DIY drill repair

- breakdown of motor parts (stator, armature) - wear of the brushes or their burning - breakdown of the regulator and reverse switch - wear of the support bearings - poor clamping in the tool chuck.

Some spare parts (switch, rotor, stator, brushes, bearings, etc.) for more popular models are bought here (but it’s better to buy through an online store, because in a regular store of this network you will like the price higher).

Replacing brushes

. The most common type of breakdown is wear of the motor brushes, which can be replaced yourself at home. Sometimes, brushes can be replaced without disassembling the drill body. For some models, it is enough to unscrew the plugs from the installation windows and install new brushes. For other models, replacement requires disassembling the housing; in this case, you must carefully remove the brush holders and remove the worn brushes from them.

Brushes are sold at all normal power tool stores, and often an extra pair of brushes is included with a new electric drill.

Don't wait for the brushes to wear down to their minimum size. This risks increasing the gap between the brush and the collector plates. As a result, increased sparking occurs, the collector plates become very hot and may move away from the base of the collector, which will lead to the need to replace the armature.

You can determine the need to replace brushes by increased sparking, which can be seen in the ventilation slots of the housing. The second way to determine this is the random jerking of the drill during operation.

Power cord

. The cord is checked with an ohmmeter, one probe is connected to the contact of the power plug, the other to the core of the cord. Lack of resistance indicates a break. In this case, repairing the drill comes down to replacing the power cord.

Electric motor diagnostics

. In second place, in terms of the number of drill breakdowns, can be placed the malfunction of engine components and, most often, the armature. Failure of an armature or stator occurs for two reasons. improper operation and poor-quality coil wire. World-famous manufacturers use expensive coil wire with double insulation with heat-resistant varnish, which significantly increases the reliability of engines. Accordingly, in cheap models the quality of insulation of the winding wire leaves much to be desired. Improper operation comes down to frequent overloading of the drill or prolonged operation without breaks to cool the engine. Repairing a drill with your own hands by rewinding the armature or stator, in this case, is impossible without special tools. Only complete replacement of the element (exclusively experienced repairmen will be able to rewind the armature or stator with their own hands).

To replace the rotor or stator, it is necessary to disassemble the housing, disconnect the wires, brushes, remove the drive gear if necessary, and remove the entire motor along with the support bearings. Replace the faulty element and install the engine in place.

An armature malfunction can be determined by a characteristic smell, an increase in sparking, and the sparks have a circular motion in the direction of movement of the armature. Pronounced burnt windings can be seen upon visual inspection. But if the engine power has dropped, but there are no signs described above, then you should resort to the help of measuring instruments. ohmmeter and megohmmeter.

Features of the asynchronous motor of the angle grinder

Almost all electrical appliances used in everyday life use an asynchronous electric motor. An important advantage of this type of motor is that when the load on it changes, the speed does not change. This means that if, for example, you cut stone for a long time and without stopping with a household grinder, there will be no noticeable external signs of engine overload. The disk rotation speed will be constant, the sound will be monophonic. Only the temperature will change, but this may not be noticed if your hands are wearing gloves.

If you are not careful, an advantage can turn into a disadvantage. Asynchronous motors are very sensitive to overheating; a significant increase in operating temperature entails melting of the insulation on the rotor windings. At first, the motor will work intermittently, and then - when an interturn short circuit occurs - the motor will stop completely. If you overheat the grinder's engine several times, it is most likely that the anchor will melt. In addition, the high temperature causes the contacts connecting the wires of the primary winding to the collector to become unsoldered, which leads to an interruption in the supply of electric current.

Features of a sequential excitation (SF) motor

In electrical devices that use a series-excited winding, a series connection to the armature winding is provided. Consequently, the current of the PV winding is equal to the current characteristic of the armature. At light loads, the last parameter is much less than the nominal one, and the magnetic system is unsaturated, the electromagnetic torque is proportional to the square of the current in the armature winding.

Varying the load upward implies proportional saturation. When operating the units, it is necessary to take into account the fact that units characterized by sequential excitation cannot be connected to the power supply network in idle mode. This is due to the fact that with a small load volume, the rotation frequency of the anchor element quickly and sharply increases. It is for this reason that such motors do not use a belt drive, because if it breaks, the unit automatically goes to idle.

But there are exceptions to the rules - motors with power up to 200 W inclusive. They can be used in idle mode as long as the volume of mechanical/magnetic losses is commensurate with the nominal characteristics of the power unit.

How to determine if an angle grinder's armature is faulty

Signs of a broken armature angle grinder are: increased sparking of the brushes on the motor commutator, vibration of the motor at low speeds, rotation of the working shaft in different directions. If such symptoms are present, you should stop using the tool - this is dangerous. Suspicions can be easily verified using simple tests.

Visual inspection from outside

Troubleshooting should begin with a visual inspection of the angle grinder:

- Carry out a general inspection of the instrument.

