In the designation of fittings

The drawings indicate the diameter in millimeters, the class and its GOST, for example:

| A periodic profile reinforcement bar with a diameter of 20 mm is designated 20 A-II GOST 5781-… | |

| A smooth reinforcement rod with a diameter of 8 mm is designated 8 AI GOST 5781-... | |

| A rod of smooth cold-drawn reinforcing wire of a periodic profile with a diameter of 4 mm has the designation 4 VR-I GOST 6727-... |

Preparation of rods of measured length

from

rod and wire reinforcement

and the manufacture

of non-tensioned reinforcement products

is carried out in accordance with the requirements of

SNiP 3.09.01-85

.

And the production of load-bearing reinforcement frames

from rods with a diameter of more than

32 mm

,

rolled profiles

are made in accordance with the requirements of

SNiP 3.03.01-87

section 8.

Preparation of reinforcing wire

and

hot-rolled reinforcement of round and periodic profiles

, supplied

in coils

, must be produced on automatic straightening machines, and supplied

in rods

- as a rule, on waste-free mechanized lines.

Preparation of reinforcing wire

and

hot-rolled reinforcement

of round and periodic profiles, supplied in coils, must be produced on automatic straightening machines, and supplied in rods - as a rule, on waste-free mechanized lines.

Reinforcing steel is produced:

- smooth hot-rolled steel

- for reinforcing reinforced concrete structures (GOST-5781), - smooth steel of periodic profile

-

for reinforcing

conventional and prestressed reinforced concrete structures (

GOST-5781

);

reinforcing and thermally strengthened

rod steel of periodic profile

- for reinforcing prestressed reinforced concrete structures (

GOST-10884

);- hot-rolled steel

according to

GOST-5781

- has 5 classes (

AI; A-II and Ac-II, A-III, A-IV, AV

); - steel thermally strengthened

according to

GOST-10884

- has 4 classes (

At-IV, At-V, At-VI, At-VII

).

For the manufacture of reinforcing bars and frames, the steels listed in Table 1 are used.

Table 1: Reinforcing steel for reinforced concrete products.

| p/p | Name | GOST | Class | steel grade | Diameter, mm | Supply |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1 | Hot rolled smooth reinforcing steel | 5781-82* | A.I. | St3 | 6…40 | 6…12mm - in skeins |

| 2 | 14…40 mm - in rods | |||||

| 3 | Hot rolled reinforcing steel of periodic profile | 5781-82* | A-II | St5 | 6…40 | 6…12mm - in skeins |

| 4 | 18G2S | 40…80 | 14...80mm - in rods | |||

| 5 | A-III | 25G2S | 10…40 | 6...10mm - in skeins | ||

| 6 | 32G2Rps | 6…22 | 12...40mm - in rods | |||

| 7 | A-IV | 80C | 10…18 | In the rods | ||

| 8 | 29ХГ2Ц | 10…32 | In the rods | |||

| 9 | AV | 23Х2Г2Т | 10…32 | In the rods | ||

| 10 | Draw-strengthened reinforcing steel | 5781-82* | A-IIv | St5 | 6…40 | 6...10mm - in skeins |

| 11 | 80G2S | 40…80 | 12...80mm - in rods | |||

| 12 | A-IIIc | 25GS | 10…40 | 7...10mm - in skeins | ||

| 13 | 32G2Rps | 6…22 | 12...40mm - in rods | |||

| 14 | Cold drawn smooth reinforcing wire | 6727-80 | B.I. | St3 | 3, 4, 5 | In skeins |

| 15 | Cold-drawn reinforcing wire of periodic profile | 6727-80 | BP-I | St3 | 3, 4, 5 | In skeins |

| 16 | Thermo-mechanical and thermally hardened steel of periodic profile | 10884-81 | At-IIIc | St5 | 10…18 | In the rods |

| 17 | At-IVc | 25G2S, 10GS2 | 10…28 | Same | ||

| 18 | AT-IV | 20GS | ||||

| 19 | At-V | |||||

| Note: Reinforcing steel with a screw profile used in construction ( TU 14-2-448-… ) has nominal diameters of rods of 18, 25, and 32 mm ; in terms of chemical composition, mechanical properties and class, it corresponds to reinforcing steels according to GOST 5781-82* and GOST 10884-81 . | ||||||

cutting

Rod and wire

reinforcement and mesh

should be produced using mechanical, hydraulic or pneumatic shears, friction saws, as well as plasma torches.

Table 2: Technical characteristics of reinforcing steels.

| p/p | Steel grade | Yield strength, MPa | Tensile strength, MPa | Standard tensile strength, MPa | Bend angle, deg. in a cold state with a mandrel diameter | |||

| 0.5d | 1d | 3d | 5d* | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | A.I. | 235 | 373 | 235 | 180 | — | — | — |

| 2 | A-II | 294 | 490 | 295 | — | — | 180 | — |

| 3 | A-III | 392 | 590 | 390 | — | — | 90° | — |

| 4 | A-IV | 590 | 883 | 590 | — | — | 90° | — |

| 5 | AV | 785 | 1030 | 785 | — | — | — | 45° |

| 6 | At-IIIc | 440 | 590 | 400 | — | — | 90° | — |

| 7 | At-IVc | 590 | 785 | 600 | — | — | — | 45° |

| 8 | At-IVk | 590 | 785 | 600 | — | — | — | 45° |

| 9 | At-V | 980 | 785 | 800 | — | — | — | 45° |

| d* – diameter of the reinforcement bar in mm. | ||||||||

For assortments of reinforcing steel by weight and diameter, see the section “Classification and assortment of reinforcing steels”.

Manufacturing of spatial frames

It is advisable to produce from welded and rolled mesh.

The production of spatial large-sized reinforcement products

is carried out in assembly jigs.

Characteristics of welded mesh

from rod reinforcement are given in

GOST 23279-85

In the manufacture of reinforcement cages

you should be guided by the instructions of

SNiP 3.03.01-87

, as well as the working drawings of the work project.

Weldless rod connections

divided into butt and cross joints:

- butt joints of rods

- overlapped or with crimp sleeves and screw couplings to ensure equal strength of the joint; - cross-shaped connections of rods

- viscous annealed wire. The use of special connecting elements (plastic and wire fasteners) is allowed.

