Slings: varieties, markings, rejects, components

Slings are simple attachments that are used for lifting and moving various fixtures. Translated from Dutch, the word “strop” means “loop”. The attachment is made up of one or several hook elements, the ends of which are closed in a loop or equipped with vantage-spitting devices.

Depending on the material of the bungee elements, slings are divided into three types: rope, lance and textile. Each type of leather is, in turn, divided into subspecies depending on the design: loop, ring, girdle.

Then the slings are attached to the hook of the crane. These types of objects are used to grasp important objects. Also, the lines can be stiffened to fasten the parachute canopy, gondolas to airships and aerostats. Widespread use of vandalism was found in everyday life, rural government, vantage transport, timber industry, metallurgical complexes and other areas.

Rope slings

With the help of rope slings, many types of vantage operations are carried out. The drink does not fall on the virobi due to its handiness and low wariness. The main element of the sling is a steel rope, made from metal darts wound into a skein. In the middle of the rope there is a hemp core. Since the suspension is made up of several ropes, they are fastened to a special strap.

Massive ropes, for work involving rope slings, require special eyelets or rings. The fixing pins are attached to them.

Depending on the design, rope slings are divided into the following types:

- SKP (USK1) – double-loop, vikorist is important for fastening the shrouds to the crane hook. Vantage value - from 0.5 to 16 tone;

- SKK (USK2) – ring-shaped, mounted during operation with lifting cranes to secure the hangers. There may be an advantage in alignment with the SKP - double the smaller diameter of the cable with the same performance indicators. Pristosuvannya can be used for robots with vantages up to 32 tons;

- 1SK – single-headed, equipped with thimbles, hooks and rings. Often used in repair kits for heavy-duty slings. Vantage value – up to 16 tons;

- 2SK – double-headed, vicorized for fastening the hangers to the tap with the help of hooks. Vantage value – up to 16 tons;

- 3SK - triohgilkovi. Required both in everyday life and in transport companies;

- 4SK – chotirigilkovi or “spiders”. The value of such installations can reach 50 tons. Vikorystvayutsya in the industrial and everyday spheres.

The length of rope slings is from 1 to 15 meters. Before preparing, it is possible to prepare vantage joints with longer gilts. The diameter of the ropes is up to 46 mm. Operation of the devices is allowed at temperatures ranging from -60 to +400 degrees.

The ends of rope slings, closed in a loop, are finished in two ways - braided and pressed. The first method today is respected by the old ones, who want to become rich in the literature. It is important to intertwine the rope with each other and fasten their ends by the frame or rub it with force. The more attention there is on the cable loop, the more force there is to fight one by one. Places where the ends of the rope are intertwined are insulated to ensure that those who work with the sling will not be damaged by washing with darts.

The pressing method depends on the placement of the ends of the cable with a sleeve made of aluminum or other soft metal. The bushing is crimped in a special manner to remove the seals completely. The process of compressing partial mechanization, which reduces its productivity and increases productivity.

Rope slings have a lot of advantages:

- resistance to increased pressure and sudden lifts (tear resistance);

- disgusting humility;

- resistance to wear;

- the ability to quickly detect defects;

- low varity.

Rope slings have some disadvantages. This is a great value, low repairability, the possibility of damage to the surface, and the likelihood of injury from contact with broken darts.

Lantsyugov's slings

The head element of the lance sling is a steel lance with a value class of 4 to 12. To connect the lance slings, welding is required. Gilks are equipped with hooks. Dovzhina hilok can reach 20 meters. Lantsyugov slings are considered universal, as they can be used for work with all types of applications. It is required in metallurgy, in chemical, nuclear, burning industries, in important machinery, as well as in warehouse facilities.

Like other types of similar attachments, lancets are classified according to design and divided into heels and rings. Virobniks use the following types of lance slings:

- 1SC – single-headed, can be used both independently and for collecting multiple-headed compounds;

- 2SC – double;

- 3SC – triohgilkovi;

- 4SC – either gilkovic or lantzug “spiders”, suitable for working with items of non-standard shape;

- VTs – Lantsyugova gіlka, equipped with rings or hooks;

- USC – universal rings, vikorista for girth of vantages;

- STs1VZ – with one closed loop;

- STs2VZ - with two closed pins.

The importance of lance slings depends on the value class of all their elements. With a higher class, the quality of the lancet decreases, and the materiality of the application increases the term of its service. Slings of various classes of value may have the following resistance (data given for temperatures up to 200 degrees for one lance with a minimum diameter):

- class 3 – up to 100 kg;

- class 5 – up to 300 kg;

- class 8 – up to 800 kg;

- class 10 – up to 1200 kg;

- class 12 – up to 3150 kg.

At elevated temperatures, the permissible intensity of the germs changes by 10-15%.

