Instructions for cutting threads using a die

The die (plate) is a metal disk with a round petal hole located in the center.

The petals have cutting edges that cut threads of a specific size and shape. The dies are made of metal whose hardness is greater than that of the pipe material. This is high speed or alloy steel. The dies are either solid or split. Solid dies are a more precise tool, but wear out faster.

The operating procedure is as follows:

- Pipe preparation. cleaning from dirt, degreasing the surface.

- Fastening in a vice. When working at the pipe location, use a gas wrench.

- Removing the end chamfer. The pipe cut must be made at right angles to its axis. The chamfer is removed with a grinding wheel or file.

- The cutting area is lubricated with technical oil.

- The die is inserted into the holder, the screws are tightened, ensuring its fixation.

- The die is brought closer to the end of the pipe perpendicular to the axis, without warping. Pressing gently, rotate the die clockwise. The first grooves will help the tool to secure itself, and then the process will become easier.

- The work is done slowly, with even effort. Higher speed will not speed up the process, but may degrade the quality. The correct parameters are obtained by passing the cutting edges along the entire length of the die.

- Make sure there is no lubricant on the cutting surface; if necessary, spray with oil from a spray bottle.

- After obtaining a threaded line of the required length, the die is turned and removed, and the surface is cleaned of chips using a rag, brush or soft-bristled brush.

The work can be done in two stages. First, a rough die is used, then the finishing die is completed. The operating principle is the same as stated above.

How to cut external threads. Thread cutting on pipes and fittings. Die. Klupp

How to cut external threads. Thread cutting on pipes and fittings. Die. Klupp. 4.46/5 (89.23%) lost 13

External threads are cut using round or sliding dies, as well as screw boards. Thread cutting can be done either on machines or manually.

Cutting threads with round dies.

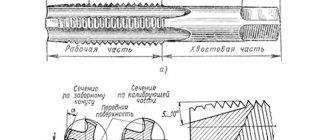

Round dies (lerks) are a disk with a cut hole. To remove chips and form feathers with cutting edges (Fig. 1), several chip holes are made in the die. The dies (lerks) are inserted into the lerk holder and clamped with screws (Fig. 2).

Rice. 1. Round split die (cutting die).

Rice. 2. Card holder:

1 - frame; 2 - handle; 3 - clamping screw.

The diameter of the cut rod is taken to be slightly smaller than the outer diameter of the thread and is sawed down in a cone shape to fit the hole. The selection of rods for cutting metric or inch threads is given in table. 1:

Table 1. Diameter of rods for threaded bolts.

| Metric thread | Inch thread | ||

| Outer diameter in mm | Rod diameter in mm | Outer diameter in inches | Rod diameter in mm |

| 5 | 4,89 | 1/4 | 6,19 |

| 6 | 5,86 | 5/6 | 7,7 |

| 8 | 7,83 | 3/8 | 9,3 |

| 10 | 9,8 | 7/16 | 10,8 |

| 12 | 11,7 | 1/2 | 12,4 |

| 14 | 13,7 | 5/8 | 15,6 |

| 16 | 15,7 | 3/4 | 18,7 |

| 20 | 19,6 | 7/8 | 21,8 |

| 22 | 21,6 | 1 | 25 |

| 24 | 23,6 | 1 1/4 | 31,3 |

| 27 | 26,6 | 1 1/2 | 37,6 |

| 30 | 29,5 | 1 3/4 | 43,8 |

| 36 | 35,4 | 2 | 50 |

Sliding dies (Fig. 3, a) consist of two prismatic halves with a cut hole. In the middle part of the hole the dies make a groove, which forms the cutting edges.

Rice. 3. Sliding dies and crackers:

a - die; b - cracker.

Clamp for thread cutting.

To fasten the dies, a clamp with a rectangular or oblique frame is used (Fig. 4). The prismatic protrusions of the die fit into the grooves of the dies, and the dies are pressed against the sides with bolts.

Rice. 4. Klupp (oblique)

1 - frame; 2 - handle; 3 - clamping screw.

To avoid direct pressure of the bolt on the dies, a so-called cracker (see Fig. 3, b), shaped like a die, is installed between the dies and the bolt.

