There are several types of rope slings. In this article you can find out the advantages, scope, technical characteristics of the four-leg rope sling “4SK”.

The steel rope sling “4SK” consists of four rope branches attached to one loop. On the other hand, each branch has a steel hook.

Scope of application of this product:

- use slings during loading and unloading;

- they are used during construction and installation work (when lifting floor slabs, pipes, various installation works);

- during lifting and moving cargo by cranes (moving tanks, construction booths, guard houses);

- widely used in metallurgical enterprises;

- during logging;

In short, this type of sling is used in both small and large production.

It is indispensable when it is necessary to lift a fairly large load using four hooks.

“4SK” is also used in large warehouses.

All cargo must be equipped with special gripping devices: loops, staples, various grips.

Types of slings and regulations for their manufacture

Lifting slings are pieces of chains, ropes or textile tapes, made in the form of a ring or equipped with end lifting elements, intended for tying and hanging loads to lifting mechanisms and ensuring their convenient, fast, safe and reliable fastening.

Currently, the following main types of slings are used as part of lifting equipment, each of which is produced in accordance with the relevant regulatory documentation that defines the technical requirements for their production, including labeling:

- rope

slings are manufactured in accordance with GOST 25573-82; RD-10-33-93 and RD 11-07-2007; - chain

slings are produced in accordance with RD 11-07-2007 and GOST 30441-97; - textile

slings - flat and round-stranded - according to RD 24-SZK-01-01; RD 11-07-2007 and PB 10-382-00.

Guiding documents RD-11-07-2007

, in particular, the symbols for all categories of slings are described, reflecting their type and main parameters. According to this regulatory document, the designation structure of slings includes: name, type, load capacity, length, design, strength class.

Selection of slings for strength depending on the slinging scheme

Initially, the selection of slings is made individually for the loads to be worked with.

- Steel has gained popularity in construction and lifting operations. This became possible thanks to the highest load-carrying capacity of the slings, long service life, practicality and low price. At the same time, a solid load can partially deform the branch, and the maximum operating temperature is only 100C, which causes a number of restrictions in the industry.

- The chain sling is suitable for working in difficult conditions with high temperatures and aggressive environments. Despite their high cost, the slings ensure reliable movement of cargo without risks, and their service life is up to 10 years, and repairs are carried out in a matter of minutes. Minimum space is required for storage and transportation.

- Textile sling is relevant for a smaller load, but it is cheap, used in the range from -80C to +100C, is extremely elastic and durable, and there is no metal in the design. It is only important to remember that ultraviolet radiation, dynamic loads and aggressive liquids are destructive to matter.

In most cases, the characteristics of the slings play a decisive role, so specialists immediately purchase equipment with the expectation of maximum lifting capacity, relying on the increasing coefficient from the angle of inclination of the sling.

Rope slings

Rope slings are metal cables with gripping elements at the ends. Slings in this category are divided into loop, ring and single- and multi-branch straight.

For loop and ring cables, the first place in the abbreviation of the designation is the letters corresponding to their name: VK

— rope branch;

SK

- sling made of round-strand rope.

Next comes a letter indicating the type of sling - P

- loop,

K

- ring.

This is followed by a number indicating the lifting capacity of the sling in tons and a number corresponding to the length of the sling in millimeters. Then come the letters indicating the design of the product: Vo

- fibrous with organic threads,

Vs

- with synthetic threads,

Vk

- combined;

W

- twisted;

Ksk

- with a sliding hook;

Pl

- from flat steel rope, etc.

Thus, a sling with the designation SKP-6.3-4000-Pl is a rope sling with a loop lifting capacity of 6.3 tons and a length of 4000 mm made of flat steel rope, and SKK-3.2-2000-Vt is a rope sling with a ring lifting capacity of 3 ,2 tons 2000 mm long of twisted round-strand rope.

For branch slings, the first place in the symbol is a number corresponding to the number of branches, respectively: 1SK

;

2SK

;

3SK

;

4SK

are one-, two-, three- and four-leg slings. And the symbol 4CK-25.0-6000-Pl-HL corresponds to a four-legged sling with a lifting capacity of 25 tons and a length of 6000 mm made of flat steel rope for cold climates. Figure 1 shows the main symbols for rope slings, and Figure 2 shows an example of product markings provided for by regulatory documents, which are applied to the sling grip and all its elements.

Picture 1

Figure 2

Differences and technical characteristics

Among the advantages of this type of slings, the following should be noted:

- Ease of manufacture - unlike other slings, they do not require special equipment and knowledge in their production.

- Reliability and resistance to various loads.

- Fairly high flexibility.

- The ability to notice damage at an early stage and replace the failed part.

- Ability to work in almost any weather conditions.

- The maximum temperature ranges from -40 to + 400 degrees.

- Inexpensive cost "4SK".

Disadvantages include the rigidity of rope slings - they are not designed for transporting more delicate loads.

Specifications

“4SK” is also called “spider”. When considering the technical characteristics, it is necessary to pay attention not only to the length and load-carrying capacity of the models, but also to the designation of links and hooks.

