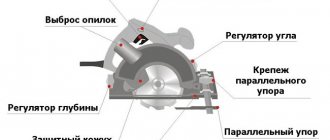

A circular (or circular) saw is another tool that can be used to make furniture parts.

To cut, you need to mark guide lines on the slabs and secure the saw to the board, but it is not a fact that the edges of the parts will be smooth. Chips appear on the back side of the slab. And they can only be processed using plastic profiles with latches on the ends of the chipboard. But a circular saw is not the cheapest pleasure, and even with it you will not avoid chips, so in this case there is no point in overpaying.

Fraser

Another option for cutting laminated chipboard is using a power hand woodworking tool. It is used in conjunction with a jigsaw. The process looks like this: first cut the chipboard with a jigsaw, moving slightly away from the markings, and then with a cutter with a bearing, which deepens the cut to the desired level.

The main disadvantages of this tool are that it is not as widespread as, for example, an angle grinder, and not everyone has it in their home. Well, its use is a rather labor-intensive process that only qualified specialists can handle, and beginners should not even approach it.

Slitting machine

The most correct cutting and a guarantee of the absence of chips can be provided by only one tool - a format-cutting machine, which is classified as professional equipment. Since the machine is very expensive and is used mainly in production, amateurs usually cannot afford it. The only optimal solution in this case is to turn to professionals. Companies specializing in cutting furniture parts usually use just such machines.

Format saws have the following settings, which are set depending on the length and width of the slab to be cut:

- workpiece position;

- depth of cut;

- cutting angle.

The machines themselves are divided into the following types:

- light (can work 5 hours);

- medium (can work from 8 to 10 hours);

- heavy (can work from 16 to 20 hours).

Components of a format-cutting machine that ensure accuracy and absence of chips in the manufacture of parts:

- the bed is the stationary base of the machine on which all other mechanisms are attached. The heavier it is, the better for cutting, since this eliminates vibrations and vibrations that could interfere with the process;

- scoring unit - an element that pre-saws the workpiece of the part and serves to ensure that there are no chips from below;

- the main saw is used for final sawing of the slab and is responsible for a clean cut without chipping on top;

- desktops - there are only three of them. The first is stationary and serves as the basis for the scoring unit, the second is movable, and on it the slab is fed to the disk, the third serves to support the parts that are sawn off from the slab;

- carriage - part of the machine that allows the format table to move;

- stops and rulers are components whose main function is to secure the plate in the desired position.

The design of format-cutting machines allows them to provide such precision in cutting laminated chipboard parts for furniture that no other tool can guarantee. In addition, this is the only method that allows you to completely avoid chipping.

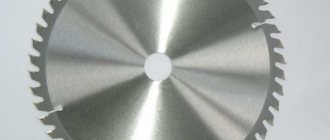

What kind of disc to cut chipboard without chipping?

Before we talk about the absence of chips when sawing laminated chipboard and deciding what to cut with , let's define what it means without chips? Everyone has their own opinion about the number of them after cutting, for some one is too much, but for others a dozen are just right. of chipboard cutting available at home , from which you can choose the most suitable one. For obvious reasons, we will not consider the use of expensive equipment designed for sawing laminated chipboard; this is for professionals. We are still amateurs in furniture making and therefore we will use the appropriate tool. In the photo there are three parts, the top one was sawn with an electric jigsaw, the middle one was sawn with a hand-held circular saw (parquet), and the bottom one was also sawed off with a hand-held circular saw, but then processed with a hand-held router. Of course, in each case you can achieve different results, it’s all a matter of experience and skill. But in general, the capabilities of the equipment under consideration give approximately the same results for chipping on laminated chipboards .

Sawing with undercut

You will need a large ruler (tire), which is fixed to the workpiece with clamps. The first cut is made to trim the laminate along the marking mowing line. The tire must be installed on the mowing line, and the cut must be made to a depth of 6-10 mm - there will be no chips.

We saw chipboard at home.