Butt and cross-shaped connections are carried out according to the design in accordance with GOST 14098-85

.

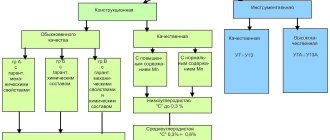

general information

It is customary to distinguish several classes of reinforcement. The division is based on the following characteristics:

- periodic profile;

- mechanical parameters.

Reinforcing steel comes in the following classes:

- AII.

- AIII.

- AIV.

- AV.

For several years now, there has been quite a strong demand on the market for the A500C class of reinforcing steel. If you study GOST 5781-82, you will not be able to find descriptions similar to it in terms of its parameters. These products are manufactured in accordance with the following standards:

- STO ASChM 7-93;

- technical conditions.

Such a standardization system, according to which hot-rolled reinforcing steel of periodic profile is grouped into categories, was introduced by enterprises operating in the field of ferrous metallurgy. They are united into a single association, which has also taken upon itself the development of rules for the production of goods.

PACKAGING, LABELING, TRANSPORTATION AND STORAGE

5.1. Packaging, labeling, transportation and storage - in accordance with GOST 7566 with the following additions:

— the ends of rods made of low-alloy steels of class A-IV (A600) must be painted with red paint, class AV - red and green, class A-VI (A1000) - red and blue. It is allowed to paint the ligaments at a distance of 0.5 m from the ends;

— the rods are packaged in bundles weighing up to 15 tons, tied with wire or wire rod. At the consumer's request, the rods are packaged in bundles weighing up to 3 and 5 tons;

On the ties, paint is applied in strips no less than 20 mm wide on the side surface around the circumference (at least 1/2 the length of the circumference) at a distance of no more than 500 mm from the end.

Paint is applied to the skeins in strips no less than 20 mm wide across the turns on the outside of the skein.

For unpackaged products, paint is applied to the end or side surface at a distance of no more than 500 mm from the end.

The label attached to each bundle of rods is marked with the accepted designation of the reinforcing steel class (for example, A-III) or the symbol of the yield strength class (A400).

(Changed edition, Amendment No. 3, 5).

A special case

The described reinforcing steel A500C is not the only exception in the world of hot-rolled products. The AI class also deserves special attention, which in GOST is usually designated as A240. The key feature is the sleek profile. 3 SP (PS) steel is used as a raw material for the production process. The diameter and deviations from it for any product with a smooth profile are regulated by GOST 2590-88. This regulatory document also specifies rolling accuracy for general cases.

Smooth reinforcing steel is produced in the following formats:

- rods;

- bays.

In skeins you can find sizes from 6 to 14 mm (pitch - 2 mm). The choice of reinforcement in rods is somewhat wider. The minimum possible diameter is 16 mm, and the largest available is 40 mm. From 16 to 22 mm the step is 2 mm, from 25 to 40 mm it increases to three.

What classes are the fittings divided into?

Reinforcing bars are manufactured and marked in accordance with industry state standards. It is marked with a combination of letters and numbers.

It is divided into three main classes:

- A – rod reinforcement intended to form the main frame;

- Вр – wire reinforcement used to connect the main elements together;

- K – rope reinforcement, which is the most important part of factory-made prestressed reinforced concrete parts and structures. It is rarely used in individual construction.

The digital index following the letters can have a value from 1 to 6. The higher it is, the stronger the product. Currently, there is a gradual shift away from the Soviet marking system, so often the same material can be designated in two ways. Table No. 1 is intended to help correlate old and new names.

Table 1. Types of fittings and their names

| Type of fittings | Reinforcement class | |

| Designation | ||

| Old | New | |

| Hot rolled rod (GOST 5781-82*): | ||

| smooth | A-I | A-I(A-240) |

| periodic profile | A-II | A-II(A-300) |

| Ac-II | Ac-II(Ac300) | |

| A-III | A-III(A-400) | |

| A-IV | A-IV(A-600) | |

| A-V | А-V(А-800) | |

| A-VI | A-VI(A-1000) | |

| Thermally strengthened reinforcing steel for reinforced concrete structures Technical specifications GOST 10884-94 | At-IV | At 400s |

| At 500s | ||

| At 600 | ||

| At 600s | ||

| At 600k | ||

| At 800k | ||

| At 1000 | ||

| At 1000k | ||

| Ordinary reinforcing wire: | ||

| smooth | B-I | — |

| periodic profile | Vr-I | — |

The type of reinforcement is determined at the design stage of a reinforced concrete product. In this case, the method of connecting individual elements into a single frame is determined. In practice, electric welding or tying with steel wire intended for this purpose is used for this.

Rod reinforcement – class A

Hot-rolled rod reinforcement is the most popular in monolithic construction. It is divided into classes marked A400, A600 and beyond. When constructing foundations that experience maximum loads, the rods are not subjected to electric welding, but are tied together with wire. In this case, due to some mobility, it is possible to avoid increased local stresses.

Let's consider the main brands of fittings of this class:

AI (A240) – smooth rods with a cross-section from 6 to 40 mm. They are characterized by high plasticity and frost resistance of the resulting monoliths. They can be welded together or tied with wire.

A II (A300) – corrugated rods with a diameter of 10 to 80 mm. They are used as part of prestressed reinforced concrete products. Parts with them as a frame rarely crack even after prolonged use.

A III (A400) - the most common type of reinforcement for high-rise and individual construction has the form of smooth or corrugated rods with a diameter of 6 to 40 mm. Products with the letter “C” in the marking are suitable for welding.

A IV (A600) – used for the frame of prestressed concrete structures. Consist of two steel alloys. They have the form of rods with a cross section of 10-32 mm.

AV (A800) – a class of corrugated rods made of high-carbon steel with a diameter of 6 to 36 mm, used in the manufacture of long-length reinforced concrete products.

A VI (A1000) – rods made of low-alloy steel with a thickness of 6-32 mm, used in the construction of stressed monolithic structures.

Bar reinforcement is made mainly of carbon steel, which is a commonly used structural material. Sometimes a small amount of alloying additives is added to it. Even at minimal concentrations, they have a beneficial effect on improving performance characteristics:

- mechanical strength;

- plasticity;

- corrosion resistance in a slightly alkaline environment of concrete solutions.

