During the manufacture of furniture or other structures made of wood, quite often the need arises to create grooves of various shapes. Making a deep rectangular groove without a specialized device is simply unrealistic. To solve such problems, a wood slotting machine is used. In this article we will figure out what types of slotting machines exist and how to make such a device yourself.

A slotting machine is a machine that is used to form grooves of different shapes and sizes. In most machines, you can change the cutting tool to cope with a specific task. This device can also be used to remove a certain layer of wood to create a unique profile. Naturally, in this case, the productivity of the equipment is not significant, however, when working with small parts, the machine can also be used to solve the problem under consideration.

Information about the manufacturer of the 7M430 slotting machine

The developer and manufacturer of the 7M430 slotting machine is the Gomel Machine Tool Plant named after. S. M. Kirov StankoGomel , founded in 1885.

Machine tools produced by the Gomel Machine Tool Plant named after. S. M. Kirova, StankoGomel

- 7D36

- cross-planing machine with hydraulic drive, 450 x 710 - 7D37

- cross-planing machine with hydraulic drive, 560 x 1000 - 7D430

- slotting machine with hydraulic drive, Ø 630 - 7D450

- slotting machine with hydraulic drive, Ø 800 - 7M36, 7M37

- cross-planing machine with hydraulic drive, 450 x 710, 560 x 1000 - 7M430

- slotting machine with hydraulic drive, Ø 630 - 737

— cross-planing machine with hydraulic drive, 450 x 900 - 7307d, 7310d

- cross-planing machine with hydraulic drive, 450 x 710, 560 x 1000 - 7403, 7405

— slotting machine with hydraulic drive, Ø 630, Ø 800 - 7430

— slotting machine with hydraulic drive, Ø 650 - GD200

- small-sized slotting machine with a mechanical drive, Ø 500 - GD320

- slotting machine with hydraulic drive, Ø 770 - GD500

- slotting machine with hydraulic drive, Ø 940 - IR-500

- horizontal multi-purpose milling machine, 500 x 500 - FSS350MR

- vertical cantilever milling machine, 315 x 1250 - FSS450MR

- vertical cantilever milling machine, 400 x 1600

7M430 slotting machine with hydraulic drive. Purpose and scope

The hydroficated slotting machine model 7M430 is designed for the production of keyways, splines and grooves on shaped and flat surfaces, for slotting flat and shaped surfaces, cutouts, grooves in cylindrical and conical holes and slotting with undercuts up to 10°.

The machine is designed for processing external surfaces of products with a height of up to 320 mm and processing of internal surfaces of products with a height of up to 250 mm. The machine is suitable for use in individual and small-scale production, as well as in repair shops.

The presence of three types of table feeds (longitudinal, transverse and circular) makes it possible to process several surfaces on this machine from one installation. The presence of mechanical table feeds, an automatic stop mechanism, and remote control allows multi-machine service.

The machine is designed for processing by chiselling flat and shaped surfaces, grooves and grooves in a variety of parts, as well as various types of dies installed directly on the table or in fixtures. The ability to rotate the frame with the cutter allows you to process inclined planes without changing the position of the part.

Brief description of the design of the 7M430 machine

The table moves both manually and mechanically. The circular feed of the table makes it possible to process round parts and gears on the machine.

The machine has hydraulic movement of the cutter and hydraulic feed of the table for each of its double strokes. The kinematic diagram of the machine ensures rapid movement of the table in the longitudinal, transverse and circular directions from a separate electric motor. The table can also be moved manually in the indicated directions. The machine table has a dividing mechanism that allows you to accurately divide the workpiece into the required number of parts.

The speed of movement of the cutter along the entire stroke length is constant. The machine has step-throttle regulation of the speed of the cutter and the movement of the table. Changing the direction of movement of the cutter occurs by switching the control spool using two stops located on the control panel cover. The same stops regulate the length and location of the cutter stroke.

There are two handles on the right side of the machine. One of them serves to switch the speeds of movement of the cutter, there are 4 such speeds in the machine. The other handle smoothly regulates the speed within each step.

The machine has a mechanism that allows you to process the product for a set processing length and automatically turns off the machine at the end of processing; The cutter stops in the upper position. The design of the machine ensures automatic retraction of the cutter from the product during reverse stroke. The machine has a remote control carried out from a pendant push-button station. From the push-button station, the main engine is started and stopped, as well as the cutter is started, stopped and adjusted. The machine has an idle speed limiter - when the cutter stops, the main engine stops. The machine is equipped with a tool cooling system. The lubrication of the cutter guides is forced from a separate reservoir using a plunger pump and manually from a manual lubricator.

