In Russia, consumption of nails has increased by 7% annually over the past few years. This growth opens a window of opportunity for new entrepreneurs. In the article we will provide a detailed business plan for a workshop for the production of nails, talk about the risks, advantages, stages of business development and provide calculations of its payback.

1. What types of nails are there? 2. Advantages of a business on nails 3. The process of producing nails: description 4. How to organize production 5. Registration of a plant 6. Equipment 7. Personnel 8. Premises (workshop) 9. What kind of wire is needed: we talk about raw materials 10. Sales and marketing 11. Is nail production profitable: financial plan 12. Business risks

What types of nails are there?

There are many types and types of nails. This is a multi-purpose fastening material, which, depending on its purpose, has its own characteristics.

We list the main classifications:

- Basic:

- Stainless steel - for boards.

- Galvanized - for working with logs.

- Brass - for concrete.

- Plastic - for drywall.

- By type of hat:

- with a wide hat;

- with a narrow hat;

- without a hat.

The types of nails are:

- construction ordinary;

- screw (brushed);

- comb;

- slate;

- finishing;

- anchor;

- roofing;

- for bitumen;

- for grids;

- for tin;

- duquerte nails;

- acid-resistant;

- copper;

- electrogalvanized;

- with anti-corrosion coating.

Types of nails and their manufacturing features

A sufficient number of nails are used for the construction and assembly of various structures. They are all divided into different categories. Let's look at them, and also explain for what purposes they are most often used.

Building

Construction nails are considered the most common, as they are used for nailing together various materials. They are usually needed to connect wooden beams in sheathings of varying thicknesses. The maximum length of such fasteners can reach 310 mm.

This type of nail is made from low carbon steel. There is a notch on the head of each element that will prevent the hammer from sliding when it comes into contact with the fastening material. Typically, such materials have a galvanized coating, which increases the resistance of the fastener to corrosion. There are also nails that are made from acid-resistant steel. These options are ideal for use in conditions of high humidity.

Model of construction nails with notches Source terra-tools.ru

Advantages of business on nails

Nails are used by professionals and amateurs - they are the main fastening material needed for construction and finishing work. The demand for the product remains high even though there is no shortage of it.

The production of nails as a business has several distinctive advantages.

Firstly, organizing industrial production is not difficult. There is no need to invest in the purchase and organization of a large workshop. A relatively small area will be required (it is possible to implement the idea at home) with low costs for heating, ventilation, and plumbing.

Secondly, production is automated and does not require special skills from workers.

Thirdly, consumables do not require special conditions for storage and transportation.

Fourthly, there are many ways to sell the finished product. You can, for example, sell nails wholesale.

In some situations, a small machine may be enough

In addition to all of the above, you can turn your attention to a mini-machine for producing nails. The need for it may arise at the very beginning of the formation of a company, when there is not enough money to purchase more expensive equipment.

However, it should be noted that productivity in this situation will be lower. For beginning entrepreneurs who do not want to spend too much money on purchasing machines, this option is optimal.

Nail production process: description

The simplicity of the product manufacturing technology is another advantage of the business:

- The metal wire (in coils) is straightened as it unwinds and enters the nailing machine.

- The machine grabs the wire and cuts it into pieces of the required length.

- The machine processes workpieces with an upsetting slider:

- caps are formed, which are given a corrugation - this reduces the risk of slipping when working with a hammer;

- notches are made on the nail shaft for stronger fastening;

- a tip is created.

- If additional surface treatment is required (galvanizing, bluing, tinning), the workpiece enters a special apparatus.

- The finished product is dumped into a receiving hopper.

Recommendations that can help in using nails

There are a number of practical tips that will help you use nails for their intended purpose without causing defects in the material being repaired. Consider the following:

- when using any type of nails, it is necessary to nail a thin part to a thick one;

- when choosing the length of the material, you should take into account that the minimum insertion of the tip should be one third;

- if the wood being fastened with a nail tends to crack, then the fastening site must first be drilled with a drill diameter corresponding to the diameter of the nail rod;

- You can prevent cracking of the wood by blunting the tip of the fastener;

- It is also not recommended to drive a nail into a knot, regardless of what type of fastener it is, since the structure of the knot is completely incompatible with the metal alloy.

On a note! Nails should be used strictly for their intended purpose in relation to a specific type of material, since incorrect use of fasteners can affect the reliability of the connection.

