In some areas of activity it is necessary to use hardness testing of materials - hardness testing. To carry it out, a special device is used - a hardness meter, which allows you to measure the hardness of a product without destroying the structure of the material.

Hardness testers are used to check the hardness of workpieces entering production, and to control the quality of finished products, in laboratory studies of structures and materials, during their development, in the engineering and railway industries, research centers and institutes, and energy industries.

Device and characteristics

The principle of operation of a hardness tester is to measure various indicators (depending on the type of device) under mechanical influence on the material.

Based on the results of these measurements, the hardness of the material is assessed.

Depending on various parameters of the workpiece, for example, dimensions, design, material properties, stationary or portable hardness testers can be used to control hardness.

Their design differs depending on the research method used.

Portable models are used in cases where it is impossible to use stationary options, for example, if the workpiece parts are too large, or because of their large mass, when the research object cannot be transported to the laboratory.

Hardness testers consist of several main elements:

• Housing with computing electronics.

It has controls, a display for displaying measurement results and displaying settings.

On stationary versions, a microscope can be mounted.

• Anvil (for stationary options) – a platform on which the test sample is installed.

• A sensor with an indenter is an element of mechanical impact on a sample with a recorder of the force of this impact.

In portable versions, it is connected to the body with a flexible wire, or rigidly.

There are wireless models.

Material

The body, anvil and all moving elements of a stationary device are usually made of metal or durable plastic.

Portable devices are almost all plastic with a sealed housing.

Models designed for use in field conditions are waterproof and have rubber pads that protect the device from shock.

Dimensions and weight

The weight of some stationary hardness testers exceeds 200 kg, and their height and length reach 1 m or more.

It is intended that these measuring instruments will be mounted stationary, so that their size and weight do not have any influence on ease of use.

For portable devices, in addition to measurement accuracy, important indicators are dimensions and weight.

Portable models typically weigh 150–200 g (about 500 g in a metal case).

Their overall dimensions are comparable to a walkie-talkie, engineering calculator or portable radio.

A shockproof case is used for transportation.

Memory

A good portable hardness tester is capable of storing data from several previous measurements of the device simultaneously.

For this purpose it is equipped with built-in memory.

To transfer indicators from the device’s memory to a computer, it can be equipped with a standard USB interface.

As a rule, the memory for storing hardness tester indicators is non-volatile.

In other words, saved data is not lost if the battery is completely discharged or is missing.

In addition, some models allow you to save not only measurement data, but also its settings.

This is convenient, since there is no need to reconfigure the device after each shutdown.

Advantages over stationary hardness testers

Working with the surface layer of metal: stationary hardness testers, under the influence of heavy loads, “press through” the surface layer subjected to fusion, spraying, mechanical, thermal and other types of surface treatment of the metal.

Large-sized products and hard-to-reach places in products: For stationary hardness testers, such hardness control is not available due to technical and design limitations.

Measurements at the site of production and operation of products: portability allows you to measure the hardness of a product directly at the site of production and operation of products in workshop, laboratory and field conditions.

8 hardness scales: express analysis of product hardness using 8 different hardness scales (as opposed to 1-3 scales in stationary hardness testers).

High productivity: the time of one measurement with a portable hardness tester is 5-10 times less than the time of measurement with a stationary one.

Types of hardness testers, purpose and methods of hardness measurement

The dimensions of these measuring instruments have a direct impact on their classification, so for measuring the hardness of materials, instruments are divided into:

Stationary

They have large dimensions and weight, and are used in laboratories to carry out measurements with minimal errors.

Optionally equipped with an interface for connecting to a computer, microscope and printer for printing research results.

Power source – household network.

They have a keyboard for entering measurement parameters, the results are displayed on the built-in displays.

Portable (portable) hardness testers

Devices with low weight and dimensions.

Most of them fit into your pocket.

Despite their size, some small-sized hardness testers have impressive functionality.

This includes a graphic display, detailed configuration of measurement parameters, a camera, and the presence of a removable memory card for storing calibrations and research results.

Measurements can be carried out on several scales simultaneously, including custom options, and recalculation between scales can be performed.

The hand-held device is powered by ordinary batteries or a built-in battery.

Classification of methods for measuring the hardness of materials that underlie the operation of hardness testers:

• Static - a group of methods that demonstrate resistance to plastic deformation.

An indenter is a diamond tip or a steel ball, which is gradually pressed into the surface of the material, after which the imprint left behind is analyzed.

• Dynamic - a group of methods that demonstrate both resistance to deformation and elasticity.

