DIY band sawmill drawings

Dear visitors of the site “ Samodelkin Friend”, from the presented material you will learn how to make your own band sawmill yourself. Every craftsman dreams of having his own sawmill on his farm, because its presence will reduce the cost of lumber tenfold. Using this machine, you can cut the logs into boards and bars yourself; it is also an excellent option for those who are building , that is, the boards can be produced directly at the construction site of the future house. It is also possible to open your own private sawmill and cut boards for money and replenish the family treasury with additional income. In general, the machine is very good from all sides, and its independent assembly will again cost much less than a factory analogue, because many spare parts can be used second-hand and available to the car enthusiast, for example: wheels from a passenger car, hubs, bearings, bolts and other things that you can get in the garage)

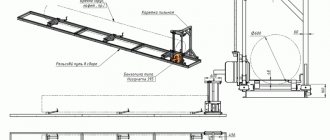

The design of a band sawmill consists of 1. a rail track 2. a frame with a power unit 3. a blade 4 adjustment and tension mechanisms 5. a carriage 6. a flat surface (preferably a foundation slab)

And so, let's take a look at the list of necessary components for assembling the machine. We will also analyze the whole process step by step.

Materials

- corner 100x100, channel, narrow-gauge rail (for the manufacture of rail beds)

- car wheels

- hubs

- bearings

- square corrugated pipe

- threaded stud

- chain

- jack

- IV

- power unit (gasoline or electric motor)

- fittings

- bolts, nuts, washers, engravers

- sheet metal 1 mm

- pulley

- belt

Tools

- welding machine

- drill

- emery

- Bulgarian

- hammer

- roulette

- set of wrenches

- Laser level)

- ruler

- corner

The process of assembling a band sawmill with your own hands.

And so, the first thing you should do is get acquainted with the drawings, because any business begins with markings, as they say, “Measure twice, cut once.

So we got acquainted with the drawings, and now I would also like to note that homemade sawmills come in several types1 Band sawmill with electric motor.

2. Band sawmill with gasoline engine.

3 Tire sawmill.

The operating principle of a band saw for sawing wood. The blade is tensioned on 2 horizontally located pulleys, in this case these are ordinary car wheels with a tire and a tube. The undeniable advantage of this design is that the saw can be tensioned by inflating the tires. The limiter and support rollers are located directly at the bottom.

Well, I hope the principle of operation is clear, then you should take care of placing a rail track along which a carriage with a saw blade will walk and cut the logs into boards. The area must be at least 3 x 6 m in size, and most importantly, level! Therefore, it is necessary to pour a foundation slab under the sawmill and level it to a perfectly flat surface. A recess is dug, a sand cushion is laid and a reinforced concrete slab is poured.

Next comes the installation of the rail track itself; at best, it can be made from rails from a narrow-gauge railway, but it is difficult to obtain, so you will have to make it from a channel or corner. Note. In the photo the corner is positioned edge up.

You can connect the corners to each other by welding, but when the metal heats up, it can lead, and we need a perfectly flat road. You can also attach the rail directly to the concrete base using anchor bolts.

Support rollers can be made from ordinary bearings, or ordered from a familiar turner.

After this, the saw frame itself is manufactured, using pipes of different diameters that can be inserted into one another. due to which the slider can rise up and down.

The frame is welded from a square-section corrugated pipe.

Support rollers are installed at the bottom. they must match the width of the rail track.

Next, the lifting mechanism is manufactured. Then the pulleys and hubs are installed.

Connection to the power unit.

The saw blade is leveled and supported by bearings.

A protective metal casing must be installed on top. Safety precautions are paramount here, because the canvas can fly out.

The tension mechanism can be made from a small jack.

After the sawmill is fully assembled, a test run is carried out; if everything is in order, the engine is turned off and the log is laid and secured.

The log unfolds into planks. You can also watch the work of the sawmill visually on video.

