Steel sheets are divided into:

by production method

- hot rolled sheet (HC)

- cold rolled sheet (CC)

by thickness

- from 0.35 to 3.99 mm - thin sheet steel

- from 4 to 160 mm - thick sheet steel

by rolling strength

- increased accuracy - A,

- normal accuracy - B

by flatness

- especially high flatness - software

- high flatness - PV;

- normal flatness - PN

by the nature of the edge

- with uncut edge - BUT;

- with cut edge - O).

In the case of hot-rolled steel sheet, the metal is heated, and then deformed using special presses and rolled.

In order to achieve a uniform thickness of the product, it is subsequently subjected to cold rolling, which significantly increases its properties. Steel sheets are widely used in mechanical engineering, construction and other industries.

Cold rolled sheet (GOST 19904-90)

Sheet thickness, mm

| Standard sheet sizes | Sheet weight, kg | Weight sq.m, kg | |

| 0,35 | 1000x2000 | 5,50 | 2,75 |

| 1250x2500 | 8,59 | ||

| 0,4 | 1000x2000 | 6,28 | 3,14 |

| 1250x2500 | 9,81 | ||

| 0,45 | 1000x2000 | 7,07 | 3,53 |

| 1250x2500 | 11,04 | ||

| 0,5 | 1000x2000 | 7,85 | 3,93 |

| 1250x2500 | 12,27 | ||

| 0,55 | 1000x2000 | 8,64 | 4,32 |

| 1250x2500 | 13,49 | ||

| 0,6 | 1000x2000 | 9,42 | 4,71 |

| 1250x2500 | 14,72 | ||

| 0,65 | 1000x2000 | 10,21 | 5,10 |

| 1250x2500 | 15,95 | ||

| 0,7 | 1000x2000 | 10,99 | 5,50 |

| 1250x2500 | 17,17 | ||

| 0,75 | 1000x2000 | 11,78 | 5,89 |

| 1250x2500 | 18,40 | ||

| 0,8 | 1000x2000 | 12,56 | 6,28 |

| 1250x2500 | 19,63 | ||

| 0,9 | 1000x2000 | 14,13 | 7,07 |

| 1250x2500 | 22,08 | ||

| 1 | 1000x2000 | 15,70 | 7,85 |

| 1250x2500 | 24,53 | ||

| 1,2 | 1000x2000 | 18,84 | 9,42 |

| 1250x2500 | 29,44 | ||

| 1,4 | 1000x2000 | 21,98 | 10,99 |

| 1250x2500 | 34,34 | ||

| 1,5 | 1000x2000 | 23,55 | 11,78 |

| 1250x2500 | 36,80 | ||

| 1,6 | 1000x2000 | 25,12 | 12,56 |

| 1250x2500 | 39,25 | ||

| 1,7 | 1000x2000 | 26,69 | 13,35 |

| 1250x2500 | 41,70 | ||

| 1,8 | 1000x2000 | 28,26 | 14,13 |

| 1250x2500 | 44,16 | ||

| 1,9 | 1000x2000 | 29,83 | 14,92 |

| 1250x2500 | 46,61 | ||

| 2 | 1000x2000 | 31,40 | 15,70 |

| 1250x2500 | 49,06 | ||

| 2,2 | 1000x2000 | 34,54 | 17,27 |

| 1250x2500 | 53,97 | ||

| 2,5 | 1000x2000 | 39,25 | 19,63 |

| 1250x2500 | 61,33 | ||

| 2,8 | 1000x2000 | 43,96 | 21,98 |

| 1250x2500 | 68,69 | ||

| 3 | 1000x2000 | 47,10 | 23,55 |

| 1250x2500 | 73,59 |

How to calculate the weight and price of steel sheet

Metal sheet sizes:

- t—thickness of the metal sheet

- a is the width of the metal sheet

- b is the length of the metal sheet

- Calculation of the theoretical weight of 1 steel sheet: Weight of 1 sheet (t) = t (mm) x h (mm) x a (mm) x 7.85 (kg/m3)