- Pay attention to the integrity of the power cord and the presence of voltage in the outlet.

- Using a voltage indicator, make sure that current is flowing to the motor commutator and the start button.

Read also: Uzo and automatic installation sequence

Inspection of the device from the inside

If everything is in order with the power supply, but the angle grinder does not work, you will have to open the case to gain access to the motor. As a rule, disassembly is not difficult. But you need to follow simple rules that will help you avoid troubles during reassembly:

- Be sure to disconnect the device from the mains before disassembling.

- Remove the working disk and protective cover from the spindle.

- Open the case in a well-lit place, on a clean table surface.

- Remember the location of all parts and assemblies before disassembling. It is recommended to sketch or photograph the internal structure of the device.

- Place screws and fastening screws in a separate place so that they do not get lost.

It is best to inspect the engine under bright lighting so that all small parts are clearly visible. The armature should rotate freely around its axis; properly functioning bearings should not make any sound during operation. There should be no traces of melted wiring on the armature, the circuit windings should be intact, without breaks. You can smell the rotor. When there is an interturn short circuit, the insulating varnish burns and emits a persistent specific odor. But such a diagnosis requires some experience.

Continuity testing of circuits with a tester

If a visual inspection does not give clear results, it is recommended to continue the examination using a multimeter. Having set the mode switch to the ohmmeter position (200 Ohm range), you need to “ring” two adjacent armature lamellas with two probes. If the resistance on all turns is the same, this means that the windings are working properly. If on some pairs the tester shows a different resistance or an open circuit, there is a malfunction in this coil.

A wire break can occur between the winding and the core. You should carefully examine the junction of the coils with the collector lamellas in the lower part of the armature, and visually check the soldering of the contacts.

Checking contacts with a light bulb

If you don’t have a tester, you can get out of the situation using a simple 12-volt light bulb. The power can be any, optimally 30–40 W. The voltage from the 12 volt battery must be applied to the plug of the angle grinder by inserting a light bulb into the gap in one wire. If the armature is working properly, if you rotate the spindle by hand, the light should light without changing brightness. If the heat changes, this is a sure sign of an interturn short circuit.

If the light does not light, this may indicate the following:

- The brushes may become stuck in the non-working position. The retaining spring has worked.

- There has been a break in the supply circuit.

- There is a short circuit or break in the stator winding.

There are other diagnostic methods, but they require more sophisticated equipment, which is not usually used at home. An experienced technician will determine the breakdown with a high degree of accuracy using a “punch” or a simple transformer with a cut toroidal core and one primary winding.

Diagnostics of the electrical part of an angle grinder

As mentioned above, most often an angle grinder refuses to work due to breakdowns of the electrical part of the unit. To correctly diagnose the electrical circuits of a tool, electrical equipment repair technicians use a special device - a tester.

If you press the start button of the unit and it does not work, then in 90% of cases the cause of the breakdown is not so serious that you cannot repair the angle grinder yourself.

The first step is to check the electrical cable and the plug at its end. If it is collapsible, then unscrew it and check the reliability of the contacts. Otherwise, you will have to disassemble the angle grinder (remove the casing of the device) and “ring” the cable with a tester, and also make sure that the current is suitable for the contacts of the “Start” button. If the device shows a break, the cable should be replaced with a new one.

The situation when current flows to the button, but does not pass further (when in the on position), indicates a malfunction of the switch. The button cannot be repaired. It needs to be replaced with a new one, but first mark the contacts you are removing so that you can connect them correctly in the future. If the contacts are connected incorrectly, the motor winding may burn out.

If during the check it turns out that both the cable and the start button are in good condition, but no current is supplied to the brushes, then it is necessary to clean the contact plates of the brush holders. If this procedure is ineffective, it is recommended to replace the brushes. Next, if everything is fine with the brushes and current is flowing to them, you should check the rotor and stator for shorts and breaks.

Checking the motor armature

The electric motor rotor may have the following malfunctions: interturn short circuit and broken conductors at the lamella contacts. You can check the armature of an angle grinder with a multimeter: the device is switched to the resistance change mode, the value is set to 200 Ohms, and the resistance between two adjacent lamellas is measured using probes. Thus, it is necessary to check all pairs of lamellas. If the resistance values are the same, then the rotor winding is not damaged. Detection of other resistance values during “ringing”, as well as detection of an open circuit, indicates a malfunction in this coil. In this case, the angle grinder's anchor will need to be repaired.

If you do not have a measuring device, you can check the rotor using a 12 V light bulb and a battery for this purpose. The power should be between 30-40 W. The test is done as follows: apply 12 V voltage from the battery to the plug of the angle grinder, connect a light bulb to the gap in one wire, and start rotating the angle grinder spindle. If the winding is in good condition, the light will burn evenly, without blinking. With an interturn short circuit, the degree of incandescence of the light bulb filament will change. In this case, repairing the angle grinder's anchor with your own hands will be difficult, since the armature winding scheme is quite complex, and the process itself requires special equipment and knowledge. Therefore, it is recommended to entrust this operation to specialists. But the best way out of the situation would be to replace the anchor on the angle grinder with a new one.