In general, this is such a wonderful sawmill, now lay out the boards and bars for construction and repair as much as you like, just have time to throw the logs)

Source: www.samodelkindrug.ru

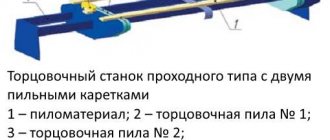

Review of popular models

One corner saw can replace multiple machines by reducing the time spent on operations, increasing productivity, and freeing up additional manpower.

PDPU-600

The single-saw (single-disc) corner rotary sawmill PDPU-600 is equipped with a circular saw with a diameter of 600 mm. The saw unit is mounted on a carriage. There is the possibility of horizontal and vertical sawing of logs. Productivity 8-12 m/min. Product yield up to 74%.

Specifications:

- diameter of the processed log – up to 900 mm;

- processed log length – up to 6000 mm;

- saw blade diameter – 600 mm;

- saw motor power – 15 kW;

- rotary unit drive power – 0.37 kW;

- engine power for vertical movement of the carriage – 0.37 kW;

- maximum dimensions of the resulting timber – 210×210 mm;

- overall dimensions of the machine (without guides) – 1400x2000x1800 (mm);

- rail track length – 10500 mm;

- assembled machine weight – 1000 kg;

- productivity of edged lumber – up to 6m3/shift;

- lumber yield – up to 74%.

The workpiece is secured to the guides using clamps. When sawing a log, it does not need to be turned or re-secured.

Main advantages:

- vertical movement of the saw carriage and rotation of the saw blade are carried out using an electric drive;

- it is possible to install additional options (laser cut indicator, electromechanical feed, etc.);

- can be equipped with a gasoline engine;

- has a small mass;

- compact;

- relatively inexpensive.

Flaws:

- it is necessary to level the rails with a level, with high accuracy;

- very thick lower croaker due to high hooks;

- sawdust constantly sticks to the chain feed roller of the portal, causing the chain to break;

- weak iron for the resulting vibrations and loads;

- To adjust the positions of the disks, the bolts are not with fine threads.

This sawmill is perfect for sawing small volumes of wood.

GRIZZLY-1000/150A

The machine is designed for sawing wood of various species into edged boards or timber.

The saw unit is a carriage with circular saws located orthogonally, which moves along a permanently fixed log. It is possible to make both tangential and radial cuts. Product yield up to 70%.

Specifications:

- diameter of the processed log – from 100 to 1000 mm;

- length of processed log – from 1000 to 6300 mm;

- vertical disk diameter – 450 mm;

- horizontal disk diameter – 400 mm;

- total power – 24.95 kW;

- feed speed – from 0 to 48 m/min;

- the maximum dimensions of the resulting timber are 150x150 mm;

- overall dimensions of the machine – 8950x2860x2960 (mm);

- machine weight – 1800 kg;

- control mode – automatic;

The design of the feed mechanism is electromechanical, which ensures rigid coupling of the mechanisms and prevents slipping or jamming when sawing.

The machine bed is a durable and wear-resistant structure, resistant to loads and vibration, which ensures reliable operation of all components and assemblies.

The Grizzly sawmill does not require a foundation, just compacted soil.

Clamps allow you to securely hold the workpiece on the sawmill bed. Due to the stationary fastening of the log, the absence of additional loads and vibrations is ensured.

Main advantages:

- maximum radial cut;

- workpiece diameter up to 1 meter;

- ability to work in any climatic conditions;

- finished products of export quality;

- compliance with safety requirements;

- there are no requirements for log curvature;

- stepless adjustment of carriage feed;

- cleaning sawdust into the machine hopper.

Flaws:

- imbalance of the structure (the left side is loaded with the carriage, the right side is empty);

- the guide beam is not fixed rigidly enough;

- For an ideal radial cut, the horizontal and vertical discs must be identical.

Thus, having considered two models with different characteristics, the consumer can choose the most suitable option for himself.

