Good day, dear readers and subscribers of Andrey Noak’s blog. In this article, I continue to talk about sawmills, namely, which band sawmill is better. To get a decent output material and make money on its production, you need to take into account all the details. I will tell you what exactly you need to pay attention to when choosing a machine.

Sawmill and output material

A sawmill is a special machine or set of machines that are designed for woodworking, namely for sawing logs. Using a sawmill you can prepare:

- Bars;

- Boards;

- Gorbyl;

- Sleepers;

- Wood chips;

- Sawdust.

The most common sawmills today are:

- Tape;

- Disk;

- Frame machines;

- Milling canter lines;

- Tire (chain);

- Combined lines.

To find out which sawmill is profitable to buy, we will compare all the advantages and disadvantages of different sawmills.

Approximate yield by variety

The following tree species are preferable for the manufacture of lumber:

- deciduous - beech, aspen, poplar, birch, alder, linden.

- conifers - pine, spruce, cedar, fir, larch.

For each breed, the yield differs in percentage. Indicators characteristic of coniferous forest:

- When working with a circular saw with a circular saw, output volumes of up to 85% are achieved.

- When sawing using machines, 70% of edged lumber is obtained.

- When cutting with a chainsaw, about 30% of unedged lumber is obtained.

When processing deciduous wood, about 60% of unedged boards are obtained. The reason for such a high rate is the curvature of the source material. To solve this problem, special additional equipment is installed on the machines. The resulting production lines increase yield by 20%.

The percentage of lumber yield depends on many factors. This indicator is influenced by the quality and size of raw materials, tools for work, and processing method. With the right approach, you can achieve fairly high results.

Tape

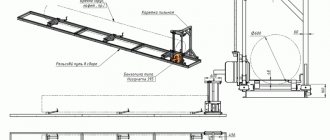

This is probably the best and most popular sawmill among small entrepreneurs and organizations that prefer to produce large volumes but with individual cutting. Models of band saws are so diverse that they can be used not only in industry, but also at home, for example, the KEDR or Altai “mini-sawmill” is very easy to install, since it requires low installation and foundation costs.

The operating principle of the machine is based on the rotation of a band saw. In turn, the sawmill can be either gasoline or electric, and this is also a big plus.

Tape is a leader in the sales market due to its small size and affordable price. In addition, it is easy to care for - sharpen the saw on time and monitor the alignment of the teeth; I wrote more about setting up such a sawmill here.

Peculiarities:

- Minimum amount of waste;

- Ability to work with very large logs (110 cm on the KEDR sawmill);

- Small cutting width (mostly 2.5 mm, but for the KEDR model it is only 1.9 mm);

- Low price;

- Excellent quality of the output material, except for problems with the wave;

- To mount the machine, you do not need a foundation or its quantity is minimal;

- No need for a warm room;

- Convenient and quick to configure operating parameters.

Other differences of the band sawmill:

- High accuracy and speed of operation;

- Best at sawing huge logs;

- Installation takes only 2 hours without installing foundations.

What to look for?

When choosing a sawmill, consider five important points:

- Type;

- Tension unit;

- Raising and lowering the dusty carriage;

- Correct pulley;

- Foundation and slot guides.

Let's look at every point so as not to make a mistake in choosing the ideal sawmill. In this matter, every nuance is important; if you really want to make money on your machine, you need to take your choice very seriously.

Type

In fact, many have already come to the conclusion that tape is one of the best options for them. But in any case, you need to find a machine with maximum performance. Consider the material with which the work will be carried out, as well as the technical conditions. So, when choosing the type of machine, pay attention to:

- Maximum and minimum diameter of sawn wood;

- Lengths of processed logs;

- Type of chainsaw - gasoline or electric;

- Dimensions;

- Power.

Tension unit

In fact, this is very important, because the service life of the band saw will depend on the tension unit.

During your work, you will encounter the fact that particles of bark or knots will get between the saw and the pulleys. The tension will determine how the saw reacts to it. If flexible tension is used (screw-nut system, with a shock-absorbing spring), the impact will be soft and the saw will last longer.

A lot of manufacturers still use rigid tension, which is bad for the saw itself. In addition, frequent replacement of mechanism parts is very expensive, and this will increase the cost of each cubic meter.

Raising and lowering the dust carriage

The dusty carriage has a fairly large mass. If it goes up and down on the chains, they will probably stretch out after a while. This can play a cruel joke on the output material. The price of low-quality products will decrease significantly. To save yourself from unnecessary costs, choose a machine with a manual or electric system.

Pulley

It often happens that the pulleys of a band sawmill cannot withstand the load and break right during the sawing process. A common cause is hidden defects in the material used. A low-quality pulley is made from recycled material or scrap metal, but it is quite difficult to detect defects, because they are painted over during production.

