Production and features of corrugated sheets

Corrugated sheet refers to an assortment of sheet metal products, which are produced by rolling a hot steel billet through the sheet-forming rolls of a rolling machine.

One of the rollers has a smooth surface, and the second has embossing that squeezes out voluminous protruding grooves. The production is based on the force of plastic deformation of metals without changing their properties at the molecular level.

After rolling, the sheet is cooled, traces of scale, burrs, and uneven edges are removed. The sheet blank is cut into pieces of a specified size using a guillotine. Additional annealing, sandblasting, etching and painting improve the appearance, increase strength, resistance to deformation and loads.

- For production, structural carbon steels of calm and semi-quiet boiling, st0, st1, st2 and st3, are used.

- The letter B in the marking means that the steel is supplied with an agreed chemical composition.

- Among stainless steels, austenitic low-carbon steel 08Х18Н10, AISI 316 with the addition of molybdenum, AISI 321 with the addition of titanium are used.

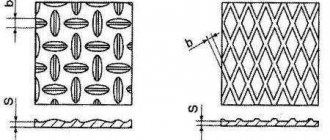

- Volumetric projections, called riffles, are oriented to each other at an angle of 900.

- Diamond-shaped corrugation forms a closed cell with diagonals from 25X25 mm to 70X70 mm.

The oval-shaped riffles, reminiscent of lentil grains, are located perpendicular to each other and parallel or at an angle of 450 to the edges of the sheet. They do not form a closed loop, which contributes to less accumulation of dirt and snow.

The quintet type of corrugation is characterized by five parallel bulges located at an angle of 900 to the next group.

The accuracy class of the thickness of corrugated sheets is established by the relevant regulatory documents and are produced in class A - high accuracy and class B - normal accuracy.

The arrangement of the grooves helps to increase wear resistance, increases resistance to abrasion, vibration loads, levels the surface without the use of plaster and screed, and has an anti-slip effect.

Dimensions of corrugated steel sheet

Products are manufactured in accordance with the norms and requirements established in the relevant standards and specifications.

- Sheet length from 1400 mm to 8000 mm in increments of 50 mm.

- The width ranges from 600 mm to 2200 mm.

- The main quality indicator that affects the service life and durability of the product is thickness.

- It ranges from 2.5 mm to 12 mm.

- The minimum height of the protruding part of the corrugation must be at least 0.5 mm and be 0.1-0.3 parts of the sheet thickness.

- The weight of 1 m2 of rolled steel depends on the thickness and ranges from 21 kg with a thickness of 2.5 mm to 99.3 kg with a thickness of 12 mm.

Permissible differences in the thickness of rolled products should not exceed 0.2 mm.

Product quality is established by GOST and stipulates the absence of shells, scales, bubbles, grooves and protrusions, cracks, burrs, traces of mechanical damage and contamination on the sheets. Minor scratches, traces of rust, and equipment marks are acceptable.

The width of the base with a diamond-shaped groove is 5 mm with a deviation of ± 0.15 mm, for oval projections 3.6 mm - 6 mm. The length of one corrugation is 24 mm, the number per sheet is 450 pieces, the distance between groups is 20 - 30 mm.

Directory of rolled metal products

On our website you can find out prices for Corrugated Steel Sheets in your region and choose your supplier.

corrugated steel sheets under our feet, mainly as non-slip floor coverings and stair steps, which ensures safety during descents and ascents. Also, corrugated sheets are used in the design of building facades, the external interior of buildings and, of course, the manufacture of metal structures. The type of sheet has the form of convex elements (ribs) on one side, the height of which, according to GOST, can be from 0.1 to 0.3 of the thickness of the sheet itself.

Basically, two main types of corrugated sheets are offered for sale: with diamond-shaped and lenticular corrugation. Corrugated sheets also come in aluminum and stainless steel, with such types of corrugations as diamonds, duets and quintets. This makes it even more versatile in use. Carbon steel of ordinary quality (St1, St2, St3) is used to manufacture corrugated steel sheets. The thickness regulated by GOST 8568-77 ranges from 2.5 to 12 mm. Sheet cutting is usually offered at 1500x6000.

Main areas of application for corrugated steel sheets:

— creation of an anti-slip floor covering;

— for decorative overlays and cladding panels in interior and exterior elements;

— production of steps and floorings of flight stairs and various fences;

— sealing of ventilation and inspection windows in devices, machine tools, agricultural machines;

— production of various types of containers;

— as reinforcement for applying plaster;

— production of support during tunneling operations in mines;

— production of light-scattering barriers on roads.

An example of the designation of a corrugated sheet: hot-rolled sheet of steel St3sp with one-sided rhombic corrugation, thickness 3.0 mm, width 1000 mm and length 2000 mm, normal thickness accuracy, improved flatness with a rolled edge:

Rhombus sheet V-K-PU-3.0×1000×2000 St3sp GOST 8568-77.

