- In the production of metal structures, C245 steel is a low-carbon grade used for building structures.

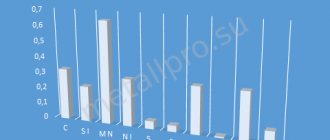

- 98% iron,

- 0.2% carbon,

- 0.65% manganese,

- from 0.05 to 0.015% silicon,

- up to 0.3% chromium, nickel and copper combined.

- St3ps5 and St3sp5 according to GOST 380 and GOST 535 (Appendix 1 GOST 27772-88)

- VSt3ps6 according to GOST 380-71 (Table 51b appendix 1 SNiP II-23-81)

- VSt3ps6-1 according to TU 14-1-3023–80 (Table 51b, Appendix 1, SNiP II-23-81)

- 18ps according to GOST 23570–79 (Table 51b appendix 1 SNiP II-23-81)

- E235-B, E235-C, Fe 360-B and Fe 360-C according to ISO 630:1995 (Appendix A GOST 380-2005)

Chemical composition

Steel consists of approximately:

The presence of up to 0.05% sulfur, 0.04% phosphorus and 0.08% arsenic is allowed.

Decoding steel C245

In the designation of steel, the letter C means “construction”, the numbers 245 are the yield strength (T) in megapascals (MPa). In more conventional units σT = 24.5 kg/sq. mm.

Among other parameters characterizing the mechanical properties of steel, we note the tensile strength = 370 MPa (37 kg/sq. mm).

Weldability

To assess weldability, use the criterion of carbon equivalent, calculated by the formula

Se=C+G/6+X/5+(N+D)/15, where C, G, X, N, D – the amount of carbon, manganese, chromium, nickel and copper as a percentage in the composition of the steel or alloy.

For C245, the equivalent carbon is below 0.25%, which means good weldability. The weld seam is not prone to the formation of hot and cold cracks. Parts can be welded by any method without additional measures - preheating, forging the heat-affected zone, etc.

Plastic

Plastic qualities, i.e. the ability to deform in a cold state without signs of destruction, are characterized by the relative elongation of the sample at break and the size of the yield area.

Steel C245 has a relative elongation at break, i.e., the elongation of the sample relative to the initial size after fracture, of 25%.

The length of the yield plateau, i.e. the change in relative elongation at which the stress does not change, is at least 2.5%.

This indicates the possibility of bending and stamping thin sheets of steel. For thick ones, local heating should be used to avoid cracks.

To understand the difference in the deformation capacity of thin and thick sheets, you should refer to the course on strength of materials. When bending a sheet, the difference in changes in the dimensions of the outer and inner sides will be greater, the greater the thickness. This means that for a thick sheet, the relative deformation will be greater and the probability of destruction - the appearance of cracks - will be higher.

With increasing temperature, the yield strength of the metal decreases, and the yield area increases. Therefore, to deform a thick steel sheet, it must be heated or the bend radius increased.

Corrosion resistance

Alloying components—silicon, copper, etc.—slightly increase the corrosion resistance of steels.

C245 has moderate oxidation resistance. It is sufficient for inter-operational storage of workpieces, as well as for operation inside dry rooms without additional protection. In other cases, paint and varnish coatings corresponding to the operating conditions of the structure should be applied.

Analogs

According to GOST 27772-88, steel grade C245 corresponds to:

Application

Grade C245 is used for the production of sheet and shaped rolled products - equal and unequal angles, channels, T-beams, I-beams. Rolled steel is used in the production of metal structures for various purposes. Due to their good weldability, welded joints are widely used in their production.

Particularly critical structures operating under conditions of constant increased vibration loads are required to be connected with rivets or other methods that prevent the spread of possible cracks.

As analogues of steel grade C245 we can name steel St.3ps, steel St.3sp, which are similar in mechanical properties and chemical composition. It should be noted that a mandatory requirement is the complete or partial completion of deoxidation of steels before the process of casting into molds. This is indicated by the letters ps and sp in the designation of brands.

Conclusion

Low-alloy structural steel C245 has properties that meet the requirements for metal structures for general use.

It can be welded well by all types of welding without additional measures to reduce red and blue brittleness.

The steel has average corrosion resistance. This requires the use of protective paint and varnish coatings for metal structures made from the described steels used outdoors.

Source: https://pellete.ru/stal/s235-plotnost-stali.html

Decoding steel C255

Marking C means that this steel is intended for use in construction, and the number 255 determines the yield strength of the finished steel in N/mm 2. It is applied to the metal surface with yellow insoluble paint.

Requirements for metal must comply with GOST 27772-88, which defines technical conditions for the production of rolled products for metal structures in construction. In accordance with the state standard, the following are made from steel C255: angles, I-beams, channels, bent profiles of various configurations, as well as smooth and corrugated metal sheets. The cross-sectional thickness of rolled elements cannot be more than 30 mm and less than 4 mm.

Compound

The mass fraction of the elements that make up this steel is given in the table of the state standard:

- about 97% iron (Fe);

- 0.22% carbon (C);

- 0.65% manganese (Mn);

- 0.15-0.3% silicon (Si);

- 0.3% chromium (Cr), nickel (Ni) and copper (Cu);

- 0.2% aluminum (Al);

- 0.05% sulfur (S);

- 0.04% phosphorus (P).

When using ores from individual deposits, an increased manganese content of 0.2% and the presence of arsenic are allowed, but not more than 0.12%.

Analogues of steel C255

Based on the chemical composition and mechanical properties, the state standard defines the following domestic brands as analogues of C255:

- VSt3sp5, VSt3ps5 and VSt3ps6;

- St3Gps and St3Gsp;

- 18sp, 18Gps and 18Gsp.

Among the foreign analogues for ISO 630 standardization, the following should be mentioned:

- Fe 360-B (E 235-B)

- Fe 360-C (E 235-C)

- Fe 360-D (E 235-D).