These shortcomings were identified during actual work on sawmills of the above-described models.

Mini sawmill

A mini sawmill will be an excellent device for starting a woodworking production or independently constructing a wooden cottage. Today, many people build and repair wooden buildings with their own hands. In order to quickly and efficiently process a tree trunk, you need to use a sawmill. In this article we will talk about how to make a mini sawmill.

Purpose

This equipment is designed for horizontal and vertical sawing of wood without turning the workpiece. It is used in the production of lumber of various qualities, including export. With its help you can make both a thin board and a square beam of various sizes.

The corner sawmill can produce all types of woodworking products from round timber of any species. For example, edged lumber (including radial), profiled timber, parquet, etc.

Using such a machine, you can make the surface of the finished product as smooth as possible. Taking this into account, circular sawmills are now widely used in the woodworking industry.

DIY mini sawmill

For domestic purposes, it is much more profitable to make a small sawmill with your own hands.

Pros of making it yourself:

- low material costs

- creating a design that fully meets your requirements and operating features

- The components needed for such a device can be found in any specialized store.

Of course, it will not be possible to create a device at the level of factory devices, for example, Murka, Kostroma, or Logosol, at home. But a simple sawmill, both mobile and stationary, can be created by any craftsman.

When creating a mini sawmill, be sure to consider the following points:

- you need to decide on the performance of your device. Unfortunately, homemade devices have poor performance. In order to calculate productivity you need to determine the volume of wood that you need to process

- dimensions of workpieces to be processed

- transportation. A mobile sawmill is more convenient because it can be easily moved for use in different areas of the home

- battery. Factory machines require power from a three-phase network of 380 V. However, for a homemade tool, 220 V is enough. For a sawmill, it is worth selecting a separate machine for 220 V. Thus, there will be no problems with other 220 V sockets. It is better to avoid using extension cords

- the type of compact sawmill being created - disk, belt or tire.

Mini disc sawmill

As an example, take a closer look at Murka and PD 2000. Such devices are in great demand in woodworking industries.

They are simple, have high productivity, and also do not cause problems when creating them yourself. The design is based on a circular saw, which can be mounted on the motor axis or the spindle shaft. To create the simplest model, you will need a shaft, a table, a motor and a circular saw. The main element of the design can be called a table. It is created from a metal frame, which is connected by welding and fastening bolts. There is a steel plate on top of the table. Such a plate must have holes that firmly fix the circular saw. It is into them that the cutting element is inserted. When installing the saw, you need to make sure that it is located in the middle of the saw.

Tire mini sawmill

The design is based on the following main elements:

- machine frame. It is the most important because it holds all the equipment equipment. Reliability, durability and safety directly depend on the frame. Dimensions are selected individually, according to the needs of woodworking

- power unit. Without a drive, of course, the sawmill will not work. For domestic use, a three-phase motor is suitable; it requires a power supply of 380 Volts. However, you can also use a gasoline engine. Power supply from 220 V is not suitable in this case, because the power parameters are very low. The minimum power parameter is 3 kW

- fastening elements. Using stationary components, you can make a cut by securing the workpiece to them. Dimensions of hardware are selected according to the parameters of the workpieces being processed

- tire. Usually the tire is 50 centimeters. The best option is to purchase it together with the chain. Thus, the thickness of the cut is minimized, and, consequently, the volume of waste is reduced

- cutting element.

The metal frame must be connected to the sawmill bar. The gap between the frame and the tire is the size of the workpieces being processed, so the drawing of the mini sawmill must include this point. If you wish, you can make it possible to adjust this gap. This useful addition will make it possible to process a wide variety of workpieces.

On the base you need to create guides along which the workpiece will move. To mount the base to the racks, you need to weld plates with drilled holes. After installation is complete, secure the position with nuts and bolts.

When making a homemade sawmill, be sure to remember to follow safety precautions. See how a mini sawmill is made correctly; a video of this process is presented below.