Types of nails for construction from different alloys Source setafi.com

How to organize production

You can set up a business on nails with a small investment. The table shows the approximate amount required to open a mini-factory, but you can start with less money. Especially if you have your own garage.

Table 1. Start-up investments for a nail business.

| Expense item | Cost, rub. |

| Registration | 20 thousand |

| Premises for rent, 50 sq. m | 60 thousand |

| Equipment | 750 thousand |

| Raw materials (for a month at full load) | 450 thousand |

| Salary, 4 people. | 130 thousand |

| Additional expenses | 150 thousand |

| Total | 1.560 million |

The calculations are relevant for a city with a population of up to 1 million people. Additional expenses - for utility bills, advertising, preparation of the premises.

Production of products for air guns

In order to produce bobbin fasteners that are used in air guns, capping machines should be used. They solder the final products onto the raw material, which is wire. To produce nails, you can also use smooth, screw or rough blanks.

Thus, in order to establish a full production cycle of products, it is necessary to purchase a whole range of equipment. The following necessary devices for creating fasteners of this type can be distinguished: nailing and rolling machines, tumbling installations and a capping machine. Also, if necessary, you will need to purchase a device that applies special coatings to workpieces.

Factory registration

A small production of nails can be registered in the form of an individual entrepreneur (individual entrepreneur). This is suitable for small production and sales volumes. Working as an individual does not allow you to cooperate with large consumers and wholesale suppliers.

You can build a large distribution network in the form of a legal entity (LLC). Here it is possible to increase the scale of work and cooperate with construction companies and intermediaries.

When registering an activity, the OKVED code 25.93 “Production of products from wire, chains and springs” is indicated.

A certificate authorizing the industrial production of nails is not required. However, it is better to submit your product for examination to obtain a voluntary GOST certificate. Such a document will provide significant advantages to a businessman when making sales and concluding supply contracts.

Formal side of the matter

The production must be formalized legally. This is the only way it can work within the framework of the country’s legislation. Choose a form of activity for the enterprise and a simplified taxation system of 6%. OKVED code for the enterprise: 25.93. It is extremely difficult to formalize legal proceedings on your own. There are a number of subtleties and nuances, ignorance of which can lead to delays in opening an organization. It is recommended to contact lawyers who will take on the formal side of the matter. The one-time remuneration for such employees will be about 30-50 thousand rubles.

Equipment

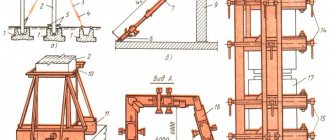

It won’t take a lot of money to purchase equipment. You'll definitely need a nailing machine. The machine is selected depending on the type of product being produced.

If the creation of ordinary construction nails requires simple equipment, then for other types additional machines are needed;

- Wire holder. Reels with raw materials are attached to it.

- Apparatus for processing the appearance of nails. Galvanizing, bluing, varnishing, hardening, tinning and other operations significantly improve the characteristics of products.

- Hydraulic trolleys for transporting raw materials and finished products in the workshop and warehouse.

In this business plan, we will take as an example a 1C 0.9-16 machine with a productivity of 450 pcs./min.

What machines are needed to create screw products?

When making nails with screw or ring knurling, you need to buy knurling machines, which in many situations are equipped with a segment roller. As raw materials, it is necessary to use smooth fasteners, the creation of which took place on a nailing machine.

It should also be understood that the raw materials must be pre-cleaned before use through the use of a tumbling machine. These types of fasteners can also be coated with a special coating that serves as protection against rust.

In order to set up a full cycle, you should buy a nailing and rolling machine. To produce nails, a tumbling device is also required. A machine for applying protective coatings will not be superfluous if this is provided for in the business plan.

Staff

Low labor costs are another feature of the business. Almost all the work is done by equipment that requires only maintenance and monitoring. The machines will be serviced by one worker-operator under the guidance of a technologist/senior in the workshop. You can “make” a technologist yourself. Manufacturers of nail machines provide training on the use of their equipment.

Workers will manage equipment and production, pack and ship finished goods, receive raw materials, and warehouse work.

A cleaner will be needed to ensure the cleanliness of the workshop.

Much attention should be paid to finding distribution channels - a sales manager can best handle this.