Steel S255: chemical composition and GOST standards for rental

Carbon steel C255 (carbon share is about 0.2%) is produced in accordance with GOST 27772-88, which determines the following composition of the chemical elements of the steel alloy:

- Fe – about 97%

- C – up to 0.22%

- Mn – up to 0.65%

- Si – 0.15-0.3%

- Ni – up to 0.3%

- Cr – up to 0.3%

- Cu – up to 0.3%

- S – up to 0.05%

- P – up to 0.04%

- N – up to 0.012%

Hot rolled shaped steel C255:

- GOST 8509 – equal angle angle

- GOST 8510 – unequal corner

- GOST 8239, 26020 – I-beam

- GOST 8240 – channel

- GOST 19425 – I-beam and special channel

In addition, carbon steel 255 is used for the production of rolled products:

- GOST 19903 – sheet

- GOST 82 – universal broadband

- GOST 8568 – sheet metal with lentil and rhombic corrugation

Bent profiles are also made from steel of this grade: according to GOST 7511, 8278, 8281, 8282, 8283, 9234, etc.

Types of processing and application

The amount of carbon and alloying additives in the chemical composition of C255 steel allows the use of any types of welding to connect parts and structural elements. Thermal, laser, hydraulic and mechanical processing technologies can be used for cutting rolled products and cutting sheets. It is noted that drilling, milling and threading are quite simple.

In construction, rolled steel C255 is used for the installation of metal structures of group 1, which includes welded elements designed to work in particularly difficult conditions. Including under vibration, dynamic and moving loads. The first group includes structural elements of bridge spans, supports for power lines, crane beams, load-bearing trusses, overpasses, stairs and others.

It is allowed to use rolled steel grades in other types of industrial production except construction. For example, for the manufacture of housings and load-bearing elements in mechanical engineering.

Corrosion protection

Steel C255 has excellent mechanical properties, but is susceptible to corrosion. Therefore, all metal structures made from it require protection from moisture and chemically active solutions and vapors. The most common type of surface protection is double painting with waterproof paints with preliminary priming. In addition, hot-dip galvanizing and powder polymer coating of finished structures and individual elements connected without welding.

Source of the article: https://prompriem.ru/stati/s255.html

Other brands in this category:

Please note that this information about the C255 brand is provided for informational purposes. The parameters, properties and composition of the actual C255 grade material may differ from the values given on this page. More detailed information about the C255 grade can be found on the information resource Brand of steel and alloys. You can check with our managers for information about the availability, delivery times and cost of materials. If you find inaccuracies in the description of materials or errors found, please inform the site administrators using the feedback form. Thanks in advance for your cooperation!

Steel grade C225 is used for the production of sheet and profile metal products intended for installation and assembly of critical metal structures with bolted, riveted, welded and seam joints. The brand is most popular and in demand in the construction industry, which has no restrictions when performing welding work.

Chemical composition

The chemical composition of steel C255 according to heat analysis of a ladle sample must comply with the standards given in table. 1 (Table 1-2 GOST 27772-88).

Chemical composition of steel S255 according to heat analysis of a ladle sample

| carbon | manganese | silicon | sulfur | phosphorus | chromium | nickel | copper | arsenic |

| Mass fraction of element, %, no more | ||||||||

| 0,22 | 0,65 | 0,15-0,30 | 0,050 | 0,040 | 0,30 | 0,08 | ||

| Maximum deviations by mass fraction of elements, % | ||||||||

| — | +0,050 −0,030 | +0,030 −0,020 | +0,005 | — | ||||

- Notes:

- It is allowed to increase the mass fraction of manganese to 0.85%.

- When smelting steel from Kerch ores, the mass fraction of arsenic is no more than 0.15%.

Rolled products with a mass fraction of manganese 0.8-1.1% and silicon 0.15-0.30% are produced with a thickness of more than 30 mm (clause 2.4 of GOST 27772-88).

The mass fraction of residual (acid-soluble) aluminum in steel with a mass fraction of manganese up to 0.85% and silicon 0.15-0.30%, intended for sheet and wide-band universal rolled products must be at least 0.20% (clause 2.8 of GOST 27772 -88).

It is allowed to treat steel with synthetic slags, vacuum degassing, blowing with argon, modifying steel with calcium and rare earth elements based on the introduction of no more than 0.02% calcium and 0.05% rare earth elements into the metal (clause 2.10 of GOST 27772-88).

It is permissible for the manufacturer not to conduct a chemical analysis of steel for chromium, nickel, copper and arsenic content. The required chemical composition is guaranteed by the manufacturer. In steel smelted from Kerch ores, the determination of arsenic is mandatory (clause 2.13.1 of GOST 27772-88).

The weldability of steel is guaranteed by the manufacturer (clause 2.18 of GOST 27772-88).

Prices for steel sheets

In APEX metal you can buy sheet steel 3 in sheets and rolls at a low price:

- for use in construction

- manufacturing of general purpose products, pipes, bent profiles

Depending on the purpose, steel sheet 3 is produced from grades with different chemical compositions and properties in accordance with GOST 380, GOST 19281, GOST 27772, TU.

- Thin-sheet and thick-sheet hot-rolled products are made from steel Z of ordinary quality with a chemical composition that must meet the requirements of GOST 380:

| steel grade | Mass fraction of chemical elements, % | |||||||||

| C | Mn | Si | S | P | N | Cr | Ni | Cu | As | |

| St3kp | 0,14. 0,22 | 0,30. 0,60 | 0,05. 0.07 | up to 0.05 | 0,04 | 0,012 | up to 0.30 | up to 0.30 | up to 0.30 | up to 0.08 |

| St3ps | 0,14. 0,22 | 0,40. 0,65 | 0,05. 0,15 | |||||||

| St3sp | 0,14. 0,22 | 0,40. 0,65 | 0,15. 0,30 | |||||||

| St3Gps | 0,14. 0,2 | 0,80. 1,10 | 0,05. 0,15 | |||||||

| St3Gsp | 0,14. 0,2 | 0,80. 1,10 | 0,15. 0,30 | |||||||

- Thick-sheet hot-rolled sheets of high strength steel 3 with a basic chemical composition in accordance with GOST 19281 are produced with regulated or controlled rolling with accelerated cooling to ensure the following strength classes:

- Hot-rolled sheets GOST 27772, intended for the manufacture of welded and other building structures:

Mechanical properties

The mechanical properties of shaped and rolled sheets made of steel C255 in tension, impact strength, as well as bending test conditions must meet the requirements of Table 2 (Table 3-4, clause 2.7 of GOST 27772-88).