Band mini sawmill

Band sawmills do the best job of cutting boards. There are several methods for creating such a device. The driving force of such devices can be either electric or gasoline engines. There is no point in describing in detail a certain home-made design indicating specific parameters, because each master takes into account both the “scale” of such production and the availability of free space.

We will describe the general manufacturing procedure:

- room. Experienced craftsmen advise that for comfortable work with logs, choose a workshop space of at least 18 m2, for example 6 x 3 m

- the saw is positioned motionless during operation. The workpiece is placed on a special movable frame (trolley) and moved by hand. For this reason, you need to mount a metal frame to secure the saw. “Rails” from the corner are placed under it, along which the cart with the workpiece moves. The cutting is carried out in a horizontal plane. It is necessary to provide for a change in the height of the saw during the “dissolution” of the workpiece into boards. To do this, the frame is equipped with a special system that operates on the principle of a clamp, for example, a “lead” screw or something similar

- as a base you can take a metal corner or more serious structures, such as an I-beam or channel. Care must be taken to rigidly fix this frame to the installation site, because during operation it will be subject to high dynamic loads. Pay main attention to the evenness and horizontality of the upper beams - guides. The gap between the guides should be approximately 50 - 70 cm larger than the diameter of the largest log you are going to work with.

- Regardless of the thickness of the workpiece, it must be firmly fixed on the trolley. Wheels need to be attached to the bottom.

These are perhaps the most significant stages of creating a sawmill that you will encounter during its installation.

The disadvantages of homemade sawmills include:

- setup difficulties. Adjustment must be carried out continuously

- wide cut, which means a high percentage of waste

- The radius of waste scattering is quite significant

- The capabilities of the equipment are not high, both in terms of the dimensions of the logs and the time of continuous operation of the mechanisms.

Source: wood-prom.ru

Purchasing sawmill equipment

The cost of purchasing sawmill equipment is the most expensive part of the estimate. Saving on it is impractical - all machines, lines, units must be of high quality. Otherwise, you will constantly invest in equipment repairs, and forced downtime will become a frequent occurrence.

The set of equipment depends on the planned concept and type of production.

Standard equipment:

- band sawmill - give preference to models;

- that produce a minimum of waste;

- disc sawmill;

- multi-saw unit;

- edge cutting machine;

- line for the production of lining - the product is widely used for interior finishing work;

- end machine;

- sharpening apparatus;

- a set of computer equipment for employees.

Note! If you are experiencing financial difficulties and are not yet ready to launch large-scale production, limit yourself to purchasing only a band sawmill. The rest can be bought later - as profits come in. Alternatively, buy used, but high-quality equipment.

As for the manufacturer, domestically produced equipment and machines manufactured in China have proven themselves well.

How to make a band sawmill with your own hands?

[Do-it-yourself band sawmill] allows you to save significantly if there is a need for constant wood processing during the construction of houses, on the farm, or if you have your own small production.

Of course, you don’t have to rack your brains and buy a tool, but making it yourself, as mentioned above, will cost much less.

The band sawmill is better known to many as a band saw. Depending on the scope of work, the type of tool is selected.

The sawmill can be belt type, chain or disk type. We are considering tape type manufacturing.

How to organize a profitable sawmill business

To implement any project, you cannot do without a competent business plan.

Include the following points in the algorithm of actions:

- market and competition analysis;

- concept definition;

- financial plan;

- registration of documents;

- rent of a plot of premises;

- equipment purchase;

- raw material base;

- hiring employees;

- searching for clients;

- assessment of probable risks.

How does a sawmill work?

The principle of operation of a band sawmill is very easy to explain using the example of spools of thread.

The whole design resembles the rotation of two spools, between which a thread is stretched. This thread plays the role of a saw, and the distance between the coils is the maximum size of the log.

