11/01/2017 Hardness is the ability of a metal to plastically deform under the influence of an object with a higher hardness (indenter). Hardness tests are very common, since they determine not only a measure of the strength of a product, but also its resistance to variable loads. The advantage of the method is that hardness tests are non-destructive, and hardness testers for metals can be either stationary or portable.

Measurements can be carried out on reference samples (made from the same material or alloy and subjected to the same heat treatment) or on finished parts. The only condition is that in the case of testing finished parts, measures must be taken to ensure that the test object (OC) does not have external damage.

The choice of hardness control method depends on:

- initial mechanical indicators of strength, elasticity and ductility of the product

- OK dimensions (or the junction of adjacent structural elements, if hardness is established in the area, for example, of a weld)

- final result: establish the hardness of the product itself, or the hardness of only its surface (performed for parts that have undergone heat treatment or another type of surface hardening).

- Requirements for testing conditions. In field conditions, portable hardness testers are used rather than stationary ones.

- Stability of measurement results and their reproducibility during repeated testing.

Hardness can be measured by three groups of methods - mechanical (static and dynamic), as well as ultrasonic. In addition, a distinction is made between hardness at room and elevated temperatures (the so-called “hot hardness”). The technical essence of all methods is the same - a deforming element is introduced into the OC, the depth of movement of which is read on a special scale.

Hardness is considered as the resistance of a metal to irreversible plastic deformation, and therefore differs from other measurements by the presence of special unified instruments - hardness testers for metals.

Brinell hardness testers: methods and equipment

Used to determine the hardness of soft alloys and non-ferrous metals, cast iron and non-hardened steels in accordance with GOST 9012-59.

Brinell hardness is measured using either a steel ball or a tungsten carbide ball. The latter allows you to find out the hardness of materials exceeding that of ordinary steel. A carbide indenter is usually needed for tool alloys. A ball made of ordinary steel is used to measure the hardness of wood, copper, aluminum, duralumin, stainless steel, and glass. That is, the hardness tester is used not only for metals.

The method for determining hardness using the Brinell method involves pressing an indenter ball (made of hardened steel or carbide) into the surface of the OC. As a result, an imprint in the form of a hemisphere of a certain diameter and depth remains on the metal, which makes it possible to determine the Brinell hardness measure (HB).

The modern design of the Brinell hardness tester allows for smooth insertion of the indenter into the sample, ensures high accuracy of load application (error no more than 1.0%), which makes it possible to obtain indentations with high repeatability necessary to ensure accurate hardness measurements.

Hard alloy balls with a diameter of 1; 2.5; 5 and 10 mm. The magnitude of the load and the diameter of the ball are selected depending on the material being studied, which is divided into 5 main groups:

1 - steel, nickel and titanium alloys; 2 - cast iron; 3 - copper and copper alloys; 4 - light metals and their alloys; 5 - lead, tin.

When measuring hardness using the Brinell method, the following conditions must be met:

- samples with a hardness higher than HB 450/650 kgf/mm2 are prohibited from testing;

- the surface of the sample must be flat and free of scale and other foreign substances;

- print diameters must be within 0.2D

- samples must have a thickness of at least 10 times the depth of the indentation (or less than the diameter of the ball);

- the distance between the centers of adjacent prints and between the center of the print and the edge of the sample must be at least 4d;

- the duration of exposure under load should be from 10 to 15 s for ferrous metals, for non-ferrous metals and alloys - from 10 to 180 s, depending on the material and its hardness.

The choice depends on the hardness of the test object and the required load:

| Ball diameter, mm | Recommended load on the indenter, kN depending on the material of the product | ||||

| Steels, cast irons, high-strength alloys | Most non-ferrous metals and alloys | Aluminum | Bearing alloys | Lead, tin, babbits | |

| 10 | 29,42 | 9,8 | 4,9 | 2,45 | 1,225 |

| 5 | 7,335 | 2,45 | 1,225 | 0,613 | 0,307 |

| 2,5 | 1,84 | 0,613 | 0,307 | 0,153 | 0,077 |

| 1,25 | 0,459 | 0,153 | 0,076 | 0,038 | 0,019 |

| 1 | 0,294 | 0,098 | 0,049 | 0,0245 | 0,013 |

| Recommended hardness measuring range, HB | 67-450 | 22-315 | 11-158 | 6-78 | 3-39 |

Limitations for Brinell hardness testers

- It is impossible to measure the HB hardness of the same part using different types of hardness testers.

