Main Difference – Alloy Steel vs Carbon Steel

The steel industry is one of the largest industries in the world. Steel is produced primarily by mixing iron with other metallic or non-metallic elements. The purpose of steel production is to obtain various properties by mixing iron with other elements. Alloy steel and carbon steel are two types of steel that differ from each other in their composition. The main difference between alloy steel and carbon steel is that alloy steel has large amounts of elements other than iron and carbon while carbon steel has trace amounts of elements other than iron and carbon.

Key areas covered

1. What is Alloy Steel - Definition, Properties, Uses 2. What is Carbon Steel - Definition, Properties, Uses 3. What is the Difference Between Alloy Steel and Carbon Steel - Main Differences Comparison

Key terms: alloy steel, carbon, carbon steel, iron, steel

Areas of use

Any steel consists of iron, carbon, impurities - but each grade is designed to solve certain, sometimes specific problems. The characteristics of the materials are specialized, and the choice of brand should be approached responsibly. It is worth considering that:

- The inclusion of alloying additives expands the range of possible uses of the metal, but significantly increases the price. Therefore, when choosing a brand, they are guided not only by improving the characteristics of the metal, but also by economic feasibility, the cost of production, and the scarcity of alloying elements.

- The weldability of low-carbon steels is high, but for alloy and high-carbon steels this is a labor-intensive operation that requires the qualification of the performer.

- Tool carbon steel has a serious disadvantage - when heated, it loses hardness and cutting ability . Therefore, if the cutting tool heats up, then alloy metal is preferable. Many alloy steels are exceptional in their properties ; there are steel grades: magnetic, hard magnetic, with increased electrical resistance, heat-resistant, stainless, and scale-resistant. They are indispensable in the aviation, chemical, and military industries.

What is alloy steel

Alloy steel is a metal alloy of iron, carbon and a large number of other elements. Other elements present in it typically include manganese, silicon, nickel, titanium, copper and chromium. These elements are called alloy elements because these elements are mixed together to form an alloy. The purpose of adding these elements is to improve the properties of the steel. Alloy steel can be divided into two categories as follows.

- Low alloy steel

- High alloy steel

Low alloy steels contain small amounts of alloying elements, while high alloy steels contain large amounts of alloying elements. Alloying elements are usually added to improve the hardness and durability of steel. Alloy steel is also resistant to corrosion due to the presence of significant amounts of other elements such as chromium.

For example, stainless steel is an alloy steel. It contains about 10% chromium along with iron and carbon in the mixture of elements. Due to its anti-corrosion resistance, stainless steel is used to make kitchen items.

Figure 1: Stainless steel (alloy steel) check valve.

Areas of use

Any steel consists of iron, carbon, impurities - but each grade is designed to solve certain, sometimes specific problems. The characteristics of the materials are specialized, and the choice of brand should be approached responsibly. It is worth considering that:

- The inclusion of alloying additives expands the range of possible uses of the metal, but significantly increases the price. Therefore, when choosing a brand, they are guided not only by improving the characteristics of the metal, but also by economic feasibility, the cost of production, and the scarcity of alloying elements.

- The weldability of low-carbon steels is high, but for alloy and high-carbon steels this is a labor-intensive operation that requires the qualification of the performer.

- Tool carbon steel has a serious disadvantage - when heated, it loses hardness and cutting ability . Therefore, if the cutting tool heats up, then alloy metal is preferable. Many alloy steels are exceptional in their properties ; there are steel grades: magnetic, hard magnetic, with increased electrical resistance, heat-resistant, stainless, and scale-resistant. They are indispensable in the aviation, chemical, and military industries.

What is carbon steel

Carbon steel is made up of iron and carbon. Alloying elements are present in trace amounts. Some of these elements are silicon, manganese, sulfur and phosphorus. Carbon steel is also divided into two groups as shown below.

- High carbon steel

- Low carbon steel

Due to the high amount of carbon present in carbon steel, it exhibits properties such as hardness, less ductility, reduced weldability and low melting point. Mild steel refers to low carbon steel with a carbon content of 0.05 to 0.25%. Due to its high iron content, it is corrosive in humid environments. High carbon steels contain between 0.6% and 1.0% carbon. These high carbon steels are very strong. Therefore, carbon steels are used as building materials.

Figure 2: Carbon steel used as a building material

Carbon steels

Carbon, while increasing hardness, also makes the alloy more brittle. The percentage content of the element is reflected in the marking - you can use it to determine what material is in front of you. Please note that the first two digits reflect the presence of hundredths of a percent of the element, one – tenths. If the carbon content is up to 0.25% , then the steel is low-carbon, and therefore inexpensive, easy to weld. If from 0.3 to 0.55% , then the alloy is medium-carbon; these are actively used in mechanical engineering. The amount of an element in the range of 0.6-2% shows that the material is high-carbon, therefore its weldability and fluidity are low, but its hardness is high.