What a band sawmill allows you to do:

- Prepare logs, that is, adjust them to the same size and shape;

- Sawing logs according to a given pattern after setting up the equipment;

- After sawing, small defects remain that cannot be eliminated using homemade sawmills, so further processing of the wood is done manually.

The band sawmill works as follows: the log is fixed on the platform and remains motionless, the mobile cart begins its movement and cuts the tree, the saw is in a horizontal position.

In order to ultimately get a board of the desired size, it is necessary to initially set the parameters by the operator. The saw acts as a saw blade, which must be well tensioned.

How a homemade sawmill works, see the video.

Before work, you need to prepare the equipment: to do this, sharpen the saw and set the teeth.

What materials are needed to create a sawmill?

It should be noted that materials are selected depending on whether drawings are made or not, because it is the correct drawing that is the basis of a quality product, thanks to which the calculation of materials is made:

- Pulleys can be taken new or old in good condition;

- Pipes of different diameters;

- Rails - you can make it yourself from corners. It is better to place the corners edge up, this is necessary in order to extend the “life” of the wheels;

- Profile pipes for creating sleepers;

- Channel.

In addition to materials, you will need the following tools:

- welding machine;

- milling machine;

- Bulgarian;

- drill, it is more convenient to use an electric one;

- hammer;

- pliers;

- sets of screwdrivers and wrenches;

- clamp;

- bolts, nuts and other fasteners;

- rulers, tape measure, squares, etc.;

- hacksaw.

Sawmill design

The organization of work is based on the block principle.

It involves various variations of the device, starting from the basic one, where the saw is fed manually, to the most complex units, when the saw is fed automatically, the cutting thickness is set, the electronic system is programmed, etc.

Components of the structure:

- to organize the movement of the saw blade, a frame with two guides is used;

- screw mechanism for lifting the belt;

- hydraulic or spring unit for tensioning the tape;

- driving and driven wheels (pulleys);

- wheel guard casing;

- tape holder;

- V-belt transmission;

- electric motor;

- rail for carrying out the movement of the band saw;

- eccentric clamps for holding the block (log);

- emphasis;

- tank with liquid for wetting.

To create a smooth, reliable product, it is necessary to make drawings according to which the entire structure will be assembled.

At the same time, the drawing must be studied and understood, otherwise you can simply lose not only time, but also money.

First, the bed (fixed part) of the machine is made, which has a U-shape.

It can be made from two channels, which can be replaced with two rails (in the absence of the first materials). If you use rails, they need to be installed so that the sole is on top.

Manufacturing recommendations

To make a homemade sawmill work more efficiently, you should pay attention to some recommendations:

- The structure must be stable and strong, since you have to work with logs of different weights and sizes;

- Equipment assembly work must be carried out directly at the site where it is planned to be located. This is due to the massiveness and heavy weight of the structure;

- It is necessary to constantly monitor the operation of the equipment and adjust the settings, since the design is done by hand, without the use of precise programs and computerization;

- Homemade sawmills are “scattered” with shavings, so you need to either build additional structures or clean up after the work is completed;

- A wide band cut affects the generation of a large amount of waste;

- To ensure efficient operation of the mobile cart, it is necessary to use gaskets and plates, and the gaskets must be 0.5 mm thicker than the channel;

- The electric motor can be easily replaced with a gasoline engine. This option will be simpler, because you can use a chainsaw, or rather its engine. The chainsaw blade will serve as a tape. How to make a gasoline band sawmill, see the video;

- All fastening elements must be securely fixed to ensure safe operation of the entire structure;

- To ensure efficient operation, the saw must be sharpened and the teeth set apart.

Main characteristics of the models and their average cost

Before you start creating a sawmill with your own hands, you can compare the cost and characteristics of factory models. After comparison, decide whether to make it yourself or buy new equipment.