- Calculation of the cost of 1 steel sheet: Price of 1 sheet (RUB) = Weight of 1 sheet (kg) x Price per 1 ton (RUB): 1000 (kg)

- Calculation of the weight of 1 m2 of steel sheet: Weight of 1 m2 = Weight of 1 sheet: Area of 1 sheet (a x b)

- Calculation of the price of 1 m2 of steel sheet: Price of 1 m2 = Price of 1 sheet: Area of 1 sheet (a x b)

See the minimum prices per ton of rolled sheet metal at metal depots in Moscow and Moscow Region here: metal sheet prices.

Hot rolled sheet (GOST 19903-74)

| Sheet thickness, mm | Standard sheet sizes | Sheet weight, kg | Weight sq.m, kg |

| 1,5 | 1250x2500 | 36,80 | 11,78 |

| 2 | 1250x2500 | 49,06 | 15,70 |

| 2,5 | 1250x2500 | 61,33 | 19,63 |

| 3 | 1250x2500 | 73,59 | 23,55 |

| 3,5 | 1250x2500 | 85,86 | 27,48 |

| 4 | 1500x6000 | 282,60 | 31,40 |

| 5 | 1500x6000 | 353,25 | 39,25 |

| 6 | 1500x6000 | 423,90 | 47,10 |

| 7 | 1500x6000 | 494,55 | 54,95 |

| 8 | 1500x6000 | 565,20 | 62,80 |

| 9 | 1500x6000 | 635,85 | 70,65 |

| 10 | 1500x6000 | 706,50 | 78,50 |

| 12 | 1500x6000 | 847,80 | 94,20 |

| 14 | 1500x6000 | 989,10 | 109,90 |

| 16 | 1500x6000 | 1130,40 | 125,60 |

| 18 | 1500x6000 | 1271,70 | 141,30 |

| 20 | 1500x6000 | 1413,00 | 157,00 |

| 22 | 1500x6000 | 1554,30 | 172,70 |

| 25 | 1500x6000 | 1766,25 | 196,25 |

| 28 | 1500x6000 | 1978,20 | 219,80 |

| 30 | 1500x6000 | 2119,50 | 235,50 |

| 32 | 1500x6000 | 2260,80 | 251,20 |

| 35 | 1500x6000 | 2472,75 | 274,75 |

| 36 | 1500x6000 | 2543,40 | 282,60 |

| 40 | 1500x6000 | 2826,00 | 314,00 |

| 45 | 1500x6000 | 3179,25 | 353,25 |

| 50 | 1500x6000 | 3532,50 | 392,50 |

| 55 | 1500x6000 | 3885,75 | 431,75 |

| 60 | 1500x6000 | 4239,00 | 471,00 |

| 65 | 1500x6000 | 4592,25 | 510,25 |

| 70 | 1500x6000 | 4945,50 | 549,50 |

| 80 | 1500x6000 | 5652,00 | 628,00 |

| 90 | 1500x6000 | 6358,50 | 706,50 |

| 100 | 1500x6000 | 7065,00 | 785,00 |

| 110 | 1500x6000 | 7771,50 | 863,50 |

| 120 | 1500x6000 | 8478,00 | 942,00 |

| 130 | 1500x6000 | 9184,50 | 1020,50 |

| 140 | 1500x6000 | 9891,00 | 1099,00 |

| 150 | 1500x6000 | 10597,50 | 1177,50 |

| 160 | 1500x6000 | 11304,00 | 1256,00 |

Which factories produce sheet steel?