Lubrication of the table - from 2 manual lubricators.

Operating principle of the equipment

If we consider the types of slotting machines, you should note that the classification is carried out according to the location of the cutting tool, type of feed, control system and many other characteristics. An example is tabletop metal slotting machines, which can be manually or electrically driven.

The features of the operating principles include the following points:

- The cutting tool performs a reciprocating movement due to which the workpiece is processed.

- The workpiece is fed using a table on which the workpiece is secured.

In this case, you can divide the equipment into two operating modes: simple and complex. Downtime can be characterized as follows:

- The cutter goes point blank.

- In this mode, ordinary holes are created.

- The holes obtained by simple processing have the same dimensions and shapes.

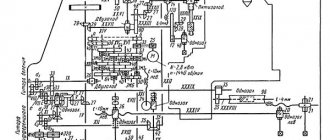

Kinematic diagram

We characterize the complex mode as follows:

- hard-to-reach holes can be processed;

- the resulting recesses and holes can be at an angle

Only professional equipment can be used for complex processing. A model that you create yourself, as a rule, does not have the required set of functions.

A homemade or manual metal slotting machine is suitable exclusively for equipping small workshops and production shops in which small batches of various parts are produced. In large-scale production, models that have CNC are often purchased. It is quite difficult to equip a slotting machine with a numerical control system with your own hands.

Setting up, adjustment and operating mode of the 7M430 slotting machine

Selecting cutting mode

To select a processing mode for a particular metal on a machine, it is recommended to use reference books on cutting modes.

Installation and adjustment of the cutter stroke

The size of the cutter stroke is adjusted using stops. For a given machining length, the stops must be installed so that the difference on the scale between one stop and the other determines the total machining length, taking into account the overruns of the cutter for each length.

The spread of the stops ensures processing of parts over the entire height.

The cutter is brought to the workpiece using the “Start the cutter” button, operating in jog mode, while the “Work - adjustment” cycle switch must be in the “Adjustment” position.

Table Feed Setting

Setting the selected table feed is carried out by turning the handwheel until the required number corresponding to the desired feed is set against the indicator line.

Machine adjustment

During the operation of the machine, the need arises to regulate individual components and elements in order to restore their normal operation.

Below are the units and methods of adjustment that require adjustment:

- Adjusting the wedge of the cutter

- Adjusting the wedges of the longitudinal and transverse table slides

- Adjustment of the tilting of the cutting head is carried out by the nut of the brake device, as well as by nuts that directly establish an adjustable gap between the folding board and the cutter;

- After some time, it may be necessary to adjust the rolling bearings, which requires slightly tightening the round nuts or flanges that create tension in these bearings;

- The safety ball clutch is adjusted using a nut and a locknut.

- Adjustment of hydraulic drive mechanisms was discussed in the section “Hydraulic drive of the machine”

- The feed box brake, which serves to prevent the shaft from rotating in the opposite direction, is adjusted with three nuts.

Roughness of the processed surface is not less than V 6

Machine accuracy class N

Technical characteristics of the hydraulically driven slotting machine 7m430

Manufacturer Gomel Machine Tool Plant, StankoGomel.

Basic parameters of the machine in accordance with GOST 1141-74.

- The stroke of the cutter is 120..320 , mm

- Distance from the table plane to the cutter guides, mm - 500 mm

- The distance from the table plane to the bottom edge of the cutter head is 10..580 mm

- Table diameter - Ø 630 mm

- Distance from the cutter to the frame (reach) - 590 mm

- The largest longitudinal table movements are 650 mm

- The largest transverse table movements are 500 mm

- The largest movements of the table are circular - 360°

- The largest dimensions of the cutter holder are 30 x 20 mm

- Electric motor power - 7 kW

- Full machine weight - 5.2 t

DIY creation

Many people are considering how to make a metal slotting machine, since a homemade version has a lower cost, but at the same time sufficient functionality. When making it yourself, you should pay attention to the following points:

- First you need to select a drawing. You can find quite a lot of different drawings on the Internet.

- Quite often, a massive slab is used as a base, which at the same time becomes a work table. You should choose plates that are made of steel. Cast iron is susceptible to impact loads: the material may burst.

- A stand is attached to the base, which is made of a steel rod: the diameter can reach 40 mm and the height 500 mm. Fastening to the base can be done by welding or threaded connection.

- A complex structure can be called a console. It is made of two hollow cylinders.

- A separate area should be allocated for the electric motor. Quite often, homemade versions have a direct connection between the engine and the cutting tool, that is, there is no transmission.

- The drive from the electric motor to the cutting tool is a combination of a belt and rollers.

- The table drive is mechanical. Quite often the feed is carried out through a worm gear.