A reinforcing frame made of alloy steel performs well in areas with increased seismic hazard and in cold climates. It is included in the most critical objects and structures operating under conditions of alternating dynamic loads.

To increase the strength of carbon steel rods, heat treatment processes (quenching and tempering) are used. Reinforcement strengthened in this way is designated as:

At.

Reinforcement resistant to alkali cracking - letter:

TO.

Products that can be welded are marked with an additional letter:

WITH.

You should pay attention to the most popular types of fittings intended for assembly using welding:

- A400S fittings are produced using hot rolling technology. The thickness of the products can reach 40 mm. A characteristic design feature is the presence of a pair of longitudinal ribs. Such reinforcement has found application in low-rise construction.

- A500C reinforcement is a common type of reinforcement reinforced by heat treatment. It is used in the production of serial reinforced concrete products not intended for use under dynamic loads.

- A600C reinforcement is a corrosion-resistant version of rods made from a carbon steel alloy with a small addition of vanadium and molybdenum. The material has found wide application in areas prone to earthquakes.

Wire reinforcement – class VR

In the manufacture of most reinforced concrete products, cold-drawn wire of ordinary quality can be used. In the case of prestressed reinforcement, special grades of high-strength wire are required.

Wire reinforcement.

Reinforcement in the form of a rope - class K

Rope reinforcement is best suited for the most heavily loaded reinforced concrete structures. It is poured with concrete in a pre-stressed state. It is better than others capable of compensating for soil movements, taking on the main bending moment acting on the foundation. To increase the service life of ropes, they are impregnated with lubricants or placed in a protective sheath of a polymer nature.

The main technical characteristics of classes and brands of building reinforcement are presented in Table No. 2.

Table 2. Standard indicators of construction reinforcement

| Reinforcement class | Nominal diameter of fittings, mm | Normal value of tensile resistance Rsn and calculated value of tensile resistance for limit states of the second group | Calculated values of reinforcement resistance for limit states of the first group | ||||

| MPa | kgf/cm2 | tensile strength, Rs | compression, Rsc | ||||

| MPa | kgf/cm2 | MPa | kgf/cm2 | ||||

| A240 | 6-40 | 240 | 2450 | 215 | 2190 | 215 | 2190 |

| A300 | 10-40 | 300 | 3060 | 270 | 2750 | 270 | 2750 |

| A400 | 6-40 | 400 | 4080 | 355 | 3620 | 355 | 3620 |

| A500 | 6-40 | 500 | 5100 | 435 | 4440 | 400 | 4080 |

| A600 | 10-40 | 600 | 6120 | 520 | 5300 | 400 | 4080 |

| A800 | 10-10 | 800 | 8160 | 695 | 7090 | — | — |

| A1000 | 10-40 | 1000 | 10200 | 830 | 8470 | — | — |

| B500 | 3-12 | 500 | 5100 | 415 | 4230 | 360 | 3670 |

| VR1200 | 8 | 1200 | 12240 | 1000 | 10200 | 400 | 4080 |

| VR1300 | 7 | 1300 | 13260 | 1070 | 10910 | — | — |

| VR1400 | 4;5;6 | 1400 | 14280 | 1170 | 11930 | — | — |

| VR1500 | 3 | 1500 | 15300 | 1250 | 12750 | — | — |

| K1400 (K-7) | 15 | 1400 | 14280 | 1170 | 11930 | — | — |

| K1500 (K-7) | 6;9;12;14 | 1500 | 15300 | 1250 | 12750 | — | — |

How and why?

The A240 grade of reinforcing steel is necessary in construction and other areas where reinforced concrete structures are used, as it is used for their reinforcement. Some experts call this category of materials “loop”, since it is customary to use reinforcement to form loop-shaped elements that strengthen reinforced concrete products. This is most relevant when the element stands out from the main plane of the structure. Hot rolled reinforcing steel A1 is suitable for creating elements that simplify loading of finished blocks, transportation and unloading. In addition, it is easier to connect different elements directly on the construction site.

The AI grade of reinforcement, like round reinforcement, is necessary for a wide range of structures. When using it, they make:

- fencing;

- furniture;

- railing

The circle and metal fittings A1, if they are manufactured in accordance with specialized standards, are used as raw materials: wire can be drawn from them. It is allowed to produce profiles:

- periodic;

- smooth.

If the reinforcement plant has the appropriate equipment, then A1 steel can be used for the manufacture of various products on lathes or milling machines. The material is processed mechanically.

Fittings according to purpose

When creating a reinforcing frame, reinforcing bars occupy a strictly defined place. There are types of fittings that differ in their position and purpose.

Working fittings

Working reinforcement is laid along the longest structural elements. For strip foundations, floor slabs and load-bearing beams it occupies a horizontal position, and in piles and columns it occupies a vertical position. In this case, it is able to take on tensile loads, thereby increasing the strength and durability of the entire part. Rods of this class always have a variable cross-section. They form the basis of the frame.

Distribution

Distribution fittings are considered auxiliary. It is responsible for connecting the main rods into a common frame with a spatial structure. In this case, the loads are optimally distributed between several elements, which reduces the risk of damage to any of them. Such rods can occupy horizontal and vertical positions. The optimal shape for them is corrugated, although in the least critical parts it is allowed to use smooth rods or pieces of pipes.

Assembly

The task of mounting reinforcement is to ensure that the shape of the reinforcing frame remains unchanged during transportation, placement in formwork and pouring with mortar. For these purposes, rods with any surface structure are used.

1. Working.

2. Distribution.

3. Assembly room.

Without losing sight of the standards

Talks about what reinforcing steel should be like, GOST 5781.82. According to the standards, the carbon content of the metal can be no more than 0.3%, only then is the product applicable for reinforced concrete. Reinforcement is used both for previously stressed raw materials and for ordinary ones.

If pre-treated and stressed reinforced concrete is used, then the reinforcement is chosen that can cope with the fairly serious loads inherent in this environment. As a rule, the stress is quite high, which requires that the metal fittings be of increased strength and made strictly from reliable steel. If wire is used, then high demands are also placed on its strength.