“4SK – 1.25”

- length – 1 m;

- rope diameter – 8.3 mm;

- thimble diameter – 34 mm;

- load – 1.25 t;

"4SK - 1.6"

- length – 1 m;

- rope diameter – 8.3 mm;

- thimble diameter – 34 mm;

- load – 1.6 t;

"4SK-2.0"

- length – 1 m;

- rope diameter – 9.8 – 11.0 mm;

- thimble diameter – 34 mm;

- load – 2.0 t;

"4SK - 2.5"

- length – 1 m;

- rope diameter – 11mm;

- thimble diameter – 34 mm;

- load – 2.5 t;

"4SK - 3.2"

- length – 1 m;

- rope diameter – 11.5 – 12.0 mm;

- thimble diameter – 40 mm;

- load – 3.2 t;

"4SK - 4.0"

- length – 1 m;

- rope diameter – 13.5 – 14 mm;

- thimble diameter – 40 mm;

- load – 4.0 t;

"4SK - 5.0"

- length – 1.5 m;

- rope diameter – 15 mm;

- thimble diameter – 45 mm;

- load – 5.0 t;

"4SK - 6.3"

- length – 1.5 m;

- rope diameter – 16.5 – 17.5 mm;

- thimble diameter – 56 mm;

- load – 6.3 t;

"4SK-8.0"

- length – 2 m;

- rope diameter – 19.5 mm;

- thimble diameter – 63 mm;

- load – 8.0 t;

"4SK - 10.0"

- length – 2 m;

- rope diameter – 21 – 21.5 mm;

- thimble diameter – 63 mm;

- load – 10.0 t;

"4SK - 12.5"

- length – 2.5 m;

- rope diameter – 23.5 – 24.0 mm;

- thimble diameter – 63 mm;

- load – 12.5 t;

"4SK - 16.0"

- length –2.5 m;

- rope diameter – 27.0 mm;

- thimble diameter –75 mm;

- load – 16.0 t;

"4SK - 20.0"

- length – 3 m;

- rope diameter – 30.5 mm;

- thimble diameter – 85 mm;

- load – 20.0 t;

All technical characteristics are given taking into account that the load is distributed evenly across all four branches.

Chain slings

Instead of ropes, chain slings use pieces of metal short-link chains made of high-strength steel by welding. They, just like cable ones, can be circular and single- or multi-branch.

The symbols of their types include a strength class, designated by a number from 1 to 8, which appears in the first place of the designation. Next are the letters corresponding to the type of sling:

- VC

- chain branch; - SCK

- ring chain sling; - 1SC

;

2SC

;

3SC

;

4SC

- one-; two-; three-; four-leg sling.

Then, as with a rope sling, the load capacity and length of the sling are indicated, and then the design. An example of a marking tag is shown in Figure 3.

Figure 3

Calculation of forces in sling branches

The lifting capacity of the sling must be indicated on the tag by the manufacturer, but this only applies to the direct slinging method. When slinging at an angle, the maximum lifting capacity of the rigging changes. It is necessary to provide a certain margin of safety and correctly calculate the maximum and minimum length of the slings.

Rostechnadzor rules recommend selecting the length of the sling branches so that the load on the branch does not increase. The shorter the length of the slings during multi-leg slinging, the greater the angle between them. At the same time, the force in the branches increases. An angle of 60-90 degrees between the branches and no more than 60⁰ deviation from the vertical axis is considered acceptable. If the angle of deviation from the vertical is not observed, torsion of the load occurs during operation, and the lifting height of the load decreases.

Formula for calculating the lifting capacity of slings (general view):

S=9.8*G/(M*Kz*Cos(b))

G – load weight

M – number of branches

Kz – a special coefficient that takes into account the slinging scheme, if the number of branches is less than 4 Kz=1, otherwise Kz=0.75

b – angle of inclination of the sling branch to the vertical

Calculation of breaking force for textile, steel rope and chain slings is carried out using the following formula

R=kzap.*S

k zap. For steel rope slings it is 6, for chain slings 4, for textile slings it is 7.

The next step is to determine the minimum length of the slings:

Lmin=1.12*Lcenter, where Lcenter is the size of the distance between the center of gravity and the attachment point of the sling branch.

Where to buy slings 2SK and USK1

offers customers from Moscow and the regions a large assortment of slings, traverses and accessories for them. We cooperate only with trusted manufacturers of rigging equipment, so we can guarantee you the quality and reliability of all the products we supply.

We recommend that our customers choose slings taking into account the characteristics of the load being moved. The price of the issue in this case is important, but not decisive. If necessary, our consultants will help you with choosing a product and making a purchase. You can use the delivery service by specialized services and receive your order in a short time.

MAIN PARAMETERS AND DIMENSIONS

2.1. The main parameters and dimensions of slings of type 1SK must correspond to those indicated in Figure 1 and Table 1.

