Sandpaper, also known as sandpaper, is the name for sandpaper, a carpentry abrasive that has no analogues today. The material is used in various sectors of industry and life, from a construction site to an art workshop. Emery cloth is intended for manual and machine processing of wooden, plastic, ceramic and metal surfaces in the production of various products to improve the adhesion of elements when gluing or to prepare the surface for painting.

General information about sandpaper

Sandpaper or sandpaper is a carpentry abrasive applied to a fabric or other flat thin base, which is intended for machine or manual processing of metal, wood, and ceramic surfaces. This material is made by impregnating the base with polymers, then applying heated glue and abrasives of the required fraction (required size). After drying in an oven at a certain temperature, the sanding paper becomes suitable for use.

Since sandpaper can be made rough or almost smooth, special markings are used for convenience. Previously, this parameter was determined according to the GOST 3647-80 standard, which determines the grain size of the sandpaper (the number of grains of different sizes per square unit of sandpaper area). Nowadays, international ISO standards are used, which still have something in common with the old state (domestic) ones.

According to modern rules, grain size is designated using the letter “P”. A number is placed next to it, by which the size of the “grains” is determined: the larger the numerical designation, the finer the sandpaper.

Correspondence table between foreign and domestic markings of sandpaper Source derevo-s.ru

For the GOST designation, other markings apply. Before the letter there is a number that indicates the size of the sieve with a certain side of the mesh. For example, the “grain” of “10-N” sandpaper corresponds to a sieve with a mesh size of 10 microns. The opposite rule applies here: the lower the indicator, the smaller the crop size.

See also: Catalog of companies that specialize in finishing materials and related work

Recommendations for dry and wet sanding

When choosing the wet grinding method, you should wet the surface with water or an inert solvent. The sanding paper must also be wetted periodically to wash away dust from the abrasive grains. As a result of such actions, the sandpaper is used much longer and improves the quality of processing. You should also ensure that there are drains through which the used water should flow. Suitable surfaces for sanding with this method are those that are water-resistant: oil-varnish, epoxy, melamine-alkyd and nitro-cellulose.

The dry type of processing is used for hard and fragile types of surfaces (varnishes, paints and putty). Given the large amount of dust generated, care should be taken to have protective face masks or a vacuum cleaner. When working with a grinder, you must read the operating instructions for the device. At the end of the process, you should blow off the coating with compressed air to remove any remaining dust and wipe the surface with a rag.

See also:

- Grinding Rules

- Grinding Features

Sandpaper-zero

“Null” sandpaper is the most delicate sandpaper with the least abrasive coating. According to the international standard, such paper has a rating from P400 to P2500 and is used for final and ultra-fine grinding of coatings:

- P2500 (M5/N-00) has a grain size of 3-5 microns;

- P2000 (M7/N-01) – 5-7 microns;

- P1500 (M10/N-0) – 7-10 µm;

- P1200 (M14) – 10-14 microns;

- P1000 (M20/N-1) – 14-20 µm;

- P600 (M28/N-2) – 10-14 µm;

- P400 (M40/N-3) – 10-14 microns.

This is interesting! The grain size of the “zero” is so small that it is practically not noticeable to the touch.

Monotonous but necessary work with “zero” Source usamodelkina.ru

Areas of application of zero sandpaper

Nulevka sandpaper has been successfully used for a long time in the construction and repair industry, as well as in the manufacture of furniture, interior accessories and other parts. It is worth listing several areas of application of this material:

- furniture;

- carpentry;

- paintwork;

- automotive repair industry;

- industrial;

- finishing;

- mechanical engineering;

- construction;

- instrument making;

- production of specialized industry equipment, fixtures and instruments (including non-standard, manual and machine ones).

It is important! “Nulevka” can be produced in both sheet and roll form.

Other abrasive characteristics

The abrasive material itself applied to the base of the sandpaper varies. Various natural and synthetic materials are used for it, the physical properties of which largely determine the scope of the material. Here are the main types:

- Silicon carbide. A widely used material, used when working with paints and varnishes, metal, plastic, fiberglass.

- Pomegranate. Natural material, mainly used for working with wood. Sandpaper with this type of abrasive is soft and elastic, convenient for processing uneven surfaces and parts with a complex surface configuration.

- Ceramic abrasive. Highly hard material, often used in shaping products.

- Alumina. Resistant abrasive, valued due to its long service life. An important quality of this type of paper is the formation of new cutting edges when the old layer is abraded.

Features of sandpaper manufacturing

The abrasive, which is the working part of the scratch, can be applied to a base of different composition. For example, on paper or fabric. The history of the production of any sandpaper goes back to ancient origins, which date back to the thirteenth century. At the same time, the first mentions of such material appeared in China. Previously, specialists in the production of sandpaper of different grain sizes added crushed shell rock, seeds of various plants, an adhesive composition, as well as agar-agar or starch for the gluing effect.

Making sandpaper Source kak-sdelano.ru

The paper base of the sandpaper gives a low level of wear resistance and water resistance, and is marked as follows: P1, P2, P3 and so on (an example of GOST product marking is given). The fabric base of the sandpaper (fabric-based sandpaper) guarantees increased durability and does not allow the product to crumble after the first serious processing of various non-smooth surfaces. Not only a more durable base made of natural cotton or artificial polyester helps here, but also the presence of a special resin impregnation. Wet-resistant paper is designated for sandpaper with different abrasive abilities as the letter “L”.