Die thread cutting technology.

Cutting with prismatic dies is somewhat different from cutting with lerks. When cutting into dies, the rods are not sawed into a cone, but the dies are moved apart.

Then they are clamped on a rod, the end of which should coincide with the upper plane of the dies. By turning the die to the right and slightly to the left, threads are cut.

The position of the holder and clamp is set strictly perpendicular to the rod being cut, otherwise the thread will be oblique and one-sided.

Cooling and lubrication during thread cutting.

When cutting threads with taps and dies, it is necessary to use lubricant. As a lubricant, you can use a regular emulsion, dissolving one part of the emulsion to one hundred and sixty parts of water. In addition, you can use: for cast iron - lard and kerosene; for steel and brass - boiled and rapeseed oil and lard; for red copper - lard and turpentine; for aluminum - kerosene.

It is not recommended to use machine and mineral oils when cutting threads, since they, while increasing the resistance to cutting, do not produce clean holes and lead to rapid wear of taps and dies.

Screw boards.

In order to cut threads on screws with diameters up to 6 mm, screw boards are used. The screw boards have several cut holes of different diameters with grooves for chips, two for each hole.

Thread cutting with dies is performed in the same way as tapping. The rod is firmly clamped in a vice, lubricated with oil, and then a clamp with dies is put on the rod, clamped with a screw and rotated a full turn in one direction and half a turn in the other. If the rod is thicker than required, it must be filed with a file.

Bolt threads are measured using ring thread gauges or a thread gauge.

Thread cutting on pipes and fittings.

Pipes and fittings (connecting parts for pipes) are cut with a special tool using fixtures.

Jig for cutting threads on pipes.

The threads on pipes are cut with a special die (Fig. 5). The device for cutting pipes differs from conventional clamps. Four steel combs fit into the slots of its clip.

By turning the top handle they can be brought closer or apart. Therefore, one die can cut pipes of various diameters. In addition, the die has guides that are adjusted by the lower handle.

The guides ensure the correct position of the die on the pipe when cutting.

Rice. 5. Jig for cutting pipes.

When cutting, pipes are secured with a special pipe clamp. The clamp consists of a frame into which crackers with cutouts for pipes of various diameters are placed.

Features of care

When using screws when cutting threads yourself, you must carry out proper care of this tool. So, upon completion of the work performed, they need to be disassembled and completely cleaned of chips and other unwanted contaminants. Next, it is recommended to lubricate the entire body with mineral oil so that rust does not appear on it and the rubbing parts “stick” to each other.

A prerequisite is to clean the instrument from dust and dried oil approximately once every 2-3 weeks, so that in the future the instrument does not crunch when used. To perform this procedure, experts recommend using the following technique:

- Using a rag, everything is cleaned of visible contaminants that appeared while it was lying there.

- Next, a caustic soda solution is made. The proportions are taken as follows: for one ten-liter bucket of warm water, 0.5 kilograms of dry matter is calculated.

- Before washing, you should completely disassemble the instrument.

- After the procedure, all parts are lubricated with oil and collected in a pile. It is advisable to then wrap the instrument in a rag or polyethylene to further protect it from contaminants.

Clips with dies should be stored in a dry place and closed. A small layer of lubricant will reliably protect the metal from rust and significantly extend its life.

To summarize and figure out how to cut a thread on a pipe, we can say that this procedure is performed using taps and dies. The first ones have no types and are selected separately for each internal diameter of the pipe. Dies can be either standard sizes, without the ability to change the diameter of the threaded hole, or with interchangeable values. Everything here depends on the type and type.

With the help of special devices called clamps, the cutting process can be significantly simplified. But, for normal operation, mandatory care is required for all instruments. They must be clean, lubricated and always ready for use. To do this, it is recommended to carry out prophylaxis once every 2-3 weeks.

Origin and appearance

Cichlazoma severum belongs to the cichlid family and originates from the waters of South America. The first mention of them is found in the records of the Australian Johann Natterer, who discovered unusual fish living in the Amazon River basin.