Damn.1. Sling with rope ends sealed

Sling with the ends of the rope sealed by crimping an aluminum or steel sleeve

Sling with braided rope ends

1

— rope branch;

2

- link;

3

- capture Drawing 1

Table 1

| Sling designation | Load capacity, t | Sling length , mm | Rope branch designation | Permissible load on link and grip, kN (tf) |

| 1SK-0.32 | 0,32 | 900-5000 | VK-0.32 | 3,14 (0,32) |

| 1SK-0.4 | 0,40 | VK-0.4 | 3,92 (0,40) | |

| 1SK-0.5* | 0,50 | 1100-10000 | VK-0.5 | 4,90 (0,50) |

| 1SK-0.63 | 0,63 | VK-0.63 | 6,18 (0,63) | |

| 1SK-0.8 | 0,80 | 1100-15000 | VK-0.8 | 7,85 (0,80) |

| 1SK-1.0* | 1,00 | VK-1.0 | 9,81 (1,00) | |

| 1SK-1.25 | 1,25 | VK-1.25 | 12,26 (1,25) | |

| 1SK-1.6 | 1,60 | 1400-16000 | VK-1.6 | 15,70 (1,60) |

| 1SK-2.0* | 2,00 | VK-2.0 | 19,62 (2,00) | |

| 1SK-2.5 | 2,50 | VK-2.5 | 24,52 (2,50) | |

| 1SK-3.2* | 3,20 | 1500-20000 | VK-3.2 | 31,40 (3,20) |

| 1SK-4.0 | 4,00 | VK-4.0 | 39,24 (4,00) | |

| 1SK-5.0* | 5,00 | VK-5.0 | 49,05 (5,00) | |

| 1SK-6.3 | 6,30 | 2000-20000 | VK-6.3 | 61,80 (6,30) |

| 1SK-8.0 | 8,00 | VK-8.0 | 78,50 (8,00) | |

| 1SK-10.0* | 10,00 | VK-10.0 | 98,10 (10,00) | |

| 1SK-12.5 | 12,50 | VK-12.5 | 122,60 (12,50) |

Note. Here and in the following tables, slings recommended for primary use are o; the numbers in the designation of the rope branch correspond to the permissible load on it in tonnage. The design and dimensions of the links and grips are given in Appendix 1. Recommendations on methods for sealing rope ends are given in Appendix 2. The symbol includes the name of the product, type, load capacity, length and designation of this standard. An example of a symbol for a single-leg sling with a lifting capacity of 1.6 tons and a length of 2000 mm:

Sling 1SK-1.6/2000 GOST 25573-82

The same, intended for use in areas with cold climates:

Sling 1SK-1.6 HL/2000 GOST 25573-82

(Changed edition, Amendment No. 1).

2.2. The main parameters and dimensions of slings of type 2SK must correspond to those indicated in Figure 2 and Table 2.

Damn.2. Main parameters and dimensions of slings type 2SK

1

— rope branch;

2

- link;

3

- capture Drawing 2

table 2

| Sling designation | Load capacity, t | Sling length, mm | Rope branch designation | Permissible load, kN (tf) | |

| per link | to capture | ||||

| 2SK-0.4 | 0,40 | 900-5000 | VK-0.32 | 3,92 (0,40) | 3,14 (0,32) |

| 2SK-0.5* | 0,50 | VK-0.4 | 4,90 (0,50) | 3,92 (0,40) | |

| 2SK-0.63 | 0,63 | 1100-10000 | VK-0.5 | 6,18 (0,63) | 4,90 (0,50) |

| 2SK-0.8 | 0,80 | VK-0.63 | 7,85 (0,80) | 6,18 (0,63) | |

| 2SK-1.0* | 1,00 | 1100-15000 | VK-0.8 | 9,81 (1,00) | 7,85 (0,80) |

| 2SK-1.25 | 1,25 | VK-1.0 | 12,26 (1,25) | 9,81 (1,00) | |

| 2SK-1.6 | 1,60 | VK-1.25 | 15,70 (1,60) | 12,26 (1,25) | |

| 2SK-2.0* | 2,00 | 1400-16000 | VK-1.6 | 19,62 (2,00) | 15,70 (1,60) |

| 2SK-2.5 | 2,50 | VK-2.0 | 24,52 (2,50) | 19,62 (2,00) | |

| 2SK-3.2* | 3,20 | VK-2.5 | 31,40 (3,20) | 24,52 (2,50) | |

| 2SK-4.0 | 4,00 | 1500-20000 | VK-3.2 | 39,24 (4,00) | 31,40 (3,20) |

| 2SK-5.0* | 5,00 | VK-4.0 | 49,05 (5,00) | 39,24 (4,00) | |

| 2SK-6.3 | 6,30 | VK-5.0 | 61,80 (6,30) | 49,05 (5,00) | |

| 2SK-8.0 | 8,00 | 2000-20000 | VK-6.3 | 78,50 (8,00) | 61,80 (6,30) |

| 2SK-10.0 | 10,00 | VK-8.0 | 98,10 (10,00) | 78,50 (8,00) | |

| 2SK-12.5 | 12,50 | VK-10.0 | 122,60 (12,50) | 98,10 (10,00) | |

| 2SK-16.0* | 16,00 | VK-12.5 | 157,00 (16,00) | 122,60 (12,50) | |

2.3. The main parameters and dimensions of slings of type 3SK must correspond to those indicated in Figure 3 and Table 3.

