Carbon steels

Carbon steels at room temperature, as already mentioned, have low electrical resistivity due to their high iron content. At 20°C, the value of their resistivity is in the range from 13·10-8 (for 08KP steel) to 20·10-8 Ohm·m (for U12).

When heated to temperatures above 1000°C, the ability of carbon steels to conduct electric current is greatly reduced.

The resistance value increases by an order of magnitude and can reach a value of 130·10-8 Ohm·m. Electrical resistivity of carbon steels ρe·108, Ohm·m

| Temperature, °C | Steel 08KP | Steel 08 | Steel 20 | Steel 40 | Steel U8 | Steel U12 |

| 0 | 12 | 13,2 | 15,9 | 16 | 17 | 18,4 |

| 20 | 13 | 14,2 | 16,9 | 17,1 | 18 | 19,6 |

| 50 | 14,7 | 15,9 | 18,7 | 18,9 | 19,8 | 21,6 |

| 100 | 17,8 | 19 | 21,9 | 22,1 | 23,2 | 25,2 |

| 150 | 21,3 | 22,4 | 25,4 | 25,7 | 26,8 | 29 |

| 200 | 25,2 | 26,3 | 29,2 | 29,6 | 30,8 | 33,3 |

| 250 | 29,5 | 30,5 | 33,4 | 33,9 | 35,1 | 37,9 |

| 300 | 34,1 | 35,2 | 38,1 | 38,7 | 39,8 | 43 |

| 350 | 39,3 | 40,2 | 43,2 | 43,8 | 45 | 48,3 |

| 400 | 44,8 | 45,8 | 48,7 | 49,3 | 50,5 | 54 |

| 450 | 50,9 | 51,8 | 54,6 | 55,3 | 56,5 | 60 |

| 500 | 57,5 | 58,4 | 60,1 | 61,9 | 62,8 | 66,5 |

| 550 | 64,8 | 65,7 | 68,2 | 68,9 | 69,9 | 73,4 |

| 600 | 72,5 | 73,4 | 75,8 | 76,6 | 77,2 | 80,2 |

| 650 | 80,7 | 81,6 | 83,7 | 84,4 | 85,2 | 87,8 |

| 700 | 89,8 | 90,5 | 92,5 | 93,2 | 93,5 | 96,4 |

| 750 | 100,3 | 101,1 | 105 | 107,9 | 110,5 | 113 |

| 800 | 107,3 | 108,1 | 109,4 | 111,1 | 112,9 | 115 |

| 850 | 110,4 | 111,1 | 111,8 | 113,1 | 114,8 | 117,6 |

| 900 | 112,4 | 113 | 113,6 | 114,9 | 116,4 | 119,6 |

| 950 | 114,2 | 114,8 | 115,2 | 116,6 | 117,8 | 121,2 |

| 1000 | 116 | 116,5 | 116,7 | 117,9 | 119,1 | 122,6 |

| 1050 | 117,5 | 117,9 | 118,1 | 119,3 | 120,4 | 123,8 |

| 1100 | 118,9 | 119,3 | 119,4 | 120,7 | 121,4 | 124,9 |

| 1150 | 120,3 | 120,7 | 120,7 | 122 | 122,3 | 126 |

| 1200 | 121,7 | 122 | 121,9 | 123 | 123,1 | 127,1 |

| 1250 | 123 | 123,3 | 122,9 | 124 | 123,8 | 128,2 |

| 1300 | 124,1 | 124,4 | 123,9 | — | 124,6 | 128,7 |

| 1350 | 125,2 | 125,3 | 125,1 | — | 125 | 129,5 |

AISI 304

International standard American ASTM A240 European EN 10088-2 Russian GOST 5632-72

| Brand designation | AISI 304 | 1.4301 | 08Х18Н10 |

| 12Х18Н9 |

AMS 5513 ASTM A 240

ASTM A 666

Classification

corrosion-resistant, heat-resistant steel

Application

- Household items

- Sinks

- Frames for metal structures in the construction industry

- Kitchen utensils and catering equipment

- Dairy equipment, brewing

- Welded structures

- Tanks on ships and land tankers for food, beverages and some chemicals

Typically, steel manufacturers divide the grade into three main classes (grades) according to their drawing ability:

- AISI 304 - Main grade

- AISI 304 DDQ (Normal and deep drawing) - Deep drawing grade

- AISI 304 DDS (Extra deep drawing) - Extra deep drawing grade

Main characteristics

- good overall corrosion resistance

- good ductility

- excellent weldability

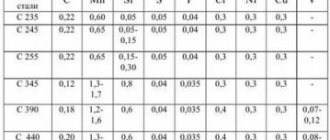

Chemical composition (% by weight)

standard grade C Si Mn PS Cr Ni

| ASTM A240 | AISI 304 | ≤0.080 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.030 | 18.00 — 20.00 | 8.00 — 10.50 |