If hot-rolled reinforcing steel is to be used in structures that are not subject to stress, then the use of ordinary raw materials is acceptable. The following steel grades are relevant here:

- ST3.

- ST5.

For prestressing, it is customary to take steel containing carbon:

- average;

- high.

Steel reinforcement can also be used, thermally treated to increase strength parameters.

Steel: which one should we take?

In order to produce high-quality reinforcing steel, GOST 5781.82 recommends using reliable steel:

- carbon;

- low alloy.

There are several grades available for different types of material mentioned. As a rule, the customer, when sending an order to the valve plant, indicates from what raw materials he wants to see the finished product. If the manufacturer does not receive such recommendations, then the manufacturing enterprise independently makes a decision in favor of the optimal option for a particular type of product. In particular, for the A800 it is customary to use the following brands:

- 22Х2Г2АУ.

- 22Х2Г2Р.

- 20X2G2SR.

Hot-rolled steel for reinforcement of ferroconcrete structures. Specifications

MKS 77.140.15

OKP 09 3004; 09 3005; 09 3006; 09 3007; 09 3008

Date of introduction 1983-07-01

Information data

1. DEVELOPED AND INTRODUCED by the Ministry of Ferrous Metallurgy of the USSR, Gosstroy of the USSR

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated December 17, 1982 N 4800

3. INSTEAD GOST 5.1459-72, GOST 5781-75

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 380-2005 | 2.3, 2.4 |

| GOST 2590-2006 | 1.6 |

| GOST 7564-97 | 4.5 |

| GOST 7565-81 | 3.4 |

| GOST 7566-94 | 3.2, 3.6, 5.1 |

| GOST 9454-78 | 4.8 |

| GOST 12004-81 | 4.6 |

| GOST 12344-2003 | 4.1 |

| GOST 12348-78 | 4.1 |

| GOST 12350-78 | 4.1 |

| GOST 12352-81 | 4.1 |

| GOST 12355-78 | 4.1 |

| GOST 12356-81 | 4.1 |

| GOST 14019-2003 | 4.7 |

| GOST 18895-97 | 4.1 |

| OST 14-34-78 | Appendix 2 |

5. The validity period was lifted according to Protocol No. 3-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 5-6-93)

6. EDITION (September 2009) with Amendments No. 1, 2, 3, 4, 5, approved in February 1984, June 1987, December 1987, October 1989, December 1990 (5 -84, 11-87, 3-88, 1-90, 3-91)

This standard applies to hot-rolled round steel of smooth and periodic profiles intended for the reinforcement of ordinary and prestressed reinforced concrete structures (reinforcing steel).

Regarding the standards for the chemical composition of low-alloy steels, the standard also applies to ingots, blooms and billets.

(Changed edition, Amendment No. 4).

Classification and assortment

1.1. Depending on the mechanical properties, reinforcing steel is divided into classes A-I (A240), A-II (A300), A-III (A400); A-IV (A600), A-V (A800), A-VI (A1000).

1.2. Reinforcing steel is produced in bars or coils. Reinforcing steel of class A-I (A240) is made smooth, classes A-II (A300), A-III (A400), A-IV (A600), A-V (A800) and A-VI (A1000) - periodic profile .

At the request of the consumer, steel of classes A-II (A300), A-III (A400), A-IV (A600) and A-V (A800) is made smooth.

1.1, 1.2. (Changed edition, Amendment No. 5).

1.3. Profile numbers, cross-sectional areas, weight of 1 m length of reinforcing steel of smooth and periodic profiles, as well as maximum mass deviations for periodic profiles must correspond to those indicated in Table 1.

Table 1

| Profile number (nominal rod diameter dK) | Cross-sectional area of the rod, cm² | Weight of 1 m profile | |

| Theoretical, kg | Limit. off, % | ||

| 6 | 0,283 | 0,222 | +9,0 |

| 8 | 0,503 | 0,395 | -7,0 |

| 10 | 0,785 | 0,617 | +5,0 -6,0 |

| 12 | 1,131 | 0,888 | |

| 14 | 1,540 | 1,210 | |

| 16 | 2,010 | 1,580 | +3,0 -5,0 |

| 18 | 2,540 | 2,000 | |

| 20 | 3,140 | 2,470 | |

| 22 | 3,800 | 2,980 | |

| 25 | 4,910 | 3,850 | |

| 28 | 6,160 | 4,830 | |

| 32 | 8,040 | 6,310 | +3,0 -4,0 |

| 36 | 10,180 | 7,990 | |

| 40 | 12,570 | 9,870 | |

| 45 | 15,000 | 12,480 | |

| 50 | 19,630 | 15,410 | +2,0 -4,0 |

| 55 | 23,760 | 18,650 | |

| 60 | 28,270 | 22,190 | |

| 70 | 38,480 | 30,210 | |

| 80 | 50,270 | 39,460 | |

(Changed edition, Amendment No. 3).

1.4. The nominal diameters of periodic profiles must correspond to the nominal diameters of smooth profiles of equal cross-sectional area.

1.5. The weight of 1 m of profile is calculated based on the nominal dimensions with a steel density of 7.85·10³ kg/m³. The probability of providing a mass of 1 m must be at least 0.9.

(Changed edition, Amendment No. 3).

1.6. Maximum deviations of the diameter of smooth profiles must comply with GOST 2590 for normal rolling accuracy.

1.7. Periodic profile reinforcing steel is a round profile with two longitudinal ribs and transverse projections running along a three-lead helix. For profiles with a diameter of 6 mm, protrusions running along a single-start helical line are allowed, with a diameter of 8 mm - along a double-start helical line.

1.8. Reinforcing steel of class A-II (A300), made in the usual version, with the profile shown in Fig. 1a, and for special purpose Ac-II (Ac300) with the profile shown in Fig. 2a, must have protrusions running along helical lines with the same approach on both sides of the profile.

Steel of class A-III (A400), manufactured with the profile shown in Fig. 1b, and classes A-IV (A600), A-V (A800), A-VI (A1000) with the profile shown in Fig. 1b, 2b, must have protrusions along helical lines that have right-hand entries on one side of the profile and left-hand entries on the other.