Mechanical properties of rolled steel C255

| Thickness, shelves, mm | Mechanical characteristics | Bending until the sides are parallel (a is the thickness of the sample, d is the diameter of the mandrel) | Impact strength KCU, J/cm² (kgf m/cm²) | |||||

| Yield strength σ t, MPa (kgf/mm²) | Temporary resistance σв, MPa (kgf/mm²) | Relative elongation δ5, % | at temperature, °C | after mechanical aging | ||||

| −20 | −40 | −70 | ||||||

| no less | no less | |||||||

| Mechanical properties of shaped steel | ||||||||

| From 4 to 10 incl. | 255 (26) | 380 (39) | 25 | d = a | 29 (3)* | — | 29 (3)* | |

| St. 10 to 20 incl. | 245 (25) | 370 (38) | 29 (3) | 29 (3) | ||||

| From 20 to 40 incl. | 235 (24) | 24 | d=2a | |||||

| Mechanical properties of sheet and wide universal rolled products | ||||||||

| From 2 to 3.9 incl. | 255 (26) | 380 (39) | 20 | d = 1.5 a | — | |||

| From 4 to 10 incl. | 245 (25) | 25 | 29 (3)** | — | 29 (3)** | |||

| St. 10 to 20 incl. | 370 (38) | 29 (3) | 29 (3) | |||||

| From 20 to 40 incl. | 235 (24) | d=2a | ||||||

- * For a profile with a thickness of 5 mm, the impact strength standard is 49 J/cm² (5 kgf m/cm²)

- ** For sheets and strips 5 mm thick, the impact strength standard is 39 J/cm² (4 kgf m/cm²)

For sheet metal with a thickness of 4-8 mm, the rate of relative elongation δ5 = 23% (clause 2.21 of GOST 27772-88).

Impact strength standards are given for rolled products with a thickness of 5 mm or more (clause 2.22 of GOST 27772-88).

It is allowed to reduce the impact strength value on one sample by 30%. In this case, the average value of the test results must not be lower than the standards in Table. 2 (clause 2.23 GOST 27772-88).

The calculated resistances in tension, compression and bending of sheet, wide-band universal and shaped rolled products made of steel grade C255 in accordance with GOST 27772–88 for steel structures of buildings and structures should be taken according to table. 3 (Table 51 Appendix 1 SNiP II -23-81)

Calculated resistance of rolled steel C255

| Rolled thickness¹, mm | Design resistance², MPa (kgf/cm²), rolled | |||

| sheet, broadband universal | shaped | |||

| Ry | Ru | Ry | Ru | |

| From 2 to 3.9 | 250 (2550) | 370 (3800) | – | |

| From 4 to 10 | 240 (2450) | 250 (2550) | 370 (3800) | |

| St. 10 to 20 | 360 (3700) | 240 (2450) | 360 (3700) | |

| St. 20 to 40 | 230 (2350) | 230 (2350) | ||

- The thickness of the shaped steel should be taken as the thickness of the flange (its minimum thickness is 4 mm).

- The values of the calculated resistances were obtained by dividing the standard resistances (yield strength and tensile strength according to GOST 27772–88) by the reliability factor for the material γm = 1.025 (clause 3.2 of SNiP II -23-81), rounded to 5 MPa (50 kgf/cm²) .

Construction steel grades - analogues and replacement

One of the important characteristics of construction rolled steel 3 is its resistance to brittle fracture. To confirm these properties, samples of steel sheets undergo impact bending tests at decreasing temperatures.

The level of resistance to brittle fracture of rolled sheets in accordance with GOST 27772 is guaranteed by the required value of impact strength (KCU - when tested for impact bending with a U concentrator). For steels smelted according to EN standards, this value is the fracture coefficient (KV).

Analogs of steel grade C255

Carbon steel C255 according to GOST 27772-88 corresponds to the following grades of steel:

- St3Gps and St3Gsp according to GOST 380 (Appendix 1 GOST 27772-88)

- VSt3sp5 , VSt3Gps5 and VSt3ps6 (rolled sheets with a thickness of over 20 to 40 mm, shaped - over 30 mm) according to GOST 380-71 (Table 51b appendix 1 SNiP II -23-81)

- VSt3sp5-1 and VSt3Gps5-1 according to TU 14-1-3023–80 (Table 51b appendix 1 SNiP II -23-81)

- 18sp , 18Gps , 18Gsp according to GOST 23570–79 (Table 51b appendix 1 SNiP II -23-81)

- E 235-B ( Fe 360-B ), E 235-C ( Fe 360-C ) and E 235-D ( Fe 360-D ) according to ISO 630:1995 (Appendix A GOST 380-2005)

We manufacture the following standard metal products:

Flight stairs, platforms, stepladders and their guards according to series 1.450.3-7.94.2:

Flight stairs, landings, stepladders and their railings according to series 1.450.3-3.2:

Steel stepladders for wells according to:

If you are interested in our metal structures

You can send us a message by filling out the following form:

Source of the article: https://www.gran-stroi.ru/stal-S255-GOST-27772-88.php

Steel s245: GOST, analogues, characteristics, interpretation - Turner

| Information sections: Steel grades / Steel grade St 3 ps |

| This page presents the technical characteristics and properties of steel grade St 3 ps (S245, St3ps5, S275). We carry out the production and sale of any grades of steel to order, you can also order from us or buy from warehouses the most popular grades of steel, always available, they are presented in the rolled metal section, also in this section the prices for this steel are presented, calculations and delivery costs You can check with our managers - we supply metal to any region of Russia, and you can also pick up the ordered steel by pick-up from warehouses in St. Petersburg. Steel production is carried out in any form convenient for you - steel circle, steel square or steel strip, in strict accordance with GOST and TU. Couldn't reach our managers? Use the function to request a call back (upper left part of the site). |

Steel grade: St3ps

|

Metal deliveries are carried out throughout Russia, and pickup from warehouses in St. Petersburg is also possible.

The price is indicated per ton; prices and prices for other steel grades can be viewed or printed from the price list page. Discounts are provided for regular customers and for large orders.

| Steel circle St3ps | Steel strip St3ps | Steel square St3ps |

Chemical composition of steel grade St3ps:

Chemical composition of the St3ps material in percent.