At first, the businessman himself can deliver products to customers (to reduce costs). The reporting will be carried out by an outsourced accountant.

How to register your business

We must immediately warn you that wholesale purchasers of products will not cooperate with an unregistered enterprise. And it is unlikely that it will be possible to “hide” the production of nails from the tax service - the scale is too large.

The choice in registering the form of business activity under which the production of nails falls is small - either individual entrepreneur or LLC. You can find out the difference between a private entrepreneur and a limited liability company in this source. You can read how to register an individual entrepreneur here, and how to register an LLC here.

Another difficult economic issue that you have to solve when organizing your business is the choice of taxation system. You can find out what types of tax regimes are preferable for small and medium-sized businesses, their main advantages for a particular form of doing business, at this link -.

OKVED code for the production of nails: 28.73.

Attention! This is important: from January 1, 2022, the classification of OKVED codes will be changed, and the production of nails will be registered under code 25.93. For existing businesses, the code will be replaced automatically. Beginning entrepreneurs will need to provide new data when registering.

Premises (workshop)

Production will not require large areas. Can accommodate 50 sq. m, some of which will be occupied by warehouses, and some by the workshop itself with equipment.

When choosing a room, consider the following:

- all communications must be connected (electricity 380 V, water supply, lighting, heating, ventilation);

- artificial lighting in the workshop should be bright - regardless of the size of the workshop and the covering of the walls;

- It is better to maintain a warm and dry atmosphere in the warehouse to prevent moisture from affecting the wire and finished products;

- production is noisy, so renting premises in residential blocks is not worth it;

- There must be vehicular access to the premises for the delivery of raw materials and shipment of goods.

Business profitability

As for the economic efficiency of this type of business, it depends on the cost of raw materials and the level of demand for finished products in a particular region. However, rough calculations suggest that when producing 4.0-4.5 tons of nails per month, the initial costs are recouped in a year (provided that all products can be sold). This means that the profitability is about 29%.

The main disadvantage of this type of business is the high level of competition. But in some regions this production may turn out to be not only stable, but also quite profitable. It is possible to increase the level of profitability only if there is a reliable supplier of raw materials that provides them at a reasonable cost.

(.rar file)

What kind of wire is needed: we talk about raw materials

The fastening material is made from steel wire of various cross-sectional diameters (depending on the type and size). The following grades of wire are used for construction nails: ST 1 KP, ST 2 KP, ST 3 KP. It is sold in reels weighing 200-1500 kg. For small production, coils weighing up to 500 kg are suitable so that the machine has enough power to unwind the skein.

Finding raw materials will not be a problem. It is sold in every Russian region at metal rolling depots. Finding high quality wire is important for long term success.

Consumables include boxes, boxes - containers in which finished products will be stored - and machine oil for the nailing machine.

Types of machines

Wire nailing machines are divided into two types:

- impact machines or press machines;

- rotary type units.

Impact press machines - form a head by hitting two hammers, and do not have a high enough productivity. In addition, the disadvantages include loud noise during operation and frequent breakdowns. Rotary type devices have higher performance and are much quieter.

In addition, the machines are divided into high-performance, powerful and multifunctional wire-nailing machines and machines for small production in small batches, with fixed sizes of manufactured parts.

The units differ in the following parameters:

- Power - usually it ranges from 3 to 20 kW.

- Different lengths of finished products - from 12 to 320 mm.

- Speed of production - here the parameter varies from 100 to 600 nails per minute.

- The ability to use wire of various diameters - from 1.2 to 9 mm, the presence of this option allows you to significantly expand the range.

- Adjustment of the head area of the hardware, which allows you to produce different types of nails.

- The weight of the machine is important when choosing a room. Devices weighing up to 0.7 tons can be installed in small spaces, but a device weighing 2 tons requires a solid concrete foundation.

Machine with nails

For production in small volumes

Due to the compactness of the corresponding special equipment, it is possible to open a mini-workshop or small production even in a room of 20 sq. m. The simplest production line consists of a hoist, a device for unwinding a reel of wire, and a wire nailing machine or mini-machine itself.

For a small workshop, it is enough to purchase a device with low power, approximately 3 to 5 kW. Devices of this type produce about 1 ton of products per shift, however, they do not have the option of adjusting product parameters and the ability to use wire of different diameters.