The second cut is made through. There will be no chips on the mowing line where the teeth enter the slab, but at the exit point the laminate has already been cut off, so they simply cannot happen.

READ The Better Way to Saw Chipboard

We saw chipboard without chips

Manufacturing

Manufacturing begins with the main components and ends with smaller ones.

Stages of making a machine for cutting chipboard with your own hands:

- Manufacturing of the bed. Square or round pipes will be required. They are cut and fastened to each other using clamps. After checking the dimensions and correct location of the components, welding begins.

- Manufacturing of a movable carriage. Install guides, preferably a beam or two round pipes connected to each other. The carriage must be equipped with rollers for smooth sliding.

- Making a desktop. The base is made of a steel sheet with a thickness of at least three millimeters, the working surface is made of a sheet of chipboard, and measuring rulers are attached to it.

- Production of clamps for sheets, for example, from a lever mechanism of any configuration.

- Upon completion, the cutting unit is connected to the chip suction unit.

The quality of finished products produced on home-made machines is higher than that of products created entirely with hand tools, but still lower than on industrially manufactured machines.

Required tools and materials

The saw unit of the machine is most often a welded structure, since it most effectively resists vibration.

- welding machine;

- “grinder” with a metal disc;

- electric drill;

- measuring tool.

In order for the equipment to operate for several years, it is better to choose those materials for its manufacture that have been subjected to heat treatment.

- square or round pipes;

- a beam or two round pipes connected to each other;

- rollers;

- steel sheet with a thickness of at least three millimeters;

- chipboard sheet;

- lever mechanism of any configuration.

The best saw blades with a diameter of 216-260 mm

Accessories for circular saws with a diameter of 216-260 mm are used for sawing boards, panels and bars of large cross-section. The maximum thickness of the workpiece should be slightly less than the radius of the disk (105-120 mm).

But if the cut edge is further processed or veneered, then it is allowed to cut through the wooden element on both sides, combining two cuts, which doubles the maximum thickness. The TOP saw blades for wood for circular saws will show you which equipment to choose for cutting wood of different moisture content and type of cut.

Dewalt DT1957 CONSTRUCT (250x30 mm; 48 ATB) - cutting raw wood with nails

Sometimes there is a need to use especially strong saw blades that can easily handle the load and will not lose their sharpness when colliding with nails. The Dewalt DT1957 CONSTRUCT saw blade is well suited for such purposes. It contains 48 teeth with a sharpening angle of +10 degrees. It has thick soldering on the tips of the teeth, providing a wide cut of 3 mm.

+ Pros Dewalt DT1957 CONSTRUCT (250x30 mm; 48 ATB)

- It cuts quickly and without jamming - it cuts through 80x80 mm timber in 1 second.

- Excellent balancing - vibration is almost not felt, despite the tool diameter of 250 mm.

- Holds an edge well.

- Due to the thickness of the disc, it does not move to the side.

- On the disc itself there are clear instructions for sharpening the teeth.

- Four large slots that compensate for thermal expansion.

— Cons Dewalt DT1957 CONSTRUCT (250x30 mm; 48 ATB)

- Due to the thick cut, there is a large amount of dust in the air and a lot of chips remain on the floor.

- A sharpening angle of +10 degrees will have a worse effect on finishing products.

- Not well suited for end cuts where you need to make precise measurements rather than just cut the timber into two pieces.

Conclusion. With such equipment, dismantling building structures with nails remaining in them will not be difficult. The owner will be able to work for more than a year without significant loss of sharpness.

CMT 292.216.64M (216x30x2.8/1.8 mm; Z64) - especially for cross cutting

Cross-cutting wood is not easy for every blade. The reason is the perpendicular arrangement of the fibers, which creates increased resistance. To understand which saw blade for wood is better in this case, you need to remember that it must have alternately beveled teeth. This provides a soft impact and allows you to make a cut without severe scoring or chipping.

CMT 292.216.64M (216x30x2.8/1.8 mm; Z64) is an excellent disc from the CMT brand of Italian origin. It has a diameter of 216 mm and 64 teeth, which are effective specifically for cross cuts.