Tire mini sawmill PTSM – 3B

It cuts logs with a diameter of up to 60 cm, their maximum length should not exceed 9 m. The equipment uses a Shtil brand chain, which is of high quality and reliability. The engine of the device is 5.2 kWh. The sawmill can process up to 6 cubic meters of wood per shift. The price of such equipment is from 60 thousand rubles.

PCM – 1E

It belongs to the bus type of device, works with logs with a diameter of up to 60 cm and a length of up to 9.5 m. The design has a three-phase motor, its power is 5.5–7.5 kW. The cost of the equipment is 30–40 thousand rubles.

Wood – Mizer LT – 15

It is characterized as a mini band sawmill, capable of working with logs whose diameter is no more than 70 cm. The length of the material being processed does not matter, the main thing is that the weight does not exceed 2 tons. The device is manufactured in two variations. It can be produced with an 11 kW electric motor, or can be powered by a gasoline engine whose power is 18 hp. With. The cost of the equipment is 220 thousand rubles.

Taiga DP – 1

Refers to a circular sawmill. It cuts logs with a diameter of up to 90 cm, their length should not exceed 7 m. This device can produce any type of lumber. Processes up to 10 cubic meters of workpiece per shift, engine power is 11 kW. The price of such a sawmill starts from 190 thousand rubles.

Disc sawmill Taiga DP 1

Disc sawmill

Let's look at a simpler type of homemade sawmill.

In order to make a circular sawmill, you will need to find a circular saw. An electric motor will be used as a motor.

First you need to make a welded frame, on which you will need to place a metal plate with a slot for the disk. From below to the plate you need to attach the plate shaft on bearings and pulleys.

The electric motor wheel is connected to the saw by a belt.

To ensure good belt tension, it is necessary to use the weight of the engine itself, and you can also use weights. The circular sawmill is ready.

Source: rezhemmetall.ru

What to look for when choosing

When choosing a corner sawmill, you need to pay special attention to the characteristics of the saw unit, namely the quality of workmanship and the diameter of the discs, the power and speed of the drive motor.

The optimal choice of saw unit parameters will contribute to the efficient operation of the entire sawmill. Do not forget about other technical characteristics, since the potential for using the equipment and the profitability of the enterprise depend on them.

A few details to remember:

- The length of the supplied workpieces depends on the size of the particular machine.

- It is better to choose machines with the same disk mounting diameter.

- The sawmill has restrictions on the diameter of the wood processed.

- More powerful circular saw motors improve operating efficiency.

If you're interested in getting the most out of miter sawing, you shouldn't skimp on cutting tools or automation.

The correct selection of a circular sawmill can significantly increase labor productivity, while saving time and reducing energy costs. In addition, a high-quality woodworking machine will have a positive effect on the quality of the finished product.

Making a sawmill at home with your own hands

When it is necessary to process a large number of boards and wood, it is best to use a self-made sawmill. Many people believe that it is best to purchase a ready-made unit, but making it yourself will not be difficult. The main thing is to decide what the volume of work ahead will be, as well as the wood, after which you need to choose the type of sawmill to successfully complete the task.

When assembling the unit with your own hands, special attention should be paid to safety issues , because such a device is considered a high-risk object. The manufacture of various types of sawmills is presented further in the video.

The principle of operation of the sawmill

explain how a sawmill works using the example of spools of thread. This device resembles the rotation of two spools with a thread stretched between them. It is this that acts as a saw, and the distance between the coils will be the optimal size of the log.

A DIY sawmill allows you to:

- adjust logs to one shape and size;

- saw logs according to a specific pattern after the equipment is set up;

- After sawing, small defects often form that cannot be eliminated, so the wood has to be processed manually.

The work of the sawmill is carried out as follows : a log is fixed on the platform, which remains motionless, and at this time the mobile cart starts moving and cuts the tree. The saw must be in a horizontal position.

In order to obtain boards of the required size, the operator initially sets the necessary parameters. The saw blade acts as a saw, and it must be well tensioned.