In conclusion, we note that to independently manufacture a slotting machine, you need to have some experience as a mechanic. When performing work, attention should be paid to the strength of all fasteners.

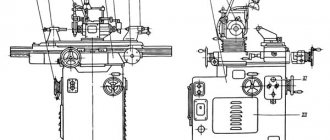

General view of a homemade slotting machine

General view drawing of a homemade slotting machine

Caliper

Console

Mandrel-tool holder

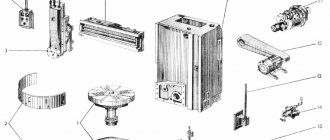

7M430 Arrangement of the components of the slotting machine

Location of the components of the 7m430 slotting machine

Location of the components of the 7m430 slotting machine

Specification of components of the 7M430 slotting machine

- 01. Bed _M30-01.001

- 02. Dolbyak with cylinder _M30-02.001

- 03. Feed box _M30-03.001

- 04. Table _M30-04.001

- 05. Cooling _M30-05.001

- 06. Electrical equipment _M30 06.001

- 07. Control _M30-07.001

- 08. Pipeline _M30-08.001

- 09. Accessories _M30-09.001

Analogs

The difficulty of self-assembling a slotting machine is that the jigsaw engine:

- travel speed is too high;

- too little power.

As a result, it does not always work satisfactorily. What to do? Assemble a milling machine instead of a slotting machine. The algorithm of actions and materials will be the same. The only difference is that instead of a jigsaw we use an electric drill with a milling attachment.

The main difference between a milling machine is that it does not produce a rectangular groove, but a hole with slightly rounded edges. However, in most cases it will do for household purposes.

7M430 Location of slotting machine controls

Location of controls for slotting machine 7m430

List of controls for the 7M430 slotting machine

- Feed rate setting handwheel

- Mechanism for adjusting table movement to a given processing amount

- Handwheel for manual longitudinal movement of the table

- Mechanical longitudinal feed switch handle

- Reverse handle

- Mechanical circular feed activation handle

- Mechanical cross feed switch handle

- Switch "Lighting"

- "Start" button for quickly moving the table

- Button “Start” of the cutter (duplicated with handle 18)

- Main engine start button

- Cycle switch “Work - Setup”

- Nuts for fixing the rotation of the cutter slide

- Square for turning the cutter sled at an angle

- Hanging "Stop" button of the main engine

- Stops for setting the stroke length of the cutter

- Handle for manual movement of the cutter stroke

- Handle for starting and stopping the cutter

- Handle for steplessly changing the speed of the cutter between stages

- Handle for step change of cutter speed

- Signal light for connecting the machine to the network

- Batch switch for electric pump

- Batch network switch

- Cross slide clamp handle

- Longitudinal slide clamp handle

- Square for manual longitudinal movement of the table

- Square for manual lateral movement of the table

- Dividing mechanism handle

- Round table fixing nuts

7M430 Kinematic diagram of a slotting machine

Kinematic diagram of the 7m430 slotting machine

Kinds

Slotting machines are classified according to many criteria, but they are all somewhat similar, which was the reason for the creation of two main groups:

- in production conditions where the level of productivity plays an important role, a centrifugal woodworking slotting machine is used. It is often large in size and capable of creating a wide variety of grooves

- For a home workshop, a manual slotting machine or wood slotting drill is more suitable. This device operates on the principle of a milling cutter.

The household slotting device has a simple design and low cost. The industrial slotting machine is most often used only in large manufacturing plants due to its high price. Such equipment is designed for mass production. organizations that conduct mass production.

Let's consider the design of the machine using the example of a slotting chain device.

Basic moments:

- a special chain is the main structural element. It has a very large number of individual links connected to each other in a hinged manner. It is worth noting that each link is represented by a milling tooth, sharpened in a special way

- the main components of the device are necessary for transmitting movement and adjusting the processing procedure. This chain is pulled onto a special guide bar along which it moves. The teeth remove wood to form a groove and chips.

Note that in the manufacturing process of different models, almost the same slotting machine design is used. It is quite simple, somewhat similar to a drilling machine. The main element of the entire machine is the bed, because all other components are mounted on it. A movable support equipped with an electric motor and a table is fixed to the frame. Please note that the unit on which the workpiece is fastened is a table with a clamping element. The electric motor is responsible for transmitting rotation using a belt. Belt drives are used in the production process of various structures.

However, there are also models that work differently. The support with the cutting element is stationary, while the table can move through a mechanical or hydraulic drive. Household models often do not have a drive. The video will tell you in more detail about what kind of slotting machines there are.