The result of the impact of the indenter on the surface of the material is analyzed.

• Indirect - a group of methods that allow one to evaluate related properties of a material, for example, a change in the frequency of a transmitted sound wave.

Stationary devices according to their operating principle are divided into:

Brinell hardness tester

It is based on the method of pressing a ball indenter into a surface, proposed by engineer Yu. Brinell more than a century ago.

The world's first method to be standardized and widely used.

Hardness designation - HB.

Rockwell hardness tester

It is based on the method of pressing a cone indenter into a surface, proposed by Professor Ludwig.

For this method, several scales have been developed that correspond to the indenter-load pair.

The scales have letter designations: A, B, C, D, E, F, G, H, K, N, T.

The method itself is designated as HR, to which the letter of the scale is added.

Super-Rockwell hardness tester

A special feature of this device is its improved operating method based on the Rockwell method.

It consists of taking two consecutive measurements.

More details can be found in GOST 22975.

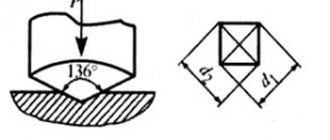

Vickers hardness tester

It is based on the method of pressing a pyramidal indenter into the material, proposed by engineers at Vickers Ltd. in 1921.

Indicated by the symbols HV.

There are modifications capable of making Micro-Vickers measurements.

Shore hardness tester

It is based on a method for measuring the height of the indenter’s rebound from the surface.

Designated as HS with the addition of the letter of one of the scales corresponding to this method (C and D are the main scales).

The practical application of this method is limited, but today it is used to control the hardness of non-metallic materials.

Hardness tester according to Barkol

It is based on the method of pressing in an indenter, which is made in the shape of a truncated cone with a flat top.

It is considered almost universal, as it allows you to determine the hardness of most materials.

Lieb hardness tester

It is based on a method for measuring the rebound speed of the indenter.

Denoted by the letters HL

When operating the device, various types of sensors are used, each of which has its own letter designation, which is indicated after HL.

Universal

These instruments can use several methods to determine the hardness of a material.

The use of each of the listed devices is limited due to the properties of the controlled materials.

The methods for determining hardness correspond to the scale of the same name.

Portable devices according to their operating principle are classified into:

Dynamic hardness testers

The work is based on fixing the speed of the sensor indenter before it hits the surface of the sample, and then after its rebound.

Ultrasonic hardness testers

The work is based on the introduction of a sensor into the surface of the material with subsequent measurement of the oscillation frequency of the indenter.

Based on the degree of change in vibration frequency, hardness is calculated.

Combined hardness testers

Capable of taking measurements using the methods described above simultaneously.

It is the best method of express control, as it allows you to obtain more accurate data.

The very name “hardness tester” generalizes instruments for measuring the hardness of materials into a subclass according to their purpose.

The most common:

• Sclerometer is a tool designed to measure the density of building materials, such as cinder block, brick, concrete and others.

The work uses the principles of indenter rebound, ultrasonic sounding, and evaluation of shock pulses.

Scratch-type hardness testers with the Friedrich Maos scale are often used.

• Pencil type – measures the hardness of paint and varnish coatings.

• Hardness tester according to Buchholz. The result is assessed through a microscope.

• Durometer – measures the Shore hardness of a material.

• Clamp hardness tester.

The density of the material is determined by mechanically clamping it.

• Pendulum

It is used to control hardness based on the oscillation parameters of a pendulum in the shape of an isosceles triangle mounted on the test plate.

Application is limited due to the specifics of the device, so it is only suitable for monitoring the hardness of paintwork.

• Universal stationary metal hardness testers are high-precision devices with low errors.

Capable of displaying results simultaneously on several scales.

• Ball - use the method of resisting indentation of an indenter in the form of a ball.

Application – measuring the hardness of polymer coatings and materials.

Also, all hardness testers can be divided into digital and analog.

The latter option is quite rare due to the relatively low measurement accuracy, which depends on the operator’s skills.

Typically used for testing soft materials.

To display the result, they have a scale in the form of a dial with an arrow, while electronic devices are equipped with a digital screen.

The choice of scale on which measurements are taken directly depends on the hardness of the test sample.

Thus, the Brinell and Shore scales are excellent for monitoring the hardness of plastic, wood, rubber and other materials with low hardness.

The Rockwell scale is used for materials of medium hardness.

The Vickers scale is suitable for very hard samples.