Special-purpose reinforcing steel of class Ac-II (Ac300) is made with profiles shown in Figure 1a or 2a.

The profile shown in Fig. 2a for special purposes is manufactured by agreement between the manufacturer and the consumer. The shape and dimensions of the profiles shown in Fig. 2a, b can be specified.

1.9. The dimensions and maximum deviations of the dimensions of reinforcing steel of periodic profile, manufactured according to Fig. 1a, b, must correspond to those given in Table 2, and for Fig. 2a, b - given in Table 3.

1.10. Relative displacements of helical projections on the sides of the profile, separated by longitudinal ribs, are not standardized.

Dimensions for which maximum deviations are not established are given for caliber construction and are not checked on the finished profile.

1.11. The ovality of smooth profiles (the difference between the largest and smallest diameters in one section) should not exceed the sum of the plus and minus maximum deviations in diameter.

1.9-1.11. (Changed edition, Amendment No. 3).

1.12. Reinforcing steel of classes A-I (A240) and A-II (A300) with a diameter of up to 12 mm and class A-III (A400) with a diameter of up to 10 mm inclusive. manufactured in coils or rods, large diameters - in rods. Reinforcing steel of classes A-IV (A600), A-V (A800) and A-VI (A1000) of all sizes is manufactured in rods with a diameter of 6 and 8 mm - by agreement between the manufacturer and the consumer, in coils.

1.13. The rods are made from 6 to 12 m long:

- measured length;

- measured length with unmeasured segments of at least 2 m in length, not more than 15% of the lot weight;

- of unmeasured length.

In a batch of rods of unmeasured length, the presence of rods with a length of 3 to 6 m is allowed, no more than 7% of the mass of the batch.

table 2

Dimensions in mm

| Profile number (nominal diameter dK) | d | h | d1 | h1 | l | b | b1 | r | ||

| Nom. | Prev. off | Nom. | Prev. off | |||||||

| 6 | 5,75 | +0,3 -0,5 | 0,5 | ±0,25 | 6,75 | 0,5 | 5 | 0,5 | 1,0 | 0,75 |

| 8 | 7,5 | 0,75 | 9,0 | 0,75 | 0,75 | 1,25 | 1,1 | |||

| 10 | 9,3 | 1,0 | ±0,5 | 11,3 | 1,0 | 7 | 1,0 | 1,5 | 1,5 | |

| 12 | 11,0 | 1,25 | 13,5 | 1,25 | 2,0 | 1,9 | ||||

| 14 | 13,0 | 15,5 | ||||||||

| 16 | 15,0 | 1,5 | 18,0 | 1,5 | 8 | 1,5 | 2,2 | |||

| 18 | 17,0 | 20,0 | ||||||||

| 20 | 19,0 | 22,0 | ||||||||

| 22 | 21,0 | +0,4 -0,5 | 24,0 | |||||||

| 25 | 24,0 | 27,0 | ||||||||

| 28 | 26,5 | +0,4 -0,7 | 2,0 | ±0,7 | 30,5 | 2,0 | 9 | 2,5 | 3,0 | |

| 32 | 30,5 | 34,5 | 10 | 2,0 | 3,0 | |||||

| 36 | 34,5 | 2,5 | 39,5 | 2,5 | 12 | 3,5 | ||||

| 40 | 38,5 | 43,5 | ||||||||

| 45 | 43,0 | 3,0 | 49,0 | 3,0 | 15 | 2,5 | 3,5 | 4,5 | ||

| 50 | 48,0 | 54,0 | ||||||||

| 55 | 53,0 | +0,4 -1,0 | ±1,0 | 59,0 | 4,0 | |||||

| 60 | 58,0 | 64,0 | 5,0 | |||||||

| 70 | 68,0 | +0,5 -1,1 | 74,0 | 4,5 | 5,5 | |||||

| 80 | 77,5 | 83,5 | ||||||||

Note. At the request of the consumer, maximum deviations of size d1 should not exceed maximum deviations d plus double maximum deviations h.

By agreement between the manufacturer and the consumer, it is possible to manufacture rods from 5 to 25 m.

1.14. The maximum deviations along the length of the measuring rods must correspond to those given in Table 4.

Table 3

Dimensions in mm

| Profile number (nominal diameter dK) | d | h | d1 | h1 | hT | hB | t | b | b1 | r1 | α | ||

| Nom. | Prev. off | Nom. | Prev. off | ||||||||||

| 10 | 8,7 | +0,3 -0,5 | 1,6 | ±0,5 | 11,9 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 1,5 | 11 | 50° |

| 12 | 10,6 | 13,8 | 2,0 | ||||||||||

| 14 | 12,5 | 2,0 | +0,65 -0,85 | 16,5 | 2,0 | 0,8 | 1,2 | 12 | 1,0 | 2,0 | 12 | ||

| 16 | 14,2 | 2,5 | 19,2 | 2,5 | 1,0 | 1,5 | |||||||

| 18 | 16,2 | 21,2 | |||||||||||

| 20 | 18,2 | 23,2 | |||||||||||

| 22 | 20,3 | +0,4 -0,5 | 25,3 | ||||||||||

| 25 | 23,3 | 28,3 | 14 | 1,2 | 14 | ||||||||

| 28 | 25,9 | +0,4 -0,7 | 3,0 | +1,0 -1,2 | 31,9 | 3,0 | 1,2 | 1,8 | 2,5 | ||||

| 32 | 29,8 | 3,2 | 36,2 | 3,2 | 2,0 | 16 | 1,5 | 3,0 | 19 | ||||

| 36 | 33,7 | 3,5 | 40,7 | 3,5 | 1,5 | 18 | |||||||

| 40 | 37,6 | 44,6 | |||||||||||

Table 4

| Length of rods, m | Prev. off along the length with cutting accuracy, mm | |

| ordinary | increased | |

| Up to 6 incl. | +50 | +25 |

| St. 6 | +70 | +35 |

High-precision rods are manufactured according to customer requirements.