If the light does not light up when testing the rotor, this indicates a break in the stator or a short circuit in its windings, as well as problems with the electric brushes.

Checking the motor stator

To check the stator of the angle grinder, use a multimeter, as in the previous case. The values need to be set to 20-200 Ohms and do the following. Touch one probe to the contact of the stator winding, and the second to the body of the part. If the device shows resistance, this means that a breakdown has occurred to the housing. Touch the probes to the contacts of one winding, and then to the contacts of the other. If the resistance is the same, then the coils are working. If the device shows an open circuit on one winding, it means that the stator will need to be rewinded or the part replaced with a new one.

Rewinding the stator at home without special knowledge, skills and equipment will be problematic. It is better to contact specialists who professionally rewind motors.

In what cases can you save an anchor and restore it yourself?

If damage to the armature is determined with guaranteed accuracy, the part must be removed from the electric motor. Disassembling the motor must be done with special care, after removing the brushes and disconnecting the power terminals. The rotor is removed along with the support bearings and the motor cooling impeller; they form a single whole with it.

If most of the wiring in the armature is damaged and the balancing is disrupted as a result of overheating, it is better to replace it entirely. An imbalance is indicated by increased vibration and an uneven hum when the mechanism operates.

How to rewind an anchor - step-by-step instructions

If the balancing of the armature is not disturbed, and the problem is only in damaged windings, then such an armature can be restored independently by rewinding the coils. Rewinding a rotor at home requires a lot of patience and accuracy.

The technician must have skills in working with a soldering iron and instruments for diagnosing electrical circuits. If you are unsure of your abilities, it is better to take the engine to a workshop for repairs or replace the entire armature yourself.

To rewind the anchor yourself you will need:

- wire for a new winding. A copper core with a diameter exactly matching the old conductor is used;

- dielectric paper for insulating the winding from the core;

- varnish for filling coils;

- soldering iron with tin-lead solder and rosin.

Before rewinding, it is important to count the number of turns of wire in the winding and wind the same amount of new conductor onto the coils.

The rewinding process consists of the following steps:

- Dismantling old windings. They must be carefully removed without damaging the metal body of the armature. If any burrs or damage are found on the body, they must be smoothed out with a file or sanded with emery. Sometimes, to completely clean the body of slag, craftsmen prefer to burn it with a torch.

- Preparing the collector for connecting a new wire. There is no need to remove the manifold. You should inspect the lamellas and measure the resistance of the contacts in relation to the housing with a megger or multimeter. It should be no more than 0.25 MOhm.

- Removing old wiring on the manifold. Carefully remove the remaining wires and cut grooves in the contacts. In the future, the ends of the coil wires will be inserted into the grooves.

- Installation of sleeves for anchors. The sleeves are made of dielectric material 0.3 mm thick, for example, electrical cardboard. Cut a certain number of sleeves and insert them into the grooves of the cleaned anchor.

- Rewinding reels. The end of the new conductor is soldered to the end of the lamella and wound in successive circular movements, counterclockwise. This laying is called “laying to the right.” Winding Repeat for all coils. Near the collector, tie the wires together with a thick thread of cotton fabric (it is prohibited to use nylon, as it melts when heated).

- Checking the winding quality. After laying all the windings, check with a multimeter for the absence of interturn short circuits and possible breaks.

- Finishing processing. Treat the finished coil with varnish or epoxy resin to secure the winding. In factory conditions, the impregnation is dried in special ovens. You can do this at home in the oven. As an option, use quick-drying varnishes for impregnation, applying the coating in several layers.

Read also: Inches designation in documentation

How to check the condition of the brushes

When installing new carbon brushes, it is recommended to grind them in for a better fit to the commutator surface.

It is best to adjust carbon brushes using a homemade grinder. The lap is a shaft on which sandpaper is attached. The easiest way is to make the shaft from wood with a diameter equal to the diameter of the commutator, turning the workpiece on a lathe. A metal rod is inserted tightly along the axis inside the shaft. The device is attached to the chuck of an electric drill, the drill is turned on, and the brushes are brought to a rotating emery wheel.

The adjustment should be carried out carefully, periodically applying the brushes to the rotor commutator to check their clearance. Having ground the brushes to the commutator, before installation it is recommended to check the correct fastening of the brush holders

When factory installed, the brush holders are set to neutral, which minimizes sparking on the commutator. If there are no factory marks, then adjusting the installation of the brush holders is carried out by moving the brush holder in the direction opposite to the rotation of the rotor until a minimum spark is formed

Having ground the brushes to the commutator, it is recommended to check the correct fastening of the brush holders before installation. When factory installed, the brush holders are set to neutral, which minimizes sparking on the commutator. If there are no factory marks, then the installation of the brush holders is adjusted by moving the brush holder in the direction opposite to the rotation of the rotor until a minimum spark is formed.