Measurement technique

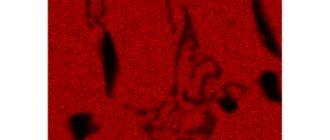

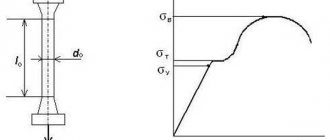

The Rockwell method of determining metal hardness is used when it is necessary to test a workpiece of small thickness. In addition, the hardness of the surface layer of a product, for example, one that has undergone hardening or a cementing process, is checked in a similar way.

The hardness of metals is determined by the Rockwell method as follows:

- The method is based on pressing a harder object into the subject. For this, a special diamond tip is used, which has the shape of a regular pyramid.

- The load is applied to the tip for a certain time. In this case, the holding time and load magnitude can vary significantly. According to established standards in GOST 9013-59, the load can be from 1 to 100 kgf. At the same time, specific values from this interval are specified.

- The resulting diamond cone impressions are measured. The most important indicators in this case are the size of the diagonals of the remaining print.

Rockwell hardness measuring principle

The obtained data is checked against table values, which take into account the magnitude of the applied force and the holding time. The method under consideration makes it possible to obtain the hardness indicator in its own conventional units.

The measurement process can be divided into several stages:

- The scale type is determined.

- A suitable indicator is installed. It is important to choose an indicator that will match the type of scale installed.

- Two trial tests are carried out, which are necessary to correct the operation of the equipment used.

- A preload of 10 kgf is applied.

- The main load is applied and a certain period is maintained, which allows you to obtain the maximum value.

- The load is removed and the result is read.

Download GOST 9013-59

Modern equipment can significantly simplify the process and increase the accuracy of the results obtained during measurements.

Features of hardness testers

Indenters for hardness testers are made in most cases from hard alloys.

This is especially true for devices operating using the elastic rebound method.

In ultrasonic devices based on the contact impedance method, the indenter is a prism made of diamond.

This material has one of the highest elastic moduli, which allows one to obtain fairly accurate measurement results.

In addition, it has a high wear resistance.

Brinell hardness testers

The method of determining hardness using the Brinell method is to press a ball of either hardened steel or carbide into the surface of the part. As a result, an imprint in the form of a hemisphere of a certain diameter and depth remains on the metal, which determines the Brinell hardness measure HB.

The method has the following requirements:

- The indenter must be of strictly defined dimensions. The standard diameters are 10; 5; 2.5; 1.25 and 1 mm. The choice depends on the approximate hardness of the test sample and the load on it:

| Ball diameter, mm | Recommended load on the indenter, kN depending on the material of the product | ||||

| Steels, cast irons, high-strength alloys | Most non-ferrous metals and alloys | Aluminum | Bearing alloys | Lead, tin, babbits | |

| 10 | 29,42 | 9,8 | 4,9 | 2,45 | 1,225 |

| 5 | 7,335 | 2,45 | 1,225 | 0,613 | 0,307 |

| 2,5 | 1,84 | 0,613 | 0,307 | 0,153 | 0,077 |

| 1,25 | 0,459 | 0,153 | 0,076 | 0,038 | 0,019 |

| 1 | 0,294 | 0,098 | 0,049 | 0,0245 | 0,013 |

| Recommended range for measuring HB hardness | 67…450 | 22…315 | 11…158 | 6…78 | 3…39 |

- It is impossible to measure the HB hardness of the same part using different types of Brinell hardness testers.

- The ratio of the load applied to the product and the area of the print must be constant.

- When referring to the NV value established during measurements, it is necessary to indicate the conditions under which the result was obtained.

- The part at the place where hardness is measured must have a smooth and well-polished surface of sufficient thickness (otherwise there may be deformation on the reverse side that impairs the accuracy of the result).

- It is unacceptable to determine hardness if the test point is located close to the edge of the part.

The Brinell method is unsuitable if the measured hardness exceeds 450 HB: in this case, deformation of the contact surface of the indenter itself occurs.

Hardness testers for metals that implement the Brinell method are divided into devices of the TSh type and the BTB type.

Stationary hardness testers for metals type ТШ, with a mechanical drive from an electric motor, consist of the following components:

- Loading unit, which includes a mandrel with an indenter, a return spring and a housing;

- Drive unit consisting of an electric motor and gear system;

- A lever mechanism that transfers the workload to the ball;

- Desktop;

- Control panels and monitoring of measurement results.

- Counterweights with weights;

- C-shaped bed.