The structure of low-carbon alloys provides plasticity, but relatively low strength of the material. An increase in carbon content leads to a loss of ductility, but significantly increases strength. Thus, high-carbon steel is a very hard, durable alloy, for which they try to avoid the use of welding whenever possible. Wire, bearings, springs, and stamped parts are produced from it.

Difference between alloy steel and carbon steel

Definition

Alloy Steel: Alloy steel is a type of steel with a high percentage of elements other than iron and carbon.

Carbon Steel: Carbon steel is a type of steel that is high in carbon and low in other elements.

Corrosion resistance

Alloy Steel: Alloy steels are resistant to corrosion.

Carbon Steel: Carbon steels are less resistant to corrosion.

Strength

Alloy Steel: The strength of alloy steel is low compared to carbon steel.

Carbon Steel: Carbon steel has high strength.

weldability

Alloy steel: The weldability of alloy steel is high.

Carbon Steel: The weldability of carbon steel is low.

Melting temperature

Alloy Steel: Alloy steels have high melting points.

Carbon Steel: Carbon steels have low melting points.

stringiness

Alloy steel: The ductility of alloy steel is high.

Carbon Steel: The ductility of carbon steel is low.

Conclusion

The composition of the elements in steel differs from one type of steel to another. Therefore, steels are classified mainly according to their composition. Alloy steel and carbon steel are such two types of steel. The main difference between alloy steel and carbon steel is that alloy steel has large amounts of elements other than iron and carbon, whereas carbon steel has trace amounts of elements other than iron and carbon.

Recommendations:

1. “Information on carbon steels and alloy steels.” Information on Carbon Steels and Alloy Steels | Engineering360. N.p., n.d. Web.

Source

Alloy steels

By adding certain substances to the composition of steel alloys, the necessary properties can be achieved; this operation is called alloying. For example:

- Chromium - increases hardness, strength, corrosion resistance, but impairs ductility.

- Nickel - increases ductility and corrosion resistance, but can reduce hardness; it is often used together with manganese.

- Tungsten , molybdenum - impart hardness, enhance heat resistance, reduce brittleness during tempering.

- Manganese - optimizes impact resistance and hardness without compromising ductility.

- Aluminum – improves heat resistance, as well as scale resistance and corrosion resistance.

- Silicon – makes the metal strong while maintaining its toughness. Improves electrical resistance, elasticity, acid resistance. Compared to other alloying elements, it is less expensive.

Alloy steels, having unique qualities, are used for the production of products where they cannot be replaced by other materials. They are classified according to purpose, structure, percentage of alloying elements, and chemical composition.

What is the difference between carbon steel and alloy steel? Help

CARBON STEEL - unalloyed structural or tool steel containing less than 2.14% carbon. Carbon steels are classified by structure, method of production and deoxidation, and quality. In terms of structure, carbon steel can be hypoeutectoid (contains up to 0.8% carbon, the structure consists of ferrite and pearlite), eutectoid (contains about 0.8% carbon, the structure consists only of pearlite), hypereutectoid (contains 0.8-2 ,14% carbon, the structure consists of pearlite grains bordered by a cementite network). According to the production method, carbon steels are distinguished, smelted in electric furnaces, open-hearth furnaces and the oxygen-converter method. According to the method of deoxidation, boiling, semi-calm, and calm steels are distinguished. According to their purpose, carbon steels are divided into structural steels and tool steels; There is also a group of special-purpose carbon steels. Based on carbon content, carbon steels are divided into low-carbon, with a carbon content of up to 0.25%; medium-carbon, with a carbon content of 0.3-0.6%; high-carbon, with a carbon content above 0.6%. There are also ordinary carbon steels and high-quality carbon steels. ALLOYED STEEL, carbon steel into which alloying elements are specially introduced in order to improve its operational and technological properties (see Alloying). There are low-alloy (total content of alloying elements up to 2.5%), medium-alloy (2.5-10%) and high-alloy (over 10%) steel. Alloying elements are introduced into steel in different quantities and in different combinations - 2, 3 or more elements. Alloy steels are used for the manufacture of heavily loaded parts for critical purposes, as they have higher mechanical characteristics.

Carbon steels

Carbon, while increasing hardness, also makes the alloy more brittle. The percentage content of the element is reflected in the marking - you can use it to determine what material is in front of you. Please note that the first two digits reflect the presence of hundredths of a percent of the element, one – tenths. If the carbon content is up to 0.25% , then the steel is low-carbon, and therefore inexpensive, easy to weld. If from 0.3 to 0.55% , then the alloy is medium-carbon; these are actively used in mechanical engineering. The amount of an element in the range of 0.6-2% shows that the material is high-carbon, therefore its weldability and fluidity are low, but its hardness is high.

