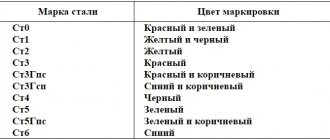

High-speed steels have high strength, which allows them to be used for processing hard materials. At the same time, the operating speed of cutting, grinding, and drilling installations exceeds those that can be achieved using parts made of tool steel. A special place in technology for high-speed samples was found in the manufacture of thread-cutting tools, especially those working with shock loads.

In general, high-speed cutters mean alloy steel, the composition of which may contain the following chemical elements:

- carbon, silicon, magnesium, nickel, sulfur, phosphorus, and cobalt less than 1%;

- strontium 3.8 – 4.4%;

- molybdenum 8 - 5.3;

- tungsten 5 - 6.5;

- vanadium 7 - 2.1.

The quick cutter R6M5 has approximately the same chemical composition. Products made from such alloys are not only hard, but also have red resistance and hot hardness, and have toughness. Despite their tendency to decarbonize, they guarantee a relatively long service life as part of equipment components.

Characteristics of high-speed steels

The category of high-speed steels includes alloys whose chemical composition is supplemented with a number of alloying additives. Thanks to such additives, steels are given properties that allow them to be used for the manufacture of cutting tools that can operate efficiently at high speeds. What distinguishes high-speed alloys from conventional carbon alloys is that the tools that are made from them can be successfully used for processing hard materials at high speeds.

Milling a part on a professional engraving machine

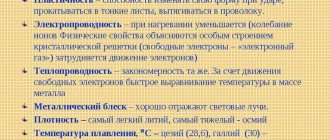

The most notable characteristics that distinguish high-speed steels of various grades include the following.

- Hardness maintained when hot (hot hardness). As is known, any tool used to perform cutting processing is intensely heated during such processing. As a result of heating, conventional tool steels are subjected to tempering, which ultimately leads to a decrease in the hardness of the tool. This does not happen if high-speed steel was used for manufacturing, which is capable of maintaining its hardness even when the tool is heated to 6000. Typically, high-speed steel grades, which are often called high-speed steels, have even lower hardness compared to conventional carbon steels if the cutting temperature is within normal limits: up to 2000.

- Increased red fastness. This parameter of any metal characterizes the period of time during which a tool made from it is able to withstand high temperatures without losing its original characteristics. High-speed steels as a material for the manufacture of cutting tools have no equal in this parameter.

- Resistance to destruction. A cutting tool, in addition to its ability to withstand exposure to elevated temperatures, must also have improved mechanical characteristics, which is fully demonstrated by high-speed steel grades. Tools made from such steels, which have high strength, can successfully operate at large depths of cut (drills) and at high feed rates (cutters, drills, etc.).

Characteristics and purpose of high-speed steels

High-speed steel R6M5. Explanation, composition and properties

High-speed steel R6M5 is self-hardening and belongs to the tool class.

The alloying components are tungsten (6%) and molybdenum (5%), and American M2 steel has the same composition. Foreign analogues have the HSS (high-speed) nomenclature in their designation. The scope of application of steel includes the processing of hard metals, which is due to the high strength of the alloy.

The material allows you to maximize the speed of operation of equipment for cutting, grinding, and drilling compared to other types of tool compositions.

A special advantage is the durability of thread-cutting tools made of R6M5 steel when working with dynamic and vibration effects.

Return

Decoding steel R6M5

The name implies the following alloy parameters:

- P – high-speed steel (rapid – fast);

- 6 – 6% tungsten;

- M5 – 5% molybdenum.

Depending on the composition of the material, the name may contain additional indices. In the presence of cobalt - K, vanadium - B, titanium - T, zirconium - C.

The electroslag production method is designated Ш, and modern manufacturing technologies involve the use of the name P6AM5. In this case, we are talking about the introduction of nitrogen into the composition of high-speed steel R6M5 as an alloying component.

It is introduced during tempering after hardening. The main area of application of this type of metal is the creation of milling wheels.

Return

Chemical composition and properties

The composition of the material according to regulatory documents includes:

- tungsten – 6.15±0.35%;

- molybdenum – 5.05±0.25%;

- strontium – 4.1±0.3%;

- vanadium – 1.9±0.2%;

- C, Si, Mg, Ni, S, P, Co – less than 1%.

The special properties of steel make it possible to produce cutters, taps, reamers and other tools from it. Their advantages include reliability and durability. The main characteristics of the metal are presented:

- the hardness of steel R6M5 with increasing temperature, which is due to minimal heating during long-term operation without interruption. This eliminates the softness of the drill or other tool during operation and reduces fragility. The maximum heating temperature at which the properties of the alloy are preserved is 600 degrees;

- resistance to incandescence under prolonged temperature exposure;

- the ability to maintain the sharpness of the cutting edge for a long time;

- impact strength;

- ease of processing and manufacturability;

- ability to perceive mechanical, including dynamic load.

Return

Application area

The scope of application of R6M5 steel includes the manufacture of knives for mass production and household use. A properly sharpened tool can cut almost any material, including soft metal.

With a fairly high cost of products, they are often found at home, among fishermen and hunters. The only drawback in this case is the difficulty of sharpening, which requires a special machine. This material is also used for the manufacture of:

- electrical tools and accessories;

- single-sided drills;

- Drill bits for drywall;

- drill with a spear-shaped shank;

- metal drill;

- scans;

- hacksaw blades;

- slotting cutters;

- dies (lerok).

Return

Specifications

The characteristics of R6M5 steel are presented:

| Rockwell hardness | 62-65; |

| yield strength | 637 MPa; |

| forging temperature | 1250-900 degrees; |

| density | 7750 kg/m3; |

| melting point | 1310-1350 degrees. |

Return

Price

The price of R6M5 steel depends on the type and shape of rolled products and transportation distance. The average cost is 520 rubles. per kilogram.

Return

Assortment

The main rolling elements are:

- circles with a specific coating;

- rods and strips;

- rods with calibration;

- forged, hot-rolled circles;

- square profile;

- high-precision gussets.

There is also a wide range of other types of rental products regulated by State standards.

Return

Regulations

The production of materials and all types of rolled products is carried out in accordance with regulatory documents - GOST and TU. They indicate not only the composition, but also the assortment, control measures during production and acceptance. Similar requirements are provided for foreign steels.

The main State Standard for high-speed steel R6M5 is 19265-73.

Return

Heat treatment

The material is called self-hardening, but it is important to observe the temperature conditions of processing and the sequence of operations. This will increase the durability of the product by 20-30%.

Hardening occurs in several stages, with pre-heating in a salt bath - at 500 C and 850 C for 15-20 seconds.

The last stage involves heating the part to 1280 degrees, and the holding time is determined depending on the thickness. For every millimeter there are 10 seconds of hardening.

The properties of R6M5 steel are improved by tempering for 3 hours, during which the temperature drops to 580-600 degrees.

The modern engineering industry often uses metal processing tools with a welded cutting edge. In this case, quenching is carried out in a saline solution, provided that the weld is located 15-20 mm above the liquid.

Return

Sharpening features

Sharpening of cutting tools is carried out at certain intervals. Conventional electrocorundum wheels are not used to sharpen the cutting edge; in this case, an abrasive based on CBN is considered the best option.

Sharpening and straightening is carried out using flat and cup wheels. When using CBN, the surface cleanliness remains insufficient, and the structure may change. To eliminate the manifestation of these shortcomings, you can use two-stage sharpening:

- preliminary, carried out with circles with a particle size of 40;

- finishing, in circles with a coarseness of 25-16.

Return

Analogs

Steel grade R6M5 has several foreign analogues:

- Japanese SKH51;

- American T11302;

- English 3343;

- French Z85WDCV;

- German HS6-5-2, S6-5-2S;

- Polish SW7M.

Return

The best manufacturing companies

Based on consumer reviews, it is worth highlighting the following factories:

- "Promet-M";

- "Atom Technologies";

- "Atis Steel".

Also pay attention to:

- ХВ5;

- P18;

- 12Х18Н10Т;

- 40ХН.

Healthy? Save it to your wall! Thank you for like!

Manufacturing method R6M5

Of course, like any other alloy, R6M5 is manufactured in various assortments. So, in some workshops, high-speed hot steel is poured into ingots. At another production facility, it is hot rolled. To do this, heated ingots are compressed between the shafts of a rolling mill. Its resulting shape will depend on the shape of the shafts themselves.