+ Pros CMT 292.216.64M (216x30x2.8/1.8 mm; Z64)

- Soldering on the teeth helps to quickly cut even hard wood.

- Suitable for circular saws of any manufacturer with a 30 mm diameter seat shaft.

- The soldering lasts a long time despite intensive use of the circular saw.

- There are no explosions when cutting down the casing.

- Markings are provided for which types of wood it is best suited for.

- Four hook-shaped cutouts to accommodate expansion.

— Cons CMT 292.216.64M (216x30x2.8/1.8 mm; Z64)

- Some users received a crooked disc (with lateral runout), although there were no signs of damage on the packaging.

- To avoid chipping at all, it is necessary to also add a zero liner.

- Once it becomes dull, it is very difficult to sharpen it correctly yourself.

- If used on hardwood, it may burn the end a little.

Conclusion. An excellent choice for making a large volume of cross cuts, which then will not have to be processed additionally - all the ends can be made to size the first time.

Makita B-04597 (260 mm; 30 mm; Z70) - clean cut

On finishing pieces used in carpentry, it is important to cut the piece exactly to size to avoid chipping. For this purpose, special wood saw blades with a number of teeth of 70 or more are used. This increases cutting time, but promotes gentle handling of the fibers and ensures high cleanliness. The resulting edge does not need to be processed and can be mounted immediately, but the price of such discs is very high.

Makita B-04597 is a Japanese disc with a diameter of 260 mm and 70 teeth. The cutting part has wide tips and ensures a clean cut thanks to its gentle action.

+ Pros Makita B-04597 (260 mm; 30 mm; Z70)

- Very clean cut - especially on enamel surfaces.

- Suitable for the most demanding topcoats.

- During operation there is no ringing inherent in cheap cutting elements.

- The steel is bending hard.

- Particularly strong alloy.

- Suitable for any circular saw with a bore diameter of 30 mm and a rotation speed of up to 3670 rpm.

— Cons Makita B-04597 (260 mm; 30 mm; Z70)

- The cost is over 4000 rubles.

- It has a decent weight, more than other models.

- The cutting width of 2.3 mm can bite the equipment at a slight inclination.

- It takes time to learn how to saw with it without further processing.

Conclusion. This is a good choice for a workshop making furniture or other carpentry products. Featuring five expansion slots and five curved grooves, the disc features low vibration and quiet operation.

Sawing rules

First you need to choose a cutting method.

Be sure to carry out the following preparation (cutting):

- To protect the laminated surface of the board from damage during operation, you need to prepare masking tape or tape;

- for marking workpieces - a ruler and a pencil;

- From the ends of the slab, mark future cutting points with a pencil;

- in order to prevent chips from appearing, you need to stick masking tape or adhesive tape to the cut area;

- after gluing the tape, connect the preliminary marking points with a pencil;

- prepare sandpaper to finalize the cut lines.

The following rule applies not to preparation, but to actions after cutting, but is general for any method: if irregularities are found on the edges, then they need to be processed with a file or rasp. The ends resulting from cutting are covered with veneer with a pattern similar to the pattern of the laminated coating.

Sawing chipboard - methods and methods of processing

[contents]If you have at least once tried to cut chipboard at home, then you know for sure that this work is by no means easy and requires not only skill, but also the availability of a good tool. Laminated chipboard is especially difficult to process; when cutting it, many chips often form. That is why many craftsmen, faced with such a problem, come to the conclusion that it is better to cut chipboard when purchasing, especially since many trading organizations provide similar services and the price is quite reasonable.

Chipboard sawing is carried out using precise format-cutting machines, which will help obtain workpieces of a given size and shape.

Modern models allow smooth sawing of slab materials not only in horizontal and vertical directions, but also at an angle.