GOST 380 - 2005

| C | Si | Mn | Ni | S | P | Cr | N | Cu | As |

| 0.14 — 0.22 | 0.05 — 0.15 | 0.4 — 0.65 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.008 | up to 0.3 | up to 0.08 |

Technological properties of steel grade St3ps:

The technological properties of steel reflect its ability to accept certain deformations, similar to those that the finished steel product will have during further processing or under further operating conditions.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Mechanical properties of steel grade St3ps:

Mechanical properties at T=20oC of the St3ps material

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Pipes, GOST 8696-74 | 372 | 245 | 23 | |||||

| Pipes, GOST 10705-80 | 372 | 225 | 22 | |||||

| Rolled goods, GOST 535-2005 | 370-480 | 205-245 | 23-26 | |||||

| Thick sheet, GOST 14637-89 | 370-480 | 205-245 | 23-26 | |||||

| Fittings, GOST 5781-82 | 373 | 235 | 25 | |||||

| Wire rod, GOST 30136-95 | 490-540 | 60 |

| Hardness St3ps | HB 10 -1 = 131 MPa |

Physical properties of steel grade St3ps:

Physical properties and characteristics of steel at various temperatures and other conditions.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 7850 |

Steel St3ps - St3ps5, s245, s275

| Among the various areas directly dependent on the quality and timely supply of rolled metal products, the lion's share of all needs falls on the construction of various buildings, structures and structures. At the same time, St3ps steel is mainly used as the main load-bearing element, including a loaded one, in the construction of load-bearing structures, like S275. The main condition is location in a zone of temperate and warm climate with a predominance of positive ambient temperatures. Our company produces St 3 PS metal in large quantities, constantly increasing the volume of rolled metal production. It is worth noting that this type of product, like the entire range of products produced, fully complies with the requirements of GOST, as well as common international quality control systems. If you decide to purchase St3ps5, then we will provide you with optimal conditions for concluding a transaction with us. Firstly, for the entire range of products sold there is a comfortable minimum order quantity of only a ton, which is beneficial for one-time buyers and small wholesale customers. It is also very convenient that c245, like any other product, is delivered to all regions of the country without exception. |

Designations of properties and characteristics of steel, metal and alloys:

Mechanical properties :

| sв | — Short-term strength limit, [MPa] |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

Physical properties:

| T | — Temperature at which these properties were obtained, [Deg] |

| E | — Modulus of elasticity of the first kind, [MPa] |

| a | — Coefficient of thermal (linear) expansion (range 20o - T), [1/degree] |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | — Material density, [kg/m3] |

| C | — Specific heat capacity of the material (range 20o — T), [J/(kg deg)] |

| R | — Electrical resistivity, [Ohm m] |

Weldability:

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Source:

Steel c245: GOST standards, physical properties, characteristics and application

Steel is obtained by combining iron and carbon. There are other chemical elements that are involved in this process. The proportion of carbon in steel C245 should be no more than 2.14%. This component provides the finished metal with strength and hardness. At the same time, its plasticity and viscosity decrease. The main features of the classification are purpose, degree of deoxidation, structure and composition.

Key Features

All other elements that make up steel are designed to improve its characteristics, depending on their quantity. Accordingly, the classification of steel grades by quality is determined. Alloy additives provide resistance to corrosion and make the finished alloy more functional. A set of such additives is present in low-carbon steel grade C245. For the same reason, I would like to dwell on it in more detail.

This is a special purpose steel. Nominal density - 7.85 g/ cm³ . This grade includes magnesium and silicon to oxidize the metal and free it from ferric oxide.

This property worsens the composition of the material. The mechanical characteristics of the alloy do not change due to this. In addition, manganese has a beneficial effect on sulfur, which in some cases makes the metal more brittle.

Steel grade C245 has the following analogues:

Do-it-yourself laser for cutting metal

Decoding st3sp5 sounds like structural carbon steel of ordinary quality. Their chemical composition is controlled by various standards. Each brand has its own letter designation.

For modification c245, the letter C is used. It stands for “construction”. 245 is a parameter indicating the yield strength. Chrome makes steel hard and able to resist the formation of rust.

Nickel has a similar effect. Copper in the alloy:

- increases viscosity;

- improves thermal conductivity.

All of these properties make it possible to successfully use steel. Low-carbon grades are characterized by good weldability. Experts who study the features of this material often note that the application characteristics of steel 20 are almost similar. Grade 20×13 can be used for the same system components as the modification in question.

Purpose and scope of application

Steel of this grade is used for the construction of building structures. It is produced for the manufacture of steel structures with support and other types of connections. This brand combines two necessary additives for long-term use of structures. They remain strong and reliable for a long time.

The brand is used in the production of hot-rolled channel products. It is used in the manufacture of angles, wide and sheet metal, bent profiles and I-beams.

The metal can also be used in other areas of industry.

For the production of rolled metal intended for building steel structures with welded joints, not only the model in question is used, but also modifications C255, C235. According to quality, any grade of steel can be:

- ordinary;

- high-quality with increased quality;

- high quality.

How to choose welding electrodes for an inverter: electric welding

According to their composition, they are divided into alloy and carbon. Quality should be understood as the combination of bones that is formed during the manufacture of metal. These include uniformity of structure, manufacturability, mechanical properties and chemical composition.

Physical and mechanical characteristics

Any physical properties and characteristics of temperature conditions under other conditions are reflected in certain parameters. These are hardness and specific gravity. The first is 10−1= 131MPa.

Source: https://nzmetallspb.ru/prochee/stal-s245-gost-analogi-harakteristiki-rasshifrovka.html

Density of steel of various types and grades: temperature dependence of density

Tables of steel densities of various types and grades are presented.

The first table shows the density of steel by type and examples of some grades of steel for each type. The density of carbon, alloy and low-alloy steels, die, roll, high-speed steels is given, the density of stainless steel, etc. is indicated. The second table contains summary data on the density of common steel grades (about 200 items) depending on temperature. The following tables allow you to determine the density of carbon, low-alloy and high-alloy steels with special properties at temperatures from 0 to 1100 ° C.

Types and grades of steel

Steel.

Types and grades of steel. Their application. Steel is an alloy of iron and carbon with other elements, the carbon content in it is no more than 2.14%.