The importance must be placed in the middle and according to the diameter of the Lancug strap. This information is presented in the table:

Lantsyugov's slings are thinner, which allows for different slinging methods. Suspension can be cured at temperatures ranging from -40 to +500 degrees. This category of slings can be repaired. Damaged lanks can be replaced and the vibrator removed. Lantsyugov's vantage-proof installations are considered to be the safest, since deformation of the straps can be detected immediately. The dovzhin of Lanzug can be changed in the future, if necessary.

If there are not enough people, then there are not enough of them. Lantsyugov's lines are wobbling a great wave. Ale lancets of high quality classes (8-12) are produced in a smaller diameter, which practically fits a small part. Another minus of pristosuvan is high varity.

Textile slings

Both lanyards and rope slings add foldables for maneuvering and importance. The stench is not suitable for robots with loud or far-fetched vantages, because they can damage the surface. In this situation, textile slings will come in handy as they provide the necessary flexibility, reliable fixation and necessary slinging.

Textile slings come in two types – stitch or round-strand. The first ones are produced in seemingly stitches from one or several balls of synthetic material (nylon, polyester or propylene). Round strand slings are made from a polyester core placed in a sleeve made of polyester or nylon fabric. For plasticity and flexibility, round-strand models are superior to stitch ones.

The design of the sling is divided into three types:

- loops (STP) – a stitch with two loops at the ends, covered with tread fabric;

- kіltsevі (STK) – a stitch, closed in a ring;

- Gilkov - can be with one (1ST), two (2ST), three (3ST) or several (4ST) sleeves equipped with vantage-spitting elements.

The designation of orbicular virobes is preceded by the letter “K”. Ring and loop options are the most universal. They are used for tying the vantages.

The slings are made in different colors. The color of the stitch means its importance. Color identification is used for clear visual distinction between colors. The width of the stitch also depends on the flexibility of the stitching.

The main advantage of textile slings is their compactness and low weight. When stored properly, they take up minimal space and are easy to transport. The top stitching does not damage the fabric. Synthetic materials, made from chemically resistant materials, are resistant to temperature changes, moisture, infusion of naphtha products and organic solvents. Fabricating textile slings is much cheaper than rope and lance slings.

The maximum temperature of the surface of the rods with which the lines are in contact must not exceed 100 degrees, and the minimum cannot be lower than -40 degrees. Textile materials are not resistant to acids or acids. Preserve drying only in closed areas due to resistance to ultraviolet radiation.

Marking of slings

The current ESKD standard ( GOST 2.114-2016

) the content and procedure for presenting technical requirements in GOSTs, TUs and RDs for the manufacture of various products are regulated.

Clause 5.3

of this standard defines the requirements for the description of the “

Marking

” subsection, including for products during the operation of which certain requirements must be met for the safety of human health and life. Slings are a type of removable lifting devices that belong specifically to this category.

How are lines marked?

When producing any types of slings, use a rubber wash and mark them. It is applied both to the virus itself and to the metal tag so that it is securely attached to the vantage-spitting devices. The method of fastening must be such as to ensure the preservation of marking until the end of the sling's service life.

Marking on the market of vandalized goods is to blame for the available information:

- for rope slings – type, weight, serial number, stamp, trademark, date of manufacture;

- for lance slings – trademark of the enterprise, type of attachment, weight, class of value, serial number in the numbering system, working day, date of testing;

- for textile slings – trademark of the manufacturer, type, quantity, value, production date, serial number after the numbering of the manufacturer, assigned to the standard.

The marking is applied to the tag with permanent paint, the color of which is liable to differ from the color of the tag.

RD 10-33-93 “General purpose cargo slings” - basic provisions

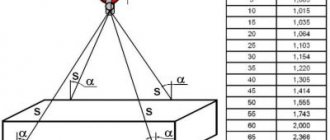

First of all, the designs of cargo slings used are determined. In total, there are two types - branch slings, equipped with a hook for gripping and a loop for attaching to a crane cable, and ring slings - closed into a loop, used for tying a load and usually used in conjunction with branch slings.

Regardless of the type of construction, sections of steel cables are used for the manufacture of rope slings; for chain slings, respectively, chains with round links of the same diameter are used. The load-carrying capacity of the structure can range from 500 kilograms to 50 tons and is necessarily indicated in the technical documentation of the product and on special tags.

The production of cargo slings can only be carried out by enterprises that have the appropriate license, certified by control authorities, and confirming the qualifications of personnel and the availability of the appropriate level of technical support for design and manufacturing in accordance with the norms of the RD.

The final documentation issued by such enterprises necessarily includes:

- a copy of the technical specifications provided by the customer;

- complete graphic diagrams of all sling elements with text explanations;

- technological map, which includes a list and detailed description of the product production processes;

- certificates confirming the suitability of the product has been tested in laboratory conditions using loads, the value of which must exceed the nominal value by an average of 25%;

- when used in the manufacturing process of welding seams - a certificate of appropriate education of the specialist who performed the welding.