The brushes should not dangle in the brush holder, but should be pressed tightly against the commutator lamellas. The pressing force is regulated by springs in the brush holder.

Sparking faulty collector

An increase in sparking on the rotor commutator may appear due to a short circuit of the armature, a break in the armature coils, or a short circuit of the windings to the armature body. All these faults can be eliminated only with a major overhaul of the rotor.

Replacing the anchor yourself at home

Practice shows that if you decide to replace the armature of an angle grinder, then it is best to change it together with the support bearings and the engine cooling impeller.

To replace you will need:

- New angle grinder anchor. Must match your model. Interchange with other models is not permitted.

- Screwdrivers, wrenches.

- A soft brush and cloth for wiping the mechanism.

How to remove an anchor

Replacing the anchor begins with disassembling the angle grinder. The following steps are performed:

- Use a screwdriver to unscrew the brush units on both sides. The brushes are removed.

Video: replacing bearings on an angle grinder

How to put an anchor in place

To install a new angle grinder anchor in place, you should take a new part, and then assemble the tool in the reverse order. The sequence of actions is as follows:

- A fixation disk is installed on the armature shaft.

- The bearing is installed using the pressing method.

- The small gear is fitted and secured with a retaining ring.

- The anchor is inserted into the gearbox housing, and the docking holes are aligned.

- The gearbox mounting bolts are tightened.

- The anchor with the gearbox is inserted into the body of the angle grinder and fixed.

- The brushes are deposited in their places and closed with lids.

After completing these steps, the grinder is ready for work. The anchor has been replaced.

Video: how to check an angle grinder

An ancient Sufi wisdom says: “A smart person is one who is able to come out of a difficult situation with dignity. But the one who does not find himself in such a situation is wise.” By following the rules for operating household appliances and preventing the motor from overheating, you can avoid breakdowns and troubles in the operation of the angle grinder. Keeping and storing the tool clean and dry will prevent its mechanisms from contamination and oxidation of current-carrying elements. Timely maintenance of the tool is guaranteed to eliminate unpleasant surprises during operation.

In many household devices and home-made structures, low-power electric machines are used as a drive. Despite the high reliability of electric motors, their failure for a number of reasons is not uncommon. Given the relatively high cost of these devices, it is more practical to repair them rather than replace them. We suggest considering the possibility of rewinding electric motors at home.

Common problems in the operation of angle grinders

The grinder is a fairly unpretentious tool, as it is designed to work with high loads and in dusty environments. The main problems in its operation in most cases are associated with improper operation, as well as non-compliance with maintenance and scheduled repairs. The most common malfunctions are:

- The angle grinder does not turn on. The most common reason for this phenomenon is a broken wire in the power cable or a faulty switch. And for grinders with electronic control, the speed control unit or soft start fails.

- The grinder operates at low speeds. As a rule, this is due to an interturn short circuit in the rotor windings or an electronic malfunction.

- The angle grinder gets very hot. This often occurs due to a violation of the ratio of recommended work cycles and breaks. In addition, heating may be a result of poor engine cooling due to dust accumulated inside the housing.

- The grinder sparkles. In this case, the main reasons are wear of the carbon brushes or wear of the electric motor commutator. Brushes also spark when there is increased contamination and oxidation of the commutator plates.

- The Bulgarian smokes. This is usually observed when the unit is used too intensively and the air cooling ducts are filled with dust. The reason that the tool smokes can also be short circuits in the rotor or stator windings.

- The angle grinder hums, but does not rotate. As a rule, this happens when the gears of the gearbox jam or the bearings fail.

- The spindle lock button is broken. The reason for this is that dust gets inside the clamp, causing wear on its rod.

- The bearings are broken. Bearing failure most often occurs after prolonged use and work with shock loads.

Another fairly common problem with angle grinders is the jamming of the clamping nut.

Features of repairing an asynchronous machine

Engine problems of any type can be mechanical or electrical in nature. In the first case, strong vibration and characteristic noise may indicate a malfunction; as a rule, this indicates problems with the bearing (usually in the end cover). If the malfunction is not corrected in time, the shaft may jam, which will inevitably lead to failure of the stator windings. In this case, the thermal protection of the circuit breaker may not have time to operate.

“Burnt” wires of the stator winding

Based on practice, in 90% of failures of asynchronous machines, problems arise with the stator winding (break, interturn short circuit, short circuit to the frame). In this case, the short-circuited armature, as a rule, remains in working condition. Therefore, even if the damage is mechanical, it is necessary to check the electrical part.

Required Tools

Multimeter Zubr. Photo 220Volt

To rewind the rotor windings, the following basic materials, tools and accessories .

1. Rewinding can be done in two ways :

- completely manually without the use of any equipment;

- Productivity increases greatly with the use of simple devices.