But you can also find severum in other bodies of water. Brazil, Guiana, Colombia, Venezuela, and the upper reaches of the Rio Negro are the main habitats of cichlases.

Upon visual comparison, the differences between severus and discus become obvious. In the photo on the left is Cichlazoma severum, on the right is Discus.

The appearance of Heros severus resembles members of the discus family (Discus Cichlid). Because of this, it is often called the “false discus.” However, true discus are much larger than severums.

Severum lives up to its name, translated from Latin meaning stern, reserved. This is expressed both in the appearance of the fish and in their temperament.

The round body of cichlids, flattened on both sides, is colored grayish-green with brown splashes. Thanks to their laterally flattened body, the fish easily maneuver in the water, avoiding dense vegetation and fallen tree branches.

How to properly cut turns on a water pipe?

If you are laying a new section in the heating (water supply) system, cutting can be done on a workbench. The workpiece is positioned strictly horizontally (or vertically) using a special vice.

Even a hand tool, be it a threading die or a wrench with a die, creates an impressive torque. Therefore, to cut a thread on a water pipe with your own hands, you need to clamp it tightly.

If the workpiece rotates, the turns can be damaged. Many home craftsmen use for fixing not a vice with a dovetail clamp, but decommissioned supports from old lathes.

After taking measurements, cut the pipe taking into account the processing of the end for the entry of the die (die). Then the length of the threaded connection is marked: for example, on a heating pipe, at the point of connection with the radiator, it is necessary to provide a bend.

Before cutting begins, the end is processed with a file under a cone, for normal entry of the die or die.

If this is not done, the entry will be made skewed, and after a couple of turns, the thread will be torn off. It is impossible to restore the damaged area; the pipe will have to be cut.

Die work

Using this tool, you can easily cut turns on a pipe around which there are no objects within a radius of 50 cm. Either from the end or from the side, there should be room for a wrench.

Of course, it is not always possible to get close to the pipeline system, especially when carrying out repair work. There are models of cranks with one handle that can be used to cut threads along the wall: the so-called ratchets.

But the configuration of the die itself does not allow holding the device strictly along the axis. If the force on the cutters is uneven (and with one lever it cannot be otherwise), there is a risk of screwing up the turns.

Therefore, before cutting threads with a ratchet, you should practice several times on unnecessary pieces of pipe.

Important! When working with a die (die), proper pipe preparation is especially important.

If the die can “forgive” some flaws, then a weakly machined chamfer at the end, or a drop from welding, can knock the die off the straight path. Cutting is performed in 2-3 passes: using dies of different cutter depths.

First, number 1 marks and removes the first layer. Then No. 2 (and No. 3) cut the turns to the working depth.

Video instructions for cutting threads on a pipe without a die (using a die)

Clupp work

Many novice craftsmen do not know how to cut carvings near a wall. This is exactly what the clamp is suitable for, since its design provides for self-centering relative to the pipe axis, therefore, tool misalignment is eliminated.

Experienced craftsmen recommend cutting any pipe thread with a die; this tool simplifies the process and improves the quality of external threads.

It is not difficult to work with the clamp; it is a design with replaceable cutters. That is, the material of the holder can be made of relatively soft (and therefore pliable) metal, and the cutters can be made of hard alloy steel.

The position of the cutters is adjustable during the cutting process: this allows you to perform primary, secondary and finishing passes without removing the die. That is, you simply tighten the cutting parts, deepening the turns each time.

The cutters are located in such a way that maintaining straightness along the axis of the pipe is easy. The probability of coil failure is minimal. Therefore, even a beginner can cope with working with a clamp in hard-to-reach places.

There are electric die-cutting models in which a powerful torque is created on the cutter block using a gearbox. The operator only needs to guide the tool along the pipe.

The prepared workpiece is lubricated with a grease, the depth of the first pass is set, and the power is turned on. There is no need to make reverse rotations, as on a knob, or to monitor the removal of chips - all this is done automatically.

It doesn’t matter what you are doing: repairing the water supply, or installing a heating system. With the help of such a tool, the work gets done much faster. Of course, not for free: the cost of an electric plug is quite high

How to use a hand clamp correctly - Video instructions

Cutting threads with an electric die

https://youtube.com/watch?v=PGIJ4763zg4

Plumbing Repair Basics

Not many people have thought about how to connect the water supply to a private house.