The most general characteristic is that steel is classified according to its chemical composition:

carbon steel (Fe – iron, C – carbon, Mn – manganese, Si – silicon, S – sulfur, P – phosphorus). Based on carbon content, it is divided into low-carbon, medium-carbon and high-carbon. Carbon steel is designed for statically loaded tools.

alloy steel - alloying elements are added: nitrogen, boron, aluminum, carbon, phosphorus, cobalt, silicon, vanadium, copper, molybdenum, manganese, titanium, zirconium, chromium, tungsten, nickel, niobium.

According to the production method and impurity content, steel differs:

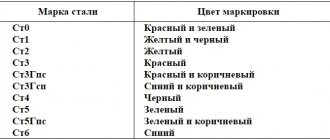

ordinary quality steel (carbon less than 0.6%) - complies with GOST 14637, GOST 380-94. St0, St1, St2, St3, St4, St5, St6. The letters “St” indicate ordinary quality steel, the numbers indicate the marking number depending on the mechanical properties. It is the cheapest steel, but inferior in other qualities.

high-quality steel (carbon or alloy) - GOST 1577, carbon content is indicated in hundredths of % - 08, 10, 25, 40, the degree of deoxidation and the nature of solidification can additionally be indicated. High-quality carbon steel has high ductility and increased weldability.

Low-carbon high-quality structural steels are characterized by low strength and high ductility. Parts for cold stamping are made from sheet steel 08, 10, 08kp. Bolts, screws, nuts, axles, hooks, studs and other parts for non-essential purposes are made from steels 15 and 20.

Medium-carbon quality steels (st. 30, 35, 40, 45, 50, 55) are used after normalization and surface hardening for the manufacture of parts that have high strength and core toughness (axles, screws, bushings, etc.)

Steel 60 - steel 85 have high strength, wear resistance, and elastic properties. Crane wheels, rolling rolls, compressor valves, springs, leaf springs, etc. are made from them.

high quality - complex chemical composition with low phosphorus and sulfur content - according to GOST 19281.

Steel is also divided by application:

a) construction steel - carbon steel of ordinary quality. Has excellent weldability. The number indicates the conditional number of the steel composition according to GOST. The higher the reference number, the higher the carbon content, the higher the strength of the steel and the lower the ductility.

St0-3 - for secondary structural elements and non-critical parts (flooring, railings, lining, washers)

St3 is used for load-bearing and non-load-bearing elements of welded and non-welded structures and parts that operate at positive temperatures. GOST 380-88.

The quality standard provides for steel with an increased amount of manganese (St3Gsp/ps, St5Gsp/ps).

Density of different types of steel

A table of densities of common types of steel at room temperature is provided. The density of steel depends significantly on the type, which is determined by its chemical composition and purpose.

Light steels with low density include some alloyed, heat-resistant and stainless steels. The minimum density of common grades of such steels is 7640-7670 kg/m 3.

The presence of a large amount of nickel in steel makes its density higher. For example, the density of nickel-based alloys can reach 8500 kg/m3. The heaviest is high-speed tool steel. It contains heavy metals such as tungsten and molybdenum. The density of such steel varies in the range from 8000 to 8800 kg/m 3.

Steel density by type

| Steel type | Examples | Density, kg/m 3 |

| Carbon quality | Art.08, Art.10, Art.15, 20, 40, 50, 85, 15K, A12, A30, OS | 7800-7870 |

| Low alloy steels | 15G, 40G, 10G2, 16GS, 18G2S, 45G2, 15Х, 35Х, 50Х | 7730-7850 |

| Alloy steels | 18ХГТ, 25ХГМ, 40ХС, 35ХМ, 40ХФА, 20ХН, 15Н5А | 7640-7880 |

| Purpose steels | 65G, 55S2, 60S2G, 70S2ХА, ШХ15, EI 229 | 7650-7850 |

| Stainless, heat-resistant and heat-resistant | 03Х8СУЦ, 12Х18Н10Т, 10Х12НД, 03Н18К9М5Т | 7670-8000 |

| Iron-nickel alloys | ХН32Т, ХН35ВТК, ХН45У, 06ХН46Б, DI65 | 7700-8170 |

| Nickel-based alloys | EI 929, KhN60Yu, EP 709, KhN70Yu, KhN78T, KhN80TBYu | 7900-8570 |

| Carbon and alloy | U7, U8, U10, 9ХС, ХВГ | 7745-7850 |

| Die steel | Х6ВФ, Х12, 7Х3, 3Х3М3Ф, EP 761, EI 958, DI 37 | 7700-7800 |

| Roll steel | 9Х, 9Х2В, 55Х, 60ХН, 75ХМ, 7Х2СМФ | 7800-7900 |

| High speed | 11R3AM3F2, R6M3, R9, R12, R18, R18K5F2 | 8000-8800 |

| Steels for castings | 15L, 30L, 70L, 40HL, 25GSL, 05Х26Н6М2Д2АБФЛ | 7730-7850 |

| Nickel-based alloys for castings | KhN58VKMTYuBL, KhN65VMTYuL, TsNK 7P, TsNK 17P | 8000-8790 |

St3sp5 decoding what 5 means

Each category of steel is characterized by its specific chemical composition. It largely determines the scope of application of the workpieces being created and the difficulties that arise during heat treatment.

The chemical composition of St3 steel makes it one of the most common materials that can be found on the market. It is difficult to imagine modern construction work without this metal.

The key points regarding the chemical composition are the following:

Density of common grades of steel at different temperatures

The table shows the density values of steel of common grades depending on temperature. It should be noted that the density of steel changes little when its temperature changes. The density of various steel grades in the dimension kg/m 3 is given in the table at temperatures from 20 to 900°C.

When steel is heated, it increases in volume and its density becomes less. For example, the density of stainless steel 12Х18Н9 at 20°С is equal to 7900 kg/m 3 or 7.9 g/cm 3 , and at a temperature of 900°С the density of this steel decreases and becomes equal to 7510 kg/m 3 or 7.51 g/cm 3.

Of the steels presented in the table, we can distinguish the lightest steel with the minimum density. Such steel is stainless heat-resistant steel 15X25T (X25T, EI439), the density of which at room temperature is 7600 kg/m 3 or 7.6 g/cm 3 . The heaviest is tool steel P18 with a density of 8800 kg/m 3 (8.8 g/cm 3 ) at room temperature (20°C).

