Quick-release couplings (QRC) are devices that are used for joining hoses, sleeves, pipes, as well as various parts in production. Such connections are used in many areas of modern life and are characterized by reliability and high tightness in environments with high pressure. Their installation does not require any special knowledge or tools.

Quick connects are a type of fitting that allows you to connect two segments of pipes or hoses without tools and in a very short time

Features of the coupling system

Most quick-release or quick-release connections are represented by devices that are made according to the ISO standard (approximately 80% of all parts). Quick-release connections have one convenient quality - interchangeability. This means that structural elements of one product can be made by different manufacturers from different countries. However, 20% of products cannot boast of this quality, since they have unique properties and can only be supplemented with products from the same manufacturer.

The materials from which the couplings are made can be different:

- stainless steel;

- alloy steel;

- aluminum;

- bronze;

- titanium;

- other metal alloys;

- polymer materials.

The service life of quick-release couplings depends on a number of factors that you should pay attention to when choosing a product:

- type of work environment;

- system pressure;

- media temperature (minimum and maximum);

- environmental conditions (high or low air temperature, humidity, precipitation, etc.).

In order to improve the quality characteristics of the product, it is usually subjected to additional anti-corrosion treatment. There are the following options for applying a protective layer to a part:

- chrome plating;

- nickel plating;

- galvanization;

- various hard surfaces.

A huge selection of such fittings allows you to connect not only identical pipes, but also products from different materials

Product characteristics

During installation, two types of fittings can be used:

- with threaded fasteners;

- collet.

The material used for their manufacture is stainless steel, various alloys (bronze, brass), technopolymers.

Fittings for any pneumatic systems are used in devices whose operating principle is based on the use of compressed air energy. In order to ensure complete tightness of the system and prevent loss of power of operating equipment, reliable pneumatic tubes and fittings are required.

Metal and polymer collet pneumatic fittings

Today, industrial enterprises specializing in the production and supply of pneumatic tubes and fittings offer a wide range of this type of product.

There are two main types of such products:

- Fittings whose purpose is to control the flow of compressed air (gas). They can change the physical characteristics of substances passing through the system in devices such as pneumatic throttles, mufflers, consumption (flow) regulators, etc.

- Push-in fittings, which require a minimum amount of time for installation (disassembly) and are used mainly for connecting individual parts of a system consisting of many tubes.

Application area

Pneumatic tubes and fittings are necessary for monitoring and reliable sealing in a variety of pneumatic systems. They are also installed in systems for transporting (pumping) air that has been previously filtered.

Using push-in fittings to connect a compressor

Their use is also possible in water supply systems, when it is necessary to create an absolutely tight connection.

In the latter case, special attention should be paid to the material from which the connectors are made, since the integrity of the entire system (its tightness) will depend on their wear resistance under various operating conditions. MV pneumatic fittings are used in systems that operate with filtered air. Such connectors can withstand internal pressure up to 12 bar, and do not lose their performance characteristics at temperatures from -10 to +70ºC

Such connectors can withstand internal pressure up to 12 bar, and do not lose their performance characteristics at temperatures from -10 to +70ºC

MV pneumatic fittings are used in systems that operate with filtered air. Such connectors can withstand internal pressure up to 12 bar, and do not lose their performance characteristics at temperatures from -10 to +70ºC.

The material used to manufacture such fittings is high-tech plastic, and the connection types are threaded or quick-release collet.

The plastic used in the manufacture of such products consists of an acetal polymer, whose properties far exceed the functional properties of conventional polymer or metal.

Such models are characterized by resistance to corrosion and have a high level of rigidity. Produced in various standard diameters.

Polymer pneumatic fittings are widely used in industry, where they can be installed in systems for the preparation, transportation, processing of compressed air or other gaseous substances.

Connecting pipes to the pneumatic system using collet fittings

The main devices on which such connectors are often used are regulators, pneumatic valves, pneumatic cylinders, filters, microfilters, lubricators and other similar mechanisms.

Advantages and disadvantages of mechanisms

Like any product, quick-release couplings have a number of advantages and are not without their disadvantages. First, let's look at the advantages of these devices:

- wide choice and prevalence (quick connectors can be purchased almost everywhere);

- the budget nature of these products allows you to purchase them for domestic use;

- are able to provide a high level of joint tightness;

- due to its design, the couplings are easy to install and, if necessary, also easy to remove;

- Couplers are reusable products;

- do not lose their properties over a long service life.