Damn.3. Main parameters and dimensions of slings type 3SK

1

— rope branch;

2

- link;

3

- capture Drawing 3

Table 3

| Sling designation | Load capacity, t | Sling length , mm | Rope branch designation | Permissible load, kN (tf) | |

| per link | to capture | ||||

| 3SK-0.63 | 0,63 | 900-5000 | VK-0.32 | 6,18 (0,63) | 3,14 (0,32) |

| 3SK-0.8 | 0,80 | VK-0.40 | 7,85 (0,80) | 3,92 (0,40) | |

| 3SK-1.0* | 1,00 | 1200-10000 | VK-0.50 | 9,81 (1,00) | 4,90 (0,50) |

| 3SK-1.25 | 1,25 | VK-0.63 | 12,26 (1,25) | 6,18 (0,63) | |

| 3SK-1.6 | 1,60 | 1200-15000 | VK-0.80 | 15,70 (1,60) | 7,85 (0,80) |

| 3SK-2.0* | 2,00 | VK-1.00 | 19,62 (2,00) | 9,81 (1,00) | |

| 3SK-2.5 | 2,50 | VK-1.25 | 24,52 (2,50) | 12,26 (1,25) | |

| 3SK-3.2* | 3,20 | 1600-16000 | VK-1.60 | 31,40 (3,20) | 15,70 (1,60) |

| 3SK-4.0 | 4,00 | VK-2.00 | 39,24 (4,00) | 19,62 (2,00) | |

| 3SK-5.0* | 5,00 | VK-2.50 | 49,05 (5,00) | 24,52 (2,50) | |

| 3SK-6.3 | 6,30 | 1700-20000 | VK-3.20 | 61,80 (6,30) | 31,40 (3,20) |

| 3SK-8.0 | 8,00 | VK-4.00 | 78,50 (8,00) | 39,24 (4,00) | |

| 3SK-10.0* | 10,00 | 2200-20000 | VK-5.00 | 98,10 (10,00) | 49,05 (5,00) |

| 3SK-12.5 | 12,50 | VK-6.30 | 122,60 (12,50) | 61,80 (6,30) | |

| 3SK-16.0* | 16,00 | VK-8.00 | 157,00 (16,00) | 78,50 (8,00) | |

| 3SK-20.0 | 20,00 | VK-10.0 | 196,20 (20,00) | 98,10 (10,0) | |

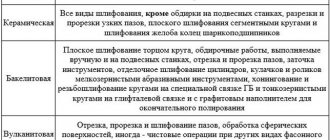

2.4. The main parameters and dimensions of slings of type 4SK, version 1, must correspond to those indicated in Figure 4 and Table 4, version 1a - in Figure 4a and Table 4 (except for column 6).

Damn.4. Main parameters and dimensions of slings type 4SK version 1

1

— rope branch;

2

- link 1;

3

— link 2;

4

- capture Drawing 4

Drawing 4a. Main parameters and dimensions of slings type 4SK, version 1a

1

- link;

2

— rope branch;

3

— capture Fig.4a

Table 4

| Sling designation | Load capacity, t | Sling length, , mm | Rope branch designation | Permissible load, kN (tf) | ||