It consists of:

- pipes,

- valves,

- valves

- taps and other components.

All this is assembled into a single system using threaded connections.

To ensure that the process of replacing an old part with a new one does not take much time, there is a thread.

Sometimes you have to deal with cases when you yourself have to change a worn-out element (for example, a pipe), but there are no grooves on it.

What to do in this case?

The way out of this situation is very simple - cut the thread with your own hands. The ideal option is when you have the opportunity to use a lathe.

But not every home craftsman has such equipment.

It is expensive, and in order to use it you need to have certain experience and skills.

If you need to equip a pipe with threads, for example, to connect a membrane tank for water supply (written here), you can use one of two types of devices designed for cutting grooves:

- thread-cutting tray,

- pipe wrench

This tool is used to cut threads in water and sewer pipes (read why a water seal is needed here), which are used in the utility networks of multi-storey buildings and private buildings.

Note! If you do not have any experience in this matter, then working with a lecher will be very difficult for you. Since even the slightest misalignment of the tool will invariably lead to the formation of a defect

In this case, it is best to use a wrench; the cutting process with its help is simplified by the presence in the design of such an important part as a guide. In order not to spoil the water pipe, to acquire a certain skill, practice on an unnecessary piece of a hollow object

In order not to spoil the water pipe, to acquire a certain skill, practice on an unnecessary piece of a hollow object.

Now let's try to refresh our memory about what the thread cutting process is:

- when grooves are applied to pipes, a helical surface is formed on the outside of the hollow object;

- the helical plane plays the role of a connecting element, which rotates steadily around the axis of the fitting;

- The thread pitch corresponds to one full turn.

In order for the junction of water pipes to be waterproof, durable, and the unit to withstand high pressure in the system, it is necessary to cut the threads so that the pitch exactly matches the pitch of the joining parts.

Types and properties of cutters

A metal turning tool consists of a holder and a working head. The quality of parts processing directly depends on these elements. The holder has a rectangular or square cross-section. With its help, the cutter is fixed on the lathe.

The working head is used to process parts. It is composed of various cutting planes and edges. The sharpening angle of the head is determined by the material from which the part is made.

External and internal threads are cut using different types of thread cutting tools.

The most used ones:

- rod;

- prismatic;

- round.

Rod cutters consist of a rod with a working head. These types come in different profiles. The most wear-resistant are cutters to which carbide working edges are soldered. They do not need frequent sharpening as they remain sharp for a long time.

Prismatic cutters are used to process only the outer side of the blank. Their advantage over rod ones is their ability to process large surfaces. But they should be sharpened more often.

Round cutters are used in the process of cutting internal and external threads. These tools are very easy to use and their scope of use is quite wide. Round cutters allow repeated sharpening.

Based on their design differences, metal-cutting tools are divided into several types:

- straight;

- curved;

- bent;

- drawn out.

The top of any threading tool is a rounded head or chamfer. The thread profile is formed by a cutter of the proper configuration. Using curved cutting tools, the threaded thread is cut on the surface of the blank.

Straight incisors are rarely used here. The carving inside the part is made with curved cutters, sometimes straight, fixed in a special holder.

Cutters are divided into categories:

- made of high-speed alloy steel;

- with carbide plates soldered onto the working element;

- cutting devices with replaceable multifaceted inserts mounted on the head.

According to the direction of the screw thread, the tools are differentiated into right-handed and left-handed. When working first, the feed goes from left to right, when working second, the feed goes to the left. The right ones use it more often.

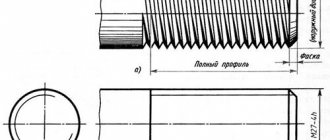

Cutting the thread with a die

Purpose

The tool allows you to cut cylindrical or conical threads. The working area consists of edges that are made like grooves; they cut the required number of threaded turns. A die consisting of a conical cutting edge and a calibrating edge is suitable for cutting cylindrical threads. For the production of tools, two types of material are used:

- Р18 and Р9 – high-speed steel;

- KhVSG, 9ХС – alloyed instrumental.