The main producers of steel sheets are:

- West Siberian Metallurgical Plant (ZSMK OJSC)

- Magnitogorsk Iron and Steel Works (OJSC MMK)

- Chelyabinsk Metallurgical Plant (ChelMK Mechel OJSC)

- Cherepovets Metallurgical Plant (JSC Severstal)

- Zaporozhye Metallurgical Plant (JSC Zaporizhstal)

- Ashinsky Metallurgical)

- Metallurgical plant "Azovstal" (OJSC MK "Azovstal")

- Novolipetsk Iron and Steel Works (JSC NLMK)

- Metalloinvest (JSC Ural Steel)

Galvanized sheet (GOST 14918-80) Zinc coating thickness classes

| Zinc coating class | Weight of galvanized coating, g/m2 |

| 1 | 142,5-258 |

| 2 | 258-570 |

| Z100 | 100 |

| Z140 | 140 |

| Z180 | 180 |

| Z200 | 200 |

| Z275 | 275 |

| Z350 | 350 |

| Thickness of galvanized sheet, mm | Standard sizes of galvanized sheet | Sheet weight, kg | Weight sq.m, kg |

| 0,35 | 1000x2000 | 5,90 | 2,95 |

| 1250x2500 | 9,22 | ||

| 0,4 | 1000x2000 | 6,68 | 3,34 |

| 1250x2500 | 10,44 | ||

| 0,45 | 1000x2000 | 7,46 | 3,73 |

| 1250x2500 | 11,66 | ||

| 0,5 | 1000x2000 | 8,26 | 4,13 |

| 1250x2500 | 12,91 | ||

| 0,55 | 1000x2000 | 9,04 | 4,52 |

| 1250x2500 | 14,13 | ||

| 0,6 | 1000x2000 | 9,82 | 4,91 |

| 1250x2500 | 15,34 | ||

| 0,65 | 1000x2000 | 10,60 | 5,3 |

| 1250x2500 | 16,56 | ||

| 0,7 | 1000x2000 | 11,40 | 5,7 |

| 1250x2500 | 17,81 | ||

| 0,75 | 1000x2000 | 12,18 | 6,09 |

| 1250x2500 | 19,03 | ||

| 0,8 | 1000x2000 | 12,96 | 6,48 |

| 1250x2500 | 20,25 | ||

| 0,9 | 1000x2000 | 14,54 | 7,27 |

| 1250x2500 | 22,72 | ||

| 1 | 1000x2000 | 16,10 | 8,05 |

| 1250x2500 | 25,16 | ||

| 1,2 | 1000x2000 | 19,24 | 9,62 |

| 1250x2500 | 30,06 | ||

| 1,4 | 1000x2000 | 22,38 | 11,19 |

| 1250x2500 | 34,97 | ||

| 1,5 | 1000x2000 | 23,96 | 11,98 |

| 1250x2500 | 37,44 | ||

| 1,6 | 1000x2000 | 25,52 | 12,76 |

| 1250x2500 | 39,88 | ||

| 1,7 | 1000x2000 | 27,10 | 13,55 |

| 1250x2500 | 42,34 | ||

| 1,8 | 1000x2000 | 28,66 | 14,33 |

| 1250x2500 | 44,78 | ||

| 1,9 | 1000x2000 | 30,24 | 15,12 |

| 1250x2500 | 47,25 | ||

| 2 | 1000x2000 | 31,80 | 15,9 |

| 1250x2500 | 49,69 | ||

| 2,2 | 1000x2000 | 34,94 | 17,47 |

| 1250x2500 | 54,59 | ||

| 2,5 | 1000x2000 | 39,66 | 19,83 |

| 1250x2500 | 61,97 | ||

| 2,8 | 1000x2000 | 44,36 | 22,18 |

| 1250x2500 | 69,31 | ||

| 3 | 1000x2000 | 47,50 | 23,75 |

| 1250x2500 | 74,22 |

Types and technical characteristics of rolled sheets

1. Flat steel sheets in sheets:

- GOST 19903-74 hot-rolled sheet

- GOST 19904-90 cold rolled sheet

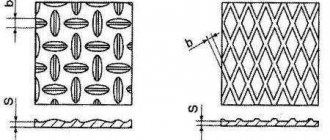

- GOST 8568-77 corrugated sheet (lentil, diamond);

