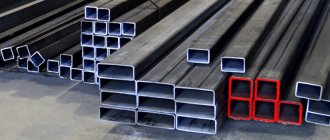

The term “strip” comes from the English word strip, which means “tape”. Indeed, this type of rolled steel product looks like a tape or strip of metal 3-4 mm thick. Strip is a “semi-finished product”, a form of storing rolled galvanized steel in the form of blanks of the required size. The material itself is not used; further processed products or finished products are made from it. Strips find their application in almost all sectors of industry and the national economy. Finished metal strips can be rolled into compact coils, which makes storage and transportation easier.

The high plasticity of the strip material allows the finished product to be subjected to cold deformation without the formation of any defects. This can be achieved through competent redistribution of local voltage.

Manufacturing regulations and standards

The production process and assortment are regulated by the following regulatory documents:

- GOST 14918-2020 Galvanized thin sheet steel with continuous lines. Technical conditions.

- TS 14-101-1080-2016.

Please note that these documents regulate the production of standard strips and define such parameters as length, width, thickness, as well as the grade of steel used. However, at the customer's request, it is possible to produce strips of other sizes.

Definition and scope of application of strips

A strip is a thin strip up to 4 mm thick, made of steel with a protective anti-corrosion coating, which has high performance characteristics.

The word “strip” itself comes from the English word “strip”. This is an environmentally friendly material used in many fields of activity, such as:

- metallurgy (pipe production);

- construction, finishing and repair work (fastening structures, laying communications, as guides, for fencing, as decorative elements);

- production of parts (household appliances, machine tools, various equipment and devices, angles, channels, springs);

- production of furniture and plastic windows;

- packaging of goods for subsequent transportation.

Production Features

The strip manufacturing process consists of the following stages:

- hot rolled steel sheets;

- cold rolling and finishing of steel sheets (it is after this stage that the metal enters the service metal shop);

- the canvas is cut into strips of the required width using longitudinal-transverse cutting technology. The use of high-precision equipment makes it possible to obtain steel strips that perfectly match the specified parameters;

- finished products are wound into coils for storage.

Types of strips and their production

Today, the market offers galvanized and steel strips, as well as products with a polymer coating and made from stainless materials. All of them have an anti-corrosion coating and high strength. The most common type is galvanized steel, because... perfectly amenable to cutting and processing. On the website you can select strips of the required width and quickly place an order.

The production of strips includes 4 stages:

- Production of sheets of certain dimensions for further cutting into strips.

- Cleaning the resulting sheets and giving them a smooth and even surface. Final preparation of sheets before cutting to give them the desired properties.

- Cutting plates into strips of a certain width using special equipment for longitudinal cutting.

- Winding the resulting product onto a drum and assembling it into rolls.

Advantages of stainless steel strips

Advantages of using tapes made of stainless steel:

- resistance to aggressive environments;

- light weight. Achieved through the use of thin-sheet material in manufacturing;

- the ability to create sheet bodies of different configurations;

- flexibility and strength;

- excellent wear resistance.

In addition, such products do not damage the surfaces that they fix.

Stainless steel strips are used in various fields and industries: the production of metal profiles, welded pipes, drainage systems and other structures of this type. It is also used for packaging goods that need to be protected from the negative influence of external factors.

What is strip?

Translated from English, the term “strip” means “tape” or “strip”. If we move from the book formulation to reality, then the meaning of the word corresponds exactly to the appearance of the blank. A strip is a narrow steel strip that is actively used in production processes for the manufacture of metal products for various purposes. The starting material for the production of strips is most often special cold steel sheets or thin metal sheets wound on a rigid shaft.

Sale of strips from the MetalGroup company

From us you can buy strips for any purpose at an inexpensive and excellent quality. We also sell strips made of stainless steel and used non-ferrous metals. Please note that it is more profitable to purchase used products - the price for such strips will be noticeably cheaper.

You are offered not only the sale of strips in, but also processing of its edges, cutting to specified sizes, straightening, bending, applying zinc coating, manufacturing metal structures of any complexity according to your specifications.

Discount on order amount: 1%

from 10,000 rub.

2%

from 50,000 rub.

3%

from 100,000 rub.

What is this

Strip is a rolled steel cut into longitudinal strips. Translated from English, the term “stripes” means strip or tape, which fully reflects the essence of the material. Metal strips are cut from sheets of structural steel containing a low percentage of carbon. A slight inclusion of alloying components ensures ductility and strength.

The general term “strip” means two types of rolled metal (bars) with a similar shape and manufacturing method:

- strip is a raw material intended for processing various types of metal products;

- the tape is a finished product, ready for use without the need for further processing.

Galvanized steel strips equipped with a polymer coating are popular. Applying a layer of polymer improves the characteristics of metal strips with a width of 10-1600 mm with a rolled sheet thickness of 0.25 to 5 mm.

Material for production

There are special requirements for the metal from which the strip is cut. Among them is the ease of rolling the finished product into something like huge rolls. The popularity of strip material in the construction market is explained by the possibility of varying the width of the unrolled strips. The length of steel strips is limited by the weight of the roll - a maximum of 10 meters.