In addition to cutting sheets, they will help you calculate and provide in the form of a visual video file several options for competent and economical cutting of sheet material (using special computer programs) and, if necessary, perform edging. However, if for some reason you prefer to do this work yourself, you will have to do some preparatory work cutting

How to choose a saw blade for circular and miter saws

5/5 — (3 votes)

The saw blade has a number of parameters that any user needs to know. First, it must be the perfect size for the specific instrument. Secondly, a whole range of shapes and design of the disk affects what material will have to be processed. Thirdly, do not forget about the many manufacturers on the market offering products of varying quality. All this and more will be discussed further in this article.

It's no secret that properly selected equipment is the key to successful work. Wood and its derivatives are very popular materials in our country. Therefore, the area of use of the saw blade is quite wide, both in a professional environment and in the domestic sphere.

The saw blade is the main attachment for the following tools:

- Circular (circular) saws;

- Miter saws;

- Woodworking machinery.

The main criteria for selecting a disk are its size ratio with a specific tool and the material that needs to be cut with this disk. Let's look at the criteria in more detail.

The saw blade has a dimension. |

In order to choose the right saw blade, you must know its internal (landing) and external diameter.

The outer diameter ( D ) of the disk directly affects the depth of cut and has certain maximum size parameters (65-500 mm), limited by the casing and design of the tool. It is permissible to install a blade on the saw with an outer diameter slightly smaller than the factory standard (by 5-10 mm). At the same time, the depth of cut will decrease slightly (2.5-5 mm, respectively).

The seat diameter ( d ) of the disk must ideally coincide with the diameter of the circular saw shaft (10-50 mm) on which it is installed; even the slightest play is unacceptable. It is possible to adjust an internal diameter of a disk that is too large using special adapter washers (example in the figure below). They are often supplied with a new drive.

The thickness (T) of the saw blade can vary from 0.7 to 4 mm and determines the thickness of the seam when cutting. Of course, the larger the outer diameter of the disk, the higher the minimum permissible thickness will be. A thin disk will cut faster and process the material more economically, while a thick disk will be more durable and durable.

As the outer diameter increases, the number of revolutions for which the saw blade is designed decreases. You need to select a disk so that its maximum speed exceeds by a margin the maximum speed on the output spindle of the tool where the saw set is installed.

Under no circumstances should you attempt to install saw blades for circular and miter saws on angle grinders (angle grinders), even if the mounting diameter is suitable. They are designed for a certain number of revolutions when used. As a rule, it is less than what a high-speed angle grinder produces. This is fraught with the risk of the saw blade flying apart during the sawing process, which is very dangerous.

The design of the cutting elements of the saw blade. |

This criterion is more extensive and includes such structural elements of the disk as the type of disk, the number of teeth and their shape.

All saw blades are divided into two main types : monolithic and carbide.

Monolithic saw blade

is the original type, which is not very popular now, but is still found on the market. It consists of a solid metal base of the body and teeth made of high-carbon (higher quality) or high-speed steel. The disc teeth are set and sharp, which must be constantly maintained. It must be said that they become dull very quickly, and sharpening them is very difficult. This is precisely the reason for the unpopularity of this type.

Types of teeth of a monolithic disk:

- Sharp teeth - suitable for cutting hard and soft wood, clean longitudinal and transverse cuts.

- Curved teeth – used for working with soft wood and simple cutting, have a wide backrest.

Carbide saw blade

has a disk body consisting of tool steel and reinforced soldering on each tooth. Soldering, in turn, can be made from cobalt, tungsten carbides, and artificial diamond. Thanks to this design, such disks are very popular, as they have many advantages:

- Very durable and strong, soldered teeth dull very slowly.

- High cutting speed, and the quality of the cut does not decrease, but on the contrary - cleaner and more accurate.

- More versatile and allow you to cut many materials (wood and its derivatives, plastic, laminate, metal tiles).

- Huge selection on the market.

The only disadvantage we can note is the difficulty of sharpening the solder tips, which requires specialized equipment. In addition, soldering tends to fly off over time, which depends on the quality of their factory soldering to the disk body. But you can use the disc even if you lose 20% of the teeth, the main thing is that they are not located in a row.