- GOST 14918-80 galvanized sheet

- TU 36.26.11-5-89 expanded metal sheet

2. Sheet metal in rolls:

- GOST 19904-90 cold rolled coil

- GOST 14918-80 galvanized roll

3. Steel sheet with polymer coating (RAL).

For the production of steel sheets, depending on the rolling method in production, the following steel grades are used:

- Hot rolled steel sheets (GOST 19903-90):

- ordinary quality steel: 3 sp/ps, 2 ps

- low alloy steel: 09G2S, 17G1S

- structural steel: 10, 20, 35, 40Х, 45, 65Г

- high-quality carbon steel, structural (08 kp/ps, 15 kp/ps, 25, 35, 45; 10 kp/ps, 20 kp/ps, 30, 40).

Corrugated sheet (steel sheet with rhombic and lentil corrugation) (GOST 8568-77)

| Thickness of corrugated sheet, mm | Standard sizes of corrugated sheet | Sheet weight, kg | Weight sq.m, kg |

| 2,5 | 1250x2500 | 62,8125 | 20,1 |

| 3 | 1250x2500 | 75,625 | 24,2 |

| 4 | 1500x6000 | 289,8 | 32,2 |

| 5 | 1500x6000 | 364,5 | 40,5 |

| 6 | 1500x6000 | 436,5 | 48,5 |

| 8 | 1500x6000 | 584,1 | 64,9 |

| 10 | 1500x6000 | 728,1 | 80,9 |

| 12 | 1500x6000 | 871,2 | 96,8 |

| Steel sheet | HC | Steel 08PS | 0,7 | 1250x2500 | 31807 |

| Steel sheet | HC | Steel 08PS | 0,8 | 1250x2500 | 31722 |

| Steel sheet | HC | Steel 08PS | 0,9 | 1250x2500 | 31690 |

| Steel sheet | HC | Steel 08PS | 1 | 1250x2500 | 31191 |

| Steel sheet | HC | Steel 08PS | 1,2 | 1250x2500 | 31665 |

| Steel sheet | HC | Steel 08PS | 1,4 | 1250x2500 | 31542 |

| Steel sheet | HC | Steel 08PS | 1,5 | 1250x2500 | 30927 |

| Steel sheet | HC | Steel 08PS | 2 | 1250x2500 | 31109 |

| Steel sheet | HC | Steel 08PS | 2,5 | 1250x2500 | 31414 |

| Steel sheet | HC | Steel 08PS | 3 | 1250x2500 | 31656 |

| Steel sheet | GK | St. 3 | 1,5 | 1250x2500 | 28755 |

| Steel sheet | GK | St. 3 | 2 | 1250x2500 | 27010 |

| Steel sheet | GK | St. 3 | 2,5 | 1250x2500 | 27359 |

| Steel sheet | GK | St. 3 | 3 | 1250x2500 | 26550 |

| Steel sheet | GK | St. 3 | 4 | 1500x6000 | 26558 |

| Steel sheet | GK | St. 3 | 5 | 1500x6000 | 26224 |

| Steel sheet | GK | St. 3 | 6 | 1500x6000 | 26415 |

| Steel sheet | GK | St. 3 | 8 | 1500x6000 | 26902 |

| Steel sheet | GK | St. 3 | 10 | 1500x6000 | 26687 |

| Steel sheet | GK | St. 3 | 12 | 1500x6000 | 26543 |

| Steel sheet | GK | St. 3 | 14 | 1500x6000 | 26778 |

| Steel sheet | GK | St. 3 | 16 | 1500x6000 | 26629 |

| Steel sheet | GK | St. 3 | 18 | 1500x6000 | 27301 |

| Steel sheet | GK | St. 3 | 20 | 1500x6000 | 27005 |

| Steel sheet | GK | St. 3 | 22 | 1500x6000 | 26533 |

| Steel sheet | GK | St. 3 | 25 | 1500x6000 | 27080 |

| Steel sheet | GK | St. 3 | 30 | 1500x6000 | 27484 |

| Steel sheet | GK | St. 3 | 40 | 1500x6000 | 28406 |

| Steel sheet | GK | St. 3 | 50 | 1500x6000 | 30025 |

| Steel sheet | fluted | St. 3 | 3 | 1250x2500 | 27916 |

| Steel sheet | fluted | St. 3 | 4 | 1500x6000 | 27462 |

| Steel sheet | fluted | St. 3 | 5 | 1500x6000 | 27458 |

On the portal metalsea.ru you will find the best prices for steel sheets!

The MetalSea metal trading system carries out daily monitoring of prices for finished metal products and ferrous metals in the Central Federal District.

Types of stainless steel sheets

Alloy steel sheets are divided into hot-rolled and cold-rolled. Both types of rental are classified according to:

- rolling accuracy (A and B);

- type of edge: trimmed and unedged (O, BUT);

- sheet flatness group (PO, PV, PU, PN).