Steel grade R6M5 is widely used for parts operating at high temperatures. For this reason, powder steel has become a very popular method of making steel lately.

When hot steel is poured into ingots, carbides are released very quickly from the melt. In some areas they form uneven areas of accumulation, which subsequently become the site of crack initiation.

In powder manufacturing, a special powder is used, which contains all the necessary components. It is sintered in a special vacuum container under high temperature and pressure. This helps ensure that the material is homogeneous.

Alloy Application

The positive characteristics of this alloy helped to find the use of this steel in household use. Knives are made from it. Moreover, if the product is sharpened correctly, it will be able to cut not only the flesh of an animal, but also a thin metal plate.

Discs made of steel R6M5

The only disadvantage of this product is its sharpening. But, if you know all the tricks of proper sharpening, then this tool will become very useful in everyday life. These products are most often used by hunters and tourists.

Despite the expensive cost, the use of alloy for knives has become very popular in everyday life.

Every man in his house has a power tool, in which drills made of this type of steel are used as auxiliary equipment. The varieties of drills that are made from this R5M6 steel include:

- crown ones, which are used for drywall;

- stepped;

- drills designed for stone, wood or metal.

Not only drills and knives are made from this material. Slotting cutters, hacksaw blades, and countersinks are made from R6M5 steel.

Products that have found a place in everyday life and in production

R6M5 steel, its characteristics and application for knives. This is a fairly common household item; there are a number of its manufacturers with a global brand, for example, Rapid. There are many videos on the Internet with experiments using knives made of R6M5 steel. Indeed, they are good at cutting such things: ropes, wood, meat and bones, etc. The most striking experiment involved an attempt to cut a metal plate several mm thick with a R6M5 knife, and it worked.

Knife blanks made of steel R6M5 - this steel is very popular in everyday life

It should be added that high-speed steel R6M5 does not have a tendency for easy turning. Therefore, quite often knife owners complain about the inability to sharpen them. In any case, this cannot be done with household sharpeners. Apparently, this is why products made from P6M5 are rarely found in everyday life; they can more often be seen as an auxiliary tool among plumbing equipment or among avid fishermen and hunters.

In almost every home you can find household power tools. Auxiliary elements (equipment) for it can be made from quick cutters.

The P6M5 drill is used in the production of household tools intended for repair work. Additionally, there is an opinion that it is better to drill hardened iron using the R6M5K5 brand. In addition, there are the following types of drills:

simple with one-sided sharpening;

crown (for drywall);

stepped;

spear-shaped for glass and porcelain stoneware;

on stone, brick, wood.

Despite the above comment, the P6M5 metal drill is also a fairly common tool. R6M5 is used to make countersinks, crowns, conical machine reamers, drills, slotting cutters, and hacksaw blades.

Video - How to make a knife from P6M5 with your own hands

How to sharpen high-speed cutters

Such products are subject to wear and dullness. Knowing the R6M5 steel, its characteristics and its application, we can assume that ordinary alumina grinding wheels will not be able to cope with the task, which, in fact, is confirmed by practice. The sharpened surface remains rough, and the cutting qualities are no longer close to the original ones. Therefore, to restore commercial properties, it is recommended to send the products to sharpening, where CBN wheels are used.

Difficulties in hardening high-speed steel

Heat treatment of P6M5 contains a number of specific features associated with the characteristics of this brand, as well as a long heating time for hardening. To reach 1230 degrees Celsius (hardening temperature according to GOST), 25 percent more working time is spent than for a similar grade P18. First, a vacation period is made at 200 and 300 degrees for an hour. Further processing is carried out in 3 stages:

- 690 degrees -3 minutes;

- 860 – also 3 minutes;

- 1230 – 1.5 minutes.

Then the steel is cooled. In further processing, a three-time vacation period at 560 degrees for 1.5 hours is used. During tempering periods, the alloy is supplemented with alloying additives that form carbides, which increases the strength of the final metal. Previous annealing of steel helps eliminate high brittleness with a high strength index.

Buying and selling quick cutters

Do you need a reliable supplier of high-quality high-speed steel? It offers its services, operating in Lyubertsy. We offer cooperation on the most favorable terms.

Our services

High-speed steels are widely used in the production of cutting tools. If you are looking for where to buy quick cutters P6M5 P18, etc., we can offer a wide range of rolled metal products of this type. Our assortment includes the following brands:

- P18 is a universal option, suitable for the manufacture of cutting tools of various types;

- R6M5 is a brand perfectly suitable for the production of thread-cutting tools;

- R6M5K5 is the best choice if you need to produce rough and semi-rough tools;

- other brands (R9K5, R6M5F3, R18F2, R18F2K8M, R9K5, R9M4K8, R12F2K8M3, etc.);

- tool steels of the following grades: (9ХС, ХВГ, 95Х18, Х12МФ, Х12М, Х12Ф1, 4Х5МФС,

- 3Х2В8Ф, 5ХНМ, 3Х3М3Ф, 4Х5В2ФС, 4Х4ВМФС, (DI22), 6ХВ2С, 5ХВ2С, Х6ВФ), etc.

Rolled metal is supplied in the form of:

- sheets;

- stripes;

- circles;

- squares.

Sales of high-speed steels are not the only area of our activity. The scope also includes:

- steel purchase. By contacting us, you can sell quick cutters P6M5 P18, etc., as well as tool steels of various grades;

- chemical analysis of the composition of metals and alloys. Our specialists travel within Moscow and the surrounding Moscow region. To perform the analysis, a modern portable XRF analyzer DELTA (OLYMPUS) is used, which makes it possible to obtain the most accurate information about the composition of the samples.

Why ZIRCON LLC?

ZIRCON LLC has been operating in the high-speed steel market since 2009. During its work, the company has excellently established itself as a conscientious supplier, which can offer customers a number of important advantages:

- high quality rolled metal. Quick cutters must undergo strict quality control. It meets the requirements of GOST 19265-73 and TU;

- optimal prices. Our company has the ability to deliver from State Reserve bases, making the cost of rolled metal as profitable as possible. Special conditions and special offers apply to regular suppliers;

- large warehouse. Rental is sold from a warehouse located in Lyubertsy. ZIRCON LLC can guarantee its availability and prompt daily updating of the list of warehouse balances on the website.

By contacting us, you will acquire an executive supplier who will never let you down!

GOST and TU steel R6M5

R6M5 steel is described by several GOSTs and TUs. Each of them contains products and technical requirements for them. Despite the transition of rolled metal to hard alloys, the characteristics of R6M5 keep this brand in the field of view of many steel foundries. The following products, described by the relevant GOSTs or specifications, are still in demand:

- cold-deformed shaped profiles of high precision TU 14-11-245-88;

- forged circles or squares, assortment - GOST 1133-7;

- hot-rolled wheels - GOST 2590-88;

- calibrated rod - GOST 7417-75;

- rods and strips - GOST 19265-73 (steel grade R6M5K5);

- circles with special surface finishing - GOST 14955-77;

- There are probably still GOSTs that are not included in the list.

These standards are still adhered to at many Russian enterprises.

Characteristics of high-speed steels

Hot hardness

At normal temperatures, the hardness of carbon steel is even slightly higher than the hardness of high-speed steel. However, during operation of the cutting tool, intense heat is generated. In this case, up to 80% of the released heat is spent on heating the instrument. Due to an increase in the temperature of the cutting edge, the tool material begins to temper and its hardness decreases.

After heating to 200 °C, the hardness of carbon steel begins to rapidly decrease. For this steel, a cutting mode in which the tool would heat up above 200 °C is unacceptable. High-speed steel retains its high hardness when heated to 500–600 °C. High speed steel tools are more productive than carbon steel tools.

Red fastness

If hot hardness characterizes what temperature steel can withstand, then red hardness characterizes how long the steel will withstand such a temperature. That is, how long will quenched and tempered steel resist softening when heated.

There are several characteristics of red fastness. Let's give two of them.

The first characteristic shows what hardness the steel will have after tempering at a certain temperature for a given time.

