Threaded connections have found wide application in creating components of various mechanisms. This phenomenon is due to the reliability of the formed interface and the ease of its creation by simply screwing the rod part into the corresponding hole. However, there are situations related to the need to perform independent manual cutting of threaded thread. And here you can’t do without specialized tools. Let's talk in more detail about its variety, called the die.

Classification

The division of dies into types is carried out according to many criteria. We will name only the most frequently used ones.

Design. According to this criterion, the dies are:

- round. Most widely used. The design is a solid ring, along the inner ridges of which the workpiece passes. This tool is characterized by high rigidity. Thanks to this property, high-quality threads with turns with a good profile are obtained;

- sliding (square). The design of such dies includes two parts. And the workpiece is fixed when they are connected. Setting the required diameter of the thread knurling is done by moving one of the parts of the die along the guides of the die (this is another name for the die holder);

- Split. They are used in case of low requirements for the quality of thread knurling.

Thanks to the existing radial cut, such a die has shock-absorbing properties. As a result, the cutting area is subject to less wear. But the end result is a thread of low precision. Its run-up (designation P) fluctuates in the range of 0.1 mm≤P≤0.3 mm;

Thread knurling direction. Dies can cut the following types of threads:

- right The thread is knurled in a clockwise direction. Such threads are present on most types of rod fasteners;

- left. The knurling direction is opposite to the clockwise movement. Used much less frequently. In particular, where the right-hand thread can unwind, in mechanisms that differ in the specificity of rotation, and in special components of vehicles. Such dies are marked with English letters LН;

Thread profile. Based on this feature, tools for cutting external threads, that is, dies, come in the following types:

- metric. As the name suggests, they are designed to form metric thread knurls. The designation in technical literature includes the letter M, followed by a figure or number indicating the thread diameter in millimeters. The values of this parameter (designation d) for round dies are approved by GOST 9740-71. They can vary in the range of 1.0 mm≤d≤68.0 mm;

- cylindrical pipes. Easily identified by the letter “G” present on the body. The unit of measurement for the threads they form is inch (indicated by a double stroke “″”). Its ratio to a millimeter looks like this: 1″ = 25.4 mm. The tool marking “G1/4” indicates that we are looking at a die for cutting quarter-inch pipe threads. Diameter change range – G1/8″≤d≤G2″;

- pipe conical. Marking with the letter “K” will prevent them from being confused with other types of such instruments. Used when it is necessary to obtain a threaded surface of a conical configuration. Scope of application – machine components, as well as critical connections operating under high pressure conditions;

- trapezoidal. The cross section of the turns has the shape of an equilateral trapezoid. Scope of application: power couples that convert rotational motion into translational motion. The simplest example is the combination of a lead screw and a nut, which are equipped with bench and machine vices.

Technology for using taps and dies

Using taps, which are a screw with several longitudinal grooves that form cutting edges and facilitate chip removal, predominantly metric threads are cut on a lathe in small-diameter holes. If machine taps are used for thread cutting, the operation is performed in one pass.

Machine taps differ from ordinary ones in that they consist of two parts - a tapping and a calibrating one. If ordinary taps are used to cut threads using a lathe, then the technology for performing this process involves the use of a set of tools. The set for cutting internal threads includes three types of taps: roughing, which does 60% of the work, semi-finishing (30%), finishing (10%). Sometimes in such a set there may be two tools: roughing, which does 75% of the work, and finishing, which accounts for 25% of the work. To distinguish a rough tap from a finishing one, just look at its cutting part: it is much longer than that of a finishing one.

Design of a tap for thread cutting

The speed of thread cutting on a lathe using taps can be quite high:

- 6–22 m per minute – for parts made of cast iron, bronze and aluminum;

- 5–12 m per minute – for steel workpieces.