Hot-rolled stainless steel has a wide size range and affordable cost, which explains the scale of demand in various fields: mechanical engineering, construction, production of equipment for the food, chemical, oil refining, pharmaceutical industries, etc. According to the quality of surface treatment, hot-rolled steel is produced:

- without additional heat treatment (5d);

- bright annealed/heat treated, etched (M2b, M3b, M4b, M5b).

Cold-rolled sheets made from stainless steel grades are produced in a small thickness (the maximum thickness of a cold-rolled sheet is 5 mm, when a hot-rolled sheet is ten times larger - 50 mm). Thanks to additional processing, cold-rolled steel has improved surface quality and additional strength (as a result of reduced deformation stresses). According to the type of surface treatment, cold-rolled steel is:

- hard-worked (H1);

- semi-hardened (PN1);

- etched or treated with light annealing (M2b, M3b, M4b, M5b).

Types of metal sheets

The metal sheet is sorted (classified) according to the types and varieties of its design, accuracy class, degree of smoothness, profile drawing, according to which a large number of identical blanks are produced. Sheet metal is a universal concept: it includes aluminum, copper and steel sheet products. Rolled sheets, along with angular, tee, rail, round and square, include an assortment according to the length of the “wave” (in the case of corrugated sheets), thickness (thin and sheets of increased thickness). For manufacturing I use both ordinary black steel St0 or St3, as well as higher quality ones - for example, grades of steel alloys like 09G2S with the ability to withstand temperatures even in Martian conditions (about -110 Celsius) without a significant increase in the fragility index (cold brittleness).

Thin-sheet steel is produced both in the form of rough sheets for basic finishing, having a rough, with errors, rolled class , and in the form of thoroughly rolled sheet blanks with an almost constant thickness, the small value of the change in thickness of which can be neglected even during finishing. Smooth sheets are produced painted, including corrugated ones, as well as galvanized (without a primer layer or finishing paint). Mesh sheets are produced both in the form of a fine mesh with galvanization, and in the form of perforated sheets - in a regular sheet blank, holes are drilled with the same space between individual ones, or they are made in groups, as a texture or pattern.

The flat sheet also has a notch along the cut edges, the role of which is to form hooks between sheets of the same type and same type.

Metal sheets by production method

Accounting for sheet blanks by production method affects only two niches: hot-rolled and cold-rolled sheet blanks. The first is characterized by a rough, rough surface, which makes it possible to produce sheet blanks in large quantities without much energy consumption, including melting the mined ore into ingots and holding at temperatures exceeding the mark at which the steel remains liquid. During the cooking process of iron, excess gases are removed (burned out): nitrogen, oxygen. The latter also removes other impurities from the steel - phosphorus and sulfur, due to which the steel becomes much more brittle than in the absence of both phosphorus and sulfur in the alloy. After heat treatment, the steel is cast into an ingot and sent to a rolling mill, which, in turn, flattens it into a kind of pancake, then rough trimming of the edges is performed. Thus, the hot-rolled sheet is ready for further processing.