The second way to characterize red hardness is based on the fact that the intensity of the decrease in hot hardness can be measured not only at high temperature, but also at room temperature, since the hardness decrease curves at high temperature and room temperature are equidistant, and measuring hardness at room temperature, of course, is much easier than at high. Experiments have shown that cutting properties are lost at a hardness of 50 HRC at cutting temperature, which corresponds to approximately 58 HRC at room temperature. Hence, red hardness is characterized by a tempering temperature at which in 4 hours the hardness decreases to 58 HRC (designation K4р58). Characteristics of heat resistance of carbon and red resistance of high-speed tool steels

| steel grade | Temperature, °C | Exposure time, hour | Hardness, HRCе |

| U7, U8, U10, U12 | 150—160 | 1 | 63 |

| P9 | 580 | 4 | |

| U7, U8, U10, U12 | 200—220 | 1 | 59 |

| R6M5K5, R9, R9M4K8, R18 | 620—630 | 4 |

Fracture Resistance

In addition to “hot” properties, high mechanical properties are also required from the cutting tool material; This means resistance to brittle fracture, since at high hardness (more than 60 HRC) fracture always occurs by a brittle mechanism. The strength of such high-hard materials is usually defined as the resistance to fracture during bending of prismatic, uncut specimens under static (slow) and dynamic (fast) loading. The higher the strength, the greater the force the working part of the tool can withstand, the greater the feed and depth of cut that can be applied, and this increases the productivity of the cutting process.

Chemical composition of high-speed steels

Chemical composition of some high-speed steels

| steel grade | C | Cr | W | Mo | V | Co |

| Р0М2Ф3 | 1,10—1,25 | 3,8—4,6 | — | 2,3—2,9 | 2,6—3,3 | — |

| R6M5 | 0,82—0,90 | 3,8—4,4 | 5,5—6,5 | 4,8—5,3 | 1,7—2,1 | < 0,50 |

| R6M5F2K8 | 0,95—1,05 | 3,8—4,4 | 5,5—6,6 | 4,6—5,2 | 1,8—2,4 | 7,5—8,5 |

| P9 | 0,85—0,95 | 3,8—4,4 | 8,5—10,0 | < 1,0 | 2,0—2,6 | — |

| P18 | 0,73—0,83 | 3,8—4,4 | 17,0—18,5 | < 1,0 | 1,0—1,4 | < 0,50 |

Manufacturing and processing of high-speed steels

High-speed steels are produced both by the classical method (casting steel into ingots, rolling and forging) and by powder metallurgy methods (spraying a jet of liquid steel with nitrogen). The quality of high-speed steel is largely determined by the degree of its forging. When insufficient forging of steel produced by the classical method, carbide segregation is observed.

A common mistake when making high-speed steels is to treat them as “self-hardening steels.” That is, it is enough to heat the steel and cool it in air, and you can get a hard, wear-resistant material. This approach absolutely does not take into account the features of high-alloy tool steels.

Before hardening, high-speed steels must be annealed. In poorly annealed steels, a special type of defect is observed: naphthalene fracture, when, despite the normal hardness of the steel, it has increased brittleness.

A competent choice of quenching temperature ensures maximum solubility of alloying additives in α-iron, but does not lead to grain growth.

After quenching, 25–30% retained austenite remains in the steel. In addition to reducing the hardness of the tool, retained austenite leads to a decrease in the thermal conductivity of steel, which is extremely undesirable for working conditions with intense heating of the cutting edge. Reducing the amount of retained austenite is achieved in two ways: by cold treating the steel or by repeated tempering. When processing steel by cold, it is cooled to −80…−70 °C, then tempered. When tempering multiple times, the “heating-holding-cooling” cycle is carried out 2-3 times. In both cases, a significant reduction in the amount of retained austenite is achieved, but it is not possible to completely get rid of it.

Principles of alloying high-speed steels

The high hardness of martensite is explained by the dissolution of carbon in α-iron. It is known that when tempering from martensite in carbon steel, tiny particles of carbide are released. While the released carbides are still in the finest dispersed dispersion (that is, at the first stage of precipitation when tempered to 200 °C), the hardness does not noticeably decrease. But if the tempering temperature is raised above 200 °C, carbide precipitation increases and the hardness decreases.

In order for steel to consistently maintain its hardness when heated, it must be alloyed with elements that would complicate the process of coagulation of carbides. If you introduce some carbide-forming element into steel in such an amount that it forms a special carbide, then the red-hardness increases abruptly. This is due to the fact that the special carbide precipitates from martensite and coagulates at higher temperatures than iron carbide, since this requires not only the diffusion of carbon, but also the diffusion of alloying elements. Almost noticeable coagulation of special carbides of chromium, tungsten, molybdenum, vanadium occurs at temperatures above 500 °C.

Red resistance is created by alloying steel with carbide-forming elements (tungsten, molybdenum, chromium, vanadium) in such an amount that they bind almost all the carbon into special carbides, and these carbides go into solution during quenching. Despite the strong difference in the general chemical composition, the composition of the solid solution is very similar in all steels, the atomic sum W + Mo + V, which determines the red resistance, is approximately 4% (atomic), hence the red resistance and cutting properties of different grades of high-speed steels are similar. High-speed steel containing cobalt has superior cutting properties to other steels (it increases red-hardness), but cobalt is a very expensive element.

How to make a knife from rapid with your own hands

Steel grades: P10, P12, P14, P18 and the P6M5 family are excellent for creating cutting elements. The fragility of saw blades is somewhat exaggerated.

You should not make blades that are too long and use them to dig into sewer manholes. There will be no problems with the knife in future use.

Rapid alloy is quite resistant to loads and is designed for long-term loads. Proper manufacturing of the blade guarantees all its available qualities. We will give brief instructions on how to make a blade with your own hands from common steel grade R6M5.

Homemade knife from a quick cutter.

Required materials and tools

The alloy is quite resistant to mechanical stress. Difficulties during production will definitely arise; it is not appropriate for a Russian master to be afraid of them. Materials needed:

- wooden block and epoxy glue (for the handle);

- a piece of brass, bronze or copper;

- impregnating varnish, oil.

Hacksaw blade steel grade R6M5 - blank. Protective glasses and gloves; the work ahead will be dusty and labor-intensive. Toolkit of the following type:

- Grinder angle grinder, set of discs for various purposes;

- vice, hammer, jigsaw, files, pliers;

- sharpening machine, wheels for it with different grains;

- needle file, drill and set of drills;

- marker, sandpaper, clamp;

- container with water.

A horse-drawn handle is ideal. The choice to stop is on her.

Manufacturing of the main profile

You should not use a template; it is better to draw with a marker on the canvas itself. The specific qualities of the steel will allow you to make cuts in accordance with the image. And use pliers to break off pieces of steel along the cut. The drawing is carried out together with the shank.

At the end of the process, we will obtain a rough, rough blade blank. We refine the part on a grinding machine. We remove excess metal by grinding on a coarse-grit wheel. The grooves on the shank will help with better bonding to the wood.

Bevels and grinding of the blade

We mark out the symmetrical bevels; the process is quite important and should be handled with care. We try to prevent overheating; periodically dip the blade in water. A special device will help to make clear descents.

Polishing a knife blade.

The grinding machine wheel needs to be changed; the finest grain is used. After making sure that the slopes are symmetrical, it is permissible to carry out the initial sharpening of the workpiece. Final sanding is done manually using sandpaper.

Along the way, we make a bolster, a suitable piece of brass, and mark it for the blade. In accordance with the markings, it is necessary to drill small holes. Then widen them using a file to insert the blade.

Making the handle

The saw workpiece must be wrapped with tape to continue safe work. The wooden block should be marked and holes should be drilled in it in accordance with the shank. Try it on together with the bolster.

Does it fit perfectly? Go ahead:

- You can start gluing the parts. It is recommended to mix epoxy with wood shavings. Fill the hole of the future handle with glue, insert the bolster and blade. We strengthen the structure with a clamp. Let the glue dry for a day.

- Once dry, release the workpiece. We mark the future handle and remove the excess with a jigsaw. The rough version of the handle is ready.

- We bring it to an anatomical or other shape using sandpaper. We process the finest grains in conclusion.

We soak the handle with oil or a special liquid. This will give the product water-repellent qualities and less susceptibility to rotting. All that remains is to sharpen the blade according to all the rules.

Sharp knife made from quick cutter R6M5

Attention!!!