If necessary, I suggest purchasing a pulley separately, from a single sheet of metal.

In addition to the material, you need to pay attention to the diameter of the pulley and its width. There are myths about its diameter, especially on thematic forums. For example, users believe that the larger the diameter, the longer the saw will last. But this is not so, quite the opposite. A large diameter will increase costs, because the length of the band saw depends on it. If you choose the pulley diameter wisely, you can save up to 100 thousand rubles just on replacing saws!

Foundation and slot guides

As I said above, it is possible to install a band sawmill without a foundation, but a minimal difference in the height of the rail track can lead to defects in the finished product. Low-quality lumber may not pay for itself, which will lead to large losses.

To remove the wave effect, slotted guides are used. They keep the saw from wobbling up or down on the material. In the absence of slot guides, the saw will look for the “easy” path in the log and at the end you will get a completely low-quality product.

From all of the above we can draw a small conclusion:

Band sawmills are very cheap both to maintain and to install. They can operate from an internal combustion engine, an electric motor of 380 Volts or 220 Volts.

They have the ability to process very large logs with a high percentage of lumber yield. This machine can be made at home.

Among sawmills, I would mention Altai, Kedr, Taiga. Here you need to compare specific cutting parameters, log diameter, price, foundation and cut thickness. In addition to band sawmills, I propose to consider other technologies for sawing wood.

What to look for when choosing?

When choosing a suitable model, you must first consider the specific needs of production. In order to choose the best option in terms of price-quality, you need to focus on the following parameters:

- size and quality of processed wood;

- place of use of the equipment;

- expected scope of work;

- quality and range of output material;

- requirements for the qualifications of working personnel;

- equipment service life;

- equipment maintenance costs;

- start-up capital.

When choosing a machine, some users consider the frame design (cast or welded). A cast frame seems to be a more reliable solution, but it significantly increases the cost of the machine. Meanwhile, practice shows that a cast frame does not guarantee a longer service life: moving parts fail much earlier. Decide in advance what material you need to get at the output. Band-type sawmills are suitable for working with very thin sections, frame sawmills are suitable for wood with a diameter of 50 cm or more. An important point for selecting a model is the type of wood with which you will be working. For logs of small diameters (thin gauge), you should not choose high-power equipment - this will increase the cost of lumber. Band sawmills will also be effective because they require a lot of labor (each cut is one “pass” of the band, and the output from thin logs is small). The optimal solution would be to use a through-type milling-canter machine, which allows you to cut a log in one pass.

Frame saws

Frame sawmills are used in large enterprises, and of course, such an enterprise must have the ability to process sawdust (a large amount of waste during operation). The installation of the machine requires a foundation, and the operation uses a large amount of energy.

Advantages:

- High cutting quality;

- Great productivity;

- Long term service;

- Easy to use even in severe frosts;

- Very reliable.

But unfortunately, this sawing technology is becoming outdated and today I would not take a new sawmill frame, since there is more productive and economical equipment, which I will discuss below.

Types of sawmills

The modern market for woodworking machinery offers the following types of sawmills:

- tire;

- tape;

- disk.

Disc sawmills come first in popularity on this list. The reason for this is ease of operation, high performance and long service life. In addition, their cost cannot be called high. However, band and tire sawmills are just as good units as disk sawmills, only their productivity is slightly lower. The design of these sawmills is more complex, which is the reason for their higher cost.

Disc sawmill and milling lines

These machines are reliable and have great capabilities. To some extent, disk ones can include both conventional ones from “KARA MASTER” and such milling-canter lines from or “LINCK”. But the cost of circular sawmills exceeds the cost of other types, and this is its main disadvantage.

Circular sawing equipment for sawing wood.

Features of disc machines:

- Has different cutting patterns;

- Easy to install, operate, and maintain;

- Convenient for transportation;

- Can be used anywhere, even in the forest;

- High speed and accuracy of work;

- Good performance.

Disadvantages of a circular sawmill:

- Large amount of waste due to increased cutting thickness;

- High price.

Sawmill technologies

To begin with, it is worth knowing what basic woodworking technologies are used today, the features of each, advantages and disadvantages. Here are the following popular sawmill technologies:

- Band saw;

- Circular saw.

In the first case, sawing of logs is carried out by a metal strip connected into a ring. It has teeth cut on it, which can be on one or both sides. The tape is flexible but durable; for operation it is attached to two simultaneously rotating drums. For machines operating using this technology, a belt with a width of 20-300 mm is used. It is divided into wide and narrow, respectively.