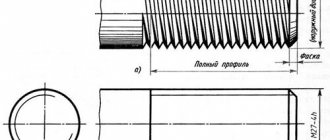

Using dies, which are a ring with an internal thread and several chip grooves, external threads are made on screws, bolts and studs. The surface of the part must be pre-ground to the required diameter, which must take into account the tolerance:

- 0.14–0.28 mm – for threads with a diameter of 20–30 mm;

- 0.12–0.24 mm – for threads with a diameter of 11–18 mm;

- 0.1–0.2 mm – for threads with a diameter of 6–10 mm.

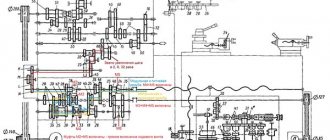

The dies with which external threads are cut are secured in a special chuck (die holder) located in the tailstock quill of the lathe.

Threading dies

Using dies, threads are cut at the following speeds (their setting also takes into account minimal tool wear during operation):

- 10–15 m per minute – on products made of brass;

- 2–3 m per minute – on cast iron parts;

- 3–4 m per minute – on steel workpieces.

In order for the die to fit smoothly onto the part, a chamfer is removed at the end of the part, the height coinciding with the height of the thread profile.

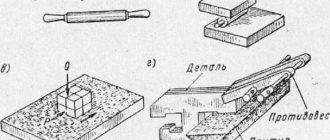

Die holders

To cut threads, in addition to a die (this is another name for a die), you will also need an auxiliary device - a die holder. With its help, the die body is fixed and held in the desired position and, in addition, the tool itself is given a rotational movement.

The design of one such device is designed for several standard sizes of grooves: for small, medium, and large thread knurling. They are inserted into the holder ring and securely fastened with a screw.

The production of dies is regulated by the provisions of GOST 9740-71. According to its requirements, the following grades of steel should be used as raw materials:

- 9XC – tool alloyed with chromium;

- XBCG – medium alloyed instrumental.

In addition, this regulatory document refers on the issue of material for the manufacture of dies to the State Standard number 19256, adopted in 1973. There, the range of brands has become much wider. Let us give as an example only the most common ones. This is high-speed tool steel:

- P18 with an average mass fraction of tungsten (element W) reaching 18%;

- P9M4K8 with an average mass fraction of tungsten equal to approximately 9%, molybdenum (Mo element) - 4% and cobalt (Co element) 4%;

- P6M5 - high-speed tool with an average mass fraction of tungsten of 6% and molybdenum (Mo element) of 5%;

- P12F3 - high-speed tool with an average mass fraction of tungsten at 12% and vanadium (letter “F”) 3%

- and alloys of other brands.

In mass production conditions, dies whose cutting edges are made of hard steel are better suited. For example, such as THM30 (tungsten-free alloy), TT10K8B (titanium-tantalum-tungsten alloy), T5K12B (titanium-tungsten alloy) and BK25 (tungsten alloy). Using this tool, thread knurling can be formed on rod fasteners made of high alloy steels.

General information about threading

When choosing a tool for cutting threads, you should take into account the characteristics of the threaded surfaces. These include the following points:

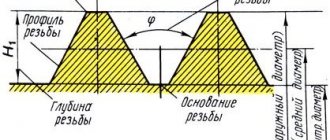

- The cutting of turns is carried out mechanically using special equipment. When metal is removed, grooves and coils are formed that fit perfectly with the surface of the second element.

- All thread cutting tools and technologies used can be divided into two categories: manual and automated. For a long period, screw-cutting lathes were used.

- When using hand tools for thread cutting, lubricant must be used. It significantly extends the service life of devices and simplifies the threading process itself.

Thread cutting with different types of dies

It is worth considering that manual versions have an internal surface, which determines the size of the turns and their location. In the case of processing on a screw-cutting lathe, the parameters of the future threaded surface are determined by the feed and speed of movement of the caliper.

Thread cutting with a die

This procedure includes several steps. Let's look at them.