It is important to note that the production of dies is regulated by GOST. If the task is a round thread, use a product that performs cutting in accordance with GOST 13536-68, conical - 6211-81, metric - 9150-81, inch - 6111-52, cylindrical - 9740-71

Methods for cutting threads on a water pipe

Cutting methods are divided into two types: manual and automatic. In the first case, you will need a set of thread-cutting devices. Dies are used for cutting external threads, and taps are used for internal threads. Tool sizes are determined using reference tables. Automatic cutting occurs on machines or power tools. The method is accurate and suitable for pipes of any diameter. The machines perform milling and thread rolling.

Die cutting

The choice of tool type depends on the quality requirements. The best result is achieved when using a solid die, which has high rigidity. The disadvantage of the device is rapid wear. Spring-loaded dies (with a cut in one of the axial holes) allow you to change the thread diameter within 0.3 mm. Their rigidity is reduced, the incisors last longer, but the purity of the threads is lost.

The prepared pipe is clamped in a vice. The die is placed in the holder and secured with screws. Lubricant is applied to the treated area and cutters. The tool is placed on the pipe at a right angle. Rotation occurs smoothly, clockwise. After making several turns, the chips are removed and lubrication is restored. For high-quality cutting, a finishing die is used after the roughing die. The finished thread is cleaned with a rag.

Using the Clupp

Using a pipe clamp is more convenient than using dies. The tool is more expensive, but for doing a large amount of work it is better to choose it. The clamp gives a clean turn, the sliding design allows you to adjust the thread diameter. Installing guides reduces the risk of distortions and facilitates the cutting process. If the design includes a ratchet, a ratchet wheel is placed near the die. When it turns, the tool head moves. The ratchet is indispensable in cramped working conditions.

The pipe is clamped in a vice, leaving a small section. The short protruding part will not allow the metal to bend from the applied forces. The pipe and cutters are lubricated with machine oil. The protruding part is inserted into the die guide. Cutting occurs with short rotational movements. It is periodically rotated back to cut off chips. Lubricant is added during operation

When cutting threads on water pipes, it is important to monitor the number of turns

Working as a tapper

Internal threads are made with a tap. Its diameter should be slightly larger than the pipe. When working, it is recommended to use a set of two or three parts. They perform rough and finishing cuts. The first tool does the main work, removing up to 70% of the chips. The finishing tap has a small chamfer and a full cutting profile. Tools are distinguished by grooves on the shank:

- one is black;

- two – average;

- three – finishing.

The inside of the pipe requires cleaning and lubrication. The tap is inserted vertically, the shank is secured in the driver. Rotation is clockwise. When working with soft metal, the tool is periodically turned out and the chips are cleaned out. Lubricant must be used. After completion of the work, the quality of the thread is checked.

Main reasons for marriage

It should be remembered that when cutting threads, defects may result.

The causes of its occurrence are classified as:

- Lubricating the thread cutting area during operation

discrepancy between the diameters of holes or rods and the thread being cut;

- using a low-quality tool (blunted, incorrectly centered);

- thread cutting without the use of lubricant;

- lack of professional skills.

Advice!

When cutting threads, be sure to lubricate the pipe with either machine oil or a special threading fluid.

This way, you will greatly simplify your work and achieve quality.

Conclusions: the best solution to the problem of installing shut-off valves on pipes for heating and water supply is to manufacture a high-quality threaded connection. To obtain it, you must purchase a pipe threading set, which greatly facilitates the work.

Did you like the article? Subscribe to our Yandex.Zen channel

Types of threads on pipes

A thread is an alternation of projections and depressions on a surface located along a helical line. It can be external and internal, left and right. Common types:

- cylindrical pipe;

- pipe conical;

- inch cylindrical (US standard);

- round;

- inch.

In plumbing installation work, the first two types are usually used. They are used to connect water fittings:

- Cylindrical (G) – the profile is represented by an isosceles triangle with an apex of 55°. The protrusions and depressions are rounded. Recommended for pipes up to 6 inches in diameter.