Different types of slotting machines can have a vertical or horizontal arrangement of the cutting tool. The most popular is the horizontal wood slotting machine, since it is compact and easy to work with.

7M430 Description of slotting machine components

The machine bed consists of 2 parts: lower and upper, fastened together with screws, studs and pins. Both parts of the bed are box-shaped and have stiffening ribs, which ensures sufficient rigidity of the machine. At the bottom of the upper frame there is a reservoir for hydraulic drive oil with a capacity of 250 liters. There, a flange is attached to the left wall, in which a coupling is placed that connects the hydraulic pumps to the flange electric motor (the hydraulic pumps are placed inside the chamber and are screwed to the flange). The middle chamber of the lower frame is the reservoir of the cooling system. A plate with a hydraulic panel is attached to the right wall of the upper frame. There is a window in the left side wall for mounting a hydraulic drive. In the rear wall of the upper frame there is a niche in which the electrical cabinet is placed. The electrical cabinet doors have sponge rubber seals and a locking device that ensures the cabinet's tightness.

Dolbyak with a cylinder . The cutter is a cast iron hollow casting with rectangular guides; inside the cutter has stiffening ribs. A cutting head with tool holders is mounted in the lower part of the cutter. This unit contains a mechanism for mechanical retraction of the cutter during the reverse stroke of the cutter.

The folding board of the cutting head is connected through a bracket, a needle bearing, an eccentric and a gear shaft to a gear rack, which is placed in the groove of the cutter.

The toothed rack, moving together with the cutter, rotates the brake gear located in the slide of the cutter.

The throwing of the folding board occurs due to the rotation of the eccentric, motionless sitting on the gear roller.

The brake device is adjusted by a spring using a nut.

The hydraulic cylinder is a steel pipe mounted on a cutter slide.

The length of the cylinder is chosen in such a way as to serve the entire distance from the table plane to the guide slide with the cutter.

A piston with a rod moves inside the cylinder, the end of which is connected to the cutter. The cylinder is attached to the cutter slide motionlessly, and the piston with the rod and the cutter receive reciprocating motion. By supplying oil to the upper cavity of the cylinder, i.e., to the rodless cavity, we obtain the working stroke of the cutter, and by supplying oil to the lower cavity of the cylinder, i.e., to the rod cavity, we obtain the idle stroke of the cutter. Forced and manual lubrication systems for the cutter guides are installed in the cutter slide.

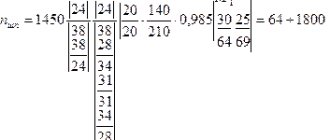

The feed box is designed to carry out transverse, longitudinal and circular working feeds of the table for each double stroke of the cutter and to quickly move the table in these directions.

Working feeds of the table are carried out as follows: When the cutter is switched to the working stroke, oil from the pump through the feed spool enters the feed box cylinder (see hydraulic and kinematic diagrams of the machine) and moves the piston to the right. The rack connected to the rod rotates a gear wheel z = 24, from which the shaft, connected through a safety clutch to the table assembly, rotates through a ratchet mechanism. Rapid movement of the table in all three directions is carried out by a separate 1.7 kW electric motor. The feed rate is adjusted by changing the piston stroke using a flywheel, a pair of gears, a nut and a screw. On the outside of the nut there is a cut rack, which engages with a gear sitting on the shaft of the G77-11 hydraulic feed throttle. Thus, at the same time, when adjusting the feed amount by changing the stroke of the feed piston, the amount of oil coming out of the rod cavity of the feed cylinder is throttled accordingly (see hydraulic diagram), which ensures feed stability at any speed. The set feed value is counted using a dial mounted on the handwheel. A brake is installed on the output shaft of the box, which counteracts the rotation of the shaft in the opposite direction.

A special mechanism for adjusting the table to a given length of processing the product with an automatic stop at the end of processing is built into the top cover of the feed box. The mechanism consists of a dial with divisions, a pointer, a pointer drive and an electric microswitch. The arrow is connected to the table assembly by a rigid kinematic chain. As it rotates, it presses a microswitch that stops the main motor of the machine. When setting the table stroke length, the arrow is secured in the specified position by tightening the nut.

The machine table mainly consists of a longitudinal slide running on the bed, a cross slide running on the longitudinal slide, a rotary table mounted on the cross slide and a gearbox.

Inside the rotary table of the slide there are channels through which the emulsion flows into the lower frame.

A gearbox is mounted at the right end of the longitudinal slide, transmitting movement from the feed box (unit 03) to the splined shaft of the circular feed worm and the screws of the longitudinal and transverse feed of the table. There are two squares on the gearbox cover, which terminate the transverse movement screw and the longitudinal feed shaft.