This homemade product is posted for informational purposes only. The creation and use as a bladed weapon is prohibited; according to Article 223.4 of the Criminal Code of the Russian Federation, it is punishable by imprisonment for up to two years!

This steel is quite durable, it is enough for long-term heavy work. This steel does not lose its strength even at high temperature loads. The only drawback of this metal is that it is very difficult to harden it with your own hands. Hardening requires repeated heating, tempering, and special chemicals, such as saltpeter, for cooling. But if you process the metal carefully, without overheating, then you won’t need to harden it. So, let's look in more detail at how to make a knife from R6M5 steel.

Materials and tools used by the author:

List of materials:

— R6M5 steel (hacksaw blade); - a piece of wood for the handle; - epoxy adhesive; - a piece of brass for the handle; - oil or varnish to impregnate the handle.

List of tools:

- Bulgarian; - vice; - grinder; — orbital sander or machine; - drill; — a clamp (the author’s homemade one is made from wood); - marker; - sandpaper; - jigsaw.

Knife making process:

Step one. Cutting out the main profile

First we need to figure out what our knife will look like. Draw the profile of the knife on the workpiece using a marker. Well, then you can start cutting. We cut the workpiece using a grinder, but when cutting P6M5 there is one nuance. This steel is quite brittle and breaks when subjected to strong bending. All we need to do is make small cuts with a grinder in the areas that we need to remove. Well, then we break them off with pliers, like glass.

Step two.

Finalizing the profile Step three.

Bevels and sanding The final finishing is done by hand using fine sandpaper soaked in water. Well, at the very end, the blade can be polished on a machine using GOI paste or another paste.

Step four. Brass insert

There is a brass insert at the front of the handle. We select the desired piece of brass and drill a series of holes in it. Then these holes are bored out with a flat file so that the shank of the blade can fit in. At the same step, you can immediately give the workpiece an oval shape on the sharpener. The author immediately polished the part on the machine, since this would be much more difficult to do later.

Step five. Blank for handle

Step six. Final modification of the knife

When the glue dries, we take out our knife and draw the desired handle profile with a pencil. Next, we cut off the excess with a jigsaw; the fastest way to do this is with a jigsaw. We grind the handle to obtain the desired profile, rough processing can be done on a sharpening machine or grinder. Well, we carry out finer processing manually using sandpaper. Making the handle absolutely smooth.

I hope you liked the project and found useful information for yourself. Good luck and creative inspiration if you want to repeat the homemade product. Don't forget to share your ideas and developments with us.

Attention!!!

This homemade product is posted for informational purposes only. The creation and use as a bladed weapon is prohibited; according to Article 223.4 of the Criminal Code of the Russian Federation, it is punishable by imprisonment for up to two years!

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Price for steel R6M5

The cost of the R6M5 is quite high. So, in Moscow, a circle with a thickness of 2 mm costs 1,350 rubles per kilogram, and a circle with a thickness of 16 mm, its price will be 600 rubles per kilogram. For comparison, ordinary carbon steel costs between 20 and 40 rubles per kilogram.

It is the high cost of the high-speed cutter that encourages enterprises that use it in their work to collect its waste and hand it over to the appropriate organizations. Then, R6M5 is sent for remelting and a new tool is made.

A little history

R6M5 steel owes its origin to the next industrial revolution that took place in Britain. In the middle of the 19th century, the issue of processing steels and alloys became acute. The cutting tool that existed at that time quickly heated up and the quality of processing was reduced to zero. As a result of research conducted by the English steelmaker R. Muschet, steel was tested that contained carbon, tungsten, manganese and other alloying additives in its chemical composition.

Almost half a century later, American metallurgists created steel, which became the prototype of the modern P18 high-speed cutter. Around the same time, the R6M5 steel recipe was formed.

It must be said that the appearance of a quick cutter served as the basis for a significant increase in productivity in metalworking.

Rating: 5/5 – 4 votes

Cost of metal in products

It is not difficult to buy R6M5 in finished products, but the cost of the alloy is quite high. Here is a small price list of steel products of this brand. So a tool circle, depending on the thickness: 2, 5 or 16 mm, costs 1350, 1200, 600 rubles per kilogram, respectively. The cost of an instrumental strip is slightly lower and amounts to 620 rubles per kilogram.

Undoubtedly, prices for R6M5 grade metal in products may vary, so the given figures should be taken relatively, only to determine the level of cost of the alloy. On the other hand, high prices for quick cutters make the metal quite popular in the sale of scrap metal (see quick cutter scrap). The cost of secondary high-speed steel is significantly higher than that of conventional metal grades. Alternatively, products made from R6M5 alloy, which have served their service life, can be used as business scrap, with a higher value.

Steel R6M5 – decoding of steel grade, GOST, material characteristics

Steel grade – R6M5

Standard – GOST 19256

Steel grade R6M5

The first letter

P

means that the steel is high-speed.

6

following the letter indicates the average mass fraction of tungsten (6%),

M5

indicates the molybdenum content in the steel of approximately 5%. Alloy steel, high-speed.

High-speed steel R6M5 is used for the manufacture of all types of cutting tools when processing carbon alloy structural steels, preferably for the manufacture of thread-cutting tools, as well as tools working with shock loads.

| Mass fraction of basic chemical elements, % | ||||||

| C – carbon | Si – silicon | Mn – manganese | Cr – chromium | W – tungsten | Mo – molybdenum | V – vanadium |

| 0,82-0,90 | 0,20-0,50 | 0,20-0,50 | 3,80-4,40 | 5,50-6,50 | 4,80-5,30 | 1,70-2,10 |

| Temperature of critical points, °C | |||

| Ac1 | Ac3 | Ar1 | Ar3 |

| 815 | 880 | 730 | 790 |

| Technological properties | |

| Forging | Forging temperature, °C: beginning 1160, end 850. Slow cooling in the well. |

| Weldability | Not applicable for welded structures. |

| Machinability | Annealed at HB 255: Kv carbide = 0.8 Kv high speed steel = 0.6 |

| Flokensensibility. | Not sensitive |

| Sandability | good |

Characteristics and grades of HSS steel

High-speed varieties are high-carbon steels. Some brands contain a fairly large amount of tungsten. In addition, they may contain cobalt and molybdenum. If we talk about the hardness of alloys, the indicator is most often in the range of 62–64 units of the HRC scale. Comparing products made from high-speed steel and carbide, it is worth noting that the first option is distinguished by a fairly affordable price and increased wear resistance.

Recently, it has been customary to distinguish 3 main groups of HSS steel, each of which has its own characteristics:

- High tungsten content (T)

- High Molybdenum (M)

- High alloy

Tungsten steels

Not the most popular variety. This is due to the fact that tungsten is quite rare and expensive. The most common grades of tungsten steel are T1 and T15. The second contains cobalt and vanadium, therefore they are suitable for the production of accessories that have increased requirements for strength and resistance to high temperatures.

Chemical composition of tungsten HSS steels

| Type | Analogue | C | Mn | Si | Cr | V | W | Mo | Co | Ni |

| T1 | P18 | 0,75 | — | — | 4,00 | 1,00 | 18,00 | — | — | — |

| T2 | R18F2 | 0,80 | — | — | 4,00 | 2,00 | 18,00 | — | — | — |

| T4 | R18K5F2 | 0,75 | — | — | 4,00 | 1,00 | 18,00 | — | 5,00 | — |

| T5 | 0,80 | — | — | 4,00 | 2,00 | 18,00 | — | 8,00 | — | |

| T6 | 0,80 | — | — | 4,50 | 1,50 | 20,00 | — | 12,00 | — | |

| T8 | 0,75 | — | — | 4,00 | 2,00 | 14,00 | — | 5,00 | — | |

| T15 | R12K5F5 | 1,50 | — | — | 4,00 | 5,00 | 12,00 | — | 5,00 | — |

Molybdenum and high alloy steels

They are very widespread. May contain cobalt and tungsten. Those brands whose formula includes carbon and vanadium are characterized by increased strength and wear resistance, and resistance to abrasives. Alloys, starting with M41, are used to produce devices that retain their characteristics even when super heated. To create equipment designed for work at low temperatures, steels with molybdenum are also used, but they are subject to additional processing.