Corrugated steel sheet with rhombic and lentil corrugation (GOST 8568-77)

Corrugated steel sheet GOST 8568-77 with one-sided rhombic and lentil corrugated general purpose. Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation. The height of the corrugations on the sheets should be 0.2 - 0.3 of the thickness of the base of the sheet, but not less than 0.5 mm.

Sheets with rhombic corrugation are made with diamond diagonals (25-30) x (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer. Peers with lentil corrugation are made with a distance between corrugations of 20, 25 m 30 mm.

Corrugated sheet with lentil corrugation A-1-PV-StZsp2-6x600x6000 TV 14-2-818-88 with a rolled edge, one-sided corrugation is made of carbon steel with a chemical composition in accordance with GOST 380. The height of the reefs on the strip is 1.5 mm at a distance of 40 mm from the side edge. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm.

By agreement between the manufacturer and the consumer, it is possible to produce sheets of other sizes.

Depending on the purpose, corrugated sheets are manufactured:

· measured length;

· multiple measured length;

· measured length with a remainder of no more than 10% of the batch mass;

· multiple measured lengths of no more than 10% of the batch mass;

Unmeasured length.

Residue is considered to be corrugated sheets of length within the unmeasured range, remaining when cutting into dimensional and multiples of dimensional.

Thickness and weight of 1m2 corrugated sheet (GOST 8568-77)

| Sheet base thickness S, mm | Width of ribbed base b, mm | Weight 1m2, kg |

| diamond knurling | ||

| 2,5 | 5 | 21 |

| 3 | 5 | 25,1 |

| 4 | 5 | 33,5 |

| 5 | 5 | 41,8 |

| 6 | 5 | 50 |

| 8 | 5 | 66 |

| 10 | 5 | 83 |

| 12 | 5 | 99,3 |

| lenticular corrugation | ||

| 2,5 | 3,6 | 20,1 |

| 3 | 4 | 24,2 |

| 4 | 4 | 32,2 |

| 5 | 5 | 40,5 |

| 6 | 5 | 48,5 |

| 8 | 6 | 64,9 |

| 10 | 6 | 80,9 |

| 12 | 6 | 96,8 |

Expanded metal sheet (cutting) is manufactured in accordance with TU 36.26.11-5-8. 1. for the manufacture of floorings and steps of flight stairs. Gratings are used for maintenance areas and walkways in the oil, gas, petrochemical industries, power plants, as well as for steel structures for all purposes.

Advantages of steel corrugated sheet

The scope of application and place of operation are influenced by the chemical composition of the steel, the additional processing process, and sheet thickness.

- Affordable cost allows you to install the product in crowded areas, high traffic areas, and production workshops.

- The product is easily installed by welding. The welding seam must be covered with anti-corrosion material.

- High resistance to deformation, not afraid of mechanical damage and shock, and can withstand high-frequency vibration.

- It is easy to process and covers well with all types of primers and paints.

- Original decorative finish with a characteristic metallic sheen and light reflection.

- The flexibility of the material allows it to be used when decorating premises, and its strength when decorating flights of stairs.

It is widely used in façade architecture and home decoration in the Art Nouveau, avant-garde, hi-tech, loft, eclectic, kitsch and steampunk styles. Emphasizes the futuristic landscape of a big city, the eccentricity of building facades, the individuality and originality of the homeowners.

- A type of sheet metal is stainless steel corrugated sheets.

- They are made of high-alloy steel and do not require additional anti-corrosion coating.

- The thickness of a stainless steel product is thinner than steel and ranges from 1.5 mm to 3 mm.

- It has increased flexibility and resistance to aggressive substances. Widely used in the food and oil refining industries.

Aluminum corrugated sheet has a matte surface, high ductility, flexibility and corrosion resistance. The material has low weight compared to steel products and high performance characteristics. They are produced from alloys of the AMG2N2 and AMG2NR brands, which have high electrical conductivity and fire safety.

Due to its inertness, it is widely used in the finishing of chemical industry premises.

A widely used type of corrugated steel is an expanded metal sheet with perforations along the entire length made in the form of longitudinal cuts. Used for the manufacture of gratings, fences, flights of stairs, car radiators.

Application of corrugated sheet metal with lentil pattern

Metal corrugated lentil sheets are widely used in organizing internal space in factories and factories. It is laid as a floor covering both in workshop areas, and it is also used to make steps of staircases, flights, and transitions. The presence of a textured pattern increases the adhesion of the soles to the surface. This reduces the likelihood of slipping when moving. Increased occupational safety and health.

Often, a sheet with a corrugated (patterned) lentil can be found outside of production areas. It is laid as a flooring in front of the entrances:

- to public assignments;

- shopping and entertainment centers;

- in front of the entrances of residential buildings.

Another way to use this rolled metal is the construction of ramps. Increased traction between wheels and metal makes it easier for people with disabilities who use wheelchairs to climb and descend inclined surfaces.

Lentil corrugated steel sheet is an absolutely fire-resistant material. Therefore, this product is used not only as a floor covering. It is also used as wall material. Rolled metal is mounted on walls in rooms that are at risk of fire.