Nailers

Large enterprises use multifunctional, powerful units. The power of such installations reaches 20 kW. They allow high-performance production of construction hardware in large quantities, of any size and different diameters. This equipment allows you to produce up to 3 tons of finished products per shift.

Popular models

Today, companies selling this type of equipment present a wide range of wire nailing machines. The most popular of them are:

- AB4116 is a single-impact unit that produces hardware from light low-carbon steel wire with a conical head, with a diameter of 2.0 - 4.2 mm, the length of the products ranges from 13 to 250 mm. Productivity - about 350 units/min. Engine power 5.5 kW. The cost of the device ranges from 1,104,000 to 1,500,000 rubles.

- K09.117.01 - wire-nail device for the production of nails with a length of 13 to 120 mm, a diameter of 2.0 - 4.2 mm. The installation has high productivity with a power of 5.5 kW. The price starts from 280 thousand rubles.

- K09.117.02 - high-performance equipment with a power of 5.5 kW. It produces products with a length of 13 to 150 mm, using wire with a cross-section of no more than 5 mm. Productivity ranges from 250 to 525 units/min. A distinctive feature is the presence of adjustment of the longitudinal size of the rod. Cost K09.117.02 from 180 thousand rubles.

- Z94-2С - produces hardware with a length of 16-50 mm, a diameter of 1.2-2.8 mm. With a power of 2.2 kW, the estimated productivity is 300 units/min. The cost of the device is 200 thousand rubles.

Equipment selection

Sales and Marketing

The business is considered highly competitive. There are many large, medium and small nail manufacturers in the market. To attract customers, you need to position yourself as a reliable supplier of high-quality goods.

We need advertising in print media (including thematic publications), as well as on the Internet. You need to publish and promote your ads and advertisements online using all possible online resources and tools.

Direct advertising and direct contact with large consumers are important. The best thing is to find a large wholesale buyer. This:

- construction companies;

- metal rolling bases;

- construction stores, including chain stores;

- furniture manufacturers;

- construction and repair teams.

You can establish business contacts by calling potential clients, sending commercial offers by email, and visiting offices.

High popularity of building element

In modern conditions, this type of hardware, such as nails, is quite in demand. There is a demand for them both among numerous construction companies and among ordinary people. Those who create this fastener understand that their companies bring stable profits. Accordingly, opening your own enterprise in this field of activity is quite profitable.

Is nail production profitable: financial plan

The amount of initial costs is 1.56 million rubles.

As an example, let's take the production of nails measuring 3.0 x 80 mm. In an 8-hour shift, 216 thousand products (935 kg) can be produced. The workshop will operate in one shift 22 days a month. The production volume for this period is 4.752 million units. (20.6 t).

The average price of 1 kg of material is 75 rubles. So in a month you can earn 1.545 million rubles.

The total monthly costs will be 740 thousand rubles.

Net profit - 805 thousand rubles.

Under ideal conditions, the business can pay for itself in less than 2 months. But given the high competition and other risks, it is almost impossible to sell all the goods produced in a month.

Taking into account that 30% of the entire monthly volume produced will be wasted, we determine that the payback period increases at least three times. And taking into account the seasonality factor - even more. If you actively promote your products, your nail business will pay for itself in about 6-9 months.

Table 2. Economic justification for the business idea.

| Basic indicators | Meaning |

| Initial investment amount | RUB 1.560 million |

| Monthly expenses | 740 thousand rubles. |

| Productivity per month | 4.752 million ed. (20.6 t) |

| Monthly income | RUB 1.545 million |

| Net profit per month | 830 thousand rubles. |

| Payback period | 2 months (6-9 months) |

How to find sales channels for finished products

You can organize the sale of products at retail and small wholesale directly during production, by opening a small store “on the side”, or by organizing the delivery of the required number of nails to order.

Although, of course, first of all, you need to focus on buyers of large wholesale quantities, preferably regular ones. This category of buyers includes:

- Construction stores and metal warehouses

- Construction companies

- Furniture manufacturing companies

You can establish contacts using “cold calls”, by submitting advertisements in thematic media or posting on thematic Internet forums. It may be that at first, in order to attract customers, you will have to resort to dumping - lowering prices in comparison with competitors. But the costs are fully compensated by the volume of purchases.

Don’t forget that you can discuss your favorite business idea with other readers on the blog forum.