Also important for scratch sandpaper with a grain size of 400-2500 (according to the international method for determining the abrasiveness of this grouting material) is the method of applying the active surface to the base. This can be an open or closed method. In the first case, the user receives sanding paper with a half-covered base; in the second, the base lining is completely covered with abrasive material.

The basis

Abrasive paper can be made on different materials:

- The bulk of products with abrasive are produced on a paper basis. To increase the strength of the paper web to tearing, abrasion, and bending, it is impregnated with polymers and resins. Thanks to these compositions, the product also acquires moisture-resistant properties. But still, paper is a fragile object and is not suitable for intensive long-term work. Fine grain is applied to it.

- Fabric-based sandpaper is more resistant to abrasion and wear. The grain holds just as well, the canvas additionally has elasticity and resistance to moisture, intensive work with various materials, even with a sander, for which they produce velcro attachments.

- Combined fabric-paper fabric (two-layer) combines the best properties of previous materials. The product is elastic, resistant to abrasion, bending, and moisture. Coarse-grained sandpaper is produced on a combined basis.

On sale you can find paper with a sponge base. This one allows dust to pass through well, is not afraid of moisture, and is suitable for manual and mechanical work for a long time.

Types of grain size by material

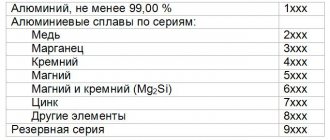

Abrasive is made on different bases:

- Silicon carbide (carborundum) is suitable for working with hard surfaces made of metal and plastic.

- Pomegranate grains are hard and soft at the same time: such abrasive paper is able to remove unevenness from the surface of the wood and seal the fibers, so that the paint or varnish coating applies evenly.

- Ceramics are used to make coarse sandpapers used for smoothing wood.

- Aluminum oxide is a material of considerable price, but it also has an impressive service life for its “compatriots”: soft crystals break during grinding, smoothing the surface, but in their place smaller particles with the same sharp edges are formed.

- Diamond sandpaper is the most durable and expensive. It hardly wears out and is used mainly for machine processing of products in industry.

General rules for using sandpaper

Sandpaper for grinding, that is, zero (as well as other abrasive versions of sandpaper) is used with a base of different processing techniques. So, when marked with the letter “J”, it becomes clear that such sandpaper should be used for grinding the edge or profile. Heavy work with a high degree of contamination is carried out using material with the letter “X”.

As for letters such as “W” and “Y”, which are used for marking, they signal to the user that this product has a higher level of strength and is suitable for a stronger impact.

This is interesting! The basic rule for choosing a suitable sandpaper (including from the “zero” line) remains the rule of moving from the minimum grain size to the maximum.

Advantages and disadvantages of dry and wet grinding methods

Each method has its advantages and disadvantages, so it is necessary to study all the nuances when choosing one of them. The most important advantage of the wet grinding method is the absence of dust formation. Among the disadvantages of using this grinding method are:

- the possibility of metal corrosion if there is a metal base under the surface being treated;

- inability to use an orbital sander;

- poor-quality appearance of the surface after grinding.

Experienced professionals prefer the dry grinding method, since this grinding method is more practical and provides high productivity. Undoubtedly, the main disadvantage of sanding without water is the huge amount of dust that arises from surface treatment residues (paint, putty). But this nuance can be eliminated by using a vacuum cleaner or an anti-dust face mask. Most manufacturing plants and auto repair shops use sanding technology with a combined design of vacuum cleaners and sanders to avoid the formation and accumulation of dust.

The advantages of dry sanding are:

- using an orbital sander;

- eliminating the occurrence of corrosion of metal surfaces;

- high productivity (if mechanical processing is used);

- excellent polishing quality.

Briefly about the main thing

Zero sandpaper is one of the many types of sanding or sanding finishing paper.

Zeroing is used in construction and finishing works, as well as in the production of piece (single) or flow (factory) products of different editions.

Sandpaper (except for grit) can be fabric, paper or a combination (depending on the base on which the abrasive material is applied).

According to state Russian and international standards, different sandpaper is manufactured under different (corresponding to the type) markings, which may contain both numbers and letters.

You can determine which sandpaper is in front of you by looking at the markings on the packaging or by touching the working surface of the material.

Ratings 0

Dry grinding

Dry grinding involves an operation for processing hard and brittle surfaces, which is carried out with an abrasive material without the use of water. This sanding method uses abrasive paper that does not meet the criteria for water resistance. If abrasive paper comes into contact with water, its grain discolors and it loses its suitability for its main purpose - surface grinding.

The dry processing method can be done manually or mechanized. For work, use a grinding machine or sandpaper if the operation is done manually. During the dry polishing process, the abrasive material should be replaced as the grain size decreases. This helps to achieve cleanliness and smoothness of the treated surface.

An orbital sander is used as a sanding tool without water, which is suitable for polishing paint and varnish. It can qualitatively eliminate various types of defects on the surface, such as shagreen (orange peel), bubbles, opus and other irregularities. The presence of such a grinding device provides the best result for achieving high results and processing speed.