Chemical composition of molybdenum HSS steels

| Type | Analogue | C | Mn | Si | Cr | V | W | Mo | Co | Ni |

| M1 | 0,80 | — | — | 4,00 | 1,00 | 1,50 | 8,00 | — | — | |

| M2 | P6M5 | 0,85 | — | — | 4,00 | 2,00 | 6,00 | 5,00 | — | — |

| M3 | P6M5Ф3 | 1,20 | — | — | 4,00 | 3,00 | 6,00 | 5,00 | — | — |

| M4 | 1,30 | — | — | 4,00 | 4,00 | 5,50 | 4,50 | — | — | |

| M6 | 0,80 | — | — | 4,00 | 2,00 | 4,00 | 5,00 | — | — | |

| M7 | 1,00 | — | — | 4,00 | 2,00 | 1,75 | 8,75 | — | — | |

| M10 | 0,85–1,00 | — | — | 4,00 | 2,00 | — | 8,00 | — | — | |

| M30 | 0,80 | — | — | 4,00 | 1,25 | 2,00 | 8,00 | — | — | |

| M33 | 0,90 | — | — | 4,00 | 1,15 | 1,50 | 9,50 | — | — | |

| M34 | 0,90 | — | — | 4,00 | 2,00 | 2,00 | 8,00 | — | — | |

| M35 | R6M5K5 | 0,82–0,88 | 0,15–0,40 | 0,20–0,45 | 3,75–4,50 | 1,75–2,20 | 5,5–6,75 | 5,00 | 4,5–5,5 | up to 0.30 |

| M36 | 0,80 | — | — | 4,00 | 2,00 | 6,00 | 5,00 | — | — |

Chemical composition of high alloy HSS steels

| Type | Analogue | C | Mn | Si | Cr | V | W | Mo | Co | Ni |

| M41 | R6M3K5F2 | 1,10 | — | — | 4,25 | 2,00 | 6,75 | 3,75 | 5,00 | — |

| M42 | 1,10 | — | — | 3,75 | 1,15 | 1,50 | 9,50 | 8,00 | — | |

| M43 | 1,20 | — | — | 3,75 | 1,60 | 2,75 | 8,00 | 8,25 | — | |

| M44 | 1,15 | — | — | 4,25 | 2,00 | 5,25 | 6,25 | 12,00 | — | |

| M46 | 1,25 | — | — | 4,00 | 3,20 | 2,00 | 8,25 | 8,25 | — | |

| M47 | R2AM9K5 | 1,10 | — | — | 3,75 | 1,25 | 1,50 | 9,50 | 5,00 | — |

| M48 | 1,42–1,52 | 0,15–0,40 | 0,15–0,40 | 3,50–4,00 | 2,75–3,25 | 9,50–10,5 | 0,15–0,40 | 8,00–10,0 | up to 0.30 | |

| M50 | 0,78–0,88 | 0,15–0,45 | 0,20–0,60 | 3,75–4,50 | 0,80–1,25 | up to 0.10 | 3,90–4,75 | — | up to 0.30 | |

| M52 | 0,85–0,95 | 0,15–0,45 | 0,20–0,60 | 3,50–4,30 | 1,65–2,25 | 0,75–1,50 | 4,00–4,90 | — | up to 0.30 | |

| M62 | 1,25–1,35 | 0,15–0,40 | 0,15–0,40 | 3,50–4,00 | 1,80–2,00 | 5,75–6,50 | 10,0–11,0 | — | up to 0.30 |

When selecting products made from molybdenum material, it is worth considering the features of a particular brand:

- M1. Ideal for releasing drills. They are flexible and shock resistant. But they cannot boast of significant red fastness.

- M2. One of the most popular materials. Often used for the production of tools for various purposes. The product is suitable for intensive work using machines. The main feature of such a tool is its exceptional red resistance, which means the cutting element will retain its qualities for a long time. Our catalog presents drills of the HSS-STANDARD series made of this alloy

- M7. Ideal for producing large drills designed for drilling materials of increased hardness or thick sheets.

- M35. It has increased red fastness due to the increased amount of cobalt in the formula. But it has low resistance to shock loads.

- M42. Contains a large amount of cobalt, therefore it has excellent red fastness. In addition, it is extremely resistant to abrasion. Ideal for making accessories for working with particularly hard or even viscous materials. Core cutters made from this material are presented in the HSS-CO 8 line of drills

- M50. Often used to produce drills that come with portable equipment.

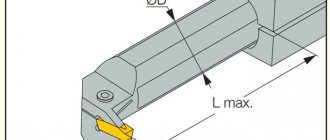

Straight turning cutting cutters made of high-speed steel (P18) TU 2-035-491-76

| Lathe scoring cutter straight 6x6x50 | 430 rub. Buy |

| Lathe scoring cutter straight 6x6x80 | 450 rub. Buy |

| Lathe scoring cutter straight 8x8x50 | 410 rub. Buy |

| Lathe scoring cutter straight 8x8x80 | 430 rub. Buy |

| Lathe scoring cutter straight 8x8x100 | 460 rub. Buy |

| Lathe scoring cutter straight 10x10x60 | 390 rub. Buy |

| Lathe scoring cutter straight 10x10x100 | 450 rub. Buy |

| Lathe scoring cutter straight 10x10x120 | 480 rub. Buy |

| Lathe scoring cutter straight 12x12x70 | 470 rub. Buy |

| Lathe scoring cutter straight 12x12x100 | 630 rub. Buy |

| Lathe scoring cutter straight 12x12x120 | 690 rub. Buy |

| Lathe scoring cutter straight 16x16x80 | 820 rub. Buy |

| Lathe scoring cutter straight 16x16x100 | 1020 rub. Buy |

| Lathe scoring cutter straight 16x16x150 | 1680 rub. Buy |

The influence of alloy elements on the properties of steel

High heat resistance of high-speed steel grades is provided by tungsten and molybdenum. On their basis, carbides are formed, which partially pass into solid solution. After heat treatment, the martensite structure is ensured. Tungsten, molybdenum, and vanadium slow down its decomposition. This is what provides the necessary red fastness. For a long time, high-speed steel alloyed only with tungsten was used. However, due to the scarcity of this metal, they began to partially replace it with molybdenum. This element also has a positive effect on the tendency of tungsten steel grades to carbide heterogeneity. Vanadium forms the hardest carbide. However, the carbon content must be sufficient for greater saturation of the solid solution. The more vanadium is introduced, the more carbon there should be in the alloy. The main task of chromium is to impart high hardenability to steel. Cobalt also increases red resistance.

High-speed steel (hardness when alloyed with this element increases to 70 HRC) in this case will have reduced strength. It is worth noting that the introduction of chromium is not widely used due to the high cost of the element.

OTHER MATERIALS USED IN THE PRODUCTION OF KNIVES (EXCEPT STEEL):

Cobalt-Stellite 6K. This is a flexible material with very high wear resistance, most often resistant to corrosion. Stellite 6K is a cobalt alloy. David Boye uses cobalt to make submariner knives. Titanium. The latest titanium alloys can have a hardness of up to 50 units, and this allows them to be used for the manufacture of cutting parts. Titanium is incredibly resistant to corrosion and is also non-magnetizable. Widely used in expensive submarine knives due to the fact that military marines use it to work with mines that detonate when metal approaches. Titanium is also used in survival knives. Tygrys produces knives with a steel core covered with layers of titanium. Ceramics. The blade on some knives is actually made of ceramic. Most often, these blades are very fragile and cannot be sharpened on their own. However, they hold the factory sharpening well. Such knives are made by Boker and Kyocera companies. Kevin McClung recently released a composite knife using ceramic that is much more durable than other ceramic knives and is quite suitable for most general jobs, and can also be sharpened at home and still holds an edge well.

Where are high speed steels used?

The scope of wear-resistant metal depends on the composition that determines its working properties. Basically, this is a tool that has high demands on strength, heat resistance, and long service life.

- Production of drills, cutters, cutters, taps;

- Manufacturing cutting edges for tools, which in some cases can be removable;

- Parts for metalworking machines and equipment;

- Manufacturing of tools used for finishing hard-to-cut metal products.

Experts give the following recommendations on the use of these metal grades:

- Tungsten-molybdenum compounds are suitable for tools intended for roughing products, manufacturing cutters, broaches and shaver.