| per link 1 | to link 2 | to capture | ||||

| 4SK1-0.63 | 0,63 | 900-5000 | VK-0.32 | 6,18 (0,63) | 4,90 (0,50) | 3,14 (0,32) |

| 4SK1-0.8 | 0,80 | 7,85 (0,80) | ||||

| 4SK1-1.0* | 1,00 | VK-0.4 | 9,81 (1,00) | 6,18 (0,63) | 3,92 (0,40) | |

| 4SK1-1.25 | 1,25 | 1200-10200 | VK-0.5 | 12,26 (1,25) | 7,85 (0,80) | 4,90 (0,50) |

| 4SK1-1.6 | 1,60 | VK-0.63 | 15,70 (1,60) | 9,81 (1,00) | 6,18 (0,63) | |

| 4SK1-2.0* | 2,00 | 1300-15000 | VK-0.8 | 19,62 (2,00) | 12,26 (1,25) | 7,85 (0,80) |

| 4SK1-2.5 | 2,50 | VK-1.0 | 24,52 (2,50) | 15,70 (1,60) | 9,81 (1,00) | |

| 4SK1-3.2* | 3,20 | VK-1.25 | 31,40 (3,20) | 19,62 (2,00) | 12,26 (1,25) | |

| 4SK1-4.0 | 4,00 | 1600-16000 | VK-1.6 | 39,24 (4,00) | 24,52 (2,50) | 15,70 (1,60) |

| 4SK1-5.0* | 5,00 | VK-2.0 | 49,05 (5,00) | 31,40 (3,20) | 19,62 (2,00) | |

| 4SK1-6.3 | 6,30 | VK-2.5 | 61,80 (6,30) | 39,24 (4,00) | 24,52 (2,50) | |

| 4SK1-8.0 | 8,00 | 1800-20000 | VK-3.2 | 78,50 (8,00) | 49,05 (5,00) | 31,40 (3,20) |

| 4SK1-10.0* | 10,00 | VK-4.0 | 98,10 (10,0) | 61,80 (6,30) | 39,24 (4,00) | |

| 4SK1-12.5 | 12,50 | VK-5.0 | 122,60 (12,5) | 78,50 (8,00) | 49,05 (5,00) | |

| 4SK1-16.0* | 16,00 | 2500-25000 | VK-6.3 | 157,00 (16,0) | 98,10 (10,0) | 61,80 (6,3) |

| 4SK1-20.0 | 20,0 | VK-8.0 | 196,20 (20,0) | 122,60 (12,5) | 78,50 (8,0) | |

| 4SK1-25.0 | 25,0 | VK-10.0 | 245,25 (25,0) | 157,00 (16,0) | 98,10 (10,0) | |

| 4SK1-32.0 | 32,0 | VK-12.5 | 313,92 (32,0) | 196,20 (20,0) | 122,60 (12,5) | |

(Changed edition, Amendment No. 1).

2.5. The main parameters and dimensions of slings of type 4SK, execution 2 must correspond to those indicated in Figure 5 and Table 5.

Library Energy

GOST 25573-82 29.05.2006STATE STANDARD OF THE UNION OF THE SSR CARGO ROPE SLINGS FOR CONSTRUCTION TECHNICAL CONDITIONS GOST 25573-82 STATE CONSTRUCTION COMMITTEE OF THE USSR Moscow STATE STANDARD OF THE UNION OF THE SSR CARGO ROPE

SLINGS FOR CONSTRUCTION Specifications Car go handling grief slings for building. Specifications

| GOST 25573-82 |

Date of introduction 01.01.84 This standard applies to cargo rope slings consisting of connecting elements (rope branches, links) and grippers (hooks, carabiners) and used in construction for slinging loads.

1. TYPES

1. Cargo rope slings must be manufactured of the following types:

- 1SK - single-branch;

- 2SK - two-branch;

- 3SK - three-branch;

- 4SK - four-branch (versions 1 and 2);

- SKP - two-loop (versions 1 and 2);

- SKK - ring (versions 1 and 2).

2. MAIN PARAMETERS AND DIMENSIONS

2.1. The main parameters and dimensions of slings of type 1SK must correspond to those indicated in the drawing. 1 and in table. 1.

3. TECHNICAL REQUIREMENTS

3.1. Cargo rope slings must be manufactured in accordance with the requirements of GOST 25032-81, this standard, the rules for the design and safe operation of load-lifting cranes of the USSR Gosgortekhnadzor, working drawings approved in the prescribed manner. (Changed edition, Amendment No. 1).

3.2. Climatic slings HL according to GOST 15150-69 must remain operational at low temperatures down to minus 60 °C.

3.3. Slings and their elements must withstand a static load exceeding 25% of their rated load.

3.4. The safety factor of sling ropes in relation to the calculated breaking force must be at least 6.

3.5. The safety factor of connecting elements (except ropes) and sling grips in relation to the breaking load must be at least 5.

3.6. The diameters of the blocks (leveling links) of the slings must be at least 8 rope diameters.

3.7. Ropes for slings must comply with the requirements of GOST 3071-88, GOST 3079-80 and GOST 7668-80. For slings of types 1SK, 2SK, 3SK and 4SK, it is allowed to use ropes in accordance with GOST 2688-80, GOST 3070-88, GOST 3077-80 and GOST 7665-80. For slings of climatic version HL, ropes in accordance with GOST 3071-88 and GOST 3079-80 should be used.

3.8. Rope branches of slings should be made from a whole rope. Splicing of ropes is not permitted.

3.9. Sling thimbles must comply with the technical requirements of GOST 2224-72. (Changed edition, Amendment No. 1).

3.10. The main parts of the slings must be made of the materials specified in table. 9.

Table 9

| Name of sling parts | Material grades for climate control parts | |

| U (temperate climate) | CL (cold climate) | |

| Hook, carabiner bracket | Steel 20 according to GOST 1050-88 | 15 HSND, 09G2S according to GOST 19281-89 |

| Parts of connecting elements bearing power load (except rope) | Steel 20 according to GOST 1050-88, St3sp according to GOST 380-88 | Same |

| Parts of connecting elements that do not bear a force load (carabiner plate, stop, half-coupling ring, hook lock). | St3ps according to GOST 380-88 | St3sp according to GOST 380-88 |

3.11. When making branches of slings of types 1SK, 2SK, 3SK and 4SK, the ends of the ropes are sealed by crimping aluminum or steel bushings or braiding. For HL slings, sealing the ends of the ropes with a steel sleeve is not allowed.

