The figure below shows eight typical states of industrial steel ingots that have been cast into identical, tapered molds. They are arranged and numbered according to the degree of suppression of gas emission during solidification. The dashed lines indicate the level to which the steel was initially poured in each mold. Depending on the carbon content, and even more so on the oxygen content, the structure of the ingots varies. Number 1 is completely calmed steel, calmed steel

, and number 8 - steel to which deoxidation operations were not applied, highly

boiling steel

.

Figure - Eight typical states of industrial steel ingots with varying degrees of deoxidation

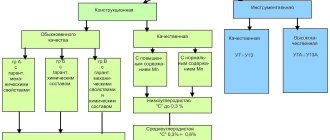

When cast into ingots, steels are classified into three main types depending on the degree of deoxidation or, which is the same, according to the amount of gases released during the solidification of the ingot.

These four types include: - mild steel; - semi-quiet steel

; - boiling steel.

Carbon steel - classification, marking and application

Steel is an alloy consisting of two essential components - iron and carbon. Additional elements: silicon less than 1%, manganese less than 1%, sulfur less than 0.05%, phosphorus less than 0.06%. Carbon content no more than 2.14%. Alloys with a C percentage greater than 2.14% are classified as cast iron. Based on their chemical composition, steel grades are divided into carbon and alloy, which contain additional additives that give the material the desired characteristics. Carbon steel alloys are classified according to the degree of deoxidation, carbon content, and quality.

Semi-quiet steel

In semi-quiet steel, the release of gases during its deoxidation is not completely suppressed, since the steel is only partially deoxidized. In English it is called semikilled

steel

. The degree of gas evolution in these steels is greater than in calm steels, but less than in boiling steels. Before the release of gases begins, a crust of considerable thickness forms in the ingot. A properly “semi-deoxidized” steel ingot does not have a shrinkage cavity, but there are bubbles widely dispersed throughout the thickness in the central zone of the upper part of the ingot. These bubbles, however, are sealed when the ingot is rolled. Semi-quiet steels typically have a carbon content of 0.15 to 0.30%. They are widely used in the production of long products, strips and pipes.

The main differences between semi-quiet steels are: 1) different degrees of heterogeneity of the chemical composition - average between the degrees of calm and boiling steels; 2) less segregation of chemical elements than in plain steel; 3) a pronounced tendency for positive chemical segregation in the center of the upper part of the ingot (figure).

Classification of carbon steels by degree of deoxidation

Calm

Such alloys have the most uniform structure. For deoxidation, aluminum, ferrosilicon and ferromanganese are used, which almost completely remove the gases present in the melt. The combination of the almost complete absence of gases with a fine-grained structure due to the presence of residual aluminum ensures good quality of the metal. These grades are suitable for the manufacture of parts, products and structures for critical purposes. The main disadvantage is the high cost.

Boiling

This is the cheapest and least quality group. Due to the use of a minimal amount of additives for deoxidation, dissolved gases are present in the material, which cause heterogeneity in the structure, chemical composition, and therefore mechanical properties. Such metals have poor weldability, since due to the presence of gases there is a high probability of cracks forming at the seams.

Semi-calm

The group occupies an intermediate position in terms of cost and characteristics. Much fewer gas bubbles form in the casting compared to boiling steels. When rolling, internal defects in the bulk are eliminated. Such materials are often used as structural alloys.

content .. 57 58 59 60 ..0.01.1.01.OE(m)-I. Tickets with answers for certification according to NAKS

General exam General exam. (m) Level: I (with answers)

1

| Question_OE/1 Which ordinary quality steel is classified as boiling steel? | |

| 1. | Steel not completely deoxidized by manganese during smelting, and containing no more than 0.05% silicon. |

| 2. | Containing silicon from 0.05 to 0.17%. |

| 3. | Containing more than 10 ml. hydrogen per 100 g of metal. |

| 2 | Question_OE/1 What type of steel of ordinary quality is considered mild steel? |

| 1. | Steel, completely deoxidized during smelting and containing 0.15-0.3% silicon |

| 2. | Containing at least 0.3% silicon and 1% manganese. |

| 3. | Containing less than 0.5 ml. hydrogen per 100 g of metal. |

| 3 | Question_OE/1 Which ordinary quality steel is classified as semi-quiet? |

| 1. | Steel deoxidized during smelting only with manganese and containing no more than 0.05% silicon. |

| 2. | Steel that is not completely deoxidized during smelting with only manganese and silicon and contains 0.05 - 0.15% silicon and up to 1% manganese |

| 3. | Containing less than 10 ml. hydrogen per 100 g of metal |

| 4 | Question_OE/1 What class of steels do welding wires Sv-08, Sv08A, Sv-08GA, Sv-10GA belong to? |

| 1. | Low carbon. |

| 2. | Alloyed. |

| 3. | Highly alloyed. |

| 5 | Question_OE/1 What are alloy steels? |

| 1. | Containing one or more elements in certain concentrations, which are introduced into them in order to impart specified physicochemical and mechanical properties. |

| 2. | Possessing certain physical and chemical properties due to reduction in the content of carbon, sulfur, phosphorus or heat treatment. |

| 3. | Possessing certain physical and chemical properties after special thermomechanical treatment. |

| 6 | Question_OE/1 What weldability do low-carbon steels have? |

| 1. | Good. |

| 2. | Satisfactory. |

| 3. | Bad. |

| 7 | Question_OE/1 What do the letters and numbers mean in the marking of low-alloy steels? |

| 1. | Manufacturer's marks. |

| 2. | Designation of heat number and batch of metal. |

| 3. | Designation of chemical elements and their percentage composition. |

| 8 | Question_OE/1 Which of the following steels are carbon steels? |

| 1. | St3sp, steel10, steel 15, steel 18kp |

| 2. | 09G2S, 17G1S, 09G2FB. |

| 3. | 08Х18Н9, 10Х2М, 15ХМ. |

| 9 | Question_OE/1 What letter of the Russian alphabet denotes carbon and nickel in the marking of alloy steels? |

| 1. | Carbon - "U"; nickel - "N". |

| 2. | Carbon - “C”; nickel - "L". |

| 3. | Carbon is not represented by a letter; nickel - "N". |

| 10 | Question_OE/1 What changes in properties occur during hardening of low-carbon steels? |

| 1. | Plasticity increases, strength characteristics do not change |

| 2. | Strength characteristics increase, ductility decreases |

| 3. | Both strength and ductility increase |

| 11 | Question_OE/1 What are the main characteristics accepted for assessing the mechanical properties of metals? |

| 1. | Tensile strength, yield strength, elongation and contraction, hardness, impact strength. |

| 2. | Heat resistance, heat resistance and cold resistance of the metal. |

| 3. | Hardness, bending resistance and number of shock loading cycles before metal failure. |

| 12 | Question_OE/1 Why are alloying elements added to steel? |

| 1. | To impart special properties to steel. |

| 2. | To improve the weldability of steel. |

| 3. | To reduce the content of harmful impurities (sulfur and phosphorus) in steel. |

| 13 | Question_OE/1 Indicate how St3kp differs from St3sp? |

| 1. | Carbon content. |

| 2. | Silicon content. |

| 3. | Content of harmful impurities S and P and gases. |

| 14 | Question_OE/1 Why is pre- and post-heating performed? |

| 1. | To reduce the number of defects in the weld and HAZ. |

| 2. | To level out uneven heating during welding, reduce the cooling rate and reduce the likelihood of cold cracks. |

| 3. | To reduce the hydrogen content in the weld metal. |

| 15 | Question_OE/1 What characteristics can be determined by tensile testing of metal samples? |

| 1. | Yield strength, tensile strength. |

| 2. | Bend angle. |

| 3. | Yield strength, tensile strength, relative elongation and transverse contraction. |

| 16 | Question_OE/1 What characteristic is determined by static bending? |

| 1. | Bend angle. |

| 2. | Bending toughness. |

| 3. | Bending strength. |

| 17 | Question_OE/1 What characteristics of the metal are determined during bending (flat samples) and flattening (pipes) tests? |

| 1. | Strength. |

| 2. | Plastic. |

| 3. | Strength and ductility. |

| 18 | Question_OE/1 What characteristics are determined during impact bending? |

| 1. | Impact bending strength. |

| 2. | Impact strength. |

| 3. | Relative elongation during impact bending. |

| 19 | Question_OE/1 What can be assessed by the type of fracture of a welded joint? |

| 1. | Strength, corrosion resistance, density. |

| 2. | The structure of the metal, its continuity and draw a qualitative conclusion about the plastic properties of the metal. |

| 3. | Presence and quantity of harmful impurities. |

| 20 | Question_OE/1 How does high sulfur and phosphorus content affect the weldability of steel? |

| 1. | Does not affect. |

| 2. | Increases weldability when the steel is preheated. |

| 3. | Promotes the appearance of cracks and impairs the weldability of steel. |

| 21 | Question_OE/1 What is a weld in fusion welding? |

| 1. | Crystallized metal from a molten electrode or welding wire. |

| 2. | A section of a welded joint formed as a result of crystallization of molten metal. |

| 3. | Liquid metal obtained by fusion of weldable and filler materials. |

| 22 | Question_OE/1 What determines the properties of a welded joint? |

| 1. | Properties of the weld metal, fusion line with the base metal and heat-affected zone. |

| 2. | Properties of the weld metal and fusion line with the base metal. |

| 3. | Properties of the fusion line with the base metal and the heat-affected zone. |

| 23 | Question_OE/1 How does uneven heating during welding affect the amount of deformation of the base metal? |

| 1. | Increases the amount of deformation. |

| 2. | Does not affect the amount of deformation. |

| 3. | Reduces the amount of deformation. |

| 24 | Question_OE/1 How does an increase in the volume of deposited metal affect the amount of deformation of the base metal? |

| 1. | Reduces the amount of deformation. |

| 2. | Does not affect the amount of deformation. |

| 3. | Increases the amount of deformation. |

| 25 | Question_OE/1 What welding deformations are called residual? |

| 1. | Deformations appearing after welding. |

| 2. | Deformations remaining after welding and complete cooling of the product. |

| 3. | Deformations formed under the influence of operational loads. |

| 26 | Question_OE/1 How does heating of products during the welding process affect the amount of residual deformation? |

| 1. | Increases product deformation. |

| 2. | Reduce product deformation. |

| 3. | Does not affect |

| 27 | Question_OE/1 What determines the amount of deformation of the metal being welded? |

| 1. | From the tendency of steel to harden. |

| 2. | From uneven heating. |

| 3. | From the brand of welding materials. |

| 28 | Question_OE/1 What structural elements characterize the shape of the edges? |

| 1. | Offset edges, angularity. |

| 2. | Bluntness, edge bevel angle. |

| 3. | Method of preparation, clearance. |

| 29 | Question_OE/1 What are the types of welded joints? |

| 1. | Single-sided and double-sided. |

| 2. | Butt, tee, corner, overlap. |

| 3. | Vertical and horizontal. |

| 30 | Question_OE/1 How is a welded joint indicated on a drawing? |

| 1. | The type of connection, welding method and method, and control methods are indicated. |

| 2. | GOST, type of connection, welding method and method, weld leg, length or pitch, special designations are indicated. |

| 3. | The method and method of welding, length or pitch, welding material, methods and scope of control are indicated. |

| 31 | Question_OE/1 What do the numbers next to the letters on the drawing indicating the weld mean? |

| 1. | The serial number of the seam according to GOST (OST). |

| 2. | Welding method and method. |

| 3. | Methods and scope of control. |

| 32 | Question_OE/1 Which line represents a visible weld in the drawing? |

| 1. | Dash-dotted. |

| 2. | Stroke. |

| 3. | Solid. |

| 33 | Question_OE/1 When should each batch of welding consumables be inspected? |

| 1. | Before the start of its production use. |

| 2. | Simultaneously with its use for production. |

| 3. | On time, regardless of its production use. |

| 34 | Question_OE/1 What parameters need to be monitored after preparing parts and assembly units for welding? |

| 1. | Shape, size and quality of edge preparation; correctness of transitions from one section to another; other characteristics and dimensions, the control of which is provided by the PKD and PDD. |

| 2. | The quality of cleaning of edges prepared for welding and adjacent surfaces of parts and assembly units. |

| 3. | All parameters specified in paragraphs. 1 and 2. |

| 35 | Question_OE/1 What are the two main groups of control methods based on the impact on the material of a welded joint? |

| 1. | Destructive and irradiating. |

| 2. | Mechanical and electronic. |

| 3. | Destructive and non-destructive. |

| 36 | Question_OE/1 What is the purpose of visual inspection of a welded joint? |

| 1. | In order to identify surface defects in the seam |

| 2. | In order to identify surface defects and defects in seam formation. |

| 3. | In order to identify non-compliance of the structural dimensions of the seam with the requirements of regulatory and technical documentation. |

| 37 | Question_OE/1 How are defects in the shape of a seam and its size detected? |

| 1. | By radiographic method. |

| 2. | Metallographic studies of the macrostructure. |

| 3. | Measuring tools and special templates. |

| 38 | Question_OE/1 What weld defects are detected using radiographic testing, ultrasonic and other equivalent methods? |

| 1. | Cracks, lack of fusion, lack of fusion, pores, non-metallic and metallic inclusions. |

| 2. | Structural changes in metal, internal stresses. |

| 3. | The quality of seam formation from the inside and outside. |

| 39 | Question_OE/1 What is inclusion? |

| 1. | Generalized name for pores, slag and tungsten inclusions. |

| 2. | Non-metallic discontinuity. |

| 3. | Accumulation of several pores. |

| 40 | Question_OE/1 At what point should defects in welded joints subject to subsequent heat treatment (tempering) be corrected? |

| 1. | Before vacation. |

| 2. | In agreement with the parent materials science organization. |

| 3. | After vacation. |

| 41 | Question_OE/1 What defects are allowed to be eliminated by a welder (without involving the work supervisor) during the process of welding a pipe joint? |

| 1. | Any defects, including cracks. |

| 2. | Cracks and inter-roller lack of fusion. |

| 3. | Surface pores, slag inclusions, lack of fusion between rollers, undercuts. |

| 42 | Question_OE/1 What is a crack called? |

| 1. | A defect in a welded joint in the form of a metal rupture in the weld and/or adjacent areas. |

| 2. | Violation of metal continuity. |

| 3. | Inadmissible deviation from the requirements of the Control Rules. |

| 43 | Question_OE/1 What is called a burn-through? |

| 1. | A cylindrical depression in a weld. |

| 2. | Through hole in the weld. |

| 3. | A funnel-shaped depression in a weld. |

| 44 | Question_OE/1 What is called beading in weld metal? |

| 1. | Irregularities in the surface of the weld metal or deposited metal. |

| 2. | A defect in the form of metal that has flowed onto the surface of the metal being welded and or a previously made bead and has not fused with it. |

| 3. | Failure of fusion of the weld metal bead with the base metal. |

| 45 | Question_OE/1 What is time? |

| 1. | A weld defect in the form of a closed cavity filled with foreign metal. |

| 2. | A weld defect in the form of a spherical cavity filled with slag. |

| 3. | A weld defect in the form of a closed cavity filled with gas. |

| 46 | Question_OE/1 What shape can pores have? |

| 1. | Linear or flat. |

| 2. | Straight and curved. |

| 3. | Spherical and elongated. |

| 47 | Question_OE/1 What is an undercut? |

| 1. | A recess along the line of fusion of the weld with the base metal. |

| 2. | Sharp, cone-shaped indentations at the interface of the weld surface with the previous weld bead or base material. |

| 3. | Sharp cone-shaped depressions at the interface between the surface of the weld and the base material. |

| 48 | Question_OE/1 What is “lack of penetration”? |

| 1. | A defect in the form of a lack of fusion between the weld metal and the base metal along the groove edge. |

| 2. | A defect in the form of lack of fusion in a welded joint due to incomplete melting of the edges or surfaces of previously made weld beads. |

| 3. | A defect in the form of lack of fusion in a welded joint due to incomplete melting of the edges or surfaces of previously made weld beads. |

| 49 | Question_OE/1 How should a removed defective section of a seam be welded if the welding was carried out with preheating? |

| 1. | With slow cooling after welding. |

| 2. | At increased welding modes. |

| 3. | Heated. |

| 50 | Question_OE/1 What are the requirements for the quality of the repaired seam section? |

| 1. | The same as for the main seam. |

| 2. | Additional requirements provided for in regulatory and technical documentation. |

| 3. | Special requirements provided for by regulatory and technical documentation. |

| 51 | Question_OE/1 Are cracks identified during visual inspection allowed in welded joints? |

| 1. | Transverse cracks in welds are allowed. |

| 2. | Cracks of all types and directions are not allowed. |

| 3. | Microcracks with an area of no more than 1 sq. mm are allowed. |

| 52 | Question_OE/2 What is “manual arc welding with a covered electrode”? |

| 1. | Arc welding performed with an electrode that does not melt during welding. |

| 2. | Arc welding, in which the initiation of the arc, supply of the electrode and its movement are carried out manually, and gas-slag protection of the molten metal is provided by the melting and decomposition of the coating components. |

| 3. | Arc welding, in which the arc and weld pool are protected by a flow of shielding gas supplied to the welding zone using special devices. |

| 53 | Question_OE/2 What is “gas shielded arc welding”? |

| 1. | Welding in which protection of the arc and weld pool is provided by gases formed during the melting and combustion of the electrode coating. |

| 2. | Arc welding, in which the arc and molten metal are in a shielding gas supplied to the welding zone using special devices. |

| 3. | Welding in which protection of the arc and weld pool is provided by a layer of welding flux. |

| 54 | Question_OE/2 What is “non-consumable electrode arc welding”? |

| 1. | Arc welding performed with an electrode that does not melt during welding. |

| 2. | Welding performed by two non-consumable electrodes, between which an arc burns. |

| 3. | Arc welding in a carbon dioxide environment. |

| 55 | Question_OE/2 What is “consumable electrode arc welding”? |

| 1. | Arc welding, in which the weld pool is protected by gas formed during the melting of the base metal. |

| 2. | Welding in which the electrode melts due to the heat of the arc or gas flame. |

| 3. | Arc welding performed with an electrode, which, when melted during welding, serves as a filler metal. |

| 56 | Question_OE/2 What is “submerged arc welding”? |

| 1. | Gas shielded arc welding with the addition of flux to alloy the weld metal. |

| 2. | Arc welding, in which an arc burns under a layer of flux between an uncovered metal electrode and the workpiece. |

| 3. | A welding process in which heat is generated by converting electrical energy into thermal energy by passing a current through molten flux. |

| 57 | Question_OE/2 What is the hallmark of flux-cored arc welding? |

| 1. | Use of special powder when welding with solid wire. |

| 2. | The use of an electrode wire consisting of a metal sheath filled with a powdery substance. |

| 3. | The use of special metal chips when welding with solid wire. |

| 58 | Question_OE/2 What is “electroslag welding”? |

| 1. | A welding process in which the base and electrode metals are melted by the heat generated when an electric current passes through a strip electrode |

| 2. | Welding process in which an arc is excited and burns between the electrode and the workpiece under a layer of flux |

| 3. | Fusion welding, which uses the heat generated by passing an electric current through molten slag for heating |

| 59 | Question_OE/2 What is pulsed arc welding? |

| 1. | A process in which welding current and voltage changes according to a certain law. |

| 2. | Arc welding, in which the arc is additionally fed with current pulses according to a given program. |

| 3. | A process in which the welding material is supplied into the weld pool in pulses due to a special drive. |

| 60 | Question_OE/2 What is magnetic arc blowing? |

| 1. | Expansion of the arc as a result of the interaction of the arc's own magnetic field with the field of the welding circuit, extraneous magnetic fields, as well as with ferromagnetic materials. |

| 2. | Deviation of the arc from the axis of the electrode as a result of the action of magnetic fields or ferromagnetic masses during welding. |

| 3. | Compression of the arc and increased penetration as a result of the interaction of the arc’s own magnetic field with the field of the welding circuit, extraneous magnetic fields, as well as with ferromagnetic materials. |

| 61 | Question_OE/2 Where should the current conductor be connected to large products for welding? |

| 1. | In the thickest part of the structure, subject to reliable contact. |

| 2. | In close proximity to the welding site, subject to reliable contact. |

| 3. | The location of the current conductor attachment does not depend on the welding location. |

| 62 | Question_OE/2 What electrical quantity is measured by an electrical device - an ammeter? |

| 1. | The strength of the electric current in the circuit. |

| 2. | Welding circuit voltage. |

| 3. | Power consumed by an electrical circuit. |

| 63 | Question_OE/2 What electrical quantity is measured with an electrical device - a voltmeter? |

| 1. | The strength of the electric current in the circuit. |

| 2. | Voltage in an electrical circuit. |

| 3. | Electrical power consumed by an electrical circuit. |

| 64 | Question_OE/2 How is an ammeter connected to an electrical circuit to measure the strength of electric current? |

| 1. | The ammeter is connected to the electrical target in series with the other elements. |

| 2. | The ammeter is connected in parallel to the section of the circuit in which the electric current is measured. |

| 3. | The ammeter is connected in parallel with the voltmeter. |

| 65 | Question_OE/2 How is a voltmeter connected to an electrical circuit to measure the voltage on a section of the electrical circuit? |

| 1. | The voltmeter is connected in parallel to the section of the circuit at which the voltage is measured. |

| 2. | The voltmeter is connected to the electrical circuit in series with the rest of the circuit elements. |

| 3. | The voltmeter is connected in series with the additional resistor and the remaining elements of the circuit section. |

| 66 | Question_OE/2 What is the main criterion when choosing a wire for electrical circuits? |

| 1. | Based on the permissible current density. |

| 2. | Based on the resistivity of the conductor. |

| 3. | Based on the resistivity of the conductor and its length. |

| 67 | Question_OE/2 What is the frequency of industrial AC power generated by power plants in Russia? |

| 1. | 50 Hz. |

| 2. | 60 Hz. |

| 3. | 100 Hz. |

| 68 | Question_OE/2 At what type of current is higher arc stability ensured? |

| 1. | With variable |

| 2. | At constant. |

| 3. | The stability of the arc does not depend on the type of current. |

| 69 | Question_OE/2 What type of power sources are designed for DC welding? |

| 1. | Welding transformers. |

| 2. | Welding sources of any type. |

| 3. | Welding rectifiers, generators, thyristor power supplies. |

| 70 | Question_OE/2 What is a transformer used for? |

| 1. | For AC frequency conversion. |

| 2. | To convert AC voltage. |

| 3. | To convert DC voltage. |

| 71 | Question_OE/2 What is the idle mode of a welding power source? |

| 1. | The primary winding of the transformer is connected to the network, and the secondary winding to the consumer. |

| 2. | The primary winding of the transformer is connected to the network, and the secondary winding is open-circuit. |

| 3. | The primary winding of the transformer is not connected to the network, and the secondary winding is short-circuited. |

| 72 | Question_OE/2 What type of power source is suitable for AC welding? |

| 1. | Welding transformers. |

| 2. | Welding rectifiers. |

| 3. | Inverter power supplies. |

| 73 | Question_OE/2 What is a welding rectifier? |

| 1. | Converter of network energy into rectified current energy used for welding work. |

| 2. | Generator for converting mains energy into alternating current energy used for welding work. |

| 3. | Generator for converting network energy into rectified current energy used for welding work. |

| 74 | Question_OE/2 What is a welding rectifier? |

| 1. | Transformer and semiconductor rectification unit. |

| 2. | Three-phase transformer and welding generator in a single-case design. |

| 3. | Welding generator and semiconductor rectifier unit. |

| 75 | Question_OE/2 What should a welding power source for manual arc welding be equipped with? |

| 1. | Ammeter |

| 2. | Ammeter and voltmeter |

| 3. | Voltmeter and device for monitoring welding speed |

| 76 | Question_OE/2 Does arc voltage depend on its length? |

| 1. | Depends |

| 2. | Does not depend |

| 3. | Depends on low and high welding current values |

| 77 | Question_OE/2 What external characteristic is most suitable for manual arc welding? |

| 1. | Steeply falling |

| 2. | Tough |

| 3. | Increasing |

| 78 | Question_OE/2 What current-voltage characteristics can welding power sources have? |

| 1. | Falling, flat falling, steep falling and hard. |

| 2. | Falling, hard and rising. |

| 3. | Gently dipping, rigid and steeply rising. |

| 79 | Question_OE/2 What is an oscillator used for? |

| 1. | To initiate an arc and increase the stability of its combustion. |

| 2. | To improve the quality of welds. |

| 3. | To improve the dynamic characteristics of the power supply. |

| 80 | Question_OE/2 How should you connect a DC source when welding with reverse polarity? |

| 1. | Negative pole to electrode. |

| 2. | Positive pole to electrode |

| 3. | Doesn't matter. |

| 81 | Question_OE/2 Which polarity provides greater penetration of the base metal during manual arc welding? |

| 1. | On straight polarity |

| 2. | On reverse polarity |

| 3. | Equally |

| 82 | Question_OE/2 What does the letter “A” mean in the marking of steel 30ХМА, 30ХГСА? |

| 1. | Nitrogen content in steel. |

| 2. | Aluminum content in steel. |

| 3. | Reduced sulfur and phosphorus content - high quality steel. |

| 83 | Question_OE/2 Within what limits does the standard cutting angle of the edges of V-shaped joints of parts of steel structures welded by manual arc welding, gas-shielded and submerged arc welding, measured after assembly, vary? |

| 1. | 10 – 30 degrees. |

| 2. | 50 – 60 degrees. |

| 3. | 60 – 90 degrees. |

| 84 | Question_OE/2 Indicate the reasons for the formation of hot cracks. |

| 1. | Increased content of carbon, silicon, sulfur, phosphorus in the weld metal, deep and narrow weld pool. |

| 2. | Reduced content of carbon, silicon, sulfur, phosphorus in the weld metal, deep and narrow weld pool. |

| 3. | Increased content of carbon, silicon, sulfur, phosphorus in the weld metal, wide weld pool. |

| 85 | Question_OE/2 How can welding technology prevent the formation of hot cracks? |

| 1. | Reducing the number of passes due to increasing heat input, increasing the amplitude of transverse vibrations of the electrode during welding. |

| 2. | Choosing the optimal form of cutting edges, reducing heat input. |

| 3. | Using narrow edge preparation and heat treatment after welding. |

| 86 | Question_OE/2 When do hot cracks form? |

| 1. | In the process of cooling the metal at a temperature of 500...700 degrees Celsius, due to a sharp decrease in plastic properties and the development of tensile stresses. |

| 2. | During the process of solidification and cooling of the metal at a temperature of 1100...1300 degrees Celsius, due to a sharp decrease in plastic properties and the development of tensile stresses. |

| 3. | During the process of metal solidification at a temperature of 1500...1650 degrees Celsius, due to a sharp decrease in plastic properties and the development of compressive stresses. |

| 87 | Question_OE/2 What are the causes of cold cracks? |

| 1. | The presence of impurities in the metal that form fusible compounds and tensile stresses that arise during welding. |

| 2. | Violation of the protection of the weld pool and the entry of nitrogen and oxygen into the weld metal. |

| 3. | High temporary and residual welding stresses and reduced ductility of the metal weld and heat-affected zone. |

| 88 | Question_OE/2 Indicate when cold cracks form. |

| 1. | At temperatures up to 120 degrees Celsius over a long period of time. |

| 2. | At temperatures of 250 degrees Celsius immediately after heating the seam or after a long period of time. |

| 3. | At temperatures of 150 degrees Celsius and below, immediately after the seam has cooled or after a long period of time. |

| 89 | Question_OE/2 What technological measures can be used to prevent the formation of cold cracks? |

| 1. | Using welding materials with a high content of carbon, sulfur, vanadium, titanium; reducing the number of passes due to welding with deep penetration, increasing the amplitude of transverse vibrations of the electrode during welding |

| 2. | Preliminary and concomitant heating, reducing the hydrogen content in the welded joint, using tempering after welding. |

| 3. | Preliminary and concomitant cooling, increasing the nitrogen content in the welded joint, and the use of hardening after welding. |

| 90 | Question_OE/2 How does the nature of electrode metal transfer affect the quality of the weld? |

| 1. | Fine-droplet regular transfer contributes to the production of defect-free seams. |

| 2. | Large droplet transfer ensures the lowest hydrogen content in the deposited metal, which significantly reduces the likelihood of cold cracks forming. |

| 3. | With small droplet transfer, the likelihood of “freezing” of the electrode increases. |

| 91 | Question_OE/2 What is a defect called a weld crater? |

| 1. | A depression formed at the end of the bead under the influence of arc pressure and volumetric shrinkage of the weld metal. |

| 2. | A funnel-shaped depression on the surface of a seam. |

| 3. | Place of end of welding (arc break). |

| 92 | Question_OE/2 Indicate the reasons for the formation of lack of penetration during manual arc welding. |

| 1. | High welding speed, insufficient welding current. |

| 2. | Low welding speed, increased welding current. |

| 3. | Low welding speed, optimal welding current. |

| 93 | Question_OE/2 Indicate the main reasons for the formation of a burn-through. |

| 1. | The welding current is too high relative to the thickness of the metal being welded. |

| 2. | Low qualification of the welder. |

| 3. | Large weld pool, and therefore its mass. |

| 94 | Question_OE/2 Should tack welds that have unacceptable external defects (cracks, external pores, etc.) be removed based on the results of visual inspection? |

| 1. | It should. |

| 2. | Do not do it. |

| 3. | External discontinuities should be removed with a mechanical tool (grinding wheel). |

| 95 | Question_OE/2 Name the main internal defects of welded joints during arc welding. |

| 1. | Cracks, lack of penetration, pores, slag inclusions. |

| 2. | Undercuts, burns, sagging, fistulas, lack of fusion. |

| 3. | Unwelded crater, lack of fusion, violation of the shape of the seam. |

| 96 | Question_OE/2 How to correct fistulas in a weld? |

| 1. | Removing the defective area to “healthy” metal mechanically, followed by welding. |

| 2. | Welding followed by mechanical processing. |

| 3. | Mechanical sampling of the defective area to the full thickness of the seam, followed by welding of the sample. |

| 97 | Question_OE/2 Indicate the procedure for correcting a weld with an accumulation of gas pores and slag inclusions on part of its cross-section. |

| 1. | The defective area of the weld is removed to the “healthy” metal with the formation of a U-shaped groove of the edges, followed by its welding after confirmation by monitoring the completeness of defect removal. |

| 2. | The defective area is completely removed with the formation of the original cutting shape and subsequent welding. |

| 3. | The defective area is not removed, but corrected by welding. |

| 98 | Question_OE/3 What is "gas welding"? |

| 1. | Arc welding, in which the weld pool is protected by gas supply. |

| 2. | Fusion welding, in which the heat of the flame of a mixture of gases burned with a torch is used for heating. |

| 3. | Arc welding with solid wire in an inert gas environment |

| 99 | Question_OE/3 What do the letters “A” and “AA” mean in the marking of welding wires Sv-08A and Sv-08AA? |

| 1. | Reduced content of sulfur and phosphorus in the wire. |

| 2. | Reduced carbon content in the wire. |

| 3. | Reduced silicon content. |

| 100 | PUE What is called an artificial grounding device when implementing protective electrical safety measures? |

| 1. | Accidental connection of live parts of an electrical installation with structural parts not insulated from the ground or directly to the ground |

| 2. | Grounding conductor specially designed for grounding purposes |

| 3. | Electrically conductive parts of communications, buildings and structures for industrial or other purposes in contact with the ground, used for grounding purposes |

| 101 | PUE At what rated voltages is grounding or grounding of electrical installations not required: |

| 1. | Up to 36 VAC and up to 120 VDC |

| 2. | Up to 42 VAC and up to 110 VDC |

| 3. | Up to 24 VAC and up to 140 VDC |

| 102 | PUE What conductors should be used as neutral protective conductors going to portable power receivers? |

| 1. | Zero working conductors connected to the housing of the electrical receiver |

| 2. | A separate conductor connected to a special contact of the plug of the plug-in connection and to the body of the electrical receiver |

| 3. | All answers are correct |

| 103 | PUE What voltage should be used to power portable electrical receivers from the network: |

| 1. | Not higher than 127 V |

| 2. | Not higher than 220 V |

| 3. | Not higher than 380/220 V |

| 104 | PUE How should electrical conductors be connected in plug-in connections of portable power receivers? |

| 1. | Conductors are connected to the socket from the power side, and to the plug - from the side of electrical receivers |

| 2. | Conductors are connected to the socket from the electrical receiver side, and to the plug from the power supply side |

| 3. | The supply of conductors can be chosen arbitrarily, based on ease of use |

| 105 | PUE What color should the electrical wiring wires be along their entire length: |

| 1. | Have a different color, and the color should indicate the purpose of the conductor |

| 2. | Have different colors, but the combination of colors does not matter |

| 3. | Be one color: black or white |

| 106 | PUE How is welding equipment grounded? |

| 1. | There must be a copper wire welded to the equipment, located in an accessible location labeled “Ground.” |

| 2. | The equipment must be provided with a bolt and a contact pad around it, located in an accessible place labeled “Ground”. |

| 3. | The equipment must be provided with a clamp located in an accessible location labeled “Ground.” |

| 107 | PUE At what distance should the cables of electric welding machines be located from the pipelines of acetylene and other flammable gases? |

| 1. | At least 5 m. |

| 2. | At least 1 m. |

| 3. | At least 10 m. |

| 108 | PEEP What is the maximum length of flexible cable allowed when connecting a mobile electric welding unit to a switching device? |

| 1. | 10 m |

| 2. | 15 m |

| 3. | 20 m |

| 109 | PEEP What electrical safety qualification group are electric welders allowed to carry out electric welding work? |

| 1. | Not lower than second. |

| 2. | Not lower than third. |

| 3. | Not lower than fourth. |

| 110 | PEEP Who should connect and disconnect electric welding installations from the network? |

| 1. | A welder working on these installations is under the supervision of a foreman or site manager. |

| 2. | Electrical technical personnel with an electrical safety group of at least II. |

| 3. | Electrical technical personnel with an electrical safety group of at least III. |

| 111 | SNiP 12-03-2001 What voltage is used for local lighting fixtures in hazardous areas? |

| 1. | For permanently installed lamps - more than 42 V, and for portable lamps - 12 V. |

| 2. | For permanently installed lamps at more than 42 V, and for portable lamps - 36 V. |

| 3. | For permanently installed lamps over 220 V, and for portable lamps – 12 V. |

| 112 | SNiP 12-03-2001 At what minimum height above the workplace is temporary electrical wiring allowed? |

| 1. | 2.5 m |

| 2. | 3.5 m |

| 3. | 6 m |

| 113 | SNiP 12-03-2001 What is the minimum height above walkways that temporary electrical wiring is allowed to be suspended? |

| 1. | 2.5 m |

| 2. | 3.5 m |

| 3. | 6 m |

| 114 | SNiP 12-03-2001 At what minimum height above driveways is temporary electrical wiring allowed? |

| 1. | 2.5 m |

| 2. | 3.5 m |

| 3. | 6 m |

| 115 | SNiP 12-03-2001 In what cases should hand-held power tools (included in the welding equipment set) be turned off and disconnected from the electrical network: |

| 1. | During breaks in work and at the end of work |

| 2. | During lubrication and cleaning |

| 3. | When changing working tools (knives, etc.) |

| 4. | Correct answers 1,2 and 3 |

| 116 | SNiP 12-03-2001 When should tools used in construction be inspected to ensure they are in good working order? |

| 1. | At least once a day |

| 2. | At least once every 10 days, and also immediately before use |

| 3. | At least once a month, and also immediately before use |

| 4. | Upon receipt of the tool from the organization's warehouse |

| 117 | SNiP 12-03-2001 At what distance should welding cables be located from oxygen cylinders? |

| 1. | At least 5 m. |

| 2. | Not less than 0.5 m. |

| 3. | Not less than 8.5 m. |

Answers

| № | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 0-9 | 1 | 1 | 2 | 1 | 1 | 1 | 3 | 1 | 3 | |

| 10-19 | 2 | 1 | 1 | 2 | 2 | 3 | 1 | 2 | 2 | 2 |

| 20-29 | 3 | 2 | 1 | 1 | 3 | 2 | 2 | 2 | 2 | 2 |

| 30-39 | 2 | 1 | 3 | 1 | 3 | 3 | 2 | 3 | 1 | 1 |

| 40-49 | 1 | 3 | 1 | 2 | 2 | 3 | 3 | 1 | 3 | 3 |

| 50-59 | 1 | 2 | 2 | 2 | 1 | 3 | 2 | 2 | 3 | 2 |

| 60-69 | 2 | 2 | 1 | 2 | 1 | 1 | 1 | 1 | 2 | 3 |

| 70-79 | 2 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 80-89 | 2 | 1 | 3 | 2 | 1 | 2 | 2 | 3 | 3 | 2 |

| 90-99 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 |

| 100-109 | 2 | 2 | 2 | 3 | 1 | 1 | 2 | 2 | 2 | 1 |

| 110-117 | 3 | 1 | 1 | 2 | 3 | 4 | 2 | 2 | ||

content .. 57 58 59 60 ..

Types of unalloyed carbon steels by carbon content

Low carbon with a C content of no more than 0.25%

Most of these products are produced in the form of cold-rolled or annealed sheets and strips. Properties, and therefore the scope of its application, depend on the percentage of components:

- Up to 0.1% C, Mn less than 0.4%. High ability to hot deformation and cold drawing. The materials are in demand in the production of wire, very thin sheets used in the manufacture of containers, and also for the manufacture of car bodies.

- C at 0.25%, Mn and Al – up to 1.5%. They have high viscosity. Aluminum is not added to metals intended for stamping, forging, the production of seamless tubes and sheets for boilers.

- C at 0.15%, Mn - up to 1.2%, Pb up to 0.3% or without it, minimum amount of Si. This group is used in mass production on automatic lines of parts not intended to withstand severe mechanical and temperature loads. For products with high requirements for ductility, toughness, and corrosion resistance, alloys are not used.

C 0.1-0.25%. The ability to deform is lower than that of the group described above, but the hardness and strength are higher. Often these grades are in demand for the production of parts with a cemented surface layer. The carburization process produces a wear-resistant surface layer combined with a tough core. This is true for shafts and gears.

Medium carbon with C0.2-0.6%

The manganese content is usually in the range of 0.6-1.65%. They are used in the production of products intended for use under high loads. They are usually produced calm. They are strengthened by cold hardening or heat treatment. All steels in this group can be forged. These metal products are widely used in mechanical engineering. Grades with a high carbon content (0.4-0.6%) are in demand in the production of railway rails, wheels and car axles.

High carbon – 0.6-2.0%

Increasing the amount of carbon to 1% leads to an increase in strength and hardness with a gradual decrease in the yield strength and plasticity. When the percentage of C increases above 1%, the formation of a coarse network of secondary martensite begins, leading to a decrease in the strength of the material. Therefore, steels with a C content of more than 1.3% are practically not produced.

High-carbon grades have a high manufacturing cost, have low ductility, and are difficult to weld. The scope of application of this group is quite limited - the production of cutting tools, including those intended for earthmoving and agricultural machinery, and the production of high-strength wire.

Characteristics

To obtain semi-quiet steels, alloys with a carbon content of 0.15-0.3% of ordinary quality and high quality are usually used. In the production of semi-deoxidized metal, before the release of gases, the ingot is covered with a crust of considerable thickness. If the steel is deoxidized correctly, then there is no shrinkage cavity, and widely scattered air bubbles are concentrated in the central upper part of the ingot, which roll up during rolling in the mills. If a sink is present, the waste is approximately 8%.

Classification of structural carbon steels by quality, their marking and application

Structural steels of ordinary quality

They are produced in accordance with GOST 380-2005 and supplied for sale in the form of sheets, sections and shaped products. GOST implies the release of the following brands:

- St0;

- St1ps, St1sp, St1kp;

- St2ps, St2sp, St2kp;

- St3ps, St3sp, St3kp, St3Gsp, St3Gps;

- St4ps, St4sp, St4kp;

- St5ps, St5sp, St5Gps;

- St6ps, St6sp.

Alphanumeric marking of this group of alloys:

- St – steel;

- numbers 0-6 indicate the brand number;

- the presence of the letter “G” in the designation indicates the presence of manganese in an amount of 0.8% or more;

- the last two letters characterize the degree of deoxidation, sp - calm, ps - semi-calm, kp - boiling.

High-quality structural steel

Manufactured in accordance with GOST 1050-2-13 of the following grades - 05, 08, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 58, 60, as well as grades 55PP, 60PP, 60PP " select” – reduced hardenability. The marking of such alloys indicates the degree of deoxidation if they are boiling or semi-quiet, for example 10 kp or 10 ps. The cn index is not indicated in the designation of quality construction grades.

Main Applications:

- production of long products (sheets, strips, circles, hexagons), profiles (angles, channels, I-beams);

- production of strip, which is a blank for pipe production;

- the most common grade of carbon steel of ordinary quality, St3ps, is used for load-bearing and non-load-bearing elements of welded structures designed to operate at temperatures above zero, structures operated under variable loads;

- St5ps – for riveted structures, bolts, nuts, rods, handles, stops, sprockets, designed to operate at positive temperatures up to +425°C.

Semi-quiet steel grades

- carbon semi-quiet steels of ordinary quality are manufactured according to GOST 380-2005, designation - “ps”;

- high-quality and high-quality are produced in accordance with GOST 1050-88, letter designation - “ps”;

- rarely - low alloy steels.

Differences between semi-quiet steel and calm steel

In relation to fully deoxidized steel, semi-deoxidized steel is characterized by:

- greater degree of heterogeneity of chemical composition;

- high yield;

- lower cost.

The presence of a certain amount of free oxygen reduces the strength and ductility of semi-quiet steel.

Source of the article: https://metallz.ru/articles/poluspokojnaya_stal/

Deoxidizers: types and functions

Ferrosilicon is used as deoxidizers in an amount of 0.12-0.3% by weight, ferromanganese, aluminum - up to 0.1%, and titanium.

A negative consequence of deoxidation is the formation of a large shrinkage cavity. To remove it, you have to cut off up to 16% by weight from the ingot of mild steel. Due to this loss of metal, as well as the cost of deoxidizing additives, the cost of calm steel significantly exceeds the price of boiling metal.

Deoxidizing additives, combining with free oxygen found in the alloy, solve the following problems:

- reduce the negative impact of free oxygen on the developing structure of the ingot;

- maintain high steel temperature for a long period, which ensures maximum slag and gas removal;

- contribute to the production of metal with a fine-grained, homogeneous structure, since the resulting silicates and aluminates increase the number of crystallization centers. This causes grain refinement and improves the quality and mechanical characteristics of the metal.

Mild steel grades

Full deoxidation alloys are divided into the following groups:

- mild carbon steels of ordinary quality - regulated by GOST 380-2005, designated “sp”;

- high-quality and high-quality - produced in accordance with GOST 1050-88, they do not have a letter index according to this standard;

- All alloy and low-alloy steels are usually made calm and do not have a letter index.

Attention! Steels produced by continuous casting are completely deoxidized during the process.

Steel deoxidation - You know how

Steel smelted by any method contains dissolved oxygen, which significantly impairs its strength and plastic properties. To reduce its content, the steel is deoxidized. In steelmaking practice, several deoxidation methods are used.

Precipitation deoxidation

The most common way to reduce dissolved oxygen is achieved by binding it with deoxidizing elements: Mn, Si, Ti, Al, Ca, REE, which is possible due to their greater affinity for oxygen than iron. When adding deoxidizing agent R

interaction takes place in metal

[O] + yR = Ry

Ox(gas, liquid, TV)

with the formation of insoluble deoxidation products, which must separate (precipitate) into a gaseous or slag phase. The deoxidation products remaining in the steel sometimes cause less harm than dissolved oxygen, but they clog the metal with non-metallic inclusions, the accumulation of which makes the steel unsuitable for further use. Therefore, it is necessary to provide conditions for the removal of deoxidation products, which depends on their size, ability to coarse, metal viscosity, and particle density.

The enlargement of deoxidation products and the ability to float are created and enhanced by the formation of liquid, fusible formations. From this point of view, and especially due to the fact that strong deoxidizers, like their deoxidation products, are difficult to melt, it is advisable to use complex deoxidizers. Complex deoxidizers are alloys that contain several deoxidizers, proportioned so that the deoxidation products acquire specified properties that favor their separation from the steel. Complex deoxidizers include silicomanganese, silicocalcium, AMS (an alloy of aluminum, manganese and silicon), etc.

The deoxidizing power of deoxidizers is determined by the isobaric potential of oxide formation or the residual concentrations of the deoxidizer and dissolved oxygen in the steel.

Deoxidation with manganese (in the form of ferromanganese) is carried out before the metal is released from the furnace. Manganese is a weak deoxidizer, so deoxidation with it is preliminary. The deoxidation products—MnO—form xMnO complexes in the metal. • y

FeO• z

SiO2 with a lower melting point and high fluid mobility.

Silicon is a stronger deoxidizing agent. The deoxidation products—SiO2—melt at a temperature of 1710° C, so inclusions of solid silica are first formed. Subsequent fusion of SiO2 with FeO and MnO gives low-melting silicates mSKVFeO'&MnO, which coarse well and float easily. Blast furnace-poor ferrosilicon is used to deoxidize the metal in a furnace. The final deoxidation with silicon occurs at the outlet, when rich ferrosilicon is released into the stream.

Aluminum has a high affinity for oxygen. Deoxidation products are solid fine particles of Al2O3. Aluminum is introduced into a ladle, and the metal is partially deoxidized when poured into molds.

Tool steels

Tool steels are products without alloying that are durable. Additives are used to seal some areas. They are subject to special requirements related to their specific use.

Tool steels are also divided into several subtypes:

- for cutting tools;

- for measuring instruments;

- stamped;

- roller

For cutting tools

Steels for cutting tools are quite expensive, so not everyone can create products from them. Typically, some parts of the tools are made from constitutional steel, such as plates or blades.

Steel of this type, in turn, is divided into the following subtypes:

- carbon tool alloys (usually contain 0.5-1.3% carbon, common for use in the manufacturing process);

- alloyed tool tools (from which you can make cutters, drills and broaches);

- high-speed (can create products with heat resistance up to -660 degrees).

Steels for measuring instruments

Steel for measuring instruments must have stable shape and dimensions during alteration and storage. Also, its surface must be perfectly smooth, well processed and polished.

Such steel can be carbon and alloyed with chromium, nickel and other elements. To increase wear resistance and improve surface quality, products are cemented and hardened. Steel is still in demand in the manufacture of the most modern measuring instruments.

Die steels

Die steel is characterized by hardness, resistance to temperature changes and hardenability. It must be wear-resistant and have a permanent shape. These alloys include the following:

- cold stamping (in addition to hardness, wear resistance, stability of dimensions and shape, a high level of viscosity and resistance to temperature changes are added; they can work under conditions of impact and high pressure; they are produced on the basis of alloys with chromium and other elements);

- hot stamping (they must have increased strength and toughness when heated to 500 degrees and high thermal conductivity in order to avoid overheating; they are subject to an alloying procedure with chromium, nickel, vanadium, etc.).

Roll steels

Rolling steel is used to produce rolling mills, dies, punches, and blades for working with metal products. They can also be used to produce components for mining and paper-making equipment.

Basic requirements for roll steel:

- high level of hardenability for product strength (hardening of steel is carried out slowly, immersing it in oil for cooling);

- high wear resistance (it allows the entire rolling mill to operate for a long time and without interruption, ensuring stable parameters);

- contact strength (it must be greater than the voltage that occurs during the process, taking into account the load from the resistance and the mass of the device).

Advantages of mild steel

Due to the homogeneity and fine-grained structure, deoxidized steels have the following advantages:

- good resistance to dynamic impacts and brittle fracture, due to which they are used in the manufacture of critical structures for which static and dynamic impacts are planned;

- steel, for the deoxidation of which aluminum additives were used, is not subject to aging, which implies a change in the properties of the material without a noticeable change in the microstructure. Plasticity, resistance to brittle fracture, and the threshold of cold brittleness are reduced, and strength is slightly increased;

- uniform distribution of sulfur and phosphorus;

- good weldability.