- Cobalt compounds are used for processing heat-resistant and corrosion-resistant products in difficult conditions.

- Vanadium alloys are used for finishing materials.

- The P9 grade is used to create equipment elements that are not subject to excessive load.

- Grade P18 is suitable for tools with complex shapes and shaped products with increased wear resistance requirements.

The range of metal products is represented by square, circle, strip, and sheet metal. Most often, cutting tools are made from a circle. Square steel is used for the production of electric planers, knives, and turning tools. If you have doubts about the correct choice of a suitable alloy, it is better to contact specialists. Specialized companies will be able to select high-quality rental products with the required performance characteristics.

Steel R6M5K5 – Vladresurs company

| Brand: | R6M5K5 |

| Classification: | High-speed tool steel |

| Addition: | The steel has an increased tendency to decarburization, good toughness, increased wear resistance, and good grindability Products offered by advertisers: No data. |

Chemical composition in % of the material R6M5K5

GOST 19265 – 73

| C | Si | Mn | Ni | S | P | Cr | Mo | W | V | Co | Cu |

| 0.86 – 0.94 | 0.2 – 0.5 | 0.2 – 0.5 | up to 0.6 | up to 0.03 | up to 0.03 | 3.8 – 4.3 | 4.8 – 5.3 | 5.7 – 6.7 | 1.7 – 2.1 | 4.7 – 5.2 | up to 0.25 |

Temperature of critical points of the material R6M5K5.

| Ac1 = 840, Ac3(Acm) = 875, Ar3(Arcm) = 805, Ar1 = 765 |

Mechanical properties at T=20oC of the material R6M5K5.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| 850 | 510 | 12 | 14 | 180 | Delivery status |

| Hardness Р6М5К5 after annealing, GOST 19265-73 | HB 10 -1 = 269 MPa |

Physical properties of the material R6M5K5.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.2 | 8200 | 458 | |||

| 100 | 27 | |||||

| 200 | 28 | |||||

| 300 | 29 | |||||

| 400 | 30 | |||||

| 500 | 32 | |||||

| 600 | 36 | |||||

| 700 | 34 | |||||

| 800 | ||||||

| 900 | 29 | |||||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Foreign analogues of the material R6M5K5

Attention! Both exact and closest analogues are indicated

| USA | Germany | Japan | France | England | European Union | Italy | Spain | China | Sweden | Bulgaria | Hungary | Poland | Czech | Austria | South Korea | ||||||||||||||||

| – | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | UNE | G.B. | SS | BDS | MSZ | PN | CSN | ONORM | KS | ||||||||||||||||

|

Rockwell hardness of steel p6m5

R6M5 steel is high-speed and belongs to one of the types of tool steel. It has a high safety margin, which allows it to process hard materials.

The operating speed of grinding and drilling devices where it is used is several times higher than the speed of a conventional alloy.

This is not the only advantage of high-speed steel, marked as P6M5.

Steel R6M5

Main characteristics

Rapid steels include metal alloys to which additional substances have been added that improve their chemical and physical properties.

Thanks to this, the metal alloy becomes strong, wear-resistant, unable to come into contact with oxygen and become covered with rust.

R6M5 high-speed steel differs from conventional carbon alloys in that it can process any hard material at high speed, while having good wear resistance.

Microstructure of R6M5 steel

It has unique properties that make it possible to produce tools such as cutters, taps or reamers. Made from this alloy, they will serve the owner faithfully for a very long time.

And the most famous and characteristics of steel grade R6M5 include:

- The hardness of steel grade R6M5 when heated. Typically, other alloys, during long-term and non-stop drilling, begin to heat up, and with increasing temperature, as is known, the metal begins to soften. And the drill loses its abilities and becomes fragile. The same high-speed steel can heat up to 6000 °C, maintaining its initial properties and without losing strength.

- Increased resistance to incandescence at fairly high temperatures.

- Holds an edge very well.

- Has high viscosity.

- Excellent processing on grinding equipment.

- Holds impact loads perfectly.

The characteristics of R6M5 steel listed above make the metal alloy indispensable in construction.

Chemical composition

The chemical composition of R6M5 steel consists of the following metals:

- tungsten;

- vanadium;

- silicon;

- copper;

- chromium;

- manganese.

Chemical composition of R6M5 steel and some other high-speed steels

An alloy with the addition of cobalt, namely R6M5K5 steel, has been used since the beginning of the twentieth century. cobalt in products made from it is not higher than 15 percent. If they alloy it with vanadium and chromium, then its metallic base only increases.

Products such as tools for cutting acid-resistant and heat-resistant metals, falling under the austenitic classification, are made from this steel. While processing such metals with products from another alloy is very difficult.

This steel is characterized by increased hardness and heat resistance.

Items obtained from a quick cutter are subject to frequent dulling. And ordinary sharpening wheels, which are made of electrocorundum, will not help improve the quality of sharpening.

Sharpening a knife made of steel R6M5

In order to properly sharpen the tool, cup wheels and flat profiles are used. But, usually, such sharpening has its disadvantages. Therefore, in order to qualitatively sharpen a tool made from this type of metal alloy, two passes are used.

- first, preliminary sharpening is done, for which a wheel with an abrasive surface of grade 40 grain is used;

- for finishing, for which grade zero is used from 25 to 16.

Alloy Application

The positive characteristics of this alloy helped to find the use of this steel in household use. Knives are made from it. Moreover, if the product is sharpened correctly, it will be able to cut not only the flesh of an animal, but also a thin metal plate.

Discs made of steel R6M5

The only disadvantage of this product is its sharpening. But, if you know all the tricks of proper sharpening, then this tool will become very useful in everyday life. These products are most often used by hunters and tourists.

Despite the expensive cost, the use of alloy for knives has become very popular in everyday life.

The global brand for the production of these cutting tools is.

Every man in his house has a power tool, in which drills made of this type of steel are used as auxiliary equipment. The varieties of drills that are made from this R5M6 steel include:

- crown ones, which are used for drywall;

- stepped;

- drills designed for stone, wood or metal.

Knife made of R6M5 steel Drills made of R6M5 steel Corrugated wedge knife

Not only drills and knives are made from this material. Slotting cutters, hacksaw blades, and countersinks are made from R6M5 steel.

Explanation of the markings of this alloy

The explanation of the R6M5 steel marking is as follows:

- The letter “P” means high-speed or rapid steel, since the marking was based on an abbreviation from the English word “rapid” (read in Russian as rapid), which translated means “fast”. And the number that follows this letter indicates the percentage of tungsten in this alloy. In this case it is equal to 6%, with minor deviations.

- The letter “M” indicates that this alloy contains molybdenum. And the number that follows the letter also shows the amount of its presence in the alloy of this metal as a percentage.

Example of decoding markings

If no additional elements are added to this steel, then its designation ends there. If cobalt is added to the alloy, then it will be designated P6M5K5. Marking "F" - vanadium, "T" - titanium and other additional elements.

According to GOST, R6M5 steel is divided into the following products, which belongs to one of the interstate standards. It describes all the technical requirements related to this brand. Although rolled metal has recently switched to hard alloys, this brand still maintains its leading position in market demand.

Listed below are some products made from an alloy of these metals and the corresponding GOST for them:

- hot-rolled circles belong to GOST number 2590-88;

- the calibrated rod has GOST 7417-75;

- strips and rods (for the manufacture of these products the steel variety R6M5K5 is used) - GOST 19265-73;

- wheels that have a special finish on the top layer have GOST 14955-77.

Download GOST 2590-88

Download GOST 7417-75

Heat treatment of R6M5 steel

Heat treatment of the R6M5 alloy has a number of subtleties that relate to its properties. The fact is that it is capable of decarbonization during heating. To prevent this from happening, it is usually heated using a slow simmer.

Hardening

R6M5 high-speed steel heats up to 1230 degrees. During heating, steel mill workers closely monitor the process.

During the first warm-up, the temperature rises to two hundred degrees and the heating stops for an hour, then another additional heating is performed to thirty degrees. And again a vacation for an hour.

After this, it is continued to be heated to 690 degrees and stopped again for an hour. And the last two heatings are brought to temperatures of 860 and 1230, respectively.

This is a very complex incandescent procedure. Thanks to such hardening, the alloy acquires properties corresponding to it, but its cost, of course, increases.