Mechanical properties

AISI 304 Tensile strength (σв), N/mm² Yield strength (σ0.2), N/mm² Yield strength (σ1.0), N/mm² Elongation (σ), % Brinell hardness (HB) Rockwell hardness (HRB)

| According to EN 10088-2 | ≥520 | ≥210 | ≥250 | ≥45 | — | — |

| According to ASTM A 240 | ≥515 | ≥205 | — | ≥40 | 202 | 85 |

Mechanical properties at high temperatures

All these values refer only to AISI 304

.

Physical properties

Physical properties Symbols Unit of measurement Temperature Value

| Density | d | — | 4°C | 7.93 |

| Melting temperature | °C | 1450 | ||

| Specific heat | c | J/kg.K | 20°C | 500 |

| Thermal expansion | k | W/mK | 20°C | 15 |

| Average coefficient of thermal expansion | α | 10-6.K-1 | 0-100°C 0-200°C | 17.5 18 |

| Electrical resistivity | ρ | Ωmm2/m | 20°C | 0.80 |

| Magnetic permeability | μ | at 0.80 kA/m DC or h/h AC | 20°C μ μ discharge air | 1.02 |

| Elastic modulus | E | MPa x 103 | 20°C | 200 |

Corrosion resistance

304 steels have good resistance to general corrosive environments, but are not recommended where there is a risk of intergranular corrosion. They are well suited for use in fresh water and urban and rural environments. In all cases, regular cleaning of external surfaces is necessary to maintain their original condition.

304 steels have good resistance to various acids:

- phosphoric acid in all concentrations at ambient temperature,

- nitric acid up to 65% at temperatures 20°C - 50°C,

- formic and lactic acid at room temperature,

- acetic acid at a temperature of 20°C - 50°C.

They are recommended for the production of equipment in contact with cold or hot food products: wine, beer, milk (fermented milk products), alcohol, natural fruit juices, syrups, molasses, etc.

Acidic environments

Temperature, °C 20 80

| Concentration, % by weight | 10 | 20 | 40 | 60 | 80 | 100 | 10 | 20 | 40 | 60 | 80 | 100 |

| Sulfuric acid | 2 | 2 | 2 | 2 | 1 | 0 | 2 | 2 | 2 | 2 | 2 | 2 |

| Nitric acid | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 1 | 2 |

| Phosphoric acid | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 1 | 2 |

| Formic acid | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 2 | 1 | 0 |

Code: 0 = high degree of protection - Corrosion rate less than 100 µm/year 1 = partial protection - Corrosion rate from 100 to 1000 µm/year

2 = no protection - Corrosion rate more than 1000 µm/year

Atmospheric influences

Comparison of 304

grades with other metals in various environments (Corrosion rate calculated for 10-year exposure).

Environment Corrosion rate (µm/year)AISI 304 Aluminum-3S Carbon steel

| Rural | 0.0025 | 0.025 | 5.8 |

| Marine | 0.0076 | 0.432 | 34.0 |

| Industrial Marine | 0.0076 | 0.686 | 46.2 |

Resistant to corrosion in boiling chemicals

Boiling environment Metal condition Corrosion rate (mm/year)

| 20% acetic acid | Regular metal Welded |

Low alloy steels

Low alloy steels are able to resist the passage of electricity slightly more than carbon steels. Their electrical resistivity is (20...43)·10-8 Ohm·m at room temperature.

It should be noted that steel grades of this type are the worst conductors of electric current - these are 18Х2Н4ВА and 50С2Г.

However, at high temperatures, the ability to conduct electric current among the steels listed in the table practically does not differ. Specific electrical resistance of low-alloy steels ρe·108, Ohm·m