2. Multimeter or other instruments.

3. The user must be able to operate an electric soldering iron.

4. The presence of a winding wire, the diameter of which must correspond to the failed wire.

5. Electrical insulating cardboard or other similar material.

6. Sandpaper, textolite plates, soft wood and other materials for performing auxiliary work.

7. Epoxy resin or other impregnating varnish.

8. Other plumbing tools : hammers, a set of screwdrivers, hacksaw blades, sharp objects, such as a well-sharpened knife, chisels and other tools.

Winding check

In most cases, the problem can be detected by its appearance and characteristic odor (see Figure 1). If the fault cannot be determined empirically, we proceed to diagnostics, which begins with a continuity test. If one is found, the engine is disassembled (this process will be described separately) and the connections are thoroughly inspected. When no defect is detected, a break can be established in one of the coils, which requires rewinding.

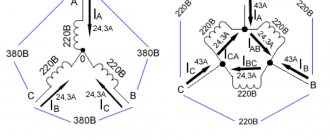

If the continuity test does not show a break, you should proceed to measuring the winding resistance, taking into account the following nuances:

- the insulation resistance of the coils to the housing should tend to infinity;

- for a three-phase drive, the windings must show the same resistance;

- For single-phase machines, the resistance of the starting coils exceeds the readings of the working windings.

In addition, it should be taken into account that the resistance of the stator coils is quite low, so to measure it it makes no sense to use devices with a low accuracy class, such as most multimeters. You can correct the situation by assembling a simple circuit using a potentiometer with the addition of an additional power source, for example a car battery.

Circuit for measuring winding resistance

The measurement procedure is as follows:

- The drive coil is connected to the circuit presented above.

- The potentiometer sets the current to 1 A.

- The coil resistance is calculated using the following formula: , where RK and UPIT were described in Figure 2. R is the resistance of the potentiometer, and is the voltage drop across the measured coil (shown by a voltmeter in the diagram).

It is also worth talking about a technique that allows you to determine the location of the interturn short circuit. This is done as follows:

The stator, freed from the rotor, is connected through a transformer to a reduced power supply, having previously placed a steel ball on it (for example, from a bearing). If the coils are working, the ball will move cyclically along the inner surface without stopping. If there is an interturn short circuit, it will “stick” to this place.

Repair: Elimination of insulation breakdown

If the insulation breakdown was small and you found it, you need to clean the area of carbon deposits and check the resistance. If its value is normal, insulate the wires with asbestos. Apply quick-drying “Super Moment” type glue on top. It will seep through the asbestos and insulate the wire well.

If you still haven’t found the location of the insulation breakdown, then try carefully soaking the winding with impregnating electrical insulating varnish. Punched and unpierced insulation will be saturated with this varnish and become stronger. Dry the anchor in a gas oven at about 150 degrees. If this does not help, try rewinding the winding or changing the armature.

Soldering the collector plates

The slats are mounted on a plastic base. They can be erased to the very base. Only the edges remain that the brushes cannot reach.

Such a collector can be restored by soldering.

- Cut the required number of lamellas to size from a copper pipe or plate.

- After you have stripped the armature of copper residues, solder it with regular tin and soldering acid.

- When all the lamellas are soldered, sand and polish. If you don't have a lathe, use a drill or screwdriver. Insert the armature shaft into the chuck. First, sand with a file. Then polish with grit sandpaper. Don't forget to clean the grooves between the slats and measure the resistance.

- There are lamellas that are not completely damaged. To restore them, more thorough preparation is necessary. Lightly grind the commutator to clean the plates.

Sometimes even a reliable electric drill breaks down.

As statistics show, failures occur not so much in its mechanical part as in its electrical part. But if a lot of advice on restoring an electrical cord, replacing worn brushes, a damaged switch or eliminating other simple faults in household appliances has been published, including on the pages of the “Model Designer” (see, for example, No. 9'95.6'96.2 '97), the same cannot be said about more complex types of repairs. In particular, there is a clear lack of materials on the features of maintenance and feasible (in a home workshop) repair of the rotor of commutator motors, usually installed in drills, impact wrenches and other hand-held power tools. Unfortunately, there are many of these features. It is hardly possible to understand them without understanding the structure and operating principle of commutator motors (Fig. 1). It is also worth remembering that, in accordance with the laws of physics, a force F acts on a conductor with current I in a magnetic field of intensity H, the direction of which is determined by the so-called left-hand rule. Moreover, judging by the simplified diagram, the greatest torque is created when the current-carrying coil is located exactly between the poles of the electromagnet.

However, a real motor develops maximum power when the working turn (loop winding) is positioned at a leading (commutation) angle, which for a drill is approximately 45°. In this case, the alternating current after the electromagnet enters brush A, passes to lamella A of the commutator and then, along the turns of the loop section, to lamella B. But the latter is electrically connected to the antipode - lamella B', from which the current through brush B goes into the power supply network .