How to make sawmills with your own hands

The most common types of sawmills are corner, band and chain , as well as devices assembled using a chainsaw.

Band sawmill

to assemble a band sawmill with your own hands at home. This is explained by the fact that it is difficult to achieve maximum coherence of all its constituent elements in the process of work. In addition, you will need the necessary components and special tools, but the main thing is that you have the necessary drawings at hand. The finished structure must work with material whose weight is about three hundred kilograms. In addition, it is necessary to adjust the adjustment of the threaded thickness and observe safety precautions.

Assembling the sawmill with your own hands is carried out on a site of the required size , which should be prepared in advance. The device will require special wheels and band saws. Then, in accordance with the drawings, the frame of the future unit is assembled. Work on the frame begins with the manufacture of special rails. To do this, you can pick up a corner and install one of the sides up. Then the wheels are installed, maintaining maximum strength.

Between two corners, set parallel, sleepers are made from a profile pipe, which are designed to ensure their reliable fastening to each other. Fasteners for logs that move freely in all directions are welded to this profile pipe. Then, according to the drawing, the cart is assembled and the wheels are attached to it.

How much can you earn

Let's calculate the income from production with reference to the national average figures:

- the cost of one cubic meter of timber is 1,800;

- price in the product - 5,700;

- the cost of a cube of finished material is 3,600. This figure is calculated taking into account 50% of waste during the sawing process;

- profit from cube - 2,100;

- with an average volume of 8,000 cubic meters per month, the entrepreneur’s income will be 1,680,000.

When the workshop reaches full capacity and the first profit begins, the initial investment will pay off after 7-9 months of operation.

To increase your income and shorten the return on investment period, find sources of additional income.

Use waste - collect pallets and wooden containers from them. Manufacture and sell decorative benches and fences through hardware stores. Skillful distribution of production waste increases profitability by 10-15%.

Essential tips and tricks

Since the sawmill is considered a rather dangerous unit of impressive size, before assembling it with your own hands, you need to carefully consider where it will be used. Good for this:

- barn;

- garage;

- an ordinary utility room with a concrete base.

Such a place should be well ventilated, spacious and have sufficient lighting. A place for this device can also be found on the street, but a canopy must be equipped for it.

If the sawmill has an electric motor , then you need to carefully consider the installation of wiring and installation of the necessary switches and machines. If there is a warehouse for finished boards near the place of work, this greatly simplifies the whole process.

When assembling the unit with your own hands, special attention must be paid to its cutting and moving parts, which are considered the most dangerous elements. In general, safety precautions should be observed when operating the device.

After assembling the sawmill and before starting work, be sure to check all fastenings and components, as well as the stability of the structure. The first start of the device is carried out after following all the necessary recommendations.

Thus, making a sawmill with your own hands is not difficult . These devices come in different types and the process of their assembly is presented in the video. You should also definitely use the drawings so as not to make any mistakes. When operating a sawmill, it is necessary to observe safety precautions, because this is a rather dangerous device.

Source: nashgazon.com

Search for clients, advertising and marketing

If you want to reduce the payback period of your investments, make sure that people know about you.

Attract customers with effective tools:

- come up with a catchy name;

- install a billboard near a construction hypermarket, hand out printed materials at the entrance - leaflets, booklets;

- tell about yourself on local television channels, launch a video on the radio, place an ad in the city newspaper - these sources of information are actively monitored by wholesalers;

- held sweepstakes, gave discounts, organized promotions - financial gain is a powerful motivation;

- If you want to have regular customers, practice a flexible pricing policy - work in installments, credit.

Advice! Start building your customer base by identifying your target audience.

Your potential buyers:

- wholesale centers;

- furniture factories;

- large supermarkets;

- carpentry shops;

- production of garden decorative furniture, gazebos.

Send them commercial proposals for cooperation. Take part in regional exhibitions and fairs - lucrative contracts are concluded there.