The structure of low-carbon alloys provides plasticity, but relatively low strength of the material. An increase in carbon content leads to a loss of ductility, but significantly increases strength. Thus, high-carbon steel is a very hard, durable alloy, for which they try to avoid the use of welding whenever possible. Wire, bearings, springs, and stamped parts are produced from it.

Carbon steel of ordinary quality

Carbon steels are divided into three main groups : carbon steels of ordinary quality, high-quality carbon steels and carbon steels for special purposes (automatic steel, boiler room, etc.).

Carbon steels of ordinary quality comply with GOST 380–2005. They are supplied in the form of rolled products in a normalized condition and are used in mechanical engineering, construction and other sectors of the national economy.

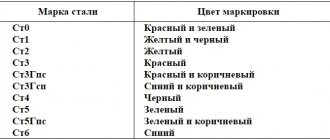

Carbon steels of ordinary quality are designated by the letters St and numbers from 0 to 6.

The numbers are the conditional number of the brand. The higher the number, the higher the carbon content, higher the strength and lower the ductility.

Depending on the purpose and guaranteed properties, carbon steels of ordinary quality are supplied in three groups : A, B, C. The indices to the right of the grade number mean:

- kp - boiling;

- ps - semi-calm;

- sp - calm.

The letter G may appear between the index and the brand number; this means a high manganese content. The grade designations to the left of the letters St indicate the groups (B and C) of steel. Ordinary quality steels are divided into categories . The steel category is indicated by the corresponding number to the right of the deoxidation degree index. For example, St5Gps3 means: steel of group A, grade St5, with a high manganese content, semi-calm, third category. Steel of the first category is written without indicating the number of the last, for example St4ps.

The chemical composition of group A steels is not regulated, but their mechanical properties are guaranteed, determined by the relevant state standard. Steels of this group are usually used for parts that are not subjected to hot processing (welding, forging, etc.) during the manufacturing process.

Group B steel is supplied according to its chemical composition and is used for parts that undergo heat treatment and hot pressure treatment (stamping, forging) during the manufacturing process. The mechanical properties of group B steel are not guaranteed. Group B steel is supplied with mechanical properties corresponding to the standards for group A steel, and a chemical composition corresponding to the standards for group B steel. Group B steel is used mainly for welded structures.

High-quality carbon steel for structural purposes

High-quality carbon steel for structural purposes complies with GOST 1050–88. differ from ordinary quality steels in having a lower content of sulfur, phosphorus and other harmful impurities, narrower limits of carbon content in each grade and, in most cases, a higher content of silicon and manganese.

Steel is marked with two-digit numbers, which indicate the carbon content in hundredths of a percent, and is supplied with guaranteed chemical composition and mechanical properties. The letter G in the grades of these steels also indicates a high manganese content (up to 1%). High-quality carbon steel is supplied rolled, forged, calibrated, round with a special surface finish (silver). Carbon steels for special purposes include steels (GOST 1414–75) with good and increased machinability by cutting (automatic steels). They are intended mainly for the production of mass-produced parts.

Automatic steels with high sulfur and phosphorus content have good machinability. Cutting machinability is also improved by introducing technological additives into steel - selenium, lead, tellurium. Automatic steels are marked with the letter A and numbers showing the average carbon content in hundredths of a percent. The following grades of automatic steel are used: A12, A20, A30, A40G. Non-critical parts are made from A12 steel, and more critical parts that operate under significant stresses and high pressures are made from steels of other grades. The range of free-cut steel includes the production of long products in the form of bars of round, square and hexagonal sections.

Sheet steel (boiler rooms, GOST 5520–79 and TU) for boilers and pressure vessels is used for the manufacture of steam boilers, ship furnaces, combustion chambers of gas turbines and other parts. They must operate at variable pressures and temperatures up to 450°C. In addition, boiler steel must be weldable well. To obtain such properties, a technological additive (titanium) is introduced into carbon steel and additionally deoxidized with aluminum. The following grades of carbon boiler steel are produced: 12K, 15K, 16K, 18K, 20K, 22K with a carbon content of 0.08 to 0.28%. These steels are supplied in the form of sheets up to 200 mm thick and forgings in the condition after normalization and tempering. The properties and purpose of high-quality structural steels are given in table. 1.

Influence of alloying elements. Marking of alloy steels

To improve the physical, chemical, strength and technological properties of steel, they are alloyed by introducing various alloying elements into their composition (chrome, manganese, nickel, etc.). Steels may contain one or more alloying elements that give them special properties.

Table 1. Mechanical properties of high-quality structural steel

become

The main structural component in structural steel is ferrite , occupying at least 90% by volume in the structure. By dissolving in ferrite, alloying elements strengthen it.