- Conical (R) - the thread has a triangular profile, forms a taper of 1:16, and is characterized by high tightness of the connection of parts.

Pipe threads can be inch or metric, respectively, measured in inches and millimeters.

Video description

This video shows how to make inch cutting with a die and die:

- Conical (R) - designated as BSPT and also has British roots. It has a pitch and profile angle similar to cylindrical threads. It is used for cutting notches into cone-shaped parts. In some cases, it is possible to connect parts with R and G notches. By creating additional tension on the turns during the joining process, the conical notch provides additional reliability of the docking units.

- Round (R) is a very rare type of pipe connection, which is used in places where it is necessary to frequently assemble and disassemble the joint. Even after frequent dismantling, such a mount does not lose its shape, reliability and tightness. The disadvantage of such a thread is that it cannot be combined with other types of notches. The round variety has a profile in the form of a circular arc with an angle of 30°.

There is an American standard for conical and cylindrical parts, which is labeled NPSM or NPTF. It has an angle not of 55°, but of 60°, similar to the metric one. This type of thread has its own thread size and profile height, but is found almost nowhere, since it is being replaced on the market by the British standard.

Example of American NPSM Source www.staniosind.com

See also: Catalog of companies that specialize in the installation of utilities: water supply, sewerage and heating

Pipe Threading Tools

How to cut threads on a pipe? Excluding mechanized cutting technologies (for example, on screw-cutting lathes), two types of devices are used for cutting threads on pipes: dies (dies) and dies.

A hand die as a tool for cutting pipe threads is a device consisting of two parts - the actual working part, and a body (die holder) equipped with two handles, with the help of which the die is rotated along the outer diameter of the pipe. An easy-to-use set of threads on pipes is manual, which consists of several sets of dies of the most common diameters. This is explained by the fact that for a high-quality connection, you should use a rough die for the initial pass, and a finishing die of the same diameter for the purpose of calibrating the profile. You can, of course, use one liner, but its wear in this case will be much higher, especially if the pipeline is made of high-carbon steel.

Unlike a lecher, a cutting die is a more structurally complex tool. It has a ratchet that locks the threading part in a certain position while the handle is turned the next revolution. Therefore, the carving is of higher quality.

In addition to hand-held thread-forming tools, mechanized tools are also used in practice to produce pipe threads. The most compact and easy-to-use thread cutting machine is equipped with an electric drive. However, in this case, the cost of the issue turns out to be significantly higher, so electric thread cutters are justified only when you have to make threads on a long section of pipe.

Preparing for slicing

Before threading a pipe, the surface of the metal must be cleaned. Tool wear increases if the original surface of the product is not cleaned of surface rust and scale, has paint residues, etc. Therefore, parts should be thoroughly cleaned before starting work. Persistent scale is removed using organic solvents, and short parts - adapters, leads, etc. – can be cleaned by dipping them in a hot (at least 60 ° C) borax solution.

Pipe stripping

After cleaning, the product is inspected to identify surface irregularities (they are often found on used pipes), as well as if the axis of the element is bent. The slightest bend leads, firstly, to distortion of the cut profile, and, secondly, provokes a sharp decrease in durability when one of the segments of the working part of the tool always experiences an increased threading force.

Immediately before work, the desired section of the pipe is lubricated. Lubricants with medium viscosity, for example, Industrial 40 oil, are suitable. Thick lubricant (solid oil) can also be applied to the working profile of the die.

How to cut a thread on a pipe with your own hands

To make threading on a pipe with your own hands, you initially need to perform a number of preparatory measures:

- Carefully clean the tube in the area where you plan to get the threads.

- Clean the end part of the product with a file.

- Lubricate the working area to reduce resistance.

In order for the thread cutting process to be convenient and the end result to meet the requirements, before carrying out the action you need to secure the product in a vice. This will allow you to fix the part so that you can perform the necessary actions with both hands. After this, the following actions are carried out:

A wrench with a die of the required diameter is used, with which a rough pass is carried out

In this case, it is important to keep the die strictly perpendicular to the pipe. The roughing pass is the basis of thread cutting, so do not rush and perform the actions slowly but efficiently. A rough cut allows you to get 2-3 threads of thread. This is exactly how many threads are needed for the tool to take a secure position. The next step is to twist the rough die and use the finishing die.