This sawing technology was introduced into the wood processing industry not so long ago, but has already shown its advantages . So a wide belt (from 100 mm) is capable of sawing frozen logs, without the risk of dulling or breaking the teeth, since they are stellited - especially durable.

Equipment for sawmills, created using band saw technology, produces raw materials with a minimum cutting width, and therefore is the most in demand. Its only drawback may be its high cost, but this makes sense, since this way the highest yield is achieved.

High-quality equipment for a hairdressing salon is the key to the success of your business.

How to make woodworking production waste-free can be found at this address.

Circular saws are available in three types:

- Vertical sawing,

- Horizontal saws,

- Angle-shaped.

Vertical sawing of round timber is carried out on machines with one vertical saw, with a diameter of 900 to 1100 mm, which requires perfect balancing. Has the highest productivity due to high cutting speed.

Horizontal technology is used in equipment with a horizontal arrangement of two saws in the same plane. It is similar to band saw technology, but the saws have to be changed much less frequently, they work longer (up to 24 hours) and do not require frequent sharpening. For comparison: band saw technology requires mandatory removal of the tape every 2 hours.

Angle saw technology involves the use of machines where two to four saws are installed at right angles to each other. Such a device is capable of producing radial cut boards, and even processes wood with a diameter of up to 1 meter.

You need to know that there is no universal sawmill technology. Each of the above has its own advantages and disadvantages, so specific needs determine the application of any of them.

Tire (chain)

According to the principle of operation, it can be compared with tape ones. Unlike them, a tire sawmill uses a chain saw.

Advantages:

- Easy to operate and repair;

- Very simple and reliable design;

- Small sizes;

- Suitable for frequent transportation.

The disadvantages include:

- Wide cut - 6 mm;

- The chain needs to be changed periodically;

- Expensive parts.

Turning a log

When the remaining height of the log reaches the desired size, it is turned over. If you need to get a beam with a thickness of 150 mm, the sawn width and the remaining height of the log should be slightly larger than this size, taking into account the slab.

When the log is turned over, the remaining height after the cut is made is measured, and the material is calculated until this size is completely used.

Calculation example:

This is how logs are cut

- The remaining height of the log after cutting is 270 mm. The goal is to obtain a beam 150 mm thick: 270–150 = 120 mm.

- From 120 mm it is necessary to obtain a block of 50 mm: 120–60–3=57 mm. A value of 3 mm is given for the cut.

- Tesina 25 mm: 67–25–3=40 mm.

- Humper 25 mm: 40–25–3=12 mm.

- Croaker 12 mm.

Further production of lumber is achieved by turning the log at an angle of 90 degrees and similar calculations. One of the common mistakes is that the cut allowance is not taken into account or is added more times. The master needs to be careful.

Characteristics

| Productivity on unedged boards | 10—12 m³/shift |

| Diameter of horizontal saw blades | 550 mm |

| Diameter of vertical saw blades | 350 mm |

| Maximum log diameter | 550 mm |

| Carriage lift motor | 0.37 kW |

| Saw motor | 2x11 kW |

| Edge trimmer motor | 2x4 kW |

| Feed motor | 0.75 kW |

| Feed rate | 5, 8, 12 m/min |

| Voltage | 380 V |

| Processed log length | up to 6000 mm |

| Maximum cutting width | 420 mm |

Where there is no electricity

“PD-2000 Buran” is a circular rotary sawmill equipped with a PM3-640-34 gasoline engine with a power of 34 hp. With. (25.35 kW). It is intended for sawing round logs and blanks into all types of lumber - timber, beams, edged and unedged boards, etc.). Edged lumber can be obtained by turning the saw 90 degrees.

Among the advantages and features of this gas-powered circular sawmill are the following:

- Low operating costs.

- There are no drive components that significantly depend on the ambient temperature.

- Cutting can be done in both directions thanks to a circular saw with a diameter of 560 mm.

- The gasoline engine allows you to work in areas with poor electrification or directly on the plot.

- When sawing, the log does not bend; the parameters of the sawmill make it possible to obtain lumber with ideal geometry.

- Due to the reliability of the cutting element, the unit allows you to work with difficult-to-cut materials - with high density, resinous and rich knots. As wear occurs, the disc is replaced.

- Easy transportation and quick installation are a consequence of the comparative compactness and simplicity of the operating principles.

- Russian-made drive elements are used: bearings, motors, belts and other available parts.

- Ease of repair - there are no complex components and parts, frame elements are made of affordable, standard rolled metal.

Characteristics of the rotating disc sawmill "Buran":

- diameter of sawn log: 800 mm;

- processed log length: 6500 mm;

- circular saw diameter (external and internal): 560/50 mm;

- productivity on unedged boards 50 mm: 10-12 shifts/m3;

- maximum cutting depth: 200 mm.