1.15. The curvature of the rods should not exceed 0.6% of the measured length.

Examples of symbols

Reinforcing steel with a diameter of 20 mm, class A-II (A300):

20-A-II GOST 5781-82

The same, with a diameter of 18 mm, class A-I (A240):

18-A-I GOST 5781-82

The index “c” is added to the designation of class A-II (A300) rods for special purposes: Ac-II (Ac300).

(Changed edition, Amendment No. 4).

Technical requirements

2.1. Reinforcing steel is manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Reinforcing steel is made from carbon and low-alloy steel of the grades indicated in Table 5. The steel grade is indicated by the consumer in the order. If there is no indication, the steel grade is determined by the manufacturer. For class A-IV (A600) rods, steel grades are established by agreement between the manufacturer and the consumer.

Table 5

| Reinforcing steel class | Profile diameter, mm | steel grade |

| A-I (A240) | 6-40 | St3kp, St3ps, St3sp |

| A-II (A300) | 10-40 | St5sp, St5ps |

| 40-80 | 18G2S | |

| Ac-II (Ac300) | 10-32 (36-40) | 10GT |

| A-III (A400) | 6-40 | 35GS, 25G2S |

| 6-22 | 32G2Rps | |

| A-IV (A600) | 10-18 (6-8) | 80C |

| 10-32 (36-40) | 20ХГ2Ц | |

| A-V (A800) | (6-8) 10-32 (36-40) | 23Х2Г2Т |

| A-VI (A1000) | 10-22 | 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR |

Notes:

1. It is allowed to manufacture reinforcing steel of class A-V (A800) from steel grades 22Х2Г2АУ, 22Х2Г2Р and 20Х2Г2СС.

2. The dimensions indicated in brackets are manufactured by agreement between the manufacturer and the consumer.

(Changed edition, Amendment No. 3, 4).

2.3. The chemical composition of reinforcing carbon steel must comply with GOST 380, low-alloy steel - with the standards given in Table 6.

Table 6

| steel grade | Mass fraction of elements, % | ||||||||||

| Carbon | Manganese | Silicon | Chromium | Titanium | Zirconium | Aluminum | Nickel | Sulfur | Phosphorus | Copper | |

| no more | |||||||||||

| 10GT | No more than 0.13 | 1,00-1,40 | 0,45-0,65 | No more than 0.30 | 0,015- 0,035 | — | 0,02- 0,05 | — | 0,040 | 0,030 | 0,30 |

| 18G2S | 0,14-0,23 | 1,20-1,60 | 0,60-0,90 | — | — | 0,30 | 0,045 | 0,040 | |||

| 32G2Rps | 0,28-0,37 | 1,30-1,75 | No more than 0.17 | 0,001- 0,015 | 0,050 | 0,045 | |||||

| 35GS | 0,30-0,37 | 0,80-1,20 | 0,60-0,90 | — | 0,045 | 0,040 | |||||

| 25G2S | 0,20-0,29 | 1,20-1,60 | |||||||||

| 20ХГ2Ц | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 0,90-1,20 | 0,05-0,14 | 0,045 | |||||

| 80C | 0,74-0,82 | 0,50-0,90 | 0,60-1,10 | No more than 0.30 | 0,015- 0,040 | — | 0,040 | ||||

| 23Х2Г2Т | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,35-1,70 | 0,02- 0,08 | 0,015- 0,050 | 0,045 | ||||

| 22Х2Г2АУ | 1,50-2,10 | 0,005- 0,030 | 0,02- 0,07 | 0,040 | 0,040 | ||||||

| 22Х2Г2Р | 1,50-1,90 | 1,50-1,90 | 0,02- 0,08 | 0,015- 0,050 | |||||||

| 20X2G2SR | 0,16-0,26 | 1,40-1,80 | 0,75-1,55 | 1,40-1,80 | |||||||

2.3.1. In steel grade 20ХГ2Ц, it is allowed to increase the mass fraction of chromium to 1.7% and replace zirconium with 0.02-0.08% titanium. In steel grade 23Х2Г2Т it is allowed to replace titanium with 0.05-0.10% zirconium. In this case, in the designation of steel grade 20KhG2Ts, the letter T is used instead of the letter C; steel grade 23Kh2G2T is marked with the letter T instead of the letter T.

In steel grade 32G2Rps, aluminum can be replaced with titanium or zirconium in equal units.

2.3.2. The mass fraction of nitrogen in steel grade 22Х2Г2АУ should be 0.015-0.030%, the mass fraction of residual nitrogen in steel grade 10GT should be no more than 0.008%.

2.3.3. The mass fraction of boron in steel grades 22Kh2G2R, 20Kh2G2SR and 32G2Rps should be 0.001-0.007%. In steel grade 22Х2Г2АУ, the addition of 0.001-0.008% boron is allowed.

2.3.4. It is allowed to add titanium to steel grades 18G2S, 25G2S, 35GS based on its mass fraction in finished rolled products of 0.01-0.03%, to steel grade 35GS based on its mass fraction in finished rolled products produced in coils of 0.01-0 .06%.

2.4. Deviations in the chemical composition in finished rolled products from carbon steels - according to GOST 380, from low-alloy steels, subject to compliance with the standards of mechanical properties - according to Table 7. Minus deviations in the content of elements (except for titanium and zirconium, and for steel grade 20Kh2G2SR - silicon) are not limited.

Table 7

| Elements | Prev. off, % |

| Carbon | +0,020 |

| Silicon | +0,050 |

| Manganese | +0,100 |

| Chromium | +0,050 |

| Copper | +0,050 |

| Sulfur | +0,005 |

| Phosphorus | +0,005 |

| Zirconium | +0,010 -0,020 |

| Titanium | ±0,010 |

Note. By agreement between the manufacturer and the consumer, steel can be manufactured with other deviations in the content of chromium, silicon and manganese.

(Changed edition, Amendment No. 3).

2.5. Reinforcing steel of classes A-I (A240), A-II (A300), A-III (A400), A-IV (A600) is made hot-rolled, class A-V (A800) - with low-temperature tempering, class A-VI ( A1000) - with low-temperature tempering or thermomechanical treatment in the flow of a rolling mill.

It is allowed not to carry out low-temperature tempering of steel of classes A-V (A800) and A-VI (A1000) provided that a relative elongation of at least 9% and a uniform elongation of at least 2% are obtained when tested within 12 hours after rolling.