A dividing mechanism is mounted in the gearbox, allowing the workpiece to be divided into the required number of parts; The mechanism is connected to the rotary table through a spline shaft and a worm pair.

The rotary table is centered on the cross slide using a cone; it has three T-slots that allow workpieces to be secured. There is a centering hole with a diameter of 32 mm in the center of the turntable.

The rotary table is on a transverse slide, the transverse is on the longitudinal, and the longitudinal slide is fixed on the frame using clamps.

Between the transverse and longitudinal slides, as well as between the longitudinal slide and the bed, there are wedges to regulate the gaps that arise during operation of the machine.

The slide guides are rectangular.

All rotating shafts and worm are mounted in roller and ball bearings.

The design of the table ensures separate activation of each of the feeds: longitudinal, transverse and circular (it is possible to switch on two feeds simultaneously).

Cooling system . The cooling system is driven by an electric pump with a capacity of 22 liters per minute.

The electric pump is attached to the tank, which, in turn, is attached to the lower frame. The tank, together with the middle chamber of the lower frame, forms a reservoir for coolant. Tank capacity 55 liters. The table turntable (unit 04) has an annular chute at the edges, into which coolant is drained from the workpieces.

This chute is connected through a system of holes and channels to the middle chamber of the lower frame (reservoir). The tank has a hole at the bottom for draining the coolant, which is closed with a plug.

The cutter control unit provides:

- setting the location and stroke size of the cutter;

- manual reversal of the cutter when necessary;

- manual stop and cutter stop;

- setting the speed of the cutter.

1. Setting the position and stroke of the cutter is carried out using the power of two stops located on the right wall of the machine.

The stops move the hydraulic panel control spool through a special lever, thereby reversing the cutter.

The angle between the stops determines the stroke of the cutter. The relative position of the stops determines the position of the cutter stroke within the specified chiselling value.

The angle between the stops and their relative location are set along the limb.

The stops are driven from the cutter through a pinion-rack transmission and two pairs of bevel gears.

2. The reverse lever with rollers, which are acted upon by stops, has a handle for manual control.

3. The sector connected to the gear of the “start”-“stop” valve of the hydraulic panel sits on the roller.

At the end of this roller there is a hub with a handle, through which you can manually start and stop the cutter.

4. In addition to the handle for starting and stopping the cutter, two more hydraulic panel handles are located on the right wall of the machine. One of them serves to switch the speeds (steps) of movement of the cutter; there are four such steps in the machine; the other is for smooth speed control within each step.

The lubrication of the parts of this unit is forced from the hydraulic drive system of the machine.

The pipeline connects the working cylinder, feed box cylinder, hydraulic panel, pumps and auxiliary equipment.

The hydraulic panel is attached through an intermediate plate to the cast frame of the control unit. Together with the frame and the intermediate plate, the hydraulic panel is attached to the right wall of the frame, which has a window for removing the hydraulic panel. Installation of the hydraulic panel with an intermediate plate and frame is carried out through a window in the left wall of the frame. The pipeline is installed and dismantled through the same window. The pipeline consists of steel pipes and end connections. One of the pipes has a hole for connecting a pressure gauge. To measure the pressure in the system, the pressure gauge is activated by a special spool. A filter for oil purification is built parallel to the drain pipe. The oil is filled through the neck, which contains its own filter; draining - through two special tubes or using a pump available to the consumer. To create a counterweight against the fall of the cutter, a pressure spool with a check valve is used. To regulate the oil supply to the feed box, use a special coupling valve and a hydraulic feed throttle, which is located directly inside the feed box housing - (node 03).

For a description of the hydraulic panel, pumps and other hydraulic equipment, see the “Hydraulic drive of the machine” section.

Selection of metal slotting equipment

When choosing a slotting machine, there are a number of factors to consider. By acting in this way, you can guarantee a long service life of the equipment and its uninterrupted operation for a long time.

First of all, you should consider such a parameter as the permissible height of the parts for the device. It can have different values, which are determined primarily by the type of surface being processed.

Along with this, the declared power of the machine , the size of the cutter and the possibility of its regulation also deserve attention. It would be useful to inquire about the presence of transverse and longitudinal stroke of the device and the value of the permissible angle of inclination.

An important characteristic that determines the quality of work of a slotting machine is the speed of movement of the working tool. Only products that are equipped with a massive cabinet can demonstrate stability during operation. This makes it possible to significantly simplify the processing of parts.

At the stage of choosing equipment, you should also take into account the size of the table , since this directly determines the ease of working with the device.