The average density of structural steel at room temperature is 7700...7900 kg/m 3 . For example, the density of steel 20 has a value of 7856 kg/m 3 at a temperature of 20°C. The density of steel is generally quite close to the density of iron since this metal is the basis of this alloy.

Table of steel density values by grade

| steel grade | Temperature, °C | Steel density, kg/m 3 |

| 02Х17Н11М2 | 20 | 8000 |

| 02X22N5AM3 | 20 | 8000 |

| 03Н18К9М5Т | 20 | 8000 |

| 03Х11Н10М2Т | 20 | 8000 |

| 03Х13Н8Д2ТМ (EP699) | 20 | 7800 |

| 03X24N6AM3 (ZI130) | 20 | 8000 |

| 06Х12Н3Д | 20 | 7810 |

| 06ХН28МДТ (0Х23Н28М3Д3Т, EI943) | 20 | 7960 |

| 07Х16Н6 (Х16Н6, EP288) | 20 | 7800 |

| Steel 08 | 20…100…200…300…400…500… 600…700…800…900 | 7871…7846…7814…7781…7745…7708… 7668…7628…7598…7602 |

| 08GDNFL | 20 | 7850 |

| 08kp | 20…100…200…300…400…500… 600…700…800…900 | 7871…7846…7814…7781…7745…7708… 7668…7628…7598…7602 |

| 08Х13 (0Х13, EI496) | 20…100…200 | 7760…7740…7710 |

| 08Х17Т (0Х17Т, EI645) | 20 | 7700 |

| 08Х17Н13М2Т (0Х17Н13М2Т) | 20…100…200…300…400…500… 600…700 | 7900…7870…7830…7790…7750…7700… 7660…7620 |

| 08Х18Н10 (0Х18Н10) | 20 | 7850 |

| 08Х18Н10Т (0Х18Н10Т, EI914) | 20 | 7900 |

| 08Х22Н6Т (0Х22Н5Т, EP53) | 20 | 7700 |

| 3Х3М3Ф | 20…100…200…300…400…500… 600…700…800…900 | 7828…7808…7783…7754…7721…7684… 7642…7597…7565…7525 |

| 4Х4ВМФС (DI22) | 20…100…200…300…400…500… 600…700…800…900 | 7808…7786…7757…7726…7693…7658… 7624…7581…7554…7550 |

| 4Х5МФ1С (EP572) | 20…100…200…300…400…500… 600…700…800…900 | 7716…7692…7660…7627…7593…7559… 7523…7490…7459…7438 |

| 9ХС | 20 | 7830 |

| 9Х2МФ | 20 | 7840 |

| Steel 10 | 20…100…200…300…400…500… 600…700…800…900 | 7856…7832…7800…7765…7730…7692… 7653…7613…7582…7594 |

| 10G2 | 20 | 7790 |

| 10kp | 20…100…200…300…400…500… 600…700…800…900 | 7856…7832…7800…7765…7730…7692… 7653…7613…7582…7594 |

| 10Х11Н20Т3Р (ЭИ696) | 20 | 7900 |

| 10Х11Н23Т3МР (EP33) | 20 | 7950 |

| 10Kh12N3M2FA(Sh) (10Kh12N3M2FA-A(Sh)) | 20 | 7750 |

| 10Х13Н3М1Л | 20 | 7745 |

| 10Х14Г14Н4Т (Х14Г14Н3Т, EI711) | 20 | 7800 |

| 10Х17Н13М2Т (Х17Н13М2Т, EI448) | 20…100…200…300…400…500… 600…700 | 7900…7870…7830…7790…7750…7700… 7660…7620 |

| 10Х18Н18У4Д (EP841) | 20 | 7630 |

| 12MH | 20…100…200…300…400…500… 600…700 | 7850…7830…7800…7760…7730…7690… 7650…7610 |

| 12ХН2 | 20 | 7880 |

| 12ХН3А | 20…100…200…300…400…500…600 | 7850…7830…7800…7760…7720…7680…7640 |

| 12X2MFB (EI531) | 20 | 7800 |

| 12X1MF (EI575) | 20…100…200…300…400…500… 600…700…800…900 | 7800…7780…7750…7720…7680…7650… 7600…7570…7540…7560 |

| 12Х2Н4А | 20…100…300…400…600 | 7840…7820…7760…7710…7630 |

| 12Х13 (1Х13) | 20…100…200…300…400…500… 600…700…800…900 | 7720…7700…7670…7640…7620…7580… 7550…7520…7490…7500 |

| 12X17 (X17, EZh17) | 20 | 7720 |

| 12Х18Н9 (Х18Н9) | 20…100…200…300…400…500… 600…700…800…900 | 7900…7860…7820…7780…7740…7690… 7650…7600…7560…7510 |

| 12Х18Н9Т (Х18Н9Т) | 20…100…200…300…400…500… 600…700…800…900 | 7900…7860…7820…7780…7740…7690… 7650…7600…7560…7510 |

| 12Х18Н10Т | 20 | 7900 |

| 12Х18Н12Т (Х18Н12Т) | 20…100…200…300…400…500… 600…700 | 7900…7870…7830…7780…7740…7700… 7850…7610 |

| 12X25N16G7AR (EI835) | 20 | 7820 |

| 13Х11Н2В2МФ-Ш (ЭИ961-Ш) | 20 | 7800 |

| 14Х17Н2 (1Х17Н2, EI268) | 20 | 7750 |

| Steel 15 | 20…100…200…300…400…500… 600…700…800…900 | 7850…7827…7794…7759…7724…7687… 7648…7611…7599…7584 |

| 15G | 20 | 7810 |

| 15kp | 20…100…200…300…400…500… 600…700…800…900 | 7850…7827…7794…7759…7724…7687… 7648…7611…7599…7584 |