Rice. 1. Scheme of operation and simplified design of the commutator motor:

1 - south pole of the stator electromagnet; 2 - rotor rotor winding (“+” is a conventional image of the current directed towards the plane of the drawing, and “-” - away from it); 3 - north pole of the stator electromagnet; 4 - copper-graphite brush A; 5 - lamella A; 6 — lamella B; 7 — lamella B'; 8 — copper-graphite brush B; 9 - rotor; a is the advance (switching) angle; H—magnetic flux; F is the pushing force of a current-carrying conductor in a magnetic field (determined by the left-hand rule); Fa is the force acting on the loop winding taking into account the commutation angle; i—electric current; w is the angular speed of rotation of the rotor

Single-phase commutator motors of most hand-held machines are non-reversible, that is, they rotate only in one direction, determined by a specific switching circuit. The brushes are located with a shift of the geometric neutral by one or two commutator divisions. The shear angle is specified experimentally based on the minimum sparking at the working surface of the commutator at rated load for the required direction of rotation. In reversible motors, which are usually used to drive thread-driving machines, the brushes are installed at a geometric neutral.

The runout of the commutator surface is monitored during engine maintenance using a dial indicator when slowly turning (manually!) the armature or rotor of electrical machines. If the engine is in a disassembled state, then the armature or rotor is installed in the centers and also rotated. When taking measurements, the indicator leg is set perpendicular to the surface of the collector. The runout value (and it, as a rule, should not exceed 0.05-0.06 mm) is determined by the difference between the largest and smallest readings of the device.

Profile control is also a very important element in determining the technical condition of the reservoir. This operation is performed visually, paying attention to the depth of the micanite spacers between the lamellas, which should be within 0.3-0.5 mm.

Soldering failures or breaks are usually determined by measuring the voltage drops at the junction of the collector plates with the armature winding (Fig. 2). The connection of the terminals of the loop windings with the corresponding collector plates is considered satisfactory if the voltage drops at the soldering points do not differ by more than ± 10 percent of the average value.

Rice. 2. Scheme for checking the electrical connection of the collector plates with the loop windings of the rotor:

1 — electric probe (4 pcs.); 2 - collector with lamellas; 3 - loop winding being tested; 4 - pointer millivoltmeter; 5 - galvanic battery; 6 - variable resistor; the values of elements 4-6 are specified during preliminary configuration of the circuit

It happens that the windings themselves are so bad that it is advisable to replace the entire rotor (armature) with a new one. Well, if this is not possible, you have to rewind even in a home workshop. This is a very troublesome matter; To carry it out, you need to have the appropriate tools, devices, consumables and, of course, a diagram (preferably with a pie diagram) of the winding.

Features of repair of commutator drives

This type of electric machine is more likely to experience mechanical failures. For example, brushes worn out or commutator contacts clogged. In such situations, repairs come down to cleaning the contact mechanism or replacing graphite brushes.

Read also: Dimensions of roofing screws for metal table

Testing the electrical part comes down to checking the resistance of the armature winding. In this case, the probes of the device are applied to two adjacent contacts (lamellas) of the collector, after taking readings, measurements are taken further in a circle.

Checking the armature winding of a commutator motor

The displayed resistance should be approximately the same (taking into account the instrument error). If a serious deviation is observed, then this indicates that there is an interturn short circuit or open circuit, therefore, rewinding is necessary.

Standard diagnostics

While you take the diagnostic device, inspect the anchor. This is where damage happens. If the wiring is melted, the burnt insulating varnish will leave black marks, also known as a specific smell. There are bent and crumpled turns or conductive particles, for example, solder residues. These particles are a prerequisite for a short circuit

between the turns. The lamellas have curved edges, called cocks, to connect to the winding.

Due to disruption of these contacts, the lamellas burn out.

Other damage to the collector: raised, worn or burnt plates. Graphite from the brushes can accumulate between the lamellas, which also indicates a short circuit.

Motor winding data

This is a reference data, so the most reliable way to obtain this information is to consult the appropriate sources. This data can also be provided in the product passport.

You can find advice online that recommends manually counting the turns and measuring the diameter of the wire when rewinding. It's a waste of time. It is much easier and more reliable to find all the necessary information using the engine markings, which will indicate the following parameters:

- rated operating characteristics (voltage, power, current consumption, speed, etc.);

- number of wires for one slot;

- Ø wire (as a rule, insulation is not taken into account in this indicator);

- information on the outer and inner diameter of the stator;

- number of grooves;

- with what step the winding is performed;

- rotor dimensions, etc.

Below is a fragment of a table with winding data for electric machines of type 5A.

Example of a table with winding data

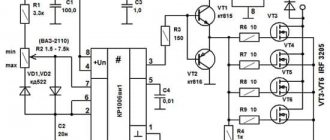

Schematic diagram of the grinder

Almost every craftsman who often works with metal knows the electrical circuit of an angle grinder. The grinder is the tool most often used for cutting metal. This tool is a source of increased danger, so you should check the serviceability of the electrical and mechanical components of the structure before each use.