What does the number of teeth on a saw blade affect?

The frequency of the teeth is related to the shape of the teeth and the sharpening of the tips. It is better to consider these elements together and identify several main types of saw blades depending on what material needs to be cut and what quality of cut is needed. Let's consider three main types of configuration:

Saw blade for wood and its derivatives (plywood, chipboard) with a positive tooth angle (a). Has high cutting speed and better performance. Alternating one-sided sharpening of teeth (A and B) is suitable for rapid longitudinal and transverse cutting of wooden workpieces.

20-24 teeth – a small number of teeth expels sawdust well and is more suitable for soft wood. An aggressive cut cuts faster, although not very cleanly.

36-48 teeth – a medium number of teeth will do a better job of cutting hardwood, plywood and chipboard. The cut will be cleaner than the previous version.

Saw blade for laminate and other materials with a laminated surface. Such discs are more often found with a positive sharpening angle, but they are also found with a negative one for working with thin workpieces. Trapezoid-shaped teeth perform dirty sawing (A), and straight teeth (B) at a lower height finalize the cleanliness of the edge.

40-64 teeth – frequent tooth arrangement, allowing use with laminated delicate materials. A good quality cut will take place slower than usual, with additional load on the tool.

Saw blades for aluminum and metal profiles have a negative tooth angle (a). Trapezoid-shaped teeth perform dirty sawing (A), and straight teeth (B) at a lower height finalize the cleanliness of the edge. As a rule, such discs are thicker or made of higher quality material, as they must withstand additional lateral load.

80-120 teeth – a large number of teeth provides the cleanest cut, smoothest edges and is suitable for working with thin materials. Theoretically, such a disk will be suitable for working with wood materials, and the cut will be of very high quality, but the work speed will be low and the load on the tool will be high.

Tooth shape

The saw blade plays a huge role in the quality of the cut. You can see a huge variety in this component. Many manufacturers improve the characteristics of the blade precisely by improving the shape of the tooth, so carefully study the purpose of a particular saw blade. Let's look at common discs depending on their tooth shape:

- Fine tooth blade with feed limiter at the end for longitudinal cutting of the hardest types of wood.

- Grooving saw blade for cutting blind grooves, as well as profiling and quartering for soft and hard wood, chipboard and plastic.

- The tapered scoring disc allows you to vary the groove thickness by increasing or decreasing the feed height in lightweight materials.

- Saw blade with almost flat, elongated teeth for cutting sheet metal, sandwich panels, metal pipes, etc.

- Diamond-tipped saw blades for angle grinders for sawing wood, metal, plastic and concrete. There are many types, you should be careful when purchasing data and choose only high-quality and trusted manufacturers.

Of course, these are not all types of tipped saw blades, but they are the most commonly used. If there is difficulty when purchasing and understanding what configuration a disk is required, then the manufacturer indicates all its data and purpose on the factory packaging.

The saw blade may have compensation and sometimes damping slots in its design, which significantly reduce its heating during operation, reduce vibration and noise. The slots are made in the form of grooves extending from the top edge to the center, with thickening or rounding towards the end to reduce the dynamic pressure on the disk body, which further increases its strength.

A little about the manufacturers - which saw blade is of better quality |

Beware of counterfeits or low-quality saw blades, these are unsafe. So, if the quality does not inspire confidence, it is better to refuse the purchase. Keep in mind that a good disc cannot be cheap. The data on the body itself of high-quality specimens is laser engraved and may even contain a barcode, rather than painted with regular paint or made in the form of a sticker.

Each manufacturer has its own way of designating the quality gradation on its saw set. For example, in the form of several quality series: master, pro and expert; number of icons - stars on the packaging of the standard, expert, etc. series. from Bosch.