2.6. The mechanical properties of reinforcing steel must comply with the standards specified in Table 8.

For steel class A-II (A300) with a diameter of St. 40 mm, it is allowed to reduce the relative elongation by 0.25% for each millimeter increase in diameter, but not more than 3%.

For steel class Ac-II (Ac300), a reduction in tensile strength to 426 MPa (43.5 kgf/mm²) is allowed with a relative elongation δ5 of 30% or more.

For steel grade 25G2S class A-III (A400), a reduction in tensile strength to 560 MPa (57 kgf/mm²) is allowed with a yield strength of at least 405 MPa (41 kgf/mm²), relative elongation δ5 of at least 20%.

Table 8

| Reinforcing steel class | Yield strength σT | Tensile strength σB | Relative elongation δ5, % | Uniform elongation δp, % | Impact strength at minus 60 °C | Cold bending test (c - mandrel thickness, d - rod diameter) | |||

| N/mm² | kgf/mm² | N/mm² | kgf/mm² | MJ/m² | kgf m/cm² | ||||

| no less | |||||||||

| A-I (A240) | 235 | 24 | 373 | 38 | 25 | — | — | — | 180°; c=d |

| A-II (A300) | 295 | 30 | 490 | 50 | 19 | 180°; c=3d | |||

| Ac-II (Ac300) | 441 | 45 | 25 | 0,5 | 5 | 180°; c=d | |||

| A-III (A400) | 390 | 40 | 590 | 60 | 14 | — | — | 90°; c=3d | |

| A-IV (A600) | 590 | 60 | 883 | 90 | 6 | 2 | 45°; c=5d | ||

| A-V (A800) | 785 | 80 | 1030 | 105 | 7 | ||||

| A-VI (A1000) | 980 | 100 | 1230 | 125 | 6 | ||||

Notes:

1. By agreement between the manufacturer and the consumer, it is allowed not to test the impact strength of class Ac-II reinforcing steel.

2. (Deleted, Amendment No. 3).

3. For reinforcing steel of class A-IV with a diameter of 18 mm and steel grade 80C, the cold bending rate is set to at least 30°.

4. For reinforcing steel class A-I (A240) with a diameter of St. 20 mm when bending in a cold state by 180°, c=2d, class A-II (A300) with a diameter of St. 20 mm - c=4d.

5. Symbols for the class of reinforcing steel according to yield strength are indicated in brackets.

(Changed edition, Amendment No. 1, 3, 5).

2.7. Statistical indicators of the mechanical properties of reinforcing steel bars of periodic profile must correspond to Appendix 1, with increased uniformity of mechanical properties - Appendix 1 and Table 9.

The probability of achieving the mechanical properties indicated in Table 8 must be at least 0.95.

(Changed edition, Amendment No. 3).

2.8. On the surface of the profile, including the surface of the ribs and protrusions, there should be no rolled cracks, stress cracks, flaws, rolled films or sunsets.

Minor damage to the ribs and protrusions is allowed, in the amount of no more than three per 1 m of length, as well as minor rust, individual rolled out stains, prints, sagging, traces of rolled out bubbles, rippling and scaliness within the permissible deviations in size.

(Changed edition, Amendment No. 2).

2.9. The weldability of reinforcing steel of all grades, except 80C, is ensured by the chemical composition and manufacturing technology.

2.10. The carbon equivalent Ceq≤C+Mn/6+Si/10 for welded rod reinforcement made of low-alloy steel of class A-III (A400) should be no more than 0.62.

(Introduced additionally, Amendment No. 5).

Table 9

| Reinforcing steel class | Profile number | S | S0 | S/X | S0/X | ||||

| For σT(σ0,2) | For σB | For σT(σ0,2) | For σB | For σT(σ0,2) | For σB | For σT(σ0,2) | For σB | ||

| MPa (kgf/mm²) | MPa (kgf/mm²) | ||||||||

| no more | |||||||||

| A-II (A300) | 10-40 | 29 (3) | 29 (3) | 15 (1,5) | 15 (1,5) | 0,08 | 0,06 | 0,05 | 0,03 |

| A-III (A400) | 6-40 | 39 (4) | 39 (4) | 20 (2,0) | 20 (2,0) | 0,07 | |||

| A-IV (A600) | 10-32 | 69 (7) | 69 (7) | 39 (4,0) | 39 (4,0) | 0,09 | 0,06 | 0,05 | |

| A-V (A800) | 78 (8) | 78 (8) | 49 (5,0) | 49 (5,0) | |||||

| A-VI (A1000) | 88 (9) | 88 (9) | 0,08 | 0,05 | 0,04 | ||||

Notes:

1. S - standard deviation in the general population of tests;

S0 is the standard deviation in the melting batch;

X is the average value in the population of tests;

X is the minimum average value in the melting batch.

2. For reinforcing steel in coils with a diameter of 6 and 8 mm, it is allowed to increase the standards for S and S0 by 4.9 MPa (0.5 kgf/mm²).

3. (Deleted, Amendment No. 5).

Acceptance rules

3.1. Reinforcing steel is accepted in batches consisting of profiles of the same diameter, one class, one melt-ladle and issued with one quality document.

The batch weight should be up to 70 tons.

It is allowed to increase the mass of the batch to the mass of the melting ladle.

3.2. Each batch is accompanied by a quality document in accordance with GOST 7566 with additional data:

- profile number;

- Class;

- minimum average value X and standard deviations S0 in a batch of values σT(σ0.2) and σB;

- results of cold bending tests;

- values of uniform elongation for steel classes A-IV (A600), A-V (800), A-VI (A1000).

3.3. To check the size and quality of the surface, select:

- in the manufacture of reinforcing steel in rods - at least 5% of the batch;

- when produced in skeins - two skeins from each batch.

(Changed edition, Amendment No. 3).

3.4. To check the chemical composition, samples are taken according to GOST 7565.

The manufacturer determines the mass fraction of aluminum periodically, but at least once a quarter.

3.5. To test for tensile, bending and impact strength, two rods are selected from the batch.

For the manufacturer, the interval for selecting rods must be at least half the time spent on rolling one profile size of one batch.

(Changed edition, Amendment No. 3).

3.6. If unsatisfactory test results are obtained for at least one of the indicators, repeated tests are carried out in accordance with GOST 7566.

Test methods

4.1. Chemical analysis of steel is carried out according to GOST 12344, GOST 12348, GOST 12350, GOST 12352, GOST 12355, GOST 12356, GOST 18895 or other methods that provide the required accuracy.

4.2. The diameter and ovality of the profiles are measured at a distance of at least 150 mm from the end of the rod or at a distance of at least 1500 mm from the end of the skein with a skein weight of up to 250 kg and at least 3000 mm with a skein weight of more than 250 kg.

4.3. Dimensions are checked with a measuring tool of the required accuracy.

4.4. One sample is cut from each selected rod for tensile, bending and impact strength testing.

4.5. Sampling for testing tensile, bending and impact strength is carried out in accordance with GOST 7564.

4.6. The tensile test is carried out according to GOST 12004.

4.7. The bending test is carried out according to GOST 14019 on samples with a cross-section equal to the cross-section of the rod.

For rods with a diameter of St. 40 mm, it is allowed to test samples cut along the axis of the rod on a mandrel with a diameter reduced by half compared to that indicated in Table 4, with a bending force applied from the side of the cut.

4.8. Determination of impact strength is carried out according to GOST 9454 on samples with a type U type 3 concentrator for rods with a diameter of 12-14 mm and type I samples for rods with a diameter of 16 mm or more. Samples are manufactured in accordance with the requirements of GOST 9454.

4.9. It is allowed to use statistical and non-destructive methods for monitoring the mechanical properties and mass of profiles.

4.10. The curvature of the rods is measured along the length of the supplied profile, but not shorter than 1 m.

4.11. Determination of statistical indicators of mechanical properties - in accordance with Appendix 2.

4.12. The quality of the surface is checked without the use of magnifying devices.

4.10-4.12. (Introduced additionally, Amendment No. 3).

4.13. The height of the transverse projections of a periodic profile should be measured along the vertical axis of the cross-section of the reinforcing bars.

(Introduced additionally, Amendment No. 4).

Packaging, labeling, transportation and storage

5.1. Packaging, labeling, transportation and storage - in accordance with GOST 7566 with the following additions:

- the ends of rods made of low-alloy steels of class A-IV (A600) must be painted with red paint, class A-V - red and green, class A-VI (A1000) - red and blue. It is allowed to paint the ligaments at a distance of 0.5 m from the ends;

- the rods are packaged in bundles weighing up to 15 tons, tied with wire or wire rod. At the consumer's request, the rods are packaged in bundles weighing up to 3 and 5 tons.

On the ties, paint is applied in strips no less than 20 mm wide on the side surface around the circumference (at least 1/2 the length of the circumference) at a distance of no more than 500 mm from the end.

Paint is applied to the skeins in strips no less than 20 mm wide across the turns on the outside of the skein.

For unpackaged products, paint is applied to the end or side surface at a distance of no more than 500 mm from the end.

The label attached to each bundle of rods is marked with the accepted designation of the reinforcing steel class (for example, A-III) or the symbol of the yield strength class (A400).

(Changed edition, Amendment No. 3, 5).

Appendix 1 (mandatory). Requirements for statistical indicators of mechanical properties

APPENDIX 1 Mandatory

1. The manufacturer guarantees to the consumer the average values of tensile strength σB and yield strength (physical σT and conditional σ0.2) in the general population - Xi and the minimum average values of these same indicators in each batch-melt - Xi, the values of which are determined from the conditions:

where Xibr are the rejection values of σB, σ0.2, indicated in Table 8 of this standard;

t is the quantile value taken equal to 2 for classes A-II (A300) and A-III (A400) and 1.64 for classes A-IV (A600), A-V (A800) and A-VI (A1000) .

2. Quality control of indicators of mechanical properties of products at the manufacturer

2.1. The required quality indicators of profiles are ensured by compliance with production technology and controlled by testing in accordance with the requirements of clause 3.5, clauses 4.4-4.8.

2.2. The values of Xi, Xi, S and S0 are set in accordance with the test results and the provisions of Appendix 2.

3. Quality control of indicators of mechanical properties of products at the consumer enterprise

3.1. The consumer, if he has a quality document for products of the highest quality category, may not test the mechanical properties.

3.2. If it is necessary to check the mechanical properties of each batch, six samples taken from different bags or skeins and from different profiles are tested, and based on the results, the fulfillment of the conditions is checked:

where X6 is the average value of mechanical properties based on the test results of six samples;

Xmin is the minimum value of the test results of six samples.

3.3. The minimum values of relative elongation δ5 and uniform elongation δp must be no less than the values given in Table 8.

(Changed edition, Amendment No. 3, 5).

What else is important?

When creating unstressed reinforced concrete structures, you should choose classes from first to third, and higher ones are useful if the structure has undergone prestressing.

If you have to work at low temperatures, and the object will continue to be operated in extreme conditions, then a brand of fittings that has a lower percentage of carbon is more suitable. As an alternative, you can choose raw materials that have undergone additional high-temperature processing.

But if it was decided to use wire as a reinforcing material, then it is better to give preference to one in which carbon is either completely absent or its content does not exceed 0.8%. This material is characterized by increased strength - up to 180 kgf/mm2 inclusive. The following parameters are provided:

- high temperature treatment;

- hardening

Range

Smooth rods with a round cross-section and reinforcement with periodically corrugated surfaces are produced using hot rolling technology. According to their mechanical properties, metal products are divided into classes AI (A-240), A-II (A-300), A-III (A-400); A-IV (A-600), AV (A-800), A-VI (A-1000). The form of supply of reinforcing steel is rods (pieces) or coils. Rods of class AI (A-240) are produced with a smooth surface; reinforced steel of other classes is produced with a corrugated surface. According to an agreed specification, fittings of all classes can be manufactured with a smooth surface.

Table 1. Dimensions and weight.

| Profile No. (corresponds to the nominal D of the rods) | Transverse area rod cross-section, cm2 | Reference weight 1 m.p., kg | Max. off, % | Weight 1000 m.p., kg | Number of meters per ton |

| 6,0 | 0.28