Schematic diagram of the grinder.

An angle grinder, which in the post-Soviet territory is called “grinder”, was the dream of every home craftsman 3-4 decades ago. 30-40 years ago, this working tool was produced by one manufacturer, the Eltos-Bulgarka plant, located on the territory of Bulgaria in the city of Plovdiv. Currently, manufacturers offer consumers various models and modifications of this tool, but the main design components have remained virtually unchanged. Most of the structural elements on different models and modifications differ only in size.

Step-by-step instructions for rewinding an electric motor with your own hands

It is necessary to immediately warn that without special equipment and operating skills, rewinding reels will most likely be a useless task. On the other hand, negative experience is also experience. Understanding the complexity of a process is the best explanation of its cost.

The first stage is dismantling

We present an algorithm of actions for asynchronous machines, it is as follows:

- Disconnect the drive from the network (380 or 220 V).

- We remove the electric motor from the structure where it was installed.

- Remove the rear cooling fan shroud.

- We dismantle the impeller.

- We unscrew the fastening of the end covers, and then remove them. It is advisable to start from the front part; after dismantling it, the rotor will easily “come out” from the rear cover.

- We take out the rotor.

This process can be greatly simplified if you use a special device - a puller. With its help, it is easy to free the motor shaft from a pulley or gear, and also remove the end covers.

Puller for dismantling

We will not provide instructions for disassembling a commutator motor, since it is not particularly different. The structure of an electric machine of this type can be found on our website.

Stage two - removing the winding

The sequence of actions is as follows:

- Using a knife, remove the bandage fasteners and insulating coating from the wire connections. Some instructions recommend recording the wiring diagram, for example, by taking a photograph. There is no particular point in doing this, since this is reference information and finding it out by engine brand is not a problem.

- Using a chisel, knock off the tops of the wires from each end of the stator.

- We release the grooves using a punch of the appropriate diameter.

- We clean the stator from dirt, soot, and impregnation varnish.

Stator freed from winding

At this stage, we recommend stopping, picking up the case and taking it to specialists. Independent dismantling will reduce the cost of restoration work. As mentioned above, without special equipment it is quite difficult to rewind reels efficiently. To understand the complexity of the process, we will describe its technology, which will make the choice easier.

Stator rewinding (final phase)

The process consists of the following steps:

- Installation of insulators in each groove (sleeving).

- The thickness of the material and its characteristics are selected from the reference book.

- Winding data is determined by motor brand.

- A special machine is used to wind the required number of turns of loose coils. You can find photos and parameters of homemade manual machines on the Internet, but the quality of their work is quite questionable.

Bulk Winding Machine - The coil groups are placed in the grooves, after which they are tied and connected. These processes are quite complex and are performed manually.

- Impregnation is carried out. To do this, the body is heated to a temperature of 45°C - 55°C and completely immersed in a container with impregnating varnish. It makes no sense to varnish the wires, since in this case there will still be voids.

- After impregnation, the body is placed in a special chamber, where drying is carried out at a temperature of 130-135°C.

- Final testing of the coils with an ohmmeter.

- Assembly and test run (if only the body, but also other parts and fasteners were transferred for repair).

If only the body was submitted for restoration, we recommend checking the coils before turning on the motor.

Laying diagram, winding Interskol 230, Makita 9558HN or 9558BN and other models

The order of winding the rotor windings depends on the number of slots in the rotor core and the commutator lamellas. The parameters that determine the location of the winding wire on the rotor include winding direction and pitch . The rotation of the spindle shaft (right or left) is precisely related to the choice of which direction the wire is laid. When performing rotor repairs, it is necessary to record the above data of the burnt winding.

The number of turns and the diameter of the wire are fixed after removing the front part of the failed winding, which will allow you to carefully remove the complete bundle of wire located in the groove.

Most of the used grinders, regardless of the model (Interskol, Makita and others), are structurally made with 24 slats and a core with 12 grooves. The winding pitch is chosen to be 6.

12 grooves and 24 slats

Rotor for INTERSKOL USHM-2300M, HAMMER. Photo 220Volt

The rotor winding with such design parameters is performed as follows.

- The direction of the winding is set (usually clockwise when viewed from the commutator side).

- Insulation made of electrical cardboard and other similar material is installed in the cleaned grooves . The winding wire is soldered to lamella No. 1 in accordance with the old installation scheme.

- The wire is placed in groove No. 1 opposite the lamella indicated by the first number and, according to the winding pitch, is directed into groove No. 6 and returning back. The number of such layings corresponds to the size of the winding turns.

- A circuit with 12 grooves and 24 lamellas is built after soldering the middle of the winding to lamella No. 2 and continuing to wind the winding wire into the same groove. The required number of turns is maintained and soldering is carried out to lamella No. 3. This is how the first complete reel is obtained.

- Next, winding is carried out in slots No. 2 and No. 7 , soldering the middle of the winding to lamella No. 4 and the end of the winding to lamella No. 5.