After heating to 1230 degrees is completed, it is cooled using saltpeter, air and oil. Then, the temperature drops to 560 degrees. This temperature is maintained for one and a half hours. At this time, various alloying elements are added to the steel, which improve its properties. They also give it the appropriate hardness.

Before such long heating begins, the metal alloy is annealed. This is done in order to reduce the fragility of future products while maintaining strength parameters at the proper level.

This metal processing is carried out in a gas environment that consists of 80 percent nitrogen and twenty percent ammonia. The time this procedure takes is about forty minutes. The heating temperature will range from 550 degrees to 6600.

Such hardening will allow the alloy to form a less brittle surface layer.

Such an alloy can be supplemented with another element, namely zinc. Galvanizing occurs in a gas or liquid environment that contains a large amount of zinc. The heating temperature in it corresponds to 5600 degrees. And the time is about thirty minutes.

, please select a piece of text and press Ctrl+Enter.

Steel grade R6M5: description and application

Steel grade R6M5 is a special type of alloy tool steel intended for the manufacture of high-speed metalworking tools. Steel has many analogues on the world market with different designations. The table summarizes both exact and closest analogues of P6M5:

| USA | Germany | Japan | France | England | European Union | Italy | Spain |

| — | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | UNE |

| 1.3343 | |||||||

| HS6-5-2 | |||||||

| S6-5-2 | |||||||

| S6-5-2S | |||||||

| SC6-5-2 | |||||||

| X82WMoCrV6-5-4 |

| HS6-5-2HC |

| X85WMoCrV6-5-4 |

| Z85WDCV |

| 1.3343 |

| HS6-5-2 |

| HS6-5-2C |

| China | Sweden | Bulgaria | Hungary | Poland | Romania | Czech | Austria | South Korea |

| G.B. | SS | BDS | MSZ | PN | STAS | CSN | ONORM | KS |

Features of strengthening heat treatment of R6M5

Although R6M5 tungsten-molybdenum steel is called “self-hardening”, the hardening process cannot be left to chance. Compliance with the recommended annealing, heating and tempering modes allows you to increase the service life of cutters and cutters by 20-30%. Hardening of the tool is carried out in stages with pre-heating in salt baths: 15-30 seconds. at temperatures of 500 and 850 °C.

The duration of final heating to a temperature of 1280°C is calculated using the empirical formula: 10 s * 1 mm of metal thickness. Vacation mode – three times for 1 hour each at T=580-600°C.

Peculiarities

Steel grades R6M5 and R18 are used not only in the manufacture of knives, but also in the production of taps, drills, and industrial cutting tools. They are distinguished by their ability to maintain hardness and sharpness when exposed to high temperatures and significant shock loads. The high content of carbon and tungsten in the composition gives steel these characteristics.

Heat treatment

To give knives made from P18 and P6M5 increased strength and wear resistance, the metal is subjected to appropriate heat treatment. It takes place in 2 stages:

- Hardening – heating to a temperature of 1200-1300C. To avoid the formation of cracks, it is carried out gradually. First, the metal is heated to a temperature of 400-500C, then to a temperature of 800-850C. At maximum heating, the workpiece is subjected to heat treatment for a limited time (10-15 seconds for each millimeter of thickness). During hardening, the carbide decomposes, the alloy is saturated with tungsten and carbon.

- Vacation is carried out at a temperature of 550-560C. It is carried out in 2-3 stages, each lasting at least an hour. At the same time, the strength characteristics of the metal increase.

Steel is heated in special salt baths, which consist of barium chloride (78%) and sodium chloride (22%). Magnesium fluoride is used to deoxidize the solution.

Production of cutting tools

After heat treatment of the steel, the production of cutting tools begins. For this purpose, the workpieces, which are previously checked for compliance with GOST requirements, are sent for grinding. Products made from P18 steel are easier to grind, but they also retain their sharpness for a shorter period of time. Knives made from R6M5 alloy can only be sharpened with professional tools and skills, but their sharpening quality is much better. In production, specialized machines are used for grinding workpieces made of steel R18 and R6M5.

Knife Grif steel P18, birch bark handle.

Use in cutting

Knives made of steel P18 and P6M5 are quick-cutting and universal in use. The metal performs well under heat and mechanical stress. It does not lose strength or deform. Manufacturers of knives made from these steel grades conducted experiments during which they successfully coped not only with slicing various food products (meat, bones, cartilage), but also with cutting wood and even metal plates several millimeters thick!

Pros and cons of R6M5 steel for knives

R6M5 steel is used for the manufacture of knives with a thin blade, designed for quick cutting or slicing of hard material .

When properly sharpened, knives made of this alloy can cut a metal plate 1-3 mm thick , depending on the hardness of the metal. The main feature is the reduction of carbon content during hardening - high strength with low weight, rapid cooling.

R6M5 steel is a combination of strength, hardness, heat resistance at the expense of toughness and corrosion properties. When making knives, it is important to follow the 5-step hardening procedure.

Explanation of markings, characteristics

R - high-speed . The term refers to the ability to cut materials of heterogeneous density and viscosity without increasing energy costs.

The number “6” - the alloy contains 6% tungsten : increased ductility, preservation of the properties of steel at high temperatures.

M5 – 5% molybdenum : high strength, uniform distribution of atoms in the alloy when the melting point is reached, slowing down the oxidation of iron, simplifying processing.

Depending on the temperature and hardening time, hardness is 61-68 Hcr . Viscosity – 0.25 mJ m2 .

In addition to the main elements, the composition also includes:

- Carbon (0.8-0.9%) – hardness, reduced thermal conductivity.

- Silicon (0.2-0.5%) – ability to withstand high temperatures and resistance to aggressive chemical compounds.

- Nickel (0.25) – slows down the oxidation of iron.

- Chromium (3-4%) – increases viscosity, slows down the oxidation of iron under the influence of moisture.

- Manganese (0.2-0.5%) – removes oxygen atoms from the alloy during calcination, increases viscosity, increases wear resistance.

If other compounds are included in the alloy, additional symbols are present in the markings.

pros

R5M5 steel for knives has the following advantages:

- Ability to cut hard and heterogeneous materials – cutting bone and cartilage tissue.

- The quality of sharpening is not affected by the cutting speed - a combination of tungsten and carbon - suitable for thin cutting of hard fruits and vegetables (radish, quince).

- Knives made of R6M5 steel practically do not become dull when slicing onions and lemons, which cannot be said about other alloys. After working with these products, immediately rinse under running water and wipe dry.

- The knife does not jump off when cutting wilted products or tendons.

- Durability – high molybdenum content.

- Maintaining blade sharpness at temperatures above 300° C .

- Increased resistance to immediate mechanical impacts, including vibration.

- Easy to clean - there is no need to use special products to clean the blade.

- Fast sharpening on lathe equipment . Possibility to start operation without waiting for the alloy to cool completely.

- The high silicon content minimizes the risk of blade destruction due to acid or alkaline exposure in an environment with low air humidity - the possibility of use for cutting building materials.

- High fire resistance - withstands short-term contact with an open flame - wash off the scale after cooling in natural conditions.

- Lack of diffusion properties - particles of the processed material do not penetrate into the structure of the blade and are easily washed off with running water (molybdenum is ideal for cutting cattle carcasses).

- Easy disinfection of food products when cutting and cutting them - manganese.

- The low weight of the alloy allows you to quickly change the direction of impact, increasing cutting accuracy.

- The stability of the crystal lattice means it can be used to work in low-strength electric and electromagnetic fields.

- Preservation of sharpening quality even with significant simultaneous temperature increases.

Minuses

The main disadvantage is that due to the low chromium content, the alloy is susceptible to corrosion . The higher the temperature, the faster the destructive processes occur.

Other cons:

- A thin sharp cutting edge , even with slight pressure, leads to damage to soft tissues - a high probability of causing injury, not suitable for tropical fruits with soft skin, hard bone (mango, avocado - risk of bone chips getting into the pulp).

- The quality of sharpening decreases with frequent simultaneous cooling - the sudden release of tungsten energy affects the atoms of other elements of the crystal lattice.

- Loss of sharpening quality when not in use for a long period of time.