- The ratio of the load applied to the product and the area of the print must be constant

- When referring to the NV value established during measurements, it is necessary to indicate the conditions under which the result was obtained

- The part at the place where hardness is measured must have a smooth and well-polished surface of sufficient thickness (otherwise there may be deformation on the reverse side, impairing the accuracy of the result)

- It is unacceptable to determine hardness if the test point is located close to the edge of the part.

- The Brinell method is unsuitable if the measured hardness exceeds 450 HB: in this case, deformation of the contact surface of the indenter itself occurs.

Brinell hardness (HB) is expressed by the ratio of the applied load P to the surface area of the indentation F: HB=P/F

If we calculate the surface of an indentation having the shape of a spherical segment, then HB will be determined by the formula:

HB=2P/(πD*√(D 2 -d 2 )

[2] where P is the applied load, kgf; D is the diameter of the ball, mm; d is the diameter of the imprint, mm. The size of the ball is selected depending on the thickness of the test sample: usually they use balls of standard sizes with diameters of 10 mm, 5 mm 2 ,5, or 1 mm. The load on the ball is selected depending on the type of material and must be proportional to the square of the diameter of the ball. Conventional standard norms adopted for various materials are as follows: for steel and cast iron P = 30D2, for copper and copper alloys P = 10D2, for babbitt and leaded bronzes P = 2.5D2. More detailed information on the choice of load, load application time for various materials is given in the corresponding table in the hardness testing laboratory. In addition, the load is considered to be selected correctly if the ratio

0.2D < d < 0.6D (3)

The diameter of the print is measured using a Brinell loupe or microscope in two mutually perpendicular directions and is determined as the arithmetic mean of two measurements. The magnifying glass has a scale, the small division of which (or the division value) is 0.05 mm. Based on the results of measuring the diameter of the indentation on a given material, the Brinell hardness is determined using formula [2] or according to the table for determining Brinell hardness numbers. As noted earlier, there is a certain relationship between mechanical properties (in particular, tensile strength σB and Brinell hardness), which can be represented by the empirical formula: σ B = C*HB*10 [MPa],

where C is the proportionality coefficient.

For steels C = 0.33...0.36 For aluminum C = 0.4 For copper C = 0.48 For duralumin C = 0.37 For brass, bronze C = 0.53

It should be noted that for brittle materials (cast iron, silumin), a reliable correlation between hardness and tensile strength cannot be obtained. In particular, to determine the tensile strength of gray cast iron, use the following empirical formula: σ B =10*(HB-40)/6 [MPa]

An example of Brinell hardness designation: 600 HBW 10/3000/20, where

600

is the Brinell hardness value, kgf/mm2;

HBW

- symbolic designation of Brinell hardness;

10

- ball diameter in mm;

3000

- approximate value of the equivalent load in kgf (3000 kgf = 29420 N);

20

— time of load action, s.

Hardness testers for metals that implement the Brinell method are divided into devices of the TSh type and the BTB type.

Stationary hardness testers for metals type ТШ, with a mechanical drive from an electric motor, consist of the following components:

- Loading unit, which includes a mandrel with an indenter, a return spring and a housing;

- Drive unit consisting of an electric motor and gear system;

- A lever mechanism that transfers the workload to the ball;

- Desktop;

- Control panels and monitoring of measurement results;

- Counterweights with weights;

- C-shaped bed.

The measurement principle is as follows: the part with the test surface facing up is placed on the table, after which it is raised to the stop in the indenter body. Next, the electric motor is turned on, which moves the indenter body. He, overcoming the resistance of the springs, sets in motion the ball, which is pressed into the metal. The final result is read on a scale. The ratio of the arms of the lever mechanism, as well as the total weight of the loads on the counterweight, is set depending on the expected measurement result (see table above).

Hardness testers for metals of the BTB type have some operational advantages over TS devices: they have an increased size of the working table space, loading modes are changed mechanically, and a more accurate optical system is used to read the result. Work on BTB hardness testers is carried out in the same sequence as on TSh devices, but after testing the sample is scanned by a measuring head, with the result displayed on the screen.

This method is also suitable for determining the hardness of products that are operated at elevated temperatures. To do this, a bath with a liquid that heats the sample is installed on the table, and oil is used for temperatures up to 3000 C, and molten salt is used for higher temperatures. The sample is placed in a bath on an asbestos board, after which the hardness is measured using the usual method.