- By winding the coils using the above method, the last of which ends on lamella No. 1, all 12 grooves and 24 lamellas will be involved in the laying pattern.

Rewinding the armature

The process of replacing the winding of a commutator motor is somewhat similar, with the exception of small nuances associated with the design features. For example, the armature is sent for rewinding, not the housing, provided that the problem does not arise with the excitation coils. In addition, there are the following differences:

- For winding, a special machine with a more complex configuration is used.

- Grooving, balancing of the armature (in the final part of the process), as well as its cleaning and grinding are required.

- The manifold is cut using a special milling machine.

The above processes require special equipment; without it, rewinding electric motors is a waste of time.

Where to begin?

Since the structure of the rotary hammer is simple, the repair of the makita rotary hammer must begin with its disassembly. It is best to disassemble the hammer drill according to the already proven procedure.

Algorithm for disassembling a hammer drill:

- Remove the back cover on the handle.

- Remove the electric carbon brushes.

- Disconnect the mechanical block housing and the stator housing.

- Disconnect the rotor from the mechanical unit.

- Remove the stator from the stator housing.

Remember, the stator housing is green, the mechanical unit housing with the rotor is black.

Having disconnected the rotor from the mechanical unit, we proceed to determine the nature of the malfunction. Rotor Makita HR2450 pos.54; article 515668-4.

How to find a short circuit in the rotor

Since you are repairing rotary hammers yourself, you need an electrical diagram for a Makita 2450, 2470 rotary hammer.

Makita 2470, 2450 rotary hammers use AC commutator motors.

Determining the integrity of a brushed motor begins with a general visual inspection. The faulty rotor pos. 54 shows traces of burnt windings, scratches on the commutator, and traces of burning on the commutator lamellas. A short circuit can only be detected in a rotor whose circuit does not have an open circuit.

To determine a short circuit (SC), it is best to use a special device IK-32.

Checking the armature for short circuit using a homemade indicator

After making sure, using the specified device or a homemade device, that the rotor has a short circuit between the turns, proceed to disassemble it.

Rotors before disassembly

Before disassembling, be sure to fix the winding direction. This is done very simply. Looking at the end of the rotor from the commutator side, you will see the winding direction. There are two winding directions: clockwise and counterclockwise. Record and write down, you will definitely need this data when winding yourself. The rotor of the Makita rotary hammer has a clockwise winding direction, right.

How to check with a multimeter

- Set the resistance to 200 ohms. Connect the probes of the device with two adjacent lamellas. If the resistance is the same between all adjacent plates, then the winding is working. If the resistance is less than 1 ohm and very close to zero, there is a short circuit between the turns. If the resistance is two or more times higher than average, then there is a break in the winding turns. Sometimes when there is a break, the resistance is so great that the device goes off scale. On an analog multimeter, the arrow will go all the way to the right. But digital won’t show anything.

Diagnosis of the armature winding with a multimeter

Video: how the check is carried out

If you don't have a tester, use a 12-volt light bulb with up to 40 watts.

How to check the rotor of an angle grinder using a light bulb

- Take two wires and connect them to the lamp.

- Make a break on the negative wire.

- Apply voltage to the wires. Place the ends of the break against the collector plates and rotate it. If the light bulb lights up without changing brightness, then there is no short circuit.

- Perform a short circuit test to the iron. Connect one wire to the lamellas and the other to the rotor iron. Then with the shaft. If the light is on, it means there is a ground fault. The winding closes to the rotor housing or shaft.

This procedure is similar to diagnostics with a multimeter.

The procedure for disassembling, repairing, and assembling a hammer drill rotor

Here is the sequence for repairing a rotor with a short circuit in the windings:

- Trimming the front part of the windings.

- Removing the collector and frontal parts and measuring the diameter of the wire being removed.

- Removal and cleaning of groove insulation, counting the number of turns along the sections.

- Selection of a new collector.

- Installation of a new collector.

- Production of blanks from insulating material.

- Installing sleeves into grooves.

- Winding the anchor.

- Wiring of conclusions.

- Heat shrink process.

- Shell reservation.

- Shell impregnation.

- Collector impregnation

- Milling the slots of the commutator lamellas

- Balancing

- Cleaning and grinding the rotor.

Now let's look at everything in order.

Stage I

At the first stage, the collector must be removed from the armature. The commutator is removed after boring or sawing the end parts of the winding.

Cutting the frontal parts of the winding

If you are repairing a rotary hammer yourself, you can cut the frontal parts of the winding using a hacksaw. Clamping the rotor in a vice through the aluminum spacers, saw the frontal parts of the winding in a circle, as shown in the photo.

Stage II

To release the collector, the latter must be held by the lamellas with a gas wrench and turned along with the cut front part of the winding, turning the wrench in different directions.

The second method of removing the manifold and frontal parts

At the same time, clamp the rotor in a vice through soft metal spacers.