The hardness of ferrite (in the state after normalization) is most strongly increased by silicon, manganese and nickel - elements with a lattice different from the -Fe lattice. Molybdenum, tungsten and chromium have a weaker effect. Most alloying elements, while strengthening ferrite and having little effect on ductility, reduce impact strength (with the exception of nickel). At levels up to 1%, manganese and chromium increase toughness . Above this content, toughness decreases, reaching the level of unalloyed ferrite at 3% Cr and 1.5% Mn.

Low carbon steel and its main characteristics

Low-carbon steel is an alloy that does not contain alloying elements, has impurities and a low carbon content, up to 0.25%. This alloy contains manganese and silicon, but due to its low percentage (manganese - no more than 1%, silicon - no more than 0.8%), they do not have a noticeable alloying effect on the material. Low-carbon steel is soft and has a low manganese content.

Due to its softness, this alloy does not allow precise surface processing, but its softness, toughness and ductility make it possible to create cemented workpieces and parts for subsequent welding/cementation. The machinability of the alloy is very poor, the surface of the workpiece has many roughnesses. Carrying out precise processing is quite difficult.

Case-hardened, temperable and high-strength steels

Case-hardened steels are low-carbon (up to 0.25 C), low- (up to 2.5%) and medium-alloyed (2.5...10% total content of alloying elements) steels. They are intended for machine parts and devices operating in friction conditions and experiencing shock and variable loads.

Steel grade 15ХА with a tensile strength σ in MPa is intended for the manufacture of small parts operating under friction conditions at medium pressures and speeds. For the manufacture of critical parts operating at high speeds, high pressures and shock loads, steel grades 18ХГ and 25ХГМ . For large, critical, heavily loaded parts, steels 20ХН and 20Х2Н4А .

In the manufacture of large, especially critical, heavily loaded parts operating at high speeds with the presence of vibration and dynamic loads, steel with a tensile strength in MPa grade 18Х2Н4МА .

The performance of such parts depends on the properties of the core and surface layer of the metal. Case-hardening steels are saturated with carbon from the surface (cemented) and subjected to heat treatment (hardening and tempering). This treatment provides high surface hardness (HRC 58...63) and maintains the required toughness and specified strength of the metal core.

Improved alloy steels are medium-carbon (0.25...0.6% C) and low-alloy steels. To ensure the necessary properties (strength, ductility, toughness), these steels are thermally improved by hardening and high tempering (at 500...600°C).

Improved and case-hardening steels after heat treatment give strength up to σ in MPa and toughness up to KS = 0.8...1.0 MJ/m 2. Such strength is not enough to create new modern machines. Steels with a strength limit of σ in MPa are required. For these purposes, complex alloyed and maraging steels are used. The properties of such steels and their purpose are shown in table. 2.

Table 2. Improved alloy steels

| Brand | Tensile limit σв , MPa | Relative elongation δ,% | Specific KS, MJ/m 2 | Purpose |

| 40ХС | 1250 | 12 | 0,35 | Some parts operating under conditions of increased stress and alternating loads |

| 40HFA | 900 | 10 | 0,9 | |

| 30HGFA | 1100 | 10 | 0,5 | Parts operating under friction conditions and critical welded structures operating under alternating loads and temperatures up to 200°C |

| 40ХН2МА | 1100 | 12 | 0,8 | Large, critical, heavily loaded parts with complex shapes |

Complex alloy steels are medium-carbon (0.25...0.6% C) alloy steels that are heat-strengthened during low tempering or subjected to thermomechanical treatment.

Maraging steels are a new class of high-strength alloy steels based on carbon-free (no more than 0.03% C) alloys of iron with nickel, cobalt, molybdenum, titanium, chromium and other elements. Maraging steels are hardened in air from 800...860°C, followed by aging at 450...500°C.

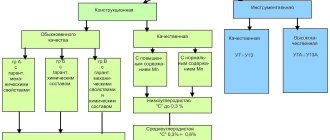

Classification of steel by purpose

The following type of steel classification is by purpose:

- structural;

- instrumental;

- with special physical and chemical characteristics.

This classification is quite arbitrary; one group may contain dozens of brands, while another may contain one or two.

Classification of steels by purpose

In addition, many brands, due to their mechanical properties, are also suitable for related purposes. When choosing a brand for a specific design or part, designers and technologists take into account, in addition to the formal purpose, many more factors, such as price, machinability, compatibility with other parts in terms of the coefficient of thermal expansion, and others. Sometimes the designer uses a brand that is obviously superior in its parameters and cost to a simple structural grade that is quite suitable for a given part. This is acceptable in conditions of unique production or especially small series, high transport costs, and a number of other cases. Any such decision must be justified from a financial point of view.

Structural

Structural steels of ordinary quality represent one of the most extensive groups.