With its help, the required number of threads is cut on a pipe that is planned to be installed in a water supply or heating system. After each pass, you need to make 0.5 turns back to clear the cutting area from chips. At the final stage, you should use the third die, which carries out a control pass.

When threading, it is important that all actions are performed slowly, and with each subsequent turn the cut area is cleared of metal shavings

Rules of procedure

When working with pipes, it is important to stock up on dies with a pipe clamp and a wrench. The die is selected taking into account the type of thread required

This can be determined by checking the stamp or inspection. The dies must be marked. The data on them will give an idea of what brand the tool is made from.

Most pipes require straight threads. Also, before working, you need to determine its direction: right or left. To do this, a letter indicator is depicted on the dies: “L” is left, and “P” is right. The die also indicates what grade of steel it belongs to, this makes it possible to choose the right tool for cutting stainless steel pipes.

The cutting rules are quite simple:

1). Prepare the pipe for cutting. To do this, the chamfer is removed with a file, and the area is treated with an oil solution.

2). Insert the die into the holder, securing it with screws.

3). Bring the die to the product and make several circular rotations in the required direction of the thread.

4). Lightly press down the die to embed it into the material.

Scrolling algorithm:

- 2-3 turns in one direction;

- half a turn to the other.

And so on until the end of cutting

In this case, it is very important to keep the pipe and die strictly perpendicular. Otherwise, the thread will “walk”, which will affect the quality of the connection.

The arrangement of elements, as well as thread cutting, is demonstrated on video and photo materials for better results. Checking thread quality is easy. To do this, it is enough to screw the nut if it is screwed along the outer diameter of the pipe. The most accurate cut is obtained with a sliding die. It will help out if you urgently need to replace a piece of pipe that has a threaded connection.

Also, when choosing dies, it is important to consider what kind of thread will be made, external or internal. High-quality work will allow you to make a sealed threaded connection even in pressure water pipes

Let's sum it up

As you can see, making your own carving using dies is not at all difficult. To do this, it is enough to choose the right tool, put in a little effort and accuracy. Probably, many representatives of the male half of humanity remember how similar problems were solved in labor lessons at school. Therefore, for the majority, it will only be necessary to remember the acquired skills and apply them in adulthood. It’s like riding a bicycle: you only need to learn once to feel confident in the saddle even after a long break.

Threading tools

Threading tool

The following tools are used for manual threading:

- The die (deck) is an all-metal washer with 4 chip removal grooves, 4 combs of blades made of durable tool steel on the inner surface. To work, the die is placed in a frame with two handles - a die holder.

- A tap is a rod consisting of a shank with a square cross-section, 4 blade combs, and 4 grooves for removing chips. When cutting the threaded part in pipes, the tap is fixed in the tap holder.

- A manual die is a special thread-cutting set consisting of replaceable dies with cutters and pipe guides located inside, a frame equipped with a ratchet, handles, and extensions.

For thread-cutting work using an automatic (machine) method, a single-spindle metal lathe is required.

In addition to threaded tools, this type of work requires a caliper, an angle grinder (grinder), a file, and machine oil.

General information

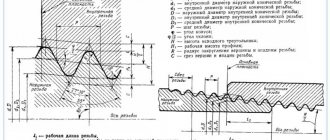

The tip of the cutter, when moving at a constant feed speed along the rotating workpiece, cuts into, leaving a helical line on its surface (Fig. 4.42).

The inclination of the helix to the plane perpendicular to the axis of rotation of the workpiece depends on the rotation speed of the spindle with the workpiece and the feed of the cutter and is called the angle μ of the helix (Fig. 4.43). The distance between the helical lines, measured along the axis of the workpiece, is called the pitch P of the helical line. If a segment on the surface of a part equal to the pitch of the helix is turned onto a plane, then from the right triangle ABC we can determine

tgμ= P/(πd),

where d is the diameter of the workpiece along the outer surface of the thread.