The base steel from which the strip is obtained must be:

- galvanized or stainless;

- have a low carbon content (no more than 0.25%).

The Gosstandart requirements for processing the strip surface are not so strict due to the use of high quality steel grades for the production of rolled metal sheets. Despite the lower quality indicators of low-carbon steel, the strips do not lose their resistance to twisting.

GOST parameters for steel strips made from different materials do not coincide in individual indicators. If the tape is cut from low-carbon material, GOST 503-81 sets the strip thickness to 0.05-4 mm with a width of 4-500 mm. To produce strips from carbon material, their width according to GOST 103-76 should be 11-200 mm with a thickness of 4-60 mm.

There are the following types of strips on the metal products market:

- solid steel strip exhibits high ductility with a low level of cold brittleness and is suitable for welding;

- durable galvanized tape is characterized by good flexibility, resistance to corrosion processes, the tape can be easily cut;

- a version of galvanized strip covered with a polymer coating gives products made from it a beautiful appearance;

- Durable stainless steel tapes are equipped with the maximum level of anti-corrosion protection.

The characteristic feature of the strips is associated with their high corrosion resistance. This is explained by the method of manufacturing steel sheets, which are first hardened by hot rolling, then subjected to cold rolling.

Advantages

- High strength and impact strength provide maximum protection against the risk of various defects (chips, cracks).

- Any type of tape is designed for long-term use due to guaranteed resistance to corrosion.

- The material is easy to work with; ordering it is not difficult due to the choice of geometric characteristics (width, thickness).

- High-strength products made from steel tape do not require additional processing if they are used as fastening material.

- No special conditions are required for transportation or storage - the strip is usually stored in compact rolls.

Product characteristics and classification

These dental consumables are used depending on the procedures being performed. It is worth noting that strips are very popular because they are used to perform therapeutic manipulations of varying complexity.

The instrument is classified according to its intended purpose:

- Surface polishing.

- Removing excess composite or cement.

- Primary grinding of the tooth crown.

As mentioned above, plastic and metal dental strips are produced. Regardless of this, they may have a coarse or fine abrasive coating, the coating is located over the entire instrument or on ½ part, or it may be completely absent.

If there is grain, it is most often represented by the following materials:

- corundum;

- pomegranate;

- carborundum;

- diamond;

- alumina.

Dental strips are also distinguished by color (blue, green, red, yellow) and by the number of working sides (one or two). Coarse abrasive strips are used to shape the tooth and remove excess cement. Medium-grained products remove roughness, and fine-grained ones are needed to polish the surface.

The length of the product ranges from 12-18 cm, and the width is 1.9-8 mm, the average thickness is 0.15-0.2 mm. For greater convenience, there are two forms of dental strips available - rolls and ready-made strips. The tool is disposable, so after use it is immediately thrown away.

Applications

Strip tape also finds its application in household use, fulfilling a role that was not originally intended for it. It is used with pleasure, for example, by summer residents. And for a wide variety of purposes:

- strengthening fences and fences;

- flooring and fixing of roofing coverings;

- decorative design of the surrounding area.

Such high functionality and diversity of applications is explained by the consumer properties of strip-type tape.

As mentioned above, strip tape, depending on the tasks assigned to it, can be steel, galvanized, made of plastic or some composite materials. In addition, a variety of spraying can be applied to the surface of the canvas, starting with ordinary paint and ending with various powder or composite suspensions. It is quite obvious that the method of surface treatment affects not only the functionality of the product, but also its cost. In any case, strip tape is distinguished by its high strength, durability and versatility.

Galvanized strips can truly last 50 years or more , especially if they are not subjected to shock, mechanical stress and stretching. A simple stainless steel strip is somewhat inferior to its zinc “brother” in terms of effective service life, but it is noticeably better in terms of cost. As for plastic, polymer and composite materials, in the hands of a good, diligent owner, they can serve him well for many, many decades.

Packing and fastening

In addition to purely “power” and load-bearing loads, strip tape is capable of performing many applied tasks. With its help, for example, you can securely fasten various structures and even structures. Of course, with the appropriate thickness and width parameters.

In addition, they are widely used in the packaging of a wide variety of parts, goods and products. A flexible and durable plate not only prevents a box , plastic container, or any other type of container from deforming, but also acts as a kind of sling that allows you to move cargo more quickly.

Application benefits

In recent years, the popularity of strips has been increasing due to the fact that they:

- easy to use (the buyer will get exactly the width and thickness that he needs, they can be easily cut, drilled, stamped);

- very durable (when working with them, the risk of damage, chipping, etc. is minimized);

- have a long service life of up to 50 years (due to special anti-corrosion coatings);

- do not require additional treatments or protective coatings (saving money and time);

- wound into rolls (and they are convenient to store and transport);

- safe (do not affect the environment and human health);

- have affordable prices (which allows them to be used everywhere).