- construction;

- cold stamping;

- cemented;

- improved;

- high strength;

- spring-spring;

- bearing;

- automatic;

- corrosion resistant;

- wear-resistant;

- heat resistant and heat resistant.

Construction

This includes a large number of grades of ordinary carbon and low alloy alloys. Such materials are used to create complex spatial structures in which the load is evenly distributed between all elements. There are no special requirements for each of them, other than good weldability.

For cold stamping

During cold stamping, the shape of the workpiece and its dimensions change significantly, therefore, for this group of low-carbon high-quality alloys, the main requirement is different - high ductility and tensile strength.

Cementable

This group is used for the production of units and parts subject to friction and variable periodic loads. The cementation procedure serves to increase the surface's resistance to wear. It includes low-carbon (0.1-0.3%) and some alloyed alloys.

Case-hardened steel products

Upgradeable

These grades are intended for special types of heat treatment, such as hardening and tempering, used to improve the strength and other mechanical characteristics of the material. The group includes both medium carbon and chromium, including those with additives of boron, manganese, nickel and molybdenum.

High strength

For high-strength, medium-carbon, high-alloy alloys, the composition and ratio of additives, as well as specific heat treatment programs, are specially selected. As a result, metallurgists achieve strength characteristics that are two or more times greater than those of structural grades. They are used in particularly critical units.

Spring

The main feature of spring spring brands is the ability to undergo repeated elastic deformations without accumulating the effect of fatigue. They are very widely used in transport and mechanical engineering, wherever depreciation, damping of vibrations or ensuring the return of parts of the mechanism to their original position after performing a working movement is required. To increase the elastic limit, carbon alloys are alloyed with silicon, manganese, boron and other elements.

Bearing

To ensure the required service life of engines, machine tools and other mechanisms that use bearings, products made from alloys of this group must be high-strength, wear-resistant and durable. Foreign inclusions, inhomogeneities, and all types of pores should be minimized. Contains about one percent carbon and 0.8-1.5% chromium, subject to special compaction and heat treatment

Automatic

The main parameter for alloys of this group is high machinability, the formation of easily breaking short chips and reduced friction between the part and the tool. They are used for the production of mass series of fastening components on automated production complexes. Sulfur, lead, selenium and tellurium are added to the composition. The downside is the reduced ductility of the material.

Wear-resistant

By adding large quantities of manganese to the alloy, wear-resistant steel grades are obtained. Their purpose is the production of units subject to strong friction, including abrasive, and large static and dynamic loads. These are elements of switches on the rail track, mining equipment, loader buckets, and tracks.

Damper made of wear-resistant steel

Corrosion resistant stainless steel

These low-carbon alloys are heavily alloyed with chromium and manganese. During crystallization, chromium forms a thin surface layer of oxides that protects the part from exposure to chemically active environments. Such alloys can be used in both mildly aggressive (water, steam) and highly aggressive environments (solutions of acids, alkalis, sea water) at temperatures up to 60 °C

The corrosion-resistant group has its own classification

- Corrosion resistant. They are used to make shafts, springs, valves, and turbine blades that can withstand high loads and up to 600 °C.

- Heat resistant. Designed to operate at high temperatures (up to 1200 °C) under limited loads.

- Heat resistant. Low-carbon alloys highly alloyed with nickel, silicon and other additives can operate under conditions of both high temperatures (up to 75% of the melting point) and high loads.

- Cryogenic. Maintain elasticity and viscosity at low and especially low temperatures (down to -200 °C). They are used for the manufacture of components for industrial and scientific refrigeration units.

In their properties, these materials differ significantly from the well-known food grade stainless steel, from which dishes and kitchen equipment are made.

Carbon tool steels

Tool steels are a special group of steels with specific properties. These steels are intended for the manufacture of cutting and measuring tools and dies.

requirements are imposed on carbon tool steels :

- steels for cutting tools (cutters, drills, taps, milling cutters, etc.) must have high hardness, wear resistance and heat resistance;

- steels for measuring instruments must be hard, wear-resistant and retain the dimensions and shape of the instrument for a long time;

- steels for dies (cold and hot deformation) must have high mechanical properties (hardness, wear resistance, toughness) that are preserved at elevated temperatures;

- Steels for hot deformation dies must be resistant to the formation of surface cracks during repeated heating and cooling.

Tool carbon steels (GOST 1435–99) are produced in the following grades: U7, U8, U8G, U9, U10, U11, U12 and U13. The numbers indicate carbon content in tenths of a percent. The letter G, for example U8G, after the number means that the steel has a high manganese content, which ensures greater hardness of the alloy.

The grade of high-quality tool carbon steel has the letter A, for example U12A: high-quality tool carbon steel containing 1.2% C. Tools whose use is associated with impact loads, for example chisels, bits, hammers, are made from steels U7A, U8A . Tools that require great hardness but are not subject to impact, such as drills, taps, reamers, scrapers, files, are made from steels U12A, U13A . Steels U7-U9 are subjected to complete hardening, and steels U10-U13 are subjected to incomplete hardening.

The disadvantage of carbon tool steels is their low heat resistance - the ability to maintain greater hardness at high heating temperatures. When heated above 200°C, tools made of carbon steels lose hardness, i.e. at elevated temperatures it is necessary to use tools made of other steels.

Carbon and alloy steels (page 1 of 2)

ABSTRACT

on the topic: “Carbon and alloy steels”

Carbon steel is an alloy of iron and carbon (carbon content up to 2%) with impurities of silicon, sulfur and phosphorus, and the main component that determines the properties is carbon. The percentage of elements in steel is approximately the following: Fe - up to 99.0; C - 0.05-2.0; Si – 0.15-0.35; Mn – 0.3-0.8; S – up to 0.06; P – up to 0.07. Depending on the carbon content, carbon steels are divided into low-carbon (up to 0.25% C), medium-carbon (0.25-0.6% C) and high-carbon (more than 0.6% C). There are carbon steels of ordinary quality and high-quality structural ones. The first group includes hot-rolled (sectioned, shaped, thick-sheet, thin-sheet, broad-sheet) and cold-rolled (thin-sheet) steel; the second includes hot-rolled and forged billets with a diameter (or thickness) of up to 250 mm, calibrated steel and silver. Carbon steel is the most common type of ferrous metal.

Structural

carbon steel is steel containing up to 0.65-0.70% carbon (as an exception, structural steels containing 0.85% carbon are produced). Structural steel is used for the manufacture of machine parts and structures. It must have sufficient strength, resist shock well and at the same time be well processed.

Based on quality, structural steel is divided into three groups:

- ordinary quality;

— improved quality;

- high quality.

Ordinary quality steel is widely used steel, used for building structures, fasteners, rolled sheets, rivets, pipes, fittings, bridges, rolled profiles.

High quality steel is used for locomotive and carriage axles, tires, boilers, wire, etc.

High-quality steel is used for parts that require higher ductility, impact resistance, operating at high pressures: for gears, pipes, screws, bolts, for parts subject to carburization, for welded products.

Instrumental

Carbon steel is steel with a carbon content of 0.7% or higher. This steel is characterized by high hardness and strength and is used to make tools. Tool carbon steel is divided into high-quality and high-quality. The content of sulfur and phosphorus in high-quality tool steel is 0.03% and 0.035%, in high-quality tool steel it is 0.02% and 0.03%, respectively.

Produced in accordance with GOST 1435-90 of the following grades: U7; U8; U8G; U9; U10; U11; U12; U13; U7A; U8A; U8GA; U9A; U10A; U11A; U12A; U13A. The standard applies to carbon tool hot-rolled, forged, calibrated steel, and silver.

The group of high-quality steels includes steel grades without the letter A; the group of high-quality steels, purer in sulfur and phosphorus content, as well as impurities of other elements, includes steel grades with the letter A. The letters and numbers in the designation of these steel grades mean: U - carbon, the number following it is the average carbon content in tenths of a percent, G is the increased manganese content.

Applications of Carbon Steel Tools

| U7, U7A | For processing wood: axes, cleavers, chisels, chisels; small pneumatic tools: chisels, crimpers, strikers; forging dies; needle wire; plumbing tools: hammers, sledgehammers, bits, screwdrivers, combination pliers, needle-nose pliers, side cutters, etc. |

| U8, U8A, U8G, U8GA, U9, U9A | For the manufacture of tools operating in conditions that do not cause heating of the cutting edge; wood processing: milling cutters, countersinks, forgings, axes, chisels, chisels, longitudinal and circular saws; knurling rollers, plates and cores for injection molds of tin-lead alloys. For plumbing and assembly tools: crimpers for rivets, punches, bits, screwdrivers, combination pliers, needle-nose pliers, side cutters. For calibers of simple shape and lower accuracy classes; cold-rolled heat-treated strip with a thickness of 2.5 to 0.02 mm, intended for the manufacture of flat and twisted springs and spring parts of complex configurations, valves, probes, reeds, lamellas of splitting knives, structural small parts, including for watches, etc. d. |

| U10A, U12A | For heart patients. |

| U10, U10A | For needle wire. |

| U10, U10A, U11, U11A | For the manufacture of tools operating in conditions that do not cause heating of the cutting edge; wood processing: hand saws and carpentry saws, machine carpentry saws, spiral drills; cold stamping dies (drawing, heading, trimming and cutting) of small sizes and without sharp transitions in cross-section; calibers of simple shape and lower accuracy classes; knurling rollers, files, bench scrapers, etc. For files, scrapers of cold-rolled heat-treated tape with a thickness of 2.5 to 0.02 mm, intended for the manufacture of flat and twisted springs and spring parts of complex configurations, valves, probes, reeds, lamellas of splitting knives , structural small parts, including for watches, etc. |

| U12, U12A | For hand taps, files, metalwork scrapers; dies for cold stamping of cut and die cut small sizes and without cross-sectional transitions, cold heading punches and stamps of small sizes, gauges of simple shape and reduced accuracy classes. |

| U13, U13A | For tools with reduced wear resistance at moderate and significant specific pressures (without heating the cutting edge); files, razor blades and knives, sharp surgical instruments, scrapers, engraving instruments. |

Disadvantages of carbon steel include:

— lack of a combination of strength and hardness with plasticity;

— loss of hardness and cutting ability when heated to 200°C and loss of strength at high temperatures;

— low corrosion resistance in an electrolyte environment, in aggressive environments, in the atmosphere and at high temperatures;

— low electrical properties;

— high coefficient of thermal expansion;

- an increase in the weight of products, an increase in their cost, and a complication of design due to the low strength of this steel.

Alloy steels:

Alloyed steel is a steel in which, along with the usual impurities, there are alloyed elements that dramatically improve its properties: chromium, tungsten, nickel, vanadium, molybdenum, etc., as well as silicon and manganese in large quantities. Impurities are introduced during the smelting process.

According to the chemical composition (GOST 5200), alloy steel is divided into three groups:

— low-alloy steel – no more than 2.5% impurities;

- medium alloyed - 2.5-10%;

– highly alloyed – over 10%.

Alloy steel has valuable properties that carbon steel does not have, and does not have its disadvantages. The use of alloy steel increases the durability of products, saves metal, increases productivity, simplifies design, and therefore becomes crucial in advanced technology. According to their purpose, alloy steels are usually divided into structural steels, tool steels and steels with special properties (electrical, stainless, heat-resistant, etc.).

Structural

Alloy steel is divided into high-quality, high-quality A and especially high-quality Sh (electroslag remelting).

Depending on the main alloying elements, this steel is divided into groups:

Chromium steel has a very wide range of applications. Chromium has a positive effect and is an inexpensive impurity. Steel grades 15Х, 20Х, 30ХА are used for parts in the automotive and tractor industries. Chromium steels with a high content of carbon (0.9-1.1%) and chromium (0.8-1.65%) are used for the manufacture of rings, balls and rollers of ball bearings. Their brands: ShKh6, ShKh9, ShKh15SG, ShKh10. They have good hardness.

Manganese steel, after appropriate chemical and thermal treatment, acquires high hardness without reducing ductility. Processes better than carbon. Steel grades 15G, 20G, 30G, etc. are widely used in production. High wear resistance.

Chromium-nickel steel is one of the most common structural steels, since after heat treatment it acquires high hardness, strength, elasticity and resistance to impact loads; its brands are 20ХНА, 12Х2Н4А, 12ХН3А

Chrome-silicon steel has high hardness and elasticity after heat treatment and is widely used for the manufacture of springs and springs.

Chromium-manganese steel partially replaces chromium-nickel steel (in order to save nickel). Steel grades 20KhG, 20KhGR, 40KhGR, 30KhSS, 18KhGT are widely used; the latter goes for car parts.

Chromium-manganese-silicon steel (chromansil) is a substitute for chromium-molybdenum steels. With a low carbon content, it is easily stamped and welded. Brand - 25ХGSD, 14ХГСА, 30ХГСА.

Chrome vanadium steel has high strength, ductility, hardness, and elasticity. Steel grade 50ХВА is used for critical springs, grade 15ХФ is used for shafts, gears, and couplings.

Chrome-molybdenum steel has high ductility and good weldability; many of these steels are heat-resistant at temperatures of 400-500°C. Steel grade 30ХМА is used for the manufacture of rotors, axles, and gears.

Chromium-nickel-tungsten and chromium-nickel-molybdenum steels are intended for loaded machine parts, gears, crankshafts, and highly loaded connecting rods. The grades of this steel are 30KhNVA, 40KHNVA, 40KHNMA, 25KH2N4VA.

Instrumental

alloy steel. This steel is used for the manufacture of various tools: impact-stamping, measuring, cutting. It has a number of advantages over tool carbon steel. Carbon steel dies have high hardness and strength, but have poor impact resistance. Taps, reamers and other long and thin tools made of carbon steel become brittle when hardened, they are unreliable in operation and often break.

Alloy tool steels

Alloyed tool steels have GOST 5950–2000. Alloying elements introduced into tool steels increase heat resistance (tungsten, molybdenum, cobalt, chromium), hardenability (manganese), toughness (nickel), wear resistance (tungsten). Compared to carbon alloy tool steels, they have the following advantages :

- good hardenability;

- high ductility in the annealed state;

- significant strength in the hardened state, higher cutting properties.

Low-alloy tool steels contain up to 2.5% alloying elements, have high hardness (HRC 62...69), significant wear resistance, but low heat resistance (200...260°C). They are used to make tools of more complex shapes. In low-alloy steels X, 9ХС, ХВГ, ХВСГ, the main alloying element is chromium . Steel X is alloyed with chromium only. The increased chromium content increases its hardenability. Steel X is calcined in oil completely in a section up to 25 mm, steel U10 - only in a section up to 5 mm.

X steel is used for the manufacture of turning, planing and slotting tools. Steel 9ХС , in addition to chromium, is alloyed with silicon. Compared to steel X, it has greater hardenability - up to 35 mm; increased heat resistance - up to 250...260°C (steel X - up to 200...210°C) and better cutting properties. Drills, reamers, cutters, taps, and dies are made from 9ХС steel. HVG steel is alloyed with chromium, tungsten and manganese ; has hardenability to a depth of 45 mm. HVG steel is used for the production of large and long broaches, long taps, long reamers, etc.

KhVSG steel is a complex alloy and, in comparison with 9ХС and KhVG steels, is better hardened and calcined. When cooled in oil, it is completely calcined in a cross section of up to 80 mm. It is less sensitive to overheating. Its heat resistance is the same as that of 9XC steel. HVSG is used for the manufacture of round dies, reamers, large broaches and other cutting tools.

High-alloy tool steels contain tungsten, chromium and vanadium in large quantities (up to 18% of the main alloying element); have high heat resistance (600...640°C). They are used to manufacture high-performance cutting tools designed for processing high-strength steels and other difficult-to-cut materials. Such steels are called high-speed (GOST 19265–73). High-speed steels are designated by the letter P, the number after which indicates the tungsten content. The content of chromium (4%) and vanadium (2%) in high-speed steel grades is not indicated. Some high-speed steels additionally contain molybdenum, cobalt and large amounts of vanadium. The grades of such steels contain, respectively, the letters M, K, F and numbers indicating their quantity. For the manufacture of measuring instruments, X, HVG and other steels are used, the chemical composition of which is given in GOST 5950–2000.

For a measuring tool, the change in dimensions of a hardened tool over time is of great importance. Therefore, when heat treating a measuring instrument, attention is paid to stabilizing the stress state. This is achieved by low tempering mode - at a temperature of 120...130°C for 15...20 hours and processing at temperatures below zero (down to –60°C).

Cold deformation dies of small size (25...30 mm cross-section), simple shape, working in light conditions, are made from carbon steels U10, UN, U12. Dies with a cross section of 75...100 mm of more complex shape and for more severe working conditions are made from steels of increased hardenability X, KhVG. To produce tools with high hardness and increased wear resistance , as well as low deformability during hardening, steels with high hardenability and wear resistance are used, for example high-chromium steel Kh12F1 (11...12.5% Cr; 0.7...0.9% V).

For tools that are exposed to high impact loads (such as pneumatic chisels, cutting knives for cold metal cutting shears), steels with a lower carbon content and high viscosity are used - 4ХС, 6ХС, 4ХВ2С, etc.

Hot deformation hammer dies are made from steels 5ХНМ, 5ХГМ, 5ХНВ. These steels contain the same amount (0.5...0.6%) of carbon and are alloyed with chromium. This carbon content makes it possible to obtain a fairly high impact strength; chromium increases the strength and hardenability of steels. Nickel is introduced into these steels to increase toughness and improve hardenability. Tungsten and molybdenum increase hardness and heat resistance, reduce brittleness, refine grain, and reduce the tendency of steel to overheat. Manganese, as a cheaper alloying element, is a substitute for nickel. Hammer die steels are characterized by deep hardenability .

Alloy steels

By adding certain substances to the composition of steel alloys, the necessary properties can be achieved; this operation is called alloying. For example:

- Chromium - increases hardness, strength, corrosion resistance, but impairs ductility.

- Nickel - increases ductility and corrosion resistance, but can reduce hardness; it is often used together with manganese.

- Tungsten , molybdenum - impart hardness, enhance heat resistance, reduce brittleness during tempering.

- Manganese - optimizes impact resistance and hardness without compromising ductility.

- Aluminum – improves heat resistance, as well as scale resistance and corrosion resistance.

- Silicon – makes the metal strong while maintaining its toughness. Improves electrical resistance, elasticity, acid resistance. Compared to other alloying elements, it is less expensive.

Alloy steels, having unique qualities, are used for the production of products where they cannot be replaced by other materials. They are classified according to purpose, structure, percentage of alloying elements, and chemical composition.