When the cutter is deepened into the surface of the workpiece along the helical line, a helical surface is formed, the shape of which corresponds to the shape of the tip of the cutter. A thread is a helical surface formed on rotating bodies and used to connect, seal or ensure specified movements of machine parts and mechanisms. Threads are divided into cylindrical and conical.

Depending on the purpose of the threaded connection, threads of various profiles are used.

The thread profile is the contour of the thread section in a plane passing through its axis. Threads with acute-angled, trapezoidal and rectangular profiles are widely used.

Threads are left and right. A screw with a right-hand thread is turned clockwise (from left to right), and a screw with a left-hand thread is turned counterclockwise (from right to left). There are single-start and multi-start threads. A single-start thread is formed by one continuous thread, and a multi-start thread is formed by several threads equidistantly located on the surface of the part. The number of threads is easy to determine at the end of the part, where the threaded surface begins (Fig. 4.44, a and b).

There are strokes Ph and pitch P of multi-start threads. The stroke of a multi-start thread (GOST 11708-82) is the distance along a line parallel to the thread axis between any initial midpoint on the side of the thread and the midpoint obtained by moving the initial midpoint along a helical line at an angle of 360° between the same points of one turn one thread of thread, measured parallel to the axis of the part. The stroke of a multi-start thread is equal to the thread pitch multiplied by the number of starts:

Ph= kP,

where k is the number of visits.

Grooving machine

The configuration is possible in different modifications, it all depends on the manufacturer. However, the essence of all machines is the same - they are used to cut threads on an industrial scale. The advantages include:

There is a function for programming diameter and pitch parameters with automatic reverse.

There is a chip removal mode. The kit includes a set of cartridges. Setting the speed of the rotating mechanism. Great time savings for the process. Full use of the machine's capabilities. Increased wear resistance. Compressing the material with a knurling roller ensures a clean surface. Increased strength by 10-30 percent compared to mechanical processing.

Will need

- Clamp for the required pipe diameter.

- Adjustable wrench (gas).

Klupp is a thread-cutting tool, like a die, only it is an attachment with a guide skirt. It must be purchased from a plumbing store. There is no shortage of them, so you can find them without problems, even in the village.

In this case, the Chinese version is presented, which is quite good.

Such a thing costs around 200-500 rubles. It all depends on the diameter and markup. Running models with diameters of 1/2, 3/4 inches and inch, as in my version.

You can ask plumbers for a Soviet equivalent, if possible. Then it will be completely free for you.

General information about thread cutting

During the threading process, a rod or hole is machined. As a result, alternating protrusions appear on the surface - turns or spiral grooves.

The list of main thread characteristics includes:

- Step. To determine it, you need to measure the distance between the peaks or valleys on adjacent turns.

- Profile. The coil cross-section can be trapezoidal, triangular or rectangular. Sanitary type elements are equipped only with a triangular profile.

- Profile angle.

- Depth. Distance from the top to the bottom of the thread.

- Diameter. Can be external, middle and internal.

To determine the outer diameter, you will need to measure the gap between two parallel sides of the thread. It is most convenient to carry out this procedure with a caliper at hand. The average diameter is the distance from the top to the base of the profiles located in opposite sections of the part. The internal diameter determines the distance separating opposite depressions from each other.

Gutter cutting machine

Special machines are often used in production. In terms of design features, they are in many ways reminiscent of vertically oriented machines. Among the features we note:

- The diameter and thread pitch are adjustable.

- If necessary, you can carefully adjust the number and speed of rotation of the cutting element.

- Almost all models are characterized by the ability to process external and internal surfaces.

Modern machines can be used even when cutting thin-walled products. Difficulties can only arise if the workpiece cannot be removed and installed vertically.

Cutting with an electric clamp

In addition to hand tools, electric tools have also become widespread. The advantage of this design option is high performance. The work when using it has the following features:

- The part to be processed is carefully prepared.

- Ensures reliable fastening of the workpiece.

- The mechanism is attached at the starting point.

- The free movement of the guides and the direction of rotation of the cutting part are checked.

- The first turns are cut in the jog mode.

On the tool you can set basic parameters, for example, the length of the cut. Application features depend on its functionality and other performance characteristics.