7M430 Hydraulic diagram of a slotting machine

Hydraulic diagram of the 7m430 slotting machine

Description of the hydraulic circuit of the 7m730 slotting machine

Working movements:

- The main movement is the reciprocating movement of the slider with the slotting cutter in the vertical direction;

- Feed movement - movement of a round table with a workpiece, longitudinal, transverse or circular, performed periodically - in one double stroke of the slide.

The main movement is carried out by a hydraulic drive (Fig. XVII. 8). The drive provides the slider with four speed stages, corresponding to four possible positions of the switching spool 1, set by handle 4 (see Fig. XVII.7), and also provides the ability to smoothly change the speed of the slider within each stage by means of handle 5 acting on throttle 2 (Fig. XVII.8) with regulator 3. Oil from two vane pumps with a capacity of Q = 50 l/min and Q = 70 l/min enters the grooves of the switching spool 1. When operating at the first stage, the speed of movement of the slider is 5-7 ,9 and 11 m/min for the working and reverse strokes, respectively, the spool takes a position at which the oil from the pump Q = 70 l/min is drained into the tank, and the oil from the pump Q = 50 l/min enters the system. The second stage of the slider speed is characterized by its value equal to 7.9-11 m/min during working and 22 m/min during the reverse stroke of the slider, and the use of oil from the pump Q = 70 l/min for operation in the system. At the third and fourth speed stages, determined by the corresponding positions of spool 1, oil enters the system from both pumps. But the absence of oil drainage during the working stroke of the slide distinguishes the fourth stage from the third, second and first. The working and return speed of the slider is: at the third stage 11 - 19.3 and 36 m/min; at the fourth stage 19.3-36 and 35 m/min. The oil circulation in the system at all four speeds of the slider is similar, despite the noted feature of the fourth stage, which does not change the general circuit diagram.

The oil that has passed the switching spool 1 enters through channel 4 through valve 5 of the G31-16 hydraulic panel and grooves 6, 7 through pipe 8 into the working cavity 9 of the hydraulic cylinder mounted on the slider slide. From the rod cavity 10 of the slider cylinder, oil is forced into the tank through pipe 11, through pressure valve 12, through pipe 25, grooves 14, 15, 16, 17 of the hydraulic panel, channel 18 of the intermediate plate, grooves 19 and 20 of stop valve 21, grooves 22 and 23 control panel G32-16 and pipe 24. The slider makes a working stroke. The speed of the working stroke of the slider within the stage is changed by throttle 2 with regulator 3, which for this purpose releases part of the oil supplied by the pump. At the end of the working stroke, the stop, fixed to the frame and connected to the slider by a transmission consisting of bevel wheels and a round rack, moves the control spool 25 to the right through a system of levers. While moving, the spool separates the grooves 16 and 17, slowing down the slider, and at the end of the stroke it “cuts off” the groove 26 from the groove 27 and connects it with the pressure supplied to the groove 28. From the cavity limited by the right end of the reverse spool 29, the oil is drained through the throttle 30 and grooves 31 and 32, and spool 29 moves from left to right. In the right position of the spool, bore 14 communicates with bore 6, and bore 7 is connected to bore 33. In this case, oil flows through bores 6, 14, pipe 13, bores of the pressure spool and pipe 11 into the rod cavity 10 of the slider cylinder and drains from the working cavity 9 along pipe 8, grooves 7, 33, 34, 35 and through filter 36 and valve 37. The slider moves in reverse, which stops when the control spool stop 25 moves to the left.

The feed movement is communicated to the table with the workpiece from a hydraulic drive. At the moment of reversing the movement of the slider from reverse to the working one, oil flows through grooves 38, 31 and pipe 39 (see Fig. XVII.8) into the cavity 40 of the reversible feed spool 41 and moves it to the extreme right position, in which oil from the pump through damper 42, channel 43, grooves 44, 45, channel 46 will enter the working cavity 47 of the feedbox hydraulic cylinder. In this case, the oil is forced out of the rod cavity 48 and is drained into the tank through pipe 49, grooves 50, 51 and pipe 52. The piston moves in one double stroke of the slider. In this case, rack 1, connected to the piston rod (Fig. XVII.9), rotates a gear wheel z = 24, from which shaft I rotates through a ratchet mechanism. From it, through a reversing mechanism consisting of three bevel wheels z = 26 with a cam clutch, and cylindrical wheels z = 39 on shafts II and III, rotation is transmitted to screws 2 and 3 of the longitudinal and transverse feed of the table and a worm pair (z = 1, z = 105), which performs its circular feed.