A Brinell hardness tester works like this. The part with the test surface facing up is placed on the table, after which it is raised to the stop located in the indenter body. Next, the electric motor is turned on, which moves the indenter body. He, overcoming the resistance of the springs, sets in motion the ball, which is pressed into the metal. The final result is read on a scale. The ratio of the arms of the lever mechanism, as well as the total weight of the loads on the counterweight, is set depending on the expected measurement result (see table above).

Hardness testers for metals of the BTB type have some operational advantages over TS devices: they have an increased size of the working table space, loading modes are changed mechanically, and a more accurate optical system is used to read the result. Work on BTB hardness testers is carried out in the same sequence as on TSh devices, but after testing the sample is scanned by a measuring head, with the result displayed on the screen.

This method is also suitable for determining the hardness of products that are operated at elevated temperatures. To do this, a bath with a liquid heating the sample is placed on the table, and oil is used for temperatures up to 300°C, and molten salt is used for higher temperatures. The sample is placed in a bath on an asbestos board, after which the hardness is measured using the usual method.

Hardness testers produced by Tochpribor

Portable hardness testers for metals of the TShP type are affordable and easy to use. The test head of the device is installed on the part at the measurement location and secured with a clamp or special grips. The load is created manually and controlled using an indicator scale. To measure the result, a portable MPB type microscope is used. The measured print is compared with the values given in the conversion tables.

Hardness testers for metals using the Brinell method have a number of limitations in their use:

- The elastic deformation of the part under load is not taken into account.

- The dynamics of the test (time and speed of indentation of the indenter) very much depend on the initial hardness of the metal.

- The surface at the test site must be strictly perpendicular to the axis of movement of the indenter.

- When repeating hardness measurements, the distance between adjacent prints must be at least 0.2...0.6 of the ball diameter.

What you need to know about hardness testers

The hardness tester, being a high-precision measuring instrument, needs to be periodically checked for serviceability.

In addition, it is calibrated regularly.

You should know that each method for determining hardness has its own calibration standard.

For example, for stationary Brinell, Vickers and Rockwell hardness testers - GOST 23677-79.

The same GOST states that for such devices the mean time between failures should be at least 25 thousand (12.5 thousand for options with computing modules) hours.

This parameter determines the duration of operation of the device before the first failure.

In this case, the full service life must exceed 10 years, in accordance with the same state standard.

Each hardness tester comes with a passport with instructions for testing and calibrating it.

Initial inspection is carried out by the manufacturer.

Hardness scales

Rockwell's measure of hardness is designated HRC. During testing of various metals, 11 scales were developed, which differ in the ratio of the geometric dimensions of the tip and the applied load. It is worth considering that today not only diamond tips are used as a pressable body. Distributed:

- spheres made of hardened steel;

- balls made of carbide and tungsten alloy.

The designation is carried out using capital letters of the Latin alphabet.

Rockwell hardness scales

Why is it so important to consider the type of scale used? There are quite a few reasons:

- The type of pressed indicator depends on it. At the same time, there is a certain connection between the geometric shape and size of the indicator and the data obtained.

- Each type of pressed object has its own maximum load limit.

The results obtained are important in the manufacture of bearings and other critical elements used in the creation of cars or aircraft. The Rockwell hardness dimension is also taken into account when choosing products made from hardened steel.

How to choose a hardness tester?

Before you start choosing a hardness tester, you need to decide what materials you will be working with.

The hardness control method directly depends on this.

If accuracy of measurements is an important requirement, and the device will be used in an enterprise laboratory, preference is given to stationary options (ideally, universal ones).

To carry out measurements outside laboratory conditions, the only correct solution is to purchase a portable hardness tester.

Since the use of each method is limited by various factors, it is necessary to rely on the given criteria.

Main criteria

• Method for determining hardness.

It is better to purchase a combined device, since the dynamic method is well suited for geometrically simple massive parts, and the ultrasonic method is well suited for small samples of material with complex shapes.

• Frame.

Modern portable devices have complex electronics that are sensitive to external influences.

It should be protected by a shock-resistant, moisture-resistant (or completely waterproof) case with rubber pads for easy holding.

• Connection with the indenter.

Manufacturers offer 3 options for connecting a sensor with an indenter to recording equipment (main module): built-in, wired or wireless (Bluetooth connection).

Ease of use depends on the choice.

• Availability of memory.

• Sensor type.

• Possibility of equipping with additional types of sensors.

• Ability to connect to a PC and external printer directly.

• Ability to work with multiple scales and convert results between scales.