3.12. Bushings for sealing the ends of ropes by crimping must be made of aluminum alloys of the ADO, AD1, AD31, AMTs grades in accordance with GOST 4784-74 or from steel grade Steel 20 in accordance with GOST 1050-88.

3.13. The design and dimensions of bushings for crimping are given in recommended Appendix 2. The surface of the bushing before crimping should not have nicks, dents or other mechanical damage. If dents with a depth of more than 35% of the bushing wall thickness and cracks appear on the aluminum bushing, the slings are rejected. The terminated end of the rope must protrude from the sleeve by at least 2 mm. Sling bushings after crimping should not have cracks. (Changed edition, Amendment No. 2).

3.14. The difference in lengths of rope branches of slings of type 4SK1 should not exceed the values indicated in table. 10.

Table 10 (mm)

| Branch length | Branch length difference |

| Up to 2000 incl. | 20 |

| St. 2000 to 3000 » | 30 |

| » 3000 > 4000 » | 40 |

| » 4000 » 6000 » | 50 |

| » 6000 | 60 |

3.15. When sealing the ends of ropes with braiding, the braided areas must be rolled with crimping rollers or pulled through a crimping sleeve. When making individual slings, it is allowed to seal the braided area by tapping with a hammer. Braiding areas with protruding ends of the strand wires must be wrapped with wire with a diameter of 1 mm in accordance with GOST 3282-74 or other material. When winding with wire or other material, it must be ensured that the area with the protruding ends of the wire strands overlaps by 10-30 mm in both directions, depending on the diameter of the rope. The turns of the wire should fit tightly to the rope and to each other, and the ends of the wire should be sealed in a way that prevents it from unwinding. (Changed edition, Amendment No. 1).

3.16. Connecting elements (links) made of round steel must be made flexible in a cold or hot state, and grips (hooks, carabiners) must be made by forging or stamping. The quality of forgings is according to group II of GOST 8479-70. The use of welding in the manufacture of hooks is not allowed.

3.17. Cracks, films, delaminations, hairlines and tears are not allowed on the surfaces of parts of links and grips. It is not allowed to weld or seal these defects.

3.18. After bending or stamping, the ends of round steel links must be resistance or fusion butt welding. The weld on a triangular link should be centered on the bottom side of the link, and on an oval link on a straight section. It is allowed to use manual arc welding of a welded joint with structural elements developed according to documentation approved in the prescribed manner. (Changed edition, Amendment No. 1).

3.19. When welding round steel links, the increase in diameter at the welding site should not exceed 10%.

3.20. The displacement of the welded ends of the link at the joint should not exceed the values given in table. eleven.

Table 11 (mm)

| Link section diameter | Link end offsets |

| Up to 13 incl. | 0,5 |

| St. 13 to 24 » | 1,0 |

| » 24 » 40 » | 1,5 |

| » 40 | 2,0 |

3.21. Welding materials used for welding sling parts must ensure the mechanical properties of the welded joint are not lower than the mechanical properties of the base metal.

3.22. There should be no lack of penetration or undercuts in the welding areas.

3.23. Welding of sling links must be carried out by welders certified in accordance with the rules for certification of welders of the USSR State Mining and Technical Supervision.

3.24. Welding of carabiner plates is carried out by spot contact welding in accordance with recommended Appendix 1. After welding, the plates must move freely without jamming.

3.25. Hooks after forging or stamping, brackets of split links after bending, and permanent links after welding must be heat treated and free of scale. Parts for slings of climatic version U must be subjected to normalization, and parts of climatic version HL must be normalized or hardened with subsequent tempering. After heat treatment, the hardness of the metal of parts of climatic version U must be no less than HB 110, of climatic version KHL - no less than HB 135, the impact strength of metal of parts of climatic version KHL must be no less than 29 J/cm2 (3 kgfChm/cm2) at a temperature of minus 40 ° WITH. The yield strength and relative elongation of the metal parts after heat treatment must be no lower than before heat treatment.

3.26. The strips for detachable links Рт1, Рт2 and Рт3 can be made from a set of plates with a thickness of at least 12 mm. (Changed edition, Amendment No. 1).

3.27. The design of the cages of equalizing blocks must exclude the possibility of spontaneous falling of ropes from the block.

3.28. The equalizing blocks must rotate freely on their axes.

3.29. The blocks must be made of steel with mechanical properties no lower than steel grade 25L-111 according to GOST 977-88.

3.30. The axles of the blocks should be manufactured in accordance with the requirements of GOST 9650-80.

3.31. The axles of the blocks must be made of steel with mechanical properties not lower than steel grade 35 according to GOST 1050-88, execution KHL - from steel 40X according to GOST 4543-71.

3.32. Before using the slings, it is necessary to remove the preservative lubricant from the rope branches.

3.33. Unspecified maximum dimensional deviations:

- according to H16, h16, ± - for parts made by flexible;

- formed during mechanical processing - according to H14, hl4, ±;

- formed by stamping - according to group II GOST 7505-89;

- formed by forging - according to GOST 7829-70.