Thus, the table receives longitudinal, transverse and circular feeds in one double stroke of the slider. The feed rate is within the following limits: longitudinal and transverse - 0.2-2.4 mm/in. stroke, circular - 0.1-1.3°/door. move. Fast (adjustment) movements in the same directions are transmitted to the table by electric motor M1. The required chiselling length is provided by a special mechanism with a kinematic chain z = 44.44, z = 1, z = 50 (see Fig. XVII.9).

During the reverse stroke of the slide, the cutter is moved away from the surface of the part by a special mechanism.

Electrical equipment of the 7M430 slotting machine

The machine is equipped with three electric motors.

- Main drive motor (flange)

- Electric motor for rapid table movement (flange)

- Cooling system electric pump

An electrical cabinet is placed in the niche at the rear of the upper frame. The cabinet doors have a locking device and a sponge rubber seal, which ensures the cabinet's tightness.

The equipment in the cabinet is attached to a steel sheet panel with a getinaks gasket.

The panel is mounted using rigid wire.

The pendant push-button station is mounted on a rubber sleeve to a bracket that can be rotated relative to the stand on which it is mounted; this makes it possible to install the push-button station in any position convenient for the worker.

The local lighting bracket is attached to the left side of the frame to a special plate.

Connections between electrical equipment are made using gas pipes.

Varieties

If we talk about the types of slotting machines, we can distinguish two groups:

- Models for private workshops, garages. They are small-sized machines that can be installed on a workbench or have a steel base. Operated manually. To do this, the master installs the workpiece and clamps it with clamps. Next, he starts the machine and manually lowers the working part with the equipment to the workpiece.

- Industrial equipment. These are large-sized machines that are used for mass production of parts. The grooving machine is equipped with movable work tables, a powerful engine, and a cooling system.

Description of the circuit diagram

The electrical circuit of the machine provides:

- Starting and stopping the main drive electric motor.

- Starting and stopping the electric pump.

- Starting and stopping the electric motor for rapid table movements.

- Remote control of the cutter from a push-button station (start and stop).

- The operation of the table movement counting mechanism.

- Limitation of idling speed of the main electric motor.

- Local lighting of the machine.

1. Starting the engine of the main drive 1M is carried out in the following sequence: by turning the packet switch BB1, a voltage of 380V is supplied from the three-phase alternating current network to the electric motors and control circuit. After pressing the 1KU (start) button, the current flows through the circuit L16-2-3-4-5-6-L26.

The current, having passed through the coil of the magnetic starter 1K, turns on the main contacts 1K at points L12-L13, L22-1S2, L32-Lzz and starts the electric motor of the main drive 1M. At the same time, the magnetic starter bypasses the 1KU button at points 3-4.

To turn off the main electric motor 1M, you must press the 2KU (stop) button, which opens its N.C. contacts at points 2-3 and de-energizes the coil circuit of the 1K magnetic starter.

2. Turning on and off the electric pump 2M is done by turning the packet switch BB2.

3. Starting and stopping the electric motor of accelerated movements “ZM” is carried out by the “ZKU” (start) button, operating in jog mode.

4. Remote control of the cutter from a push-button station can be carried out in two modes - setup and working.

- Work mode. The PC cycle switch at points 9-10 is open. To start the cutter, you need to press the 4KU button, which, with its NO contacts at points 7-8, will close the circuit of the electromagnet EM-2, which, through a gear drive, will turn the hydraulic panel control valve to the “start” position. The dolly will begin to move. To stop the cutter, you need to press the “2KU” button, which with its NO contacts will close the circuit of the electromagnet EM-1 at points L16-10. The latter, through a gear transmission, will turn the hydraulic panel valve to the “stop” position. The goon will stop.

- Setup mode. The PC cycle switch is closed at points 9-10. The cutter is controlled by only one button 4KU, which turns on EM-2 with its NO contacts, and with N. 3. contacts along the L16-7-9-10-L26 circuit turns on the EM1 electromagnet. The cutter can be started only after the main engine has started, when the N.O. contacts L16-7.

5. The final microswitch of the table movement counting mechanism “1KB” is built into the control circuit of the main electric motor “1M”. When receiving a command from the reference mechanism, the limit switch “1KB” opens the circuit L16 2-3-4-5-6-L26 at points L16-2 and de-energizes the coil circuit of the magnetic starter 1K.

6. The idling speed of the main electric motor is limited by the “2KU” button, which has (N. 3.) contacts in the main engine control circuit at points 2-3 and N.O. contacts in the cutter stop circuit at points L16-10. Thus, when the cutter stops, the main engine will also stop.

7. The local lighting lamp is powered by a reduced voltage of 36 V AC from the secondary winding of a 380/36/6 V transformer. In the light bulb circuit “L1” there is a fuse “ZPR” and a switch “VO”. The signal light L is connected to pin 6v through the damping resistance PS.