The main disadvantages of such products include:

- if the consumer uses a combination of coupling gear parts from different manufacturers, the warranty will be removed from the product;

- 20% of such products are produced without interchangeable properties.

Scope of use

Today, quick-release couplings have penetrated into many areas of human activity and are firmly entrenched there, thanks to their unique qualities and ease of use. Let's consider the main operational areas of the coupling system:

- Automotive industry;

- aviation industry;

- connection of pneumatic devices;

- defense sector;

- alternative sources of energy supply;

- shipbuilding;

- chemical industry;

- medical equipment;

- railway transport;

- polymer industry;

- mining industry;

- construction sector.

Quick-release connections are used in many areas, including in everyday life

Helpful information! It should be noted that the shafts use a special quick-release connection that has a hinged clamp. This device connects steel pipelines with a cross-section from 50 to 400 mm. The working pressure of the medium in such communications is, as a rule, 32 MPa.

EXECUTION

Clamps and connection adapters are manufactured using the most advanced technologies: precision investment casting, processing is carried out on high-precision CNC equipment. High precision and cleanliness of processing of the adapter groove ensures reliable adhesion of the connection, which allows its use in vibration conditions. During the production process, each connection undergoes a full cycle of quality control: analysis of the chemical composition of the melt, radiography for internal defects, bench testing for leaks.

On the body of each product there is information made by casting: manufacturer “Armite”, letter name of the Type of connection part and its size in inches, nominal operating pressure of the connection and its nominal bore in mm. The press-fit pins are made of high-strength steel, which ensures a high degree of reliability. The connection levers are made of stainless steel, have a rectangular profile that prevents breakage and are polished for soft locking that does not require much effort. The levers of all connections have the inscription “Armite”, made by casting. For greater locking reliability, all connections are equipped with locking cotter pins. We use only high-quality sealing materials: BUNA-N (NBR) (Nitrile Rubber), EPDM (Ethylene Propylene Terpolymer), VITON (FKM) (Fluorocarbon Rubber), PTFE envelope/filler VITON (Fluoroplastic/Fluorocarbon Rubber), Silicone.Device and dimensions

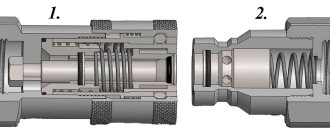

The quick release coupling consists of two main parts. The names of these parts are quite varied. However, it would be most correct to call them “coupling” and “nipple”. People also call them “mom and dad.”

A conventional coupling (“mother”) consists of the following structural elements:

- frame;

- a clamp for fixation, which consists of a locking sleeve and clamping balls;

- check valve;

- O-ring to seal the joint;

- connection adapter (separate or integrated).

Quick-release couplings may have other components, however, such products are less common than standard ones.

The nipple includes the following structural elements:

- frame;

- check valve;

- connection adapter (same as in the case of a coupling, can be separate or integrated);

- sealing element.

Fittings vary in design, diameter and purpose

Quick-release connections have a wide range of products that differ in length, diameter, weight, etc. The most popular are products with diameters from 12 to 150 mm. Many companies produce coupling systems for individual orders. The diameter of such products can reach up to 540 mm.

The characteristics of some types of coupling systems are presented in Table No. 1.

Table 1

| Du, mm | D1, mm | D2, mm | Length, mm | Weight, kg |

| 200 | 218 | 278 | 60 | 14,07 |

| 150 | 168 | 224 | 60 | 6,05 |

| 100 | 114 | 172 | 60 | 4,8 |

| 70 | 78 | 132 | 60 | 2 |

| 50 | 60 | 110 | 50 | 1,45 |

OPTIONS

Ф13 Welded nipple (thread) Chain 275 mm Material 08Х19Н10 Lever O-ringOperating principle

Installation of a quick-release coupling can be performed by any person who does not have special construction skills and professional tools. The quick release device is connected as follows:

- First you need to press out the locking sleeve on the coupling. The spin is performed towards the adapter. The clamping balls retract, making it easy to insert the coupling into the nipple.

- Then the previously prepared coupling is inserted into the nipple.

- Next you need to loosen the bushing. As a result of these manipulations, the coupling is securely fixed in the nipple, and simultaneously with the fixation, the check valves open.

To make a connection, you just need to insert the fitting parts into each other

Note! You can remove the coupling by performing the above steps in reverse order.

There are products that do not require clamping the sleeve for installation. In such devices, the coupling is inserted into the nipple without pressing the sleeve, that is, automatically. You just need to apply a little pressure and the connection is ready.

Types of connections

Based on the location and number of valves, all couplings are divided into three main groups:

- having free passage (not equipped with valves);

- the valve is located on one side;

- have valves on both sides.