3.34. Slings having detachable links of the RT2 type with an increased bending radius of the bracket and oval links of the Ov2 type are hung on the hooks of lifting machines with a lifting capacity of 3 to 25 tons according to Table. 11a.

Table 11a

| Hook capacity | Link type | |

| lifting machine, t | RT2 | Ov2 |

| 3,0 | — | Ov2-0.4 Ov2-0.5 Ov2-0.63 |

| 5,0 | Рт2-0.8 Рт2-1.0 Рт2-1.25 | Ov2-0.8 Ov2-1.0 Ov2-1.25 |

| 10,0 | Рт2-1.6 Рт2-2.0 Рт2-2.5 Рт2-3.2 | Ov2-1.6 Ov2-2.0 Ov2-2.5 Ov2-3.2 |

| 16,0 | Rt-4.0 Rt-5.0 Rt2-6.3 Rt2-8.0 | Ov2-4.0 Ov2-5.0 Ov2-6.3 Ov2-8.0 |

| 25,0 | Рт2-10.0 Рт2-12.5 Рт2-16.0 | Ov2-10.0 Ov2-12.5 Ov2-16.0 |

3.35. It is allowed to make the end of a sling of type 1SK similar to the type of sling SKP1.

3.36. It is allowed to use safety locks in hooks, manufactured in accordance with GOST 12840-80 or working drawings of manufacturers, approved in the prescribed manner and agreed upon with the base organization for load-handling devices of the USSR State Construction Committee.

3.37. The sleeve for slings of types SKP2 and SKK2 must move freely along the rope. The guaranteed gap between the bushing wall and the rope must be at least 5 mm.

3.38. Bushings for slings of types SKP2 and SKK2 must be made of steel grade 20 in accordance with GOST 1050-88 and steel grade 25L in accordance with GOST 977-88.

3.39. The bushing hook for slings of types SKP2 and SKK2 must withstand a load equal to half the lifting capacity of the sling and directed parallel to its branch.

3.40. The safety factor of the bushing hook for slings of types SKP2 and SKK2 in bending must be at least 1.25 of the force acting on it.

3.41. Bushings for slings of types SKP2 and SKK2 must be manufactured according to the working drawings of the manufacturing enterprises. approved in the prescribed manner and agreed with the base organization for load-handling devices of the USSR State Construction Committee.

3.33-3.41. (Introduced additionally, Amendment No. 1).

4. SAFETY REQUIREMENTS 4.1. When manufacturing slings, the following safety requirements must be observed: for the production process in accordance with GOST 12.3.002-75, for electrical safety in accordance with GOST 12.1.019-79, for working with abrasive tools in accordance with GOST 12.1.001-83.

4.2. When cutting rope with an abrasive wheel, wear safety glasses or face shields.

4.3. Sling hooks must be equipped with safety locks, the design and dimensions of which are given in the recommended Appendix 1. It is allowed to use safety hook locks in accordance with GOST 12840-80 and according to the working drawings of manufacturers, approved and agreed upon with the base organization for load-handling devices of the USSR State Construction Committee. (Modified edition, Rev. No. 2).

4.4. During testing, the sling or rope branch must be protected by a solid or mesh casing to protect workers from injury.

4.5. Testing and operation of slings must be carried out in accordance with the requirements of the “Rules for the design and safe operation of load-lifting cranes” of the USSR State Mining and Technical Supervision and SNiP 111-4-80 “Safety in Construction”.

4.6. Load slings that have not passed the technical examination established by the rules for the design and safe operation of load-lifting cranes of the USSR Gosgortekhnadzor are not allowed to work.

5. ACCEPTANCE RULES

5.1. To verify compliance of slings with the requirements of this standard, the manufacturer must conduct acceptance tests.

5.2. During acceptance tests, each sling is checked for compliance with the requirements of paragraphs. 3.7-3.10, 3.12-3.15 and 3.17. For compliance with the requirements of paragraphs. 3.3-3.22, 10% of the slings from the batch are checked in the case of sealing the ends of the ropes by crimping aluminum and steel bushings, including the first and last sling, and 2% - in the case of sealing the ends of the ropes with braiding. The total number of slings being checked must not be less than 2. A batch of slings must consist of products of the same type and load capacity, made from rope from one drum (coil) and parts from the same batch. A batch of parts must consist of parts of the same standard size, made of the same grade of metal and undergone heat treatment together. When manufactured individually, each sling is checked for compliance with the requirements of clause 3.3. (Changed edition, Amendment No. 2).

5.3. Hooks, carbines and links should be checked for compliance with the requirements: paragraphs. 3.16, 3.18-3.21, 3.22 (undercut), 3.24 - all products; clause 3.3-2% of products from the batch; GOST 8479-70 - all hook blanks made by free forging and the first and last hook from a batch made by hot stamping; clause 3.22 (lack of penetration) - 2% of links from the batch; clause 3.25 (steel hardness) - 1% staples of detachable links and carabiners; triangular, ovoid and oval links; hook blanks from the batch. For hook blanks, the yield strength and relative elongation of the metal should be checked to the extent indicated in the table. 12.

