A DIY sawmill can be made at home with little financial outlay. Consequently, you will receive a large amount of materials for your own construction, the surplus can be sold, which will cover all your costs for making the sawmill.

A tire sawmill can be made by yourself with minimal financial costs.

The construction boom, which has not abated throughout the post-Soviet space over the past 10 years, requires a large amount of materials. Despite the abundance of forests, lumber has been and remains the most popular material. And these materials are not cheap.

What is a tire sawmill used for?

The main purpose of a chain sawmill tire is to quickly and correctly saw a log to obtain lumber. Why is the design called that? The fact is that to create such a mechanism, a saw bar is used.

The cutting part is designed in the form of a chain bar with a sharp chain. The main advantage of this design is its simple design and the ability to use it in various fields.

Most craftsmen prefer to use a regular chainsaw as the cutting part.

The principle of operation is to pre-harvest logs of the required size, and then, when installing the saw in the frame, it is possible to cut the elements into blanks of different lengths and widths. Thanks to this, it is possible to achieve high cutting accuracy.

Types of tire sawmills

A simple saw bar design can consist of any drive. That is why homemade models are divided into several types depending on the type of engine.

These include the following designs:

- Gasoline. In this case, a four-stroke engine operating on the principle of internal combustion is used;

- Electric. In this case, three-phase asynchronous operation of an electric motor with high power is observed.

The use of an electric motor is cost-effective if the equipment will be used as a stationary device. The sawmill will be used outside a closed space. In this case, it is better to choose a package consisting of an asynchronous motor.

- A sawmill with an electric motor requires high power consumption.

- Experts recommend choosing models with a power of at least 4 kW. A cable consisting of a large cross-section of wires will provide power.

- In the process of longitudinal sawing a log, it is important to take into account that such a mechanism is movable.

- It can deviate from its original position up to 5 m in length.

- In this case, it is necessary to consider isolating the cutting base from surrounding objects. The working part must be plastic and movable.

If you install a gasoline engine in a tire sawmill, you will not need an electrical cable. The design of a gasoline engine has significant disadvantages.

For example, if an engine running on medium-power gasoline is chosen for the mechanism, then a battery may be required to start it. If a chainsaw drive is used, a powerful cord-based starter will allow the mechanism to be prepared for operation.

Operating highlights

The tire sawmill is installed in any room or outdoor area.

- The room must be well ventilated and lit, since the unit is classified as dangerous.

- Outdoor electrical equipment must be protected from precipitation.

- The area for the equipment must be level. If the surface is uneven, the rail track is placed on anchors.

- The rail track and tire must be horizontal.

- The sawmill is installed on four support rollers, which roll it along guide rails.

- The thickness of the sawn board is regulated by a vertical screw, which, when rotated, raises or lowers the cart with the saw unit.

- During operation of the sawmill, the log is fixed motionless along the frame.

- The clamping stops for supporting the log have a simple and convenient design: screws press the log against the stop flags.

How to make a sawmill at home

Before starting the work process, it is important to correctly determine the type of launch and the supply of material. You can follow a technique in which the moving part is the material, or you can do the opposite.

When you have decided on the type of lumber supply, it is important to take into account one more fact that the location of this mechanism should take up enough space so that no additional inconvenience arises during operation.

The correct position of the runners requires special attention. The fact is that a wooden log will move along them.

The surface of the conveyors must be promptly cleaned of sawdust and small branches.

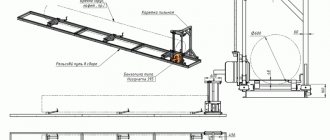

To create a tire sawmill at home, you will need the following components:

- Mechanism drawing;

- Metal corner size 50/50. We will use it to create a staging path;

- Rectangular pipe made of dense metal. The length of the elements must be at least 60/60. We will use it to construct the carriage;

- Round metal pipe. It is necessary to fix the power part of the unit;

- Metal sheet 1 sq.m. The thickness of the workpiece must be at least 4 mm;

- Metal wheels with axles – 4 pieces;

- Tire, drive sprocket and chain;

- Electric welding;

- Electric motor;

- Drill with a set of drills of different diameters;

- Bulgarian;

- Ruler;

- Building level;

- Chalk for making notches.

You can determine the length of the corner to create a staging path by following several recommendations.

They include:

- Length of the wooden piece + distance from the wheel to the edge of the tire. We multiply the result by 2. Allowances of 10 cm will help to avoid mistakes.

- You can determine the size of the pipes for the carriage by taking into account the type of tire. The design should be 30 cm larger than the cutting part.

Transferring the structure to the base

Now place the resulting working block on a metal frame. It's not difficult to make. First, weld two shapes (in the shape of the letter P) from strong metal tubes. In the upper part, these forms are secured to each other (either welding or bolted connections can be used). In the central part of this frame, weld 4 tubes vertically. On each of them, make small indentations on the outside (no more than half the thickness of the metal) at a distance of 2 cm from each other. It is also necessary to weld 4 tubes to the working unit, but their internal diameter must exactly match the external size of the vertical pipes. All elements must be positioned so that the tubes of the working unit fit onto the tubes of the supporting frame.

Let us briefly explain the principle of operation: the working unit will be able to move freely vertically and be fixed with bolts. You loosen all 4 bolts, move the working unit vertically to the level you need and tighten the bolts again. The working unit will be rigidly fixed, therefore, you will be able to make longitudinal cuts of wood in a strictly horizontal plane.

How to assemble a sawing mechanism

It is necessary to weld a square from metal pipes. Externally, such a blank will look like an ordinary box. It should not have external walls, bottom and lid.

The bottom side should be short, and the top side should be about 20 cm longer. As a result, we have the appearance of a carriage. Wheels will be attached to the protruding elements.

After this, we move on to making a platform for the engine location. We make several holes on the metal sheet to fix the electric motor.

After that, we will weld another flat strip to the platform, which will hold the tire from the chainsaw.

- We will mount the axle on this site. From it we will fix the drive sprocket for the chain.

- It is necessary to attach the tire in such a way that it is possible to maintain the possibility of adjustments for the tension of the cutting part.

- If the chain is poorly tensioned, it may become deformed or break during the cutting process.

- If the cutting part is too tight, it will put additional stress on the sprocket axle.

- As a result, you can observe severe load on the electric motor and overheating of the circuit.

The final step will be to fix the power cable at one of the edges of the site. To start, simply connect the electrical cord to a power outlet. When the equipment is turned on, the carriage with the tire will begin to move slowly along the metal frame.

Stationary unit

A concrete base is sometimes made for a stationary sawing unit.

You can install the clutch yourself. This is an intermediate transmission mechanism from the engine to the drive gear. Transmission is carried out by belts stretched over engine pulleys and gears. The belts are pressed with special rollers. This device makes the sawmill more efficient.

The assembly process is multi-stage, but it is quite possible to make such a unit with your own hands. Installing a tire sawmill on a country plot or in a country house will bring a lot of benefits. After all, with its help you can make a large assortment of the necessary wooden products, rather than running around looking for expensive materials in stores. A handmade product will not require large expenses.