Products for quick fixation of sleeves are equipped with a convenient snap mechanism. Installation of such couplings is easy and such connections reliably fix the tubes.

Today, the range of these products is incredibly wide, which allows you to choose the appropriate coupling system for a particular case. Today you can purchase several types of quick-release couplings:

- Quick couplings equipped with a locking wedge;

- cam devices (Camlock);

- products from European manufacturers (BAUER and Perrot);

- ISO connections, which include a conical valve.

Camlock type connection is considered the most effective and practical

Couplers are capable of joining flexible hoses or metal and plastic pipelines. Quick-release fittings for various pipelines can be made in various variations: couplings, tees, crosses, etc. This connection is made using a special clamping device - a collet.

Quick-disconnect (QRC) collet connections also allow for quick installation and dismantling of the pipeline structure. The main feature of this connection is that it allows the transition to thread.

Basic criteria for choosing an irrigation hose

After choosing the material for making the hose, you should decide on its diameter and length. Depending on these criteria, the sleeve can be purchased as a cut or in a coil. The most common are products whose length reaches 15, 20, 25, 35 and 50 m. This parameter is selected based on the size of the area and the method of laying the hose. If you intend to water different beds, you should add up all the lengths. To connect elements of different sizes, you will need to purchase quick-release hose connections. They can be made in the form of a tee, herringbone or cross.

Quick-release connections are convenient because their installation is accessible to anyone. Please note! A large number of garden hose quick releases will reduce the speed and power of water flow.

Based on the diameter, hoses with a cross section of ½, ¾, 1 or 1 ½ inches are most often purchased. The value is selected based on the rule suggesting that the diameter of the internal hole should be directly proportional to the length of the sleeve. Compliance with this condition can ensure sufficient constant water pressure.

The next criterion is to select a product in accordance with the operating pressure in the system. This is determined by the thickness of the hose wall. Single-layer products can withstand up to 2 Bar, multi-layer with reinforcement - 6-10 Bar. The hose must withstand a wide range of temperatures, which will eliminate the possibility of expansion and cracking of the walls.

For convenient operation of the hose, it is worth purchasing a functional device in the form of a coil on which the product is wound

Before using a hose reel, it is important to know some rules. Before winding, you should disconnect the hose from the water supply and allow the water to drain

Methodically rotating the reel, the hose must be cleaned of dirt using a rag.

The geometric shape of the product allows you to quickly connect and disconnect the connection.

Hose quick release coupling

Hoses are widely used in various enterprises and in everyday life. They are made from various materials: polyvinyl chloride (PVC), rubber, silicone, etc. Pneumatic tools are connected using hoses, and they are also used for hydraulic structures. In everyday life, watering work is carried out using hoses.

Note! Couplers simplify and speed up the assembly of hoses; sometimes the connection is made without turning off the water (on the go). This is very convenient and saves a lot of effort and time, and also allows you to assemble the watering system during operation, adjusting its configuration as necessary.

A quick-release hose connector allows you to connect a hose, extend it, or connect it to a pump. The diameters of such connecting devices vary from 12 to 150 mm.

It is worth remembering that reliable products are not always the most expensive. Of course, it is better to purchase products from well-known manufacturers. But you cannot be completely insured against counterfeit or defective parts. Therefore, when purchasing a quick-release coupling, it is recommended to carefully examine it visually, as well as study all the certificates attached to it.

Manufacturing materials

The quick-release fitting can be made of stainless steel, carbon and alloy steel. After manufacturing, the part can be coated with special zinc. This coating prevents rust. If the fitting is used in a non-aggressive environment, then it can be used without zinc. Each of the materials has its own characteristics.

- Stainless steel. Allows you to securely and tightly connect the hose to the system. Can be used in both steel and combined pipelines. The elements are not afraid of high temperatures and do not corrode. Stainless steel does not enter into chemical reactions and withstands mechanical stress.

- Brass. Typically, the fitting is used in pipelines and engineering systems. Such parts are not afraid of water and external influences, and are durable and wear-resistant. Brass elements save energy costs due to low electrical conductivity. The fittings easily withstand a pressure of 16 bar and a temperature of 120°C.

- Plastic. Such fittings are used for domestic purposes. This is a good solution when organizing watering flowers or a vegetable garden. The plastic is quite durable and lightweight. It is very convenient to use such fittings. However, if handled carelessly, there is a risk that the plastic element will break. Usually this does not frighten home craftsmen, since the cost is very affordable.