Despite further processing, hot-rolled steel, as the cheapest analogue of cold-rolled steel, has found its application in construction. The first thing that comes to mind is, for example, blanks 2-3 mm thick were widely used in the construction of pure steel garages.

In combination with the corner and U-profiles, from which the guide “backbone” of the garage building is constructed, hot-rolled sheets are screwed onto this frame using fastening holes in the corner and in the sheet blanks themselves. But the simplest method is to weld the sheets to the corner and U-contour directly, without fasteners

Cold-rolled steel goes through two stages of processing: high-precision rolling using rollers that exert significant pressure (a hundred or more atmospheres per square centimeter of sheet surface) and cutting the edges with the same precision. An unbent, smooth sheet, for example, made of stainless steel, has an almost perfectly smooth surface, without roughness and multiple grooves, which are easily recognizable on a hot-rolled sheet. The surface of the sheet is so smooth that bent corrugated sheets can be immediately produced from these blanks. Cold-rolled sheets are used in finishing decorative finishing of premises. A typical example is electrical and radio measuring laboratories, where shielding from external radiation is used , various archives and museums with especially valuable things and objects of historical value, and more.

A household example is a smooth or corrugated sheet in a country house with galvanization as a fence or roof deck.

Metal sheets according to rolling accuracy

Thickness accuracy is a parameter by which the degree of compliance of the real thickness value with the nomenclature value is monitored. It is determined by the tolerance value - deviation from the thickness specified according to GOST, which cannot be exceeded. Cold-rolled steel sheets are produced in the following modifications: VT - high-precision sheets, AT - increased precision of sheet blanks, BT - basic precision of blanks. Hot-rolled sheet steel is produced in two modifications: B – basic accuracy, A – increased.

Metal sheets by flatness

Flatness is a characteristic, according to the criteria of which each point of the surface comes into contact with the reference workpiece. According to GOST 19904, four degrees of flatness are assessed in the sheet rolling industry: ultra-high, moderately high, improved and normal. According to GOST 26877, wave-like differences per 1 m2 of the surface of such a sheet blank should not exceed the level specified in production standards. Laser processing mills, which perform trimming and through cutting, and perforation of sheet blanks, do not tolerate the slightest irregularities in the sheet. Cold-rolled sheets, even with a uniform impact of the shaft on the hot-rolled workpiece, lose their shape - the outlines along the edges become uneven.

After achieving optimal or maximum flatness, the freshly rolled cold-rolled blanks undergo a laser plasma cutting process. The flatness of the sheet is checked using the same laser machine, turned on in meter mode: the slightest inhomogeneity during the propagation of an oblique beam (1 degree of inclination relative to the earth's horizon or less) will immediately indicate a broken flatness.

In accordance with the data obtained after the next pass when rolling out the sheet blank, additional “rolling” is performed, after which the sheet is cut along the edges in accordance with the dimensional accuracy class (length and width).

Metal sheets by surface quality

The previous parameter by which sheets are classified - flatness - takes into account the specific rate of sheet unevenness. The actual quality of the surface is associated with it - the absence of roughness, “mirror” and smoothness of the workpiece. The use of such sheets is in high-precision equipment, for which quality of workmanship is important.

Metal sheets by degree of elongation

The degree of stretching of sheet metal is divided into regular and deep. Sheet stretching is important in the production of expanded metal sheets, in which it is important to prevent breaks in the mesh structure. If a rupture does occur, then the workpiece is considered defective and is not allowed to proceed to the further, final stage of processing - pressing.

A normal or deep degree of drawing is selected depending on the parameters of the steel alloy, the frequency (number) of cuts per square centimeter (or square decimeter), the length of the cut, and so on.