The signal light L2 lights up when voltage is applied from the network by turning the package switch BB1.

Technical characteristics of the 7M430 slotting machine

| Parameter name | 7403 | 7405 | 7M430 | 7D430 |

| Basic machine parameters | ||||

| Machine accuracy class | N | N | N | N |

| Stroke of the cutter, mm | 120..320 | 120..500 | 120..320 | 120..320 |

| Table diameter, mm | 630 | 800 | 630 | 630 |

| Distance from the table plane to the cutter guides, mm | 500 | 710 | 500 | 500 |

| Distance from the cutter to the frame (reach), mm | 615 | 710 | 590 | 615 |

| Maximum height of the workpiece when processing the outer surface, mm | 500 | 650 | 320 | 500 |

| Maximum height of the workpiece when processing the internal surface, mm | 250 | 325 | 250 | 250 |

| Slotting head of the machine (slotter) | ||||

| Maximum movement of the cutter within the working area, mm | 500 | 700 | 570 | 500 |

| Maximum angle of rotation of the cutter in the direction of longitudinal feed, degrees | 10° | 10° | 10° | 10° |

| Largest cutter section, mm | 32 x 20 | 40 x 25 | 40 x 25 | 32 x 20 |

| Cutter speed under load, m/min | 3..38 | 3..38 | 3..38 | |

| Machine work table | ||||

| Maximum longitudinal movements of the table (along the frame guides), mm | 650 | 800 | 650 | 650 |

| Maximum transverse table movements (along the slide guides), mm | 510 | 650 | 500 | 510 |

| The largest movements of the table are circular, degrees | 360° | 360° | 360° | 360° |

| The cost of dividing the dial for longitudinal and transverse movement of the table, mm | 0,1 | 0,1 | 0,2 | 0,1 |

| Movement of the table per revolution of the dial during longitudinal and transverse movement of the table, mm | 0,7 | 1,4 | ||

| The cost of dividing the dial when moving the table in a circular motion, degrees | 1° | 1° | 1° | 1° |

| Movement of the table per revolution of the dial during circular movement of the table, deg | 0,86° | 0,86° | ||

| Feed limits for one double stroke, longitudinal, mm | 0,1..2,5 | 0,1..2,5 | 0,2..2,4 | 0,1..2,5 |

| Feed limits for one double stroke, transverse, mm | 0,1..2,5 | 0,1..2,5 | 0,2..2,4 | 0,1..2,5 |

| Feed limits for one double stroke, circular, deg | 0,1..1,4° | 0,1..1,4° | 0,1..1,4° | 0,1..1,4° |

| Speed of rapid table movement longitudinal, mm/min | 2,8 | 2,8 | 2,5 | 2,8 |

| Speed of rapid table movement transverse, mm/min | 2,8 | 2,8 | 2,5 | 2,8 |

| Speed of rapid movement of the table circular, rpm | 4,5 | 4,5 | 4,07 | 4,5 |

| Electrical equipment. Drive unit | ||||

| Number of electric motors on the machine | 3 | 3 | 3 | 3 |

| Hydraulic drive electric motor (main movement), kW (rpm) | 11 (970) | 11 (970) | 7 | 10 |

| Electric motor for rapid table movement, kW | 2,2 | 3,0 | 1,7 | 2,2 |

| Coolant electric pump electric motor, kW | 0,12 | 0,12 | 0,12 | 0,12 |

| Total power of all electric motors, kW | 13,32 | 14,12 | ||

| Dimensions and weight of the machine | ||||

| Machine dimensions (length width height), mm | 2850 x 2160 x 3010 | 3440 x 2760 x 3465 | 2650 x 1810 x 2890 | 3030 x 2175 x 3010 |

| Machine weight, kg | 5660 | 8160 | 5200 | 5700 |

- Hydroficated slotting machine 7M430. Manual for the machine, 1961

- Petrukha P.G. Cutting of structural materials, cutting tools and machines, 1974, p. 438

- Yakovtsev A.D. Working on planing and slotting machines, 1966

- Kopylov R.B. Working on planing and slotting machines, 1975

Bibliography:

Related Links. Additional Information

- Hydraulic drive of the 7M430 slotting machine. Typical faults

- Repair of hydraulic systems of metal-cutting machines

- Designations of hydraulic circuits of metal-cutting machines

- Classification of metal-cutting machines

- Selecting the right metalworking machine

- Testing and checking metal-cutting machines for accuracy

- Directory of factories producing metal-cutting machines

- Manufacturers of metal-cutting machines

- Directory of slotting machines

- Articles on the topic

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers