cutting

| Initial data | Machinability Ku |

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | 103–107 | 460 | 2,1 | 1,65 |

Characteristics of steel grade St0

St0 - Structural carbon steel of ordinary quality, welds well, welding is carried out without heating and without subsequent heat treatment, welding methods: manual arc welding, automatic submerged arc welding and gas protection, KTS, ESW.

Steel welding methods 0:

- manual arc welding

- manual argon arc welding

- automatic submerged arc welding

- mechanized welding with a consumable electrode in a carbon dioxide environment

- electroslag welding

- contact welding

For welding with a thickness of more than 36 millimeters, heating and subsequent heat treatment are recommended; it is not prone to flake sensitivity, and there is no tendency to temper brittleness. Machinability by cutting in the hot-rolled state at НВ 103-107 and σв=460 MPa, Kυ hard alloy. = 2.1 and Kυ b.st. = 1.65, has found its application in load-bearing elements of welded and non-welded structures and parts operating at positive temperatures, and is actively used in general construction solutions. This grade of steel is used to produce parts and components of freight cars, power transmission line supports, excavators and forestry equipment, offshore structures, road bridges, building structures, oil and gas platforms. Forging is carried out at temperatures from 1300 to 700 0C, cooling is carried out in air.

Material St0 – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | st | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa |

| Rental | 535–2005 | 15–18 | 300 |

| The leaf is thick | 14637–89 | 20–23 | 300 |

| Wire rod | 30136–95 | 58–68 | 420–470 |

Delivery St0

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

Grade St0 – physical properties

| t | r | R 109 | E 10-5 | l | a 106 | C |

| 0C | kg/m3 | Ohm m | MPa | W/(m deg) | 1/Grad | J/ (kg deg) |

| 20 | 7850 |

Delivery type St0

| B20 - Classification, nomenclature and general standards | GOST 380-2005; |

| B22 – Long and shaped rolled products | GOST 535-2005; GOST 5422-73; GOST 8239-89; GOST 8240-97; GOST 8278-83; GOST 8281-80; GOST 8283-93; GOST 8510-86; GOST 8509-93; GOST 30136-95; GOST 9234-74; GOST 10551-75; GOST 30565-98; GOST 19771-93; GOST 19772-93; GOST 19240-73; GOST 2590-2006; GOST 2591-2006; GOST 19425-74; GOST 2879-2006; GOST 11474-76; |

| B23 - Sheets and strips | GOST 8568-77; GOST 14637-89; GOST 14918-80; GOST 103-2006; GOST 19903-74; GOST 82-70; |

| B24 - Tapes | GOST 6009-74; GOST 3560-73; |

| B34 - Tapes | GOST 503-81; |

| B62 — Steel pipes and connecting parts for them | GOST 3262-75; |

| B71 – Low carbon steel wire | GOST 3282-74; |

| B72 – Medium and high carbon steel wire | GOST 17305-91; |

Steel St0 - exact and closest foreign analogues

| Austria | England | Belgium | Bulgaria | Hungary | Germany | European Union | Spain | Italy |

| ONORM | B.S. | NBN | BDS | MSZ | DIN, WNR | EN | UNE | UNI |

| St00H |

15HR

FE310-0

ASt0

Fe310O

1.0035

|

| 1.0035 |

| Fe310-0 |

| S185 |

| St33 |

| St33-1 |

| St33-2 |

1.0035

A310-0

Fe320

| Inter | China | Poland | Romania | USA | France | Czech | Sweden | Japan |

| ISO | G.B. | PN | STAS | — | AFNOR | CSN | SS | JIS |

| E185 |

| Fe310 |

Q195

St0S

OL32.1

A283(A)

A33

10000

1300

SS330

Brand: steel, metal St0

Brand: St0

| Brand: | St0 |

| Classification: | Structural carbon steel of ordinary quality |

| Application: | for minor aspects of structures and non-critical parts: decking, fittings, lining, washers, railings, casings, cladding and others. |

| Foreign analogues: |

| C | S | P |

| up to 0.23 | up to 0.06 | up to 0.07 |

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Rolled goods, GOST 535-2005 | 300 | 15-18 |

| Thick sheet, GOST 14637-89 | 300 | 20-23 |

| Wire rod, GOST 30136-95 | 420-470 | 58-68 |

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 7850 |

Foreign analogues of the material

Both exact and closest analogues are indicated!

| USA | Germany | Japan | France | England | European Union | Italy | Belgium | Spain | China | Sweden | Bulgaria | Hungary | Poland | Romania | Czech | Austria | Inter |

| — | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | NBN | UNE | G.B. | SS | BDS | MSZ | PN | STAS | CSN | ONORM | ISO |

|

| Gr.A |

|

| Fe310-0 |

| S185 |

| St33 |

| St33-1 |

| St33-2 |

| | | | | | | | | | Mechanical properties : | | sв | — Short-term strength limit, [MPa] | | sT | — Proportional limit (yield strength for permanent deformation), [MPa] | | d5 | — Elongation at break, [%] | | y | — Relative narrowing, [%] | | KCU | — Impact strength, [kJ/m2] | | HB | — Brinell hardness, [MPa] |

| Physical properties: | | T | — Temperature at which these properties were obtained, [Deg] | | E | — Modulus of elasticity of the first kind, [MPa] | | a | — Coefficient of thermal (linear) expansion (range 20o - T), [1/degree] | | l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] | | r | — Material density, [kg/m3] | | C | — Specific heat capacity of the material (range 20o — T), [J/(kg deg)] | | R | — Electrical resistivity, [Ohm m] |

| Weldability: | | no limits | — welding is performed without heating and without subsequent heat treatment | | limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment | | difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

|

|

|

|

|

|

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Mechanical properties of steel St0

Mechanical properties of steel St0 according to GOST 380-94 regulations is sold in the form of hot-rolled steel with a cross-section of up to 20 mm, from 20 mm to 40 mm, over 40 mm to 100 mm, and also over 100 mm. Tensile strength 300-470 MPa. Relative elongation after rupture is 23 – 26%.

Mechanical properties of St3ps steel according to the regulations of GOST 16523-89 and GOST 19903-2006 in the form of hot-rolled sheets. The cross-section is made from 1.5 mm inclusive to 100 mm inclusive. The elongation rates after rupture are 15%, 18%, 20 and 23%. Below is the data in tabular form:

| ND | Heat treatment mode | Section, mm | σв, N/mm2 | δ, % | Bend |

| no less |

| GOST 535-2005 | Hot rolled | Up to 20 | 300 | 18 |

| Over 20 to 40 | 300 | 18 |

| Over 40 | 300 | 15 |

| GOST 14637-89 | Hot rolled | Up to 20 | 300 | 23 | d=2.5a |

| St. 20 to 40 | 300 | 23 | d=3.5a |

| St. 40 to 160 | 300 | 20 | d=3.5a |

| GOST 380-71 (not supplied) | Hot rolled products | Up to 20 | 300 | 23 |

| St. 20 to 40 | 300 | 22 |

| St. 40 | 300 | 20 |

| GOST 16523-70 (Transverse samples) (not supplied) | Hot rolled sheets | Up to 2.0 | 300 | -11 |

| St. 2.0 to 3.9 | 300 | -13 |

| Cold rolled sheets | Up to 2.0 | 300 | -14 |

| St. 2.0 to 3.9 | 300 | -16 |

Steel St0 – State Enterprise Stalmash

reference Information

Characteristics of the material: steel St0.

Steel grade: St0

Steel classification: Structural carbon steel of ordinary quality

Application of steel St0: For minor aspects of structures and non-critical parts: decking, fittings, lining, washers, railings, casings, cladding and others.

Mechanical properties at T=20oC steel St0.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m 2 | — |

| Rolled hot rolled products. | up to 20 | 300 | 23 |

| Rolled hot rolled products. | 20 — 40 | 300 | 22 |

Technological properties of steel St0.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Foreign analogues of steel St0 Attention! Both exact and closest analogues are indicated.

| USA | Germany | Japan | France | England | European Union | Italy | Belgium | Spain | China | Sweden | Bulgaria | Hungary | Poland | Romania | Czech | Austria |

| — | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | NBN | UNE | G.B. | SS | BDS | MSZ | PN | STAS | CSN | ONORM |

|

| Fe310-0 |

| S185 |

| St33 |

| St33-1 |

| St33-2 |

Designations:

| Mechanical properties : |

| sв | — Short-term strength limit, [MPa] |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

| Weldability: |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

yaruse.ru

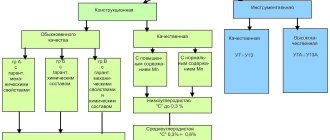

Structural carbon steel of ordinary quality St0 - characteristics, properties, analogues

This page shows the technical, mechanical and other properties, as well as the characteristics of steel grade St0.

Classification of material and application of grade St0

Brand: St0 Material classification: Structural carbon steel of ordinary quality Application: for minor aspects of structures and non-essential parts: decking, fittings, lining, washers, railings, casings, cladding and others.

Chemical composition of material St0 as a percentage

| C | S | P |

| up to 0.23 | up to 0.06 | up to 0.07 |

Mechanical properties St0 at a temperature of 20oC

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Rolled goods, GOST 535-2005 | 300 | 15-18 |

| Thick sheet, GOST 14637-89 | 300 | 20-23 |

| Wire rod, GOST 30136-95 | 420-470 | 58-68 |

Technological properties St0

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Explanation of symbols, abbreviations, parameters

| Mechanical properties : |

| sв | — Short-term strength limit, [MPa] |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

| Physical properties: |

| T | — Temperature at which these properties were obtained, [Deg] |

| E | — Modulus of elasticity of the first kind, [MPa] |

| a | — Coefficient of thermal (linear) expansion (range 20o— T), [1/degree] |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | — Material density, [kg/m3] |

| C | — Specific heat capacity of the material (range 20o—T), [J/(kg deg)] |

| R | — Electrical resistivity, [Ohm m] |

| Weldability: |

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Other brands in this category:

Please note that this information about the St0 brand is provided for informational purposes. The parameters, properties and composition of the actual St0 grade material may differ from the values given on this page. More detailed information about the St0 grade can be found on the information resource Brand of steel and alloys. You can check with our managers for information about the availability, delivery times and cost of materials. If you find inaccuracies in the description of materials or errors found, please inform the site administrators using the feedback form. Thanks in advance for your cooperation!

c-met.ru

Steel grade St0 technical specifications, explanation

Purpose of steel St0

St0 steel is used for minor structural elements and non-critical parts: decking, fittings, lining, washers, railings, casings, cladding and others.

Substitute, analogues

No data

Chemical composition of steel St0, % (GOST 380-71)

Mechanical properties

| GOST | Delivery status | Section, mm | σв, MPa | δ5, δ4, % |

| no less |

| 380-71 | Hot rolled products | Up to 20 Over 20 Up to 40 Over 40 | 300 | 23 22 20 |

| 16523-70 (Transverse samples) | Hot rolled sheets

Cold rolled sheets | Up to 2.0 incl. St. 2.0 to 3.9 incl. Up to 2.0 incl. St. 2.0 to 3.9 incl. | 300 | (11) (13) (14) (16) |

At σв = 305 MPa, endurance limit σ-1 = 167 MPa

Technical characteristics of steel St0

Forging temperature, °C: beginning 1300, end 700. Weldability - weldable without restrictions; welding methods: RDS, ADS under submerged arc and gas shield, ESW and KTS. Machinability by cutting - in the hot-rolled state at HB 103-107 and σв = 460 MPa Kνb. st = 1.65 and Kνtv. spl = 2.1. Tendency to temper brittleness - not prone. Flock sensitivity - not sensitive.

Corrosion resistance

| Wednesday | Test temperature, °C | Corrosion rate, mm/year |

| Sea water | 20 | 0,105 |

Type of delivery

Long products, including shaped steel: GOST 380-71, GOST 2590-71, GOST 2591-71, GOST 19771-74, GOST 19772-74, GOST 8278-75, GOST 8281-80, GOST 8283-77, GOST 8509 -86, GOST 8910-86, GOST 8239-72, GOST 8240-72. Thick sheet GOST 19903-74.

Thin sheet GOST 19903-74. Tape GOST 503-81, GOST 6009-74. Strip GOST 103-76, GOST 82-70. Wire GOST 3282-74, GOST 17305-71.

enginiger.ru

Steel 3kp - decoding of steel grade, GOST, material characteristics

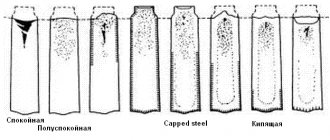

Steel grade - St3kp

Standard - GOST 380

Substitute - St3ps

Letters St

denote carbon steels of ordinary quality, number

3

- indicates the conventional number of the steel grade,

kp

- degree of deoxidation of steel (boiling).

Carbon steel of ordinary quality St3kp is used for minor and lightly loaded elements of welded and non-welded structures operating in the temperature range from -40 to 400°C.

| Mass fraction of basic chemical elements, % |

| C - carbon | Mn - manganese | Si - silicon |

| 0,14-0,22 | 0,30-0,60 | No more than 0.05 |

| Temperature of critical points, °C |

| Ac1 | Ac3 | Ar1 | Ar3 |

| 735 | 850 | 680 | 835 |

| Technological properties |

| Forging | Forging temperature, °C: beginning 1300, end 750. Cooling in air. |

| Weldability | Weldable without restrictions. Welding methods: manual arc welding, automatic arc welding, electroslag welding, resistance welding. For thicknesses greater than 36 mm, heating and mandatory subsequent heat treatment are recommended. |

| Machinability | In the hot-rolled state at HB 124 and σв = 400 MPa: Kv carbide = 1.8 Kv high-speed steel = 1.6 |

| Flokensensibility. | Not sensitive |

| Tendency to temper brittleness | Not inclined |

tekhnar.ru