| steel grade | 20 | 100 | 300 | 500 | 700 | 900 | 1100 | 1300 |

| 15HF | — | 28,1 | 42,1 | 60,6 | 83,3 | — | — | — |

| 30X | 21 | 25,9 | 41,7 | 63,6 | 93,4 | 114,5 | 120,5 | 125,1 |

| 12ХН2 | 33 | 36 | 52 | 67 | — | 112 | — | — |

| 12ХН3 | 29,6 | — | — | 67 | — | 116 | — | — |

| 20ХН3 | 24 | 29 | 46 | 66 | — | 123 | — | — |

| 30ХН3 | 26,8 | 31,7 | 46,9 | 68,1 | 98,1 | 114,8 | 120,1 | 124,6 |

| 20ХН4Ф | 36 | 41 | 56 | 72 | 102 | 118 | — | — |

| 18Х2Н4ВА | 41 | 44 | 58 | 73 | 97 | 115 | — | — |

| 30G2 | 20,8 | 25,9 | 42,1 | 64,5 | 94,6 | 114,3 | 120,2 | 125 |

| 12MH | 24,6 | 27,4 | 40,6 | 59,8 | — | — | — | — |

| 40Х3М | — | 33,1 | 48,2 | 69,5 | 96,2 | — | — | — |

| 20Х3ФВМ | — | 39,8 | 54,4 | 74,3 | 98,2 | — | — | — |

| 50S2G | 42,9 | 47 | 60,1 | 78,8 | 105,7 | 119,7 | 124,9 | 128,9 |

| 30N3 | 27,1 | 32 | 47 | 67,9 | 99,2 | 114,9 | 120,4 | 124,8 |

High alloy steels

High-alloy steels have electrical resistivity several times higher than carbon and low-alloy steels. According to the table, it can be seen that at a temperature of 20°C its value is (30...86)·10-8 Ohm·m.

At a temperature of 1300°C, the resistance of high- and low-alloy steels becomes almost the same and does not exceed 131·10-8 Ohm·m.

Electrical resistivity of high-alloy steels ρе·108, Ohm·m

| steel grade | 20 | 100 | 300 | 500 | 700 | 900 | 1100 | 1300 |

| G13 | 68,3 | 75,6 | 93,1 | 95,2 | 114,7 | 123,8 | 127 | 130,8 |

| G20H12F | 72,3 | 79,2 | 91,2 | 101,5 | 109,2 | — | — | — |

| G21X15T | — | 82,4 | 95,6 | 104,5 | 112 | 119,2 | — | — |

| Х13Н13К10 | — | 90 | 100,8 | 109,6 | 115,4 | 119,6 | — | — |

| Х19Н10К47 | — | 90,5 | 98,6 | 105,2 | 110,8 | — | — | — |

| P18 | 41,9 | 47,2 | 62,7 | 81,5 | 103,7 | 117,3 | 123,6 | 128,1 |

| EH12 | 31 | 36 | 53 | 75 | 97 | 119 | — | — |

| 40Х10С2М (EI107) | 86 | 91 | 101 | 112 | 122 | — | — | — |

Electrical resistivity of steel at different temperatures

Tables of electrical resistivity values of steels of various types and grades are presented depending on temperature - in the range from 0 to 1350°C.

In general, resistivity is determined only by the composition of the substance and its temperature; it is numerically equal to the total resistance of an isotropic conductor having a length of 1 m and a cross-sectional area of 1 m 2.

The electrical resistivity of steel depends significantly on composition and temperature. As the temperature of this metal increases, the frequency and amplitude of vibrations of the atoms of the crystal lattice increases, which creates additional resistance to the passage of electric current through the thickness of the alloy. Therefore, with increasing temperature, the resistance of steel increases.

Changing the composition of steel and the percentage of alloying additives in it significantly affects the value of electrical resistance. For example, carbon and low-alloy steels conduct electric current several times better than high-alloy and heat-resistant steels, which have a high nickel and chromium content.

Chromium stainless steels

Chromium stainless steels have a high concentration of chromium atoms, which increases their resistivity - the electrical conductivity of such stainless steel is not high.

At normal temperatures, its resistance is (50...60)·10-8 Ohm·m. Electrical resistivity of chromium stainless steels ρе·108, Ohm·m

| steel grade | 20 | 100 | 300 | 500 | 700 | 900 | 1100 | 1300 |

| X13 | 50,6 | 58,4 | 76,9 | 93,8 | 110,3 | 115 | 119 | 125,3 |

| 2Х13 | 58,8 | 65,3 | 80 | 95,2 | 110,2 | — | — | — |

| 3Х13 | 52,2 | 59,5 | 76,9 | 93,5 | 109,9 | 114,6 | 120,9 | 125 |

| 4Х13 | 59,1 | 64,6 | 78,8 | 94 | 108 | — | — | — |

Chromium-nickel austenitic steels

Chromium-nickel austenitic steels are also stainless, but due to the addition of nickel they have a resistivity almost one and a half times higher than that of chromium steels - it reaches a value of (70...90)·10-8 Ohm·m.