The “low” series uses simpler steel, while the high series uses high-carbon steel of better quality. The brazing on the teeth can also be made of carbide or stronger diamond plates. Solders are attached to the disk body by thermal crimping or laser spot welding. Any quality addition will add to the cost of the product. Because of this, the “high” series are often an order of magnitude more expensive, but they will last much longer and their reviews are mostly positive.

| Site rating: prof. manufacturers | ||

| 1. | Bosch | They have exclusively positive user reviews. A huge range of quality, size and disc accessories. |

| 2. | CMT | Simply excellent wheels, no worse in quality than Bosch. Not in first place only because of the very high price and so far poor distribution in our market |

| 3. | DeWalt | Professionals also praise these discs; they are especially pleased with the Extreme series, which is not afraid of either hard wood or nails in it. |

| Site rating: budget manufacturers | ||

| 1. | Attack | The Korean company has long proven its products, which are often purchased even by professionals |

| 2. | Practice | The best price-quality ratio, a huge range of sizes from different series. |

| 3. | Bison | Another pretty good saw blades at an affordable price. |

If for some reason you cannot determine the size of the blade for a circular or miter saw, then you can select it by company and specific model of the tool in a separate article on our website.

| ¦¦ THIS IS INTERESTING ¦¦ |

|

Conclusion. |

The first thing you need to pay attention to when selecting a saw blade is its exact size. Having decided on the material that needs to be processed, the optimal disk design, number and shape of teeth will become clear. A correctly selected blade will cut faster and cleaner, plus there will be less load on the tool’s engine. And of course, don’t forget about quality and safety! We strongly advise against purchasing saw blades of dubious quality or using them for other purposes.

Have a good job!

4.2 12 votes

Article rating

Tools and materials

If possible, it is best to cut chipboard with a hand router using homemade guides. This method is not very convenient when cutting large sheets, because when working with this tool you need a table. In addition, with this method it is necessary to change cutters frequently. But as a result, you will get cleanly processed, “trimmed” edges.

READ Which blade is best for a circular saw

An electric jigsaw is the most popular tool for cutting chipboard.

Some craftsmen use a jigsaw in their work, however, in the absence of skill, it is difficult to make an even cut, and chips may form.

You can try installing a bimetallic blade with teeth pointed inward, designed for laminate, on a jigsaw. When cutting with a jigsaw, you should increase the speed, with a small feed, so that breaks do not form.

If such methods do not suit you, then to cut chipboard at home, we will prepare for work:

- a hacksaw with fine teeth (the one designed for metal work is best). In this case, the teeth must be set apart by 1/2 the thickness of the blade and be hardened;

- paper adhesive tape;

- file for rough processing of cutting line;

- sandpaper for finishing the cut of the mowing line.

The best saw blades with a diameter of 190 mm

This equipment is used for cutting small wooden materials - boards and timber up to 75 mm high. The small size of the disc allows it to be used on compact hand-held circular saws. Here is a rating of wood saw blades for circular saws with this diameter, which are characterized by fast cutting, cleanliness and fine cuts, and are also suitable for chipboard and MDF.

Bosch 2.608.640.633 190x30 mm - fast cutting

When cutting speed is a priority, discs with a small number of teeth are chosen. This design has less resistance during rotation and facilitates faster cutting of material. But due to the large distance between the cutting elements, the cut sides turn out to be rough and will have to be ground for finishing.

This disc from the German brand has 12 soldered teeth and additional reinforcement on the rear side. Leaves a kerf 2.6 mm wide.

+ Pros Bosch 2.608.640.633 190x30 mm

- Suitable not only for wood, but also for aerated concrete, cement-based fiber boards.

- It even cuts boards with nails.

- Very low price and proven brand.

- Interacts with a tool delivering speeds up to 4900 per minute.

— Cons Bosch 2.608.640.633 190x30 mm

- It can lead to metal if you cut for a very long time - the disk does not have cutouts for thermal expansion.

- The cut is not clean and requires additional post-processing.

- It is more suitable for longitudinal cutting - on a transverse cut it tears the fibers more, which spoils the quality.

- Over time, it begins to cut more slowly - the estimated service life is 4 years.

- The sharpening looks dull (a feature of the shape and technology), so it is not possible to determine the quality in a store - you just need to install it on the saw and try it.