Table 12

| Batch size | Number of hook blanks |

| Up to 6 incl. | |

| St. 7 to 30 » | 2 |

| "31 to 200" | 3 |

| » 200 | 5 |

Samples for testing hook blanks produced by free forging must be cut from the allowance for the blanks, and those produced by hot stamping - from the body of the hook blank or from a separately forged sample according to the regime established for stampings from metal of the same heat. The tensile strength and impact strength of steel should be checked at the request of the consumer. (Changed edition, Amendment No. 1, 2).

5.4. If unsatisfactory test results are obtained for any of the indicators, double the number of samples taken from the same batch must be re-tested for this indicator. In case of unsatisfactory results of the re-inspection, the batch is rejected.

6. TEST METHODS

6.1. Strength testing of slings is carried out with a static load in accordance with the rules for the design and safe operation of load-lifting cranes of the USSR State Technical Supervision Authority. When testing a sling, its branches should be located at an angle of 90° to each other. Tests from a different angle with appropriate recalculation of the effective loads are allowed. When slings are produced in series, their holding time under load is 3 minutes; when individually produced, it is 10 minutes. The load when determining the forces in the slings is determined by a dynamometer or a control load.

6.2. The compliance of the materials of sling parts and welding materials with those specified in the working drawings is checked using certificates or laboratory analysis results.

6.3. The quality of the surfaces of the parts of the links and grips, the correct location of the welds of the links, the quality of the sealing of the ends of the ropes, the integrity of the ropes of the sling branches are checked visually.

6.4. The increase in the cross-sectional diameter of the links and the displacement of their ends at the welding site, the size of the end of the rope protruding from the sleeve after embedding, as well as the difference in the lengths of the rope branches are checked with a ruler, calipers, templates or gauges.

6.5. The quality of welded connections of links is checked by inspection, measurement and mechanical tests of links for static tension in accordance with GOST 6996-66.

6.6. Metal hardness is determined according to GOST 9012-59 and GOST 9013-59. The yield strength, tensile strength and relative elongation of the metal are determined according to GOST 1497-84. The impact strength of the metal is determined according to GOST 9454-78.

7. LABELING, PACKAGING, TRANSPORTATION AND STORAGE

7.1. Each sling must be equipped with a brand or firmly attached metal tag indicating:

- name or trademark of the manufacturer;

- sling number according to the manufacturer’s numbering system;

- sling load capacity;

- test date (month, year).

7.2. On each link and grip of the sling, at the place designated for marking, the following must be applied by impact or stamping:

- name or trademark of the manufacturer;

- permissible load;

- year of testing (last two digits).

7.1, 7.2. (Changed edition, Amendment No. 2).

7.3. Slings of the same type, length and the same load-carrying capacity, rolled into a ring, are assembled into one common coil, which is tied around the perimeter in at least three places. Rope slings with a diameter of up to 11.5 mm and a length of up to 3.5 m can be bundled or placed in containers. The weight of the pack should not exceed 100 kg.

7.4. Marking of packages of coils and bundles is in accordance with GOST 14192-77.

7.5. Transportation of slings - according to the group of storage conditions OZHZ in accordance with GOST 15150-69 by transport of any type.

7.6. Storage of slings - according to the group of storage conditions OZh4 according to GOST 15150-69.

7.7. Information about manufactured slings must be entered into a log in accordance with the rules for the design and safe operation of load-lifting cranes of the USSR State Mining and Technical Supervision.

7.8. A sling, rope branch, link or batches thereof, manufactured for third parties, must be accompanied by a document (passport) certifying their compliance with the requirements of this standard, which indicates:

- name or trademark of the manufacturer;

- product type;

- load capacity (permissible load);

- length (for slings and rope branches);

- serial number according to the manufacturer's numbering system;

- quantity in the lot;

- year and month of issue;

- results of inspections and tests;

- warranty obligations;

- designation of this standard.

8. MANUFACTURER WARRANTY

8.1. The manufacturer must guarantee compliance of the slings with the requirements of this standard, subject to the consumer's compliance with the storage and operating conditions established by the standard.

8.2. The warranty period for slings of the SKP and SKK types is 3 months, for the rest - 6 months for single-shift operation.

APPENDIX 1 Recommended DESIGN AND DIMENSIONS OF LINKS AND GRAPS

1. The following can be used as connecting elements:

- detachable triangular links RT of versions RT1, RT2, RT3 and RT4;

- split oval links Rov;

- triangular T links;

- ovoid links O;

- oval links Ov, versions Ov1 and Ov2.

1.1. The design and dimensions of the RT links of execution RT1, operated in areas with a temperate climate, must correspond to those indicated in the drawing. 1 and in table. 1, and in areas with cold climates - to hell. 1 and in table. 2.

1.1.1. The design and dimensions of the bracket St, version St1, for links RT1, operated in areas with a temperate climate, must correspond to those indicated in the drawing. 2 and in table. 3, and in areas with cold climates - to hell. 2 and in table. 4.

GOST 25573-82 Cargo rope slings for construction