| 15K | 20 | 7850 |

| 15L | 20 | 7820 |

| 15X | 20…100…200…400…600 | 7830…7810…7780…7710…7640 |

| 15ХМ | 20…100…200…300…400…500…600 | 7850…7830…7800…7760…7730…7700…7660 |

| 15HF | 20…100…200…300…400…500… 600…700 | 7760…7730…7710…7670…7640…7600… 7570…7530 |

| 15Х5М (12Х5МА, Х5М) | 20…100…200…300…400…500…600 | 7750…7730…7700…7670…7640…7610…7580 |

| 15X12VNMF(EI802, EI952) | 20…100…200…300…400…500… 600…700 | 7850…7830…7800…7780…7760…7730… 7700…7670 |

| 15Х25Т (Х25Т, EI439) | 20 | 7600 |

| 16GS | 20 | 7850 |

| 17Х18Н9 (2Х18Н9) | 20 | 7850 |

| 18Х2Н4МА (18Х2Н4ВА) | 20…100…200…300…400…500…600 | 7950…7930…7900…7860…7830…7800…7760 |

| 18Kh12VMBFR-Sh (EP 993-Sh) | 20 | 7850 |

| 18ХГТ | 20 | 7800 |

| Steel 20 | 20…100…200…300…400…500… 600…700…800…900 | 7856…7834…7803…7770…7736…7699… 7659…7617…7624…7600 |

| 20G | 20 | 7820 |

| 20K | 20 | 7850 |

| 20L | 20 | 7850 |

| 20kp | 100…200…300…400…500…600… 700…800…900 | 7834…7803…7770…7736…7699…7659… 7617…7624…7600 |

| 20X | 20…100…200…400…600 | 7830…7810…7780…7710…7640 |

| 20ХГР | 20 | 7800 |

| 20ХГСА | 20 | 7760 |

| 20HML | 20…100…200…300…400…500…600 | 7800…7780…7750…7720…7690…7650…7620 |

| 20ХН3А | 20…100…300…600 | 7850…7830…7760…7660 |

| 20Х2Н4А | 20 | 7850 |

| 20Х3МВФ (EI415, EI579) | 20…400…500…600 | 7800…7690…7660…7620 |

| 20X5ML | 20 | 7730 |

| 20Х13 (2Х13) | 20…100…200…300…400…500… 600…700…800 | 7670…7660…7630…7600…7570…7540… 7510…7480…7450 |

| 20Х13Л | 20 | 7740 |

| 20Х20Н13 (Х23Н13, EI319) | 20…100…600…800 | 7820…7790…7580…7480 |

| 20Х20Н14С2 (Х20Н14С2, EI211) | 20…100…600…700…800…900 | 7800…7760…7550…7510…7470…7420 |

| 20Х23Н18 (Х23Н18, EI417) | 20…400…500…600…700…900 | 7900…7760…7720…7670…7620…7540 |

| 20Х25Н20С2 (Х25Н20С2, EI283) | 20…100…800…900 | 7720…7680…7440…7390 |

| Steel 25 | 20 | 7820 |

| 25L | 20 | 7830 |

| 25ХГСА | 20…100…200…300…400…500… 600…700 | 7850…7830…7790…7760…7730…7690… 7650…7610 |

| 25Х1МФ (EI10) | 20…200…400…600 | 7840…7790…7720…7650 |

| 25Х2М1Ф (EI723) | 20…100…200…300…400…500…600 | 7800…7780…7750…7720…7680…7650…7600 |

| 25Х13Н2 (2Х14Н2, EI474) | 20 | 7680 |

| Steel 30 | 20 | 7850 |

| 30G | 20 | 7810 |

| 30L | 20 | 7810 |

| 30X | 20…100…200…300…400…500… 600…700…800…900 | 7820…7800…7770…7740…7700…7670… 7630…7590…7610…7560 |

| 30ХМ, 30ХМА | 20…100…200…300…400…500 | 7820…7800…7770…7740…7700…7660 |

| 30ХН3А | 20…100…200…300…400…500… 600…700…800…900 | 7850…7830…7800…7760…7730…7700… 7670…7690…7650…7600 |

| 30Х13 (3Х13) | 20…100…200…300…400…500… 600…700…800…900 | 7670…7650…7620…7600…7570…7540… 7510…7480…7450…7460 |

| 31Х19Н9МВБТ (ЭИ572) | 20 | 7960 |

| 33ХС | 20 | 7640 |

| 34ХН3М, 34ХН3МА | 20…100…200…400…600 | 7830…7810…7780…7710…7650 |

| Steel 35 | 20…100…200…300…400…500… 600…700…800…900 | 7826…7804…7771…7737…7700…7662… 7623…7583…7600…7549 |

| 35G2 | 20 | 7790 |

| 35L | 20 | 7830 |

| 35ХГСЛ | 20 | 7800 |

| 35ХМ | 20…100…200…400…600 | 7820…7800…7770…7770…7630 |

| 35HML | 20 | 7840 |

| 35ХМФЛ | 20 | 7820 |

| 37Х12Н8Г8МФБ (ЭИ481) | 20 | 7850 |

| 38ХА | 20…200…600 | 7850…7800…7650 |

| 38ХН3МФА | 20 | 7900 |

| 38ХС | 20 | 7800 |

| 38Х2МУА (38ХМУА) | 20 | 7710 |

| Steel 40 | 20 | 7850 |

| 40G | 20 | 7810 |

| 40G2 | 20 | 7800 |

| 40L | 20 | 7810 |

| 40X | 20…200…500 | 7850…7800…7650 |

| 40HL | 20 | 7830 |

| 40ХН | 20…100…200…300…400 | 7820…7800…7770…7740…7700 |

| 40ХН2МА (40ХНМА) | 20 | 7850 |

| 40ХС | 20…100…200…400…600 | 7740…7720…7690…7620…7540 |

| 40HFA | 20 | 7810 |

| 40Х9С2 (4Х9С2, ESH8) | 20…100…200…400…600…800 | 7630…7610…7580…7510…7440…7390 |

| 40Х10С2М (4Х10С2М, EI107) | 20…100…800 | 7620…7610…7430 |

| 40Х13 (4Х13) | 20…100…200…300…400…500… 600…700…800 | 7650…7630…7600…7570…7540…7510… 7480…7450…7420 |

| 40Х24Н12СЛ (ЭИ316Л) | 20 | 7800 |

| Steel 45 | 20…100…200…300…400…500… 600…700…800 | 7826…7799…7769…7739…7698…7662… 7625…7587…7595 |