Conclusion. This inexpensive blade is useful for quickly cutting wood when doing rough work.

CMT 272.190.42M (190x30/20/16x1.7/1.1 mm; Z42) - clean thin cut

For particularly fine cuts with a clean edge, thin blades with a large number of teeth are needed. Such equipment is used in the production of furniture, where neat, precise cuts and rational consumption of material are needed. But the price for this is the thin cross-section of the metal, which leads to snagging or deformation. This type of disk should be used more carefully than others.

CMT 272.190.42M (190x30/20/16x1.7/1.1 mm; Z42) - a particularly thin disk with a thickness of 1.1 mm. It has 42 teeth and leaves a kerf with a width of 1.7 mm. Manufactured directly in Italy and designed for finishing cuts.

+ Pros CMT 272.190.42M (190x30/20/16x1.7/1.1 mm; Z42)

- Suitable for circular saws with speeds up to 8000 rpm.

- Very quiet operation.

- It makes it easy to make longitudinal and transverse cuts in materials of various densities.

- Does not leave bristling fibers on the edges.

— Cons CMT 272.190.42M (190x30/20/16x1.7/1.1 mm; Z42)

- The price is much higher than analogues.

- Complex sharpening, which is not easy to restore at home.

- To install on some circular saws, you need adapter rings - those included in the kit are thicker than the disk itself, so the latter is not clamped to the end.

- You can’t rush too much when making a cut, otherwise it will be chipped.

Conclusion. Ideal for a furniture workshop. Allows you to cut through OSB and similar materials as cleanly and accurately as possible. Eight slots inside the disc provide good vibration damping and promote quiet operation.

Figure cutting

It is even more difficult to obtain curved surfaces of a given configuration at home, and you will have to spend additional money on purchasing a router that will help you get rid of chips and nicks formed when you cut chipboard.

The price of a hand router can vary significantly, depending on the manufacturer, power, and the presence of additional functions. If you do not plan to produce furniture professionally, then it is advisable to purchase an inexpensive model.

To cut chipboard you need to follow these steps:

- Having marked the contours of the required part on a sheet of chipboard, we cut it out with a jigsaw, trying to cut just a couple of millimeters away from the intended cutting line;

- we make templates of the design radius from fiberboard or plywood and carefully sand the ends with sandpaper;

- Having attached the template to the part to be finished, clamp it with clamps and process it with a hand-held copying cutter with a bearing, removing excess material exactly to the intended mowing line.

In this case, it does not matter which cutter (with two or four knives is used). The only condition is that the knives must cover the entire thickness of the cut being processed. After processing, all that remains is to glue the edge onto the part. How this is done - look at

How to cut chipboard without chipping?

Before starting to cut chipboard, especially laminated chipboard, we cut a line with a sharp tool along which we will cut and glue paper tape with a sticky layer along it. This will help minimize damage to the decorative chipboard layer.

To ensure that there are as few chips as possible, it is necessary to direct the movement of the hacksaw at an acute angle to the surface (no more than 30°). Movements should be smooth, without excessive pressure on the plate or sudden jerks.

If chips still cannot be avoided, we process the cut first with a file, working in the direction from the edges to the center, and then with fine-grained sandpaper. You can also mask all defects by using, where possible, a flexible profile.

What not to cut chipboard

If the volume of work is large enough and the quality requirements are low, some craftsmen advise sawing chipboard at home using a grinder (angle grinder, commonly called an “grinder”). In doing so, they use a disk designed for working with wood. To make cutting easier, a guide bar is secured along the cutting line using clamps. Cutting chipboard using a grinder can sometimes be seen in the video.

Attention, important! This method is absolutely unacceptable, since the likelihood of injury during operation is very high, especially if large-diameter discs are used and the protective casing is removed from the grinder.

Sources:

https://stroi-obzor.ru/strojka/kakim-diskom-pilit-dsp-bez-skolov/ https://drevplity.ru/dsp/raspilovka-dsp-sposoby-i-metody-obrabotki