- Loss of properties due to prolonged exposure to negative temperatures in an environment with high humidity. reduction of service life due to icing and defrosting. If this happens, gradually defrost it in an oily, non-acidic solution. carefully remove plaque. During the first operation, after getting rid of ice, heat it up gradually.

- Difficulty of manual processing - without turning equipment it is difficult to sharpen the blade yourself.

- When sharpening by hand, it is not recommended to cut shortcrust pastry - one edge crumbles, the other shrinks.

- Contrary to its intended purpose, rapid manual cutting without proper training may result in personal injury . This also applies to work not at a right angle.

- Such knives will not be able to separate products of different densities (fish fillets from bones).

Results

The main advantages of R6M5 steel for knives are maintaining sharpening quality at high temperatures, the ability to quickly cut, slicing hard materials - thin metal sheet .

The main disadvantage is exposure to moisture. To extend service life, store at a relative humidity of no higher than 70%. After cutting moisture-containing materials, wipe dry.

If overheated, cool naturally.

Use a hard board or stand. Do not cut on the kitchen table - damage to the coating is inevitable. It is optimal to sharpen knives on cup wheels. Remove plaque with a solution of coarse rock salt and bleach (2/3 salt 1/3 bleach). Do not clean with sandpaper - damage to the structure - the sharpening does not hold well even after equipment (true for knives made of any steel).

Characteristics of steel

The main properties of this steel grade include increased toughness, good wear resistance and acceptable grindability. Has an increased tendency to decarbonization. This allows this metal to be used for all types of cutting tools sharpened for processing alloyed carbon structural products, in particular, shot blasting.

The tungsten-molybdenum series retains its properties at high temperatures. The bending strength is 4700 megapascals. The superiority in thermoplasticity and toughness is about 50 percent.

Another undeniable advantage of this brand is the ability to hold an edge. For this it is better to use a quick cutter. Excellent performance against impact loads makes it relevant in terms of use for creating drills, reamers and taps.

Types of HSS steels

HSS steels come in three categories:

- tungsten (T1-T15);

- molybdenum (M1-M36);

- highly alloyed (M41-M62).

The most commonly used grade is T1 and the alloy with the addition of cobalt and vanadium T15. T15 steel is used to produce tools that are needed to work at high temperatures and increased wear.

Tungsten steels

Not the most popular variety. This is due to the fact that tungsten is quite rare and expensive. The most common grades of tungsten steel are T1 and T15. The second contains cobalt and vanadium, therefore they are suitable for the production of accessories that have increased requirements for strength and resistance to high temperatures.

Molybdenum HSS drills

The main alloying component of steels in this group is molybdenum. Also in different quantities may contain:

- tungsten,

- cobalt;

- vanadium;

- carbon;

- and other components.

The most widely used are HSS drills made from the following types of molybdenum high-speed steels.

- M1. General purpose tools are produced from this grade of steel (8% molybdenum). These HSS drills are highly flexible and resistant to impact loads. Red fastness is lower than that of analogues.

- M2 (domestic equivalent - P6M5). This is the most common material for the production of HSS drills. The alloy contains 6% tungsten and 5% molybdenum. It has balanced strength, hardness and heat resistance.

- M3 (domestic equivalent - R6M5F3). This alloy also contains 3% vanadium. HSS drills made from this steel have lower abrasive wear.

- M7. The main alloying components are molybdenum (8.75%), vanadium (2%) and tungsten (1.75%). Drills made from this HSS steel are used for drilling hard and thick sheet metals.

- M35 (domestic equivalent - R6M5K5). In addition to tungsten, molybdenum and vanadium, this alloy contains cobalt (5%), as well as small amounts of manganese, silicon and nickel. The advantages of this material are good toughness, excellent grindability, heat and wear resistance. HSS drills made from this alloy are used when processing workpieces made of improved alloy and stainless steels under conditions of increased heating of the cutting edge.

High alloy HSS drills

To produce high-alloy HSS drills (having high impact strength and operating in cold conditions), molybdenum group alloys are used, which are subjected to special heat treatment.

- M47 (domestic analogue - R2AM9K5). Contains large quantities of molybdenum (9%) and cobalt (4.7–5.2%). The alloy has an increased tendency to decarburization and overheating during quenching. Sandability is low. HSS drills made from this alloy are used for machining workpieces made of improved alloy and stainless steels.

- M42. Contains a large amount of cobalt and molybdenum (8 and 9.5%, respectively). HSS drills made from this alloy are characterized by increased red hardness and abrasion resistance. Such tools are used when processing viscous and complex metals.

This is interesting: Design, operating principle and circuit diagram of a welding inverter. Types and classifications

Decoding - what do the marking symbols mean?

What is the meaning of the abbreviation R6M5 - spelling out steel? Such designations turned out to be a legacy of Soviet times.

The letter "P" is a designation for high-speed steels. The word is taken from the transcription of the English “rapid”, translated as “fast”.

The number behind the letter “P” indicates the percentage of tungsten in the alloy. For the brand described, it fluctuates around 6% with minor deviations.

Next comes the letter “M”, indicating the presence of molybdenum in the alloy. The next parameter is the proportion of the substance present in the composition.

In addition to Mo, high-speed steels may contain the following designations in their markings: “K” - cobalt, “F” - vanadium, “T” - titanium, “C” - zirconium.

Analyzing further the abbreviation P6M5, the decoding of steel may include additional letters. If the metal is produced by electroslag remelting, the nomenclature “Ш” (Р6М5-Ш) appears. With the introduction of new P6M5 technologies, decoding began to be found in this interpretation, P6AM5. This means alloying with nitrogen, which occurs at the stage of cooling the alloy after heating it to the hardening temperature (more details below). This steel is used in the manufacture of milling wheels.

Drill from Japanese company Nachi made of HSS steel

Imported analogues of high-speed cutters are labeled as HSS, which means High Speed Steel, literally translated, this is high-speed steel, and analogues of P6M5 are steels:

1.3343 (Germany DIN);

S600/S601 (standard D-016);

M2 (USA according to AISI/ASTM standards).

Improving product performance

Tools made from high-speed cutters are subject to high demands, and in order for them to meet them to the fullest, their surface is processed. Various methods are used for this, including:

- The surface layer of the part is subjected to nitriding. Such treatment can be carried out in a gaseous environment consisting of either 80% nitrogen and 20% ammonia, or 100% ammonia. The process takes 10-40 minutes at a temperature of 550 - 6600 degrees. This operation makes the top layer less fragile.

- The surface is saturated with carbon and nitrogen - the so-called cyanidation, which occurs by immersing the part in molten sodium cyanide. Depending on the final purpose of the part, cyanidation takes place at different temperatures. The longer the time and the higher the temperature, the thicker the layer becomes.

- Sulfidation is performed in a liquid sulfide melt with the addition of sulfur. This process is carried out from 45 minutes to 3 hours at temperatures from 450 to 5600 degrees Celsius

All of the above procedures are performed with a ready-made tool: the cutting part is sharpened, the surface is polished and hardened.

High speed steel knife.

Chemical composition

The chemical composition of R6M5 includes, in addition to the carbon and molybdenum listed above, the following components:

- carbon (C) 0.82 – 0.90%;

- manganese (Mn) 0.20 – 0.50%;

- chromium (Cr) 3.8 – 4.4%;

- silicon (Si) 0.20 – 0.50%;

- molybdenum (Mo) 4.8 – 5.3%;

- vanadium (V) 1.7 – 2.1%;

- cobalt (Co) 0.5%;

- nickel (Ni) 0.4%;

- phosphorus (P) 0.03%;

- sulfur (S) 0.025%;

- tungsten (W) 5.5 – 6.5%.

An alloy with cobalt additives has been used since the beginning of the twentieth century. It is used to produce devices for cutting acid-resistant metals that are resistant to high temperatures. Processing such metals with devices from a different brand requires additional costs. This steel is characterized by high hardness and heat resistance.

Main characteristics

The basic parameters of steel of this grade are: high toughness, excellent wear resistance, and a good level of grindability. This grade is used in the production of many types of blades and cutting equipment for working with structural strength steels.

Knife with a blade made of steel R6M5.

A tungsten-molybdenum alloy is the second name of this brand, which can retain its characteristic qualities even under extreme temperature changes. Moreover, its bending strength reaches 4700 MPa. Its combination with impact strength gives it a noticeable superiority over many of its peers.