- Preparation of the workpiece. First of all, the core part being processed must be securely secured in a strictly vertical direction in a vice.

- The die is inserted into the die holder and centered in it.

- Then it is recommended to grind the section of the rod on which the threaded knurling will be formed with sandpaper or a flat file to a depth of 0.4 millimeters.

- Next, the end of the rod is chamfered at an angle to its longitudinal axis equal to 40°. This will make it easier to center the tool and start the thread.

- Then a die is placed on the rod and the initial turns are cut. This point is the most important from the point of view of the finishing quality of the thread. In addition to centering, you need to control the strict horizontal position of the die in relation to the plane of the workbench.

- Actually, the procedure for forming a thread involves forcibly pressing the tool into the workpiece with its simultaneous smooth rotation using the handles of the die holder. The axis of the ladder must coincide with the longitudinal axis of the part. In this case, you need to monitor the amount of forward feed. It must match the thread pitch. Skewing the die is unacceptable, especially when the initial turns are formed.

- After the rod enters the die about half its thickness, you can stop putting pressure on the tool. But the section of the workpiece on which the thread will be formed must be lubricated with machine oil.

- Subsequently, self-tightening is carried out. Thread knurling continues under the influence of rotating force. It should be reciprocating in nature: several turns to the right, after which about half a turn back, that is, to the left. As a result of such actions, the chips are broken and removed through special holes in the die.

Threaded dies for increased productivity

Some thread cutting tools are characterized by high efficiency when used. An example is thread dies, which can be used to produce threads of almost any size. Their advantages include the following:

- Simple design.

- Versatility in use.

- High efficiency.

- Manufacturability.

The combs are represented by multi-filament shaped cutters, which are of prismatic, round and rod type. Most often they are used for cutting threads with fine pitches and low profile heights.

Clupp work

To carry out the work in question, a clamp can be used. It resembles a die, but is large in size. It is often used for cutting threads on pipes and is supplied in special sets with handles. Among the application features we note:

- The clamp is characterized by high efficiency, so the process of cutting turns is simplified.

- The instructions for using the die and die are almost identical, the only difference is how much force needs to be applied to obtain the required result.

A thread cutting kit is often represented by a combination of nozzles of various diameters. In the manufacture of the working part, wear-resistant material is also used, which does not dull during prolonged use.

Tapping internal threads

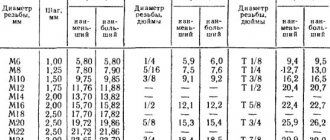

Using a tap, cut the internal thread in the pre-drilled hole. The hole should be smaller by approximately the thread size (the thread size is indicated on the tap). Approximately as in the table:

Hole diameter for internal thread with tap

It is worth remembering that the drill will not give an absolutely accurate diameter; it will be larger by a few fractions of a mm. This is especially noticeable on diameters up to 3 mm. This should be taken into account and take a drill less than a tenth of a mm.

Just like with dies, there is a tap holder.

There are rough and finishing taps. Sometimes they cut first with a rough tap, then with a finishing tap, but mostly they use finishing taps straight away.

Manual cutting of internal threads with a tap (video)

The process is almost identical to thread cutting with a die. The tap is attached to the holder and installed perpendicular to the hole. The part with the hole must be securely fastened.

The tap and hole are lubricated and this is done periodically, after several turns. Just like with a die, you need to make 1-2 turns and 0.5 turns back to remove chips.

To check the accuracy of thread cutting, use a square, checking the verticality of the tap after several turns.

Hand tools

Manual pipe threading tools are the main type for cutting threads in everyday life; their use has the following features:

- Availability. Manual devices have the lowest price among devices of this type and are therefore available to any owner.

- Functionality. When applying cutting, a main device (die holder, knob) is used, into which a cutting tool with the required parameters is inserted.

Rice. 5 Bison die and taps in thread-cutting tool sets

- Compactness. Manual devices take up little space and do not require large spaces for operations.