| 45G2 | 20 | 7810 |

| 45L | 20 | 7800 |

| 45X | 20 | 7820 |

| 45ХН | 20 | 7820 |

| 45Х14Н14В2М (ЭИ69) | 20…200…400…600…800 | 8000…7930…7840…7760…7660 |

| Steel 50 | 20 | 7810 |

| 50G | 20 | 7810 |

| 50G2 | 20 | 7500 |

| 50L | 20 | 7820 |

| 50X | 20 | 7820 |

| 50ХН | 20 | 7860 |

| 50HFA | 20…100…200…300…400…500…600 | 7800…7780…7750…7720…7680…7650…7610 |

| Steel 55 | 20 | 7820 |

| Steel 60 | 20 | 7800 |

| 60С2, 60С2А | 20…100…200…300…400…500 | 7680…7660…7630…7590…7570…7520 |

| 65G (ZMI3) | 20…100…200…400 | 7850…7830…7800…7730 |

| 75ХМ | 20 | 7900 |

| 95Х18 (9Х18, EI229) | 20…100…800 | 7750…7730…7540 |

| Х23У5Т | 20 | 7210 |

| ХН32Т (EP670) | 20 | 8160 |

| ХН35ВТ (ЭИ612) | 20 | 8164 |

| KhN35VTYu (EI787) | 20 | 8040 |

| ХН45У (EP747) | 20 | 7700 |

| KhN55VMTKYu (EI929), KhN55VMTKYu-VD (EI929-VD) | 20 | 8400 |

| KHN58VKMTUBL (TsNK8MP) | 20 | 8210 |

| ХН60У (ЭИ559А) | 20 | 7900 |

| ХН60ВТ (ЭИ868) | 20 | 8350 |

| KHN60KVMYUTBL (TsNK21P) | 20 | 8110 |

| KHN60KVMYUTL (TsNK7P) | 20 | 8200 |

| KHN62MBVYU (EP709) | 20 | 8700 |

| KhN62MVKYu (EI867), KhN62MVKYu-VD (EI867-VD) | 20 | 8570 |

| KHN64VMKYUTL (ZMI3) | 20 | 8250 |

| KHN65VKMBYUTL (EI539LMU) | 20 | 8220 |

| KhN65VMTYu (EI893) | 20 | 8790 |

| KHN65VMTYUL (EI893L) | 20 | 8790 |

| KHN65KMVYUTL (ZhS6K) | 20 | 8200 |

| KhN67MVTYu (EP202, EI445R) | 20 | 8360 |

| KHN70KVMYUTL (TsNK17P) | 20 | 8000 |

| KhN70VMTYuF (EI826), KhN70VMTYuF-VD (EI826-VD) | 20 | 8470 |

| KhN70VMUT (EI765) | 20 | 8570 |

| ХН70У (ЭИ652) | 20 | 7900 |

| KHN73MBTYU (EI698) | 20 | 8320 |

| ХН75ВМУ (ЭИ827) | 20 | 8430 |

| KHN77TYUR (EI437B) | 20 | 8200 |

| ХН78Т (EI435) | 20 | 8400 |

| ХН80ТБУ (ЭИ607) | 20 | 8300 |

| KhN80TBYuA (EI607A) | 20 | 8300 |

| Х15Н60-Н | 20 | 8200 |

| Х20Н80-Н | 20 | 8400 |

| Х27У5Т | 20 | 7190 |

| HVG | 20…100…300…600 | 7850…7830…7760…7660 |

| A12 | 20 | 7830 |

| R6M3 | 20 | 8000 |

| R6M5K5 | 20 | 8200 |

| P9 | 20 | 8300 |

| R9M4K8 | 20 | 8300 |

| P12 | 20 | 8300 |

| P18 | 20 | 8800 |

| U7, U7A | 20 | 7830 |

| U8, U8A | 20…100…200…300…400…500… 600…700…800 | 7839…7817…7786…7752…7714…7676… 7638…7600…7852 |

| U9, U9A | 20…100…200…300…400…500… 600…700…800…900 | 7745…7726…7717…7690…7686…7655… 7622…7586…7568…7523 |

| U10, U10A | 20 | 7810 |

| U12, U12A | 20…100…200…300…400…500… 600…700…800…900 | 7830…7809…7781…7749…7713…7675… 7634…7592…7565…7489 |

| ШХ15 | 20…100…200…300…400…500 | 7812…7790…7750…7720…7680…7640 |

| SHH15SG | 20 | 7650 |

Density of carbon steels

The density of carbon steel at room temperature ranges from 7.83 to 7.87 g/cm 3 . The table shows the density values of the following carbon steels: steel 08KP, steel 08, steel 20, steel 40, steel U8, steel U12.

The density values in the table are indicated depending on the temperature - in the range from 0 to 1100°C. When steel is heated, it becomes less dense. For example, the density of steel 20 is 7859 kg/m 3 at a temperature of 15°C, and when heated to a temperature of 1100°C, the density of this steel decreases to 7496 kg/m 3 .

Note: The density of carbon steels in the table is expressed in units of kg/m3.

Density of low alloy steels

The density values of the following low-alloy steels are presented: steel 15М, 12МХ, 15ХМ, 15ХФ, 30Х, 30Н3, 30ХН3, 12Х5СМА, Х6М, 30Г2, 50С2Г. The average density of low-alloy steels ranges from 7725 to 7855 kg/m 3 at a temperature of 20°C. The data in the table is given depending on temperature - in the range from 0 to 1000°C. The density dimension in the table is kg/m3.

Density of high alloy steels with special properties

The density values of the following grades of high-alloy steels are presented: steel G13, G20Kh12F, Kh21Kh15T, R18. The steel density values in the table are indicated depending on the temperature - in the range from 0 to 1100°C. Density dimension - kg/m3. Additionally, you can familiarize yourself with the table of substance densities.

- Kazantsev E.I. Industrial furnaces. Reference manual for calculations and design.

- Brand of steels and alloys. 2nd ed., add. and corr. A. S. Zubchenko, M. M. Koloskov and others. Under the general editorship. A. S. Zubchenko - M.: Mechanical Engineering, 2003. 784 p.: ill.

Source of the article: https://thermalinfo.ru/svojstva-materialov/metally-i-splavy/plotnost-stali-temperaturnaya-zavisimost