Electrical resistivity of chromium-nickel stainless steels ρe·108, Ohm·m

| steel grade | 20 | 100 | 300 | 500 | 700 | 900 | 1100 |

| 12Х18Н9 | — | 74,3 | 89,1 | 100,1 | 109,4 | 114 | — |

| 12Х18Н9Т | 72,3 | 79,2 | 91,2 | 101,5 | 109,2 | — | — |

| 17Х18Н9 | 72 | 73,5 | 92,5 | 103 | 111,5 | 118,5 | — |

| Х18Н11Б | — | 84,6 | 97,6 | 107,8 | 115 | — | — |

| Х18Н9В | 71 | 77,6 | 91,6 | 102,6 | 111,1 | 117,1 | 122 |

| 4Х14НВ2М (ЭИ69) | 81,5 | 87,5 | 100 | 110 | 117,5 | — | — |

| 1Х14Н14В2М (ЭИ257) | — | 82,4 | 95,6 | 104,5 | 112 | 119,2 | — |

| 1x14N18M3T | — | 89 | 100 | 107,5 | 115 | — | — |

| 36Х18Н25С2 (ЭЯ3С) | — | 98,5 | 105,5 | 110 | 117,5 | — | — |

| Х13Н25М2В2 | — | 103 | 112,1 | 118,1 | 121 | — | — |

| Х7Н25 (ЭИ25) | — | — | 109 | 115 | 121 | 127 | — |

| Х2Н35 (ЭИ36) | 87,5 | 92,5 | 103 | 110 | 116 | 120,5 | — |

| H28 | 84,2 | 89,1 | 99,6 | 107,7 | 114,2 | 118,4 | 122,5 |

Heat-resistant and heat-resistant steels

In terms of their electrical conductive properties, heat-resistant and heat-resistant steels are close to chromium-nickel steels. The high content of chromium and nickel in these alloys does not allow them to conduct electric current, like ordinary carbon alloys with a high concentration of iron.

The significant electrical resistivity and high operating temperature of such steels make it possible to use them as working elements of electric heaters.

In particular, steel 20Х23Н18 in its resistance and heat resistance in some cases can replace such a popular alloy for heaters as nichrome Х20Н80. Specific electrical resistance of heat-resistant and heat-resistant steels ρе·108, Ohm·m

| Temperature, °C | 15Х25Т (EI439) | 15Х28 (EI349) | 40Х9С2 (ESH8) | Х25С3Н (ЭИ261) | 20Х23Н18 (EI 417) | Х20Н35 |

| 0 | — | — | — | — | — | 106 |

| 20 | — | — | 75 | 80 | — | — |

| 100 | — | — | — | — | 97 | — |

| 200 | — | — | — | — | 98 | 113 |

| 400 | 102 | — | — | — | 105 | 120 |

| 600 | 113 | — | — | — | 115 | 124 |

| 800 | — | 122 | — | — | 121 | 128 |

| 900 | — | — | — | — | 123 | — |

| 1000 | — | 127 | — | — | — | 132 |

Sources:

- Kazantsev E.I. Industrial furnaces. Reference manual for calculations and design.

- Physical quantities. Directory. Ed. I. S. Grigorieva, E. Z. Meilikhova. - M.: Energoatomizdat, 1991. - 1232 p.

Steel Specifications

Before considering the resistivity of steel in detail, you should familiarize yourself with its basic physical and mechanical properties. Due to its qualities, this material is widely used in the manufacturing sector and other areas of people’s lives and activities.

Steel is an alloy of iron and carbon, contained in an amount not exceeding 1.7%. In addition to carbon, steel contains a certain amount of impurities - silicon, manganese, sulfur and phosphorus. In terms of its qualities, it is much better than cast iron; it can easily be hardened, forged, rolled and other types of processing. All types of steels are characterized by high strength and ductility.

According to its purpose, steel is divided into structural, instrumental, and also with special physical properties. Each of them contains a different amount of carbon, thanks to which the material acquires certain specific qualities, for example, heat resistance, heat resistance, resistance to rust and corrosion.

A special place is occupied by electrical steels, produced in sheet format and used in the production of electrical products. To obtain this material, silicon is doped, which can improve its magnetic and electrical properties.

In order for electrical steel to acquire the necessary characteristics, certain requirements and conditions must be met. The material must be easily magnetized and remagnetized, that is, have high magnetic permeability. Such steels have good magnetic induction, and their magnetization reversal occurs with minimal losses.

The dimensions and weight of magnetic cores and windings, as well as the efficiency of transformers and their operating temperature depend on compliance with these requirements. The fulfillment of the conditions is influenced by many factors, including the resistivity of steel.