Portable (portable) hardness testers for metals are affordable and easy to use. The test head of the device is installed on the part at the measurement location and secured with a clamp or special grips. The load is created manually and controlled using an indicator scale. A portable microscope is used to measure the result. The measured print is compared with the values given in the conversion tables.

Hardness testers for metals using the Brinell method have a number of limitations:

- The elastic deformation of the part under load is not taken into account.

- The dynamics of the test (time and speed of indentation of the indenter) very much depend on the initial hardness of the metal.

- The surface at the test site must be strictly perpendicular to the axis of movement of the indenter.

- When repeating hardness measurements, the distance between adjacent prints must be at least 0.2...0.6 of the ball diameter.

If you want to purchase a Brinell hardness tester, we recommend model TB 5005A or model LC-200R

Hardness concept

The hardness of a material is its resistance to destruction when a harder material is introduced into the outer layer. In other words, the ability to resist deforming forces (elastic or plastic deformation).

The hardness of metals is determined by introducing a solid body called an indenter into a sample. The role of the indenter is performed by: a metal ball of high hardness; diamond cone or pyramid.

After exposure to the indenter, an imprint remains on the surface of the test sample or part, the size of which determines the hardness. In practice, kinematic, dynamic, and static methods of measuring hardness are used.

The kinematic method is based on the compilation of a diagram based on continuously recorded readings that change as the tool is pressed into the sample. Here the kinematics of the entire process is traced, and not just the final result.

The dynamic method is as follows. The measuring tool acts on the part. The reverse reaction allows you to calculate the expended kinetic energy. This method allows you to test the hardness of not only the surface, but also a certain volume of metal.

Static methods are non-destructive methods that allow you to determine the properties of metals. The methods are based on smooth indentation and subsequent holding for some time. The parameters are regulated by methods and standards.

The applied load can be applied:

- pressing;

- scratching;

- cutting;

- rebound

Machine-building enterprises currently use the Brinell, Rockwell, Vickers methods, as well as the microhardness method, to determine the hardness of materials.

Based on the tests carried out, a table is compiled indicating the materials, the applied loads and the results obtained.

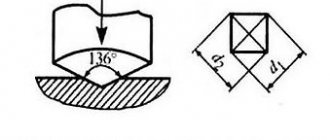

Rockwell hardness testers: methods and equipment

The Rockwell method of determining the hardness of metals consists of pressing a diamond cone or hardened steel ball into the previously ground surface of the sample. Unlike the previous method, Rockwell hardness involves determining the depth of indentation. The Rockwell method is considered more efficient, and in such hardness testers both the testing process and the subsequent processing of its results are automated.

The essence of the Rockwell method is that a certain reference point is preliminarily selected, and the indenter penetration depth obtained for this coordinate is subtracted from the arbitrarily selected maximum indentation depth.

There are 11 Rockwell hardness scales (A; B; C; D; E; F; G; H; K; N; T), based on the indenter (tip) - load combination. The two most widely used types of indenters are a 1/16 inch (1.5875 mm) tungsten carbide ball or hardened steel ball, or a conical diamond tip with a 120° apex angle. Possible loads are 60, 100 and 150 kgf. The hardness value is determined as the relative difference in the depth of penetration of the indenter when applying the main and preliminary (10 kgf) load.

To indicate hardness determined by the Rockwell method, the symbol HR is used, to which a letter is added indicating the scale on which the tests were carried out (HRA, HRB, HRC).

Brinell hardness table

| Print diameter d 10 or 2d 5 , or 4d 2.5 | Brinell hardness number at a load P (kgf) equal to | Print diameter d 10 or 2d 5 , or 4d 2.5 | Brinell hardness number at a load P (kgf) equal to | ||||

| 30 D2 | 10D2 | 2.5D2 | 30 D2 | 10D2 | 2.5D2 | ||

| 2,00 | 955 | 4,00 | 229 | 76,3 | 19,1 | ||

| 2,05 | 910 | 4,05 | 223 | 74,3 | 18,6 | ||

| 2,10 | 868 | 4,10 | 217 | 72,4 | 18,1 | ||

| 2,15 | 4,20 | 207 | 68,8 | 17,2 | |||

| 2,20 | 764 | 4,25 | 201 | 67,1 | 16,8 | ||

| 2,25 | 735 | 4,30 | 197 | 65,5 | 16,4 | ||

| 2,30 | 707 | 4,35 | 192 | 63,8 | 16,0 | ||

| 2,35 | 682 | 4,40 | 187 | 62,4 | 15,6 | ||

| 2,40 | 659 | 4,45 | 183 | 60,9 | 15,2 | ||

| 2,45 | 616 | 4,50 | 179 | 59,5 | 14,9 | ||

| 2,50 | 597 | 4,55 | 174 | 58,1 | 14,5 | ||

| 2,55 | 579 | 4,60 | 170 | 56,8 | 14,2 | ||

| 2,60 | 562 | 4,65 | 167 | 55,5 | 13,9 | ||

| 2,65 | 531 | 4,70 | 163 | 54,3 | 13,6 | ||

| 2,70 | 516 | 4,75 | 159 | 53,0 | 13,3 | ||

| 2,75 | 489 | 4,80 | 156 | 51,9 | 13,0 | ||

| 2,80 | 477 | 4,85 | 152 | 50,7 | 12,7 | ||

| 2,85 | 455 | 4,90 | 149 | 49,6 | 12,4 | ||

| 2,90 | 444 | 4,95 | 146 | 48,6 | 12,2 | ||

| 2,95 | 429 | 5,00 | 143 | 47,5 | 11,9 | ||

| 3,00 | 415 | 34,6 | 5,05 | 140 | 46,5 | 11,6 | |

| 3,05 | 401 | 33,4 | 5,10 | 137 | 45,5 | 11,4 | |

| 3,10 | 388 | 129 | 32,3 | 5,15 | 134 | 44,6 | 11,2 |

| 3,15 | 375 | 125 | 31,3 | 5,20 | 131 | 43,7 | 10,9 |

| 3,20 | 363 | 121 | 30,3 | 5,25 | 128 | 42,8 | 10,7 |

| 3,25 | 352 | 117 | 29,3 | 5,30 | 126 | 41,9 | 10,5 |

| 3,30 | 341 | 114 | 28,4 | 5,35 | 123 | 41,0 | 10,3 |

| 3,35 | 331 | 110 | 27,6 | 5,40 | 121 | 40,2 | 10,1 |

| 3,40 | 321 | 107 | 26,7 | 5,45 | 118 | 39,4 | 9,86 |

| 3,45 | 311 | 104 | 25,9 | 5,50 | 116 | 38,6 | 9,66 |

| 3,50 | 302 | 101 | 25,2 | 5,55 | 114 | 37,9 | 9,46 |

| 3,55 | 293 | 97,7 | 24,5 | 5,60 | 111 | 37,1 | 9,27 |

| 3,60 | 285 | 95,0 | 23,7 | 5,65 | 109 | 36,4 | 9,10 |

| 3,65 | 277 | 92,3 | 23,1 | 5,70 | 107 | 35,7 | 8,93 |

| 3,70 | 269 | 89,7 | 22,4 | 5,75 | 105 | 35,0 | 8,76 |

| 3,75 | 262 | 87,2 | 21,8 | 5,80 | 103 | 34,3 | 8,59 |

| 3,80 | 255 | 84,9 | 21,2 | 5,85 | 101 | 33,7 | 8,43 |

| 3,85 | 248 | 82,6 | 20,7 | 5,90 | 99,2 | 33,1 | 8,26 |

| 3,90 | 241 | 80,4 | 20,1 | 5,95 | 97,3 | 32,4 | 8,11 |

| 3,95 | 235 | 78,3 | 19,6 | 6,00 | 95,5 | 31,8 | 7,96 |

Selection of method depending on test conditions

| Method option | A | IN | WITH | F | N | T |

| Indenter shape | Cone | Ball | Cone | Ball | Cone | Ball |

| Indenter material | Diamond | Steel | Diamond | Steel | Diamond | Steel |

| Hardness symbol | HRA | HRB | H.R.C. | HRF | HRN | HRT |

| Hardness measuring range | 60…80 | 35…100 | 30…70 | 60…100 | 17…92 | 5…94 |

| Metals | Very high hardness steels | Medium hard steels, non-ferrous alloys | High-hardness steels | Thin sheet metals | For testing thin or small products | |

Stationary hardness testers for metals using the Rockwell method (type TK) are divided into devices with electrical and mechanical drives. Manual hardness tester TK includes:

- Movable measuring table on which the part is mounted

- Lever load drive

- Measuring system (digital or analogue indication of the result)

- Working measuring head (with adjustable settings)

- Oil shock absorber

- bed

The principle of operation of a Rockwell hardness tester: The sample (ground surface up) is placed on the measuring table, after which it is moved upward until the indenter begins to press into the surface, which is monitored on the hardness tester scale.

This is a preliminary load, the end of which is indicated by the vertical position of the large arrow. This means that the indenter has penetrated into the surface to a depth at which the elastic deformation of the metal has already turned into plastic. Then the handle is released, which is returned to the stop by the shock absorber, and the test product is loaded with the main force. In the final position, the load on the part must be at least 5...10 s, when the desired Rockwell hardness value appears on the indicator. Most commonly used Rockwell scales

| Scale | Abbreviation | Test load | Indenter type | Application area | N | s |

| A | HRA | 60 kgf | 120° diamond spheroconic* | Wolfram carbide | 100 | 0.002 mm |

| B | HRB | 100 kgf | Diameter 1⁄16" (1.588 mm) steel, spherical | Aluminum alloys, bronze, mild steels | 130 | 0.002 mm |

| C | H.R.C. | 150 kgf | 120° diamond, spheroconic | Hard steels with HRB > 100 | 100 | 0.002 mm |

| D | HRD | 100 kgf | 120° diamond, spheroconic | 100 | 0.002 mm | |

| E | HRE | 100 kgf | Diameter 1⁄8" (3.175 mm) steel, spherical | 130 | 0.002 mm | |

| F | HRF | 60 kgf | Diameter 1⁄16" (1.588 mm) steel, spherical | 130 | 0.002 mm | |

| G | HRG | 150 kgf | Diameter 1⁄16" (1.588 mm) steel, spherical | 130 | 0.002 mm | |

| *Radius of spherical rounding of the cone apex 0.2 mm | ||||||

Factors affecting measurement accuracy

- An important factor is the thickness of the sample. Testing of samples with a thickness less than ten times the tip penetration depth is not allowed.

- The minimum distance between prints is limited (3 diameters between the centers of the nearest prints)

- Parallax when reading results from the dial of pointer instruments

- The simplicity of the Rockwell method (mainly the absence of the need to measure the diameter of the indentation) has led to its widespread use in industry for testing hardness. Also, high cleanliness of the measured surface is not required (for example, the Brinell and Vickers methods involve measuring the print using a microscope and require surface polishing)

The disadvantage of the Rockwell method is lower accuracy compared to the Brinell and Vickers methods.

If you want to purchase a Brinell hardness tester, we recommend model TP 5008A or model LC-200R

Black metals

The Rockwell hardness of cast iron SCH20 HRC 22, which corresponds to 220 HB. Steel: tool – 640-700 HB, stainless steel – 250 HB.

To convert from one measurement system to another, tables are used. The values in them are not true, because they are derived imperially. Not the full volume is presented in the table.

| HB | H.V. | H.R.C. | HRA | HSD |

| 228 | 240 | 20 | 60.7 | 36 |

| 260 | 275 | 24 | 62.5 | 40 |

| 280 | 295 | 29 | 65 | 44 |

| 320 | 340 | 34.5 | 67.5 | 49 |

| 360 | 380 | 39 | 70 | 54 |

| 415 | 440 | 44.5 | 73 | 61 |

| 450 | 480 | 47 | 74.5 | 64 |

| 480 | 520 | 50 | 76 | 68 |

| 500 | 540 | 52 | 77 | 73 |

| 535 | 580 | 54 | 78 | 78 |

Hardness values, even if produced by the same method, depend on the applied load. The lower the load, the higher the readings.

Application of stone

The diamond hardness indicator is also used in industry. Not all stones found in pipes at deposits are suitable for jewelry processing. Most of the material has too many defects. Such minerals are sent to the needs of industry, where diamond is used as an abrasive. Equipment coated with diamond chips works longer and with better quality. Diamond is used in such devices and tools as:

- medical equipment (scalpels, surgical instruments);

- drills, cutters, grinding wheels, glass cutters, scissors and metal saws, drilling rigs;

- in telecommunications and electronics, diamond is used to transmit signals of different frequencies through one cable;

- protective element in the chemical and physical industries;

- the space industry, which even uses lonsdaleite, which is stronger than diamond.

Diamond is a substance that has unique properties. The hardness of the mineral also makes it possible to use it in various fields. The use of stone is relevant, and its value continues to rise. And artificial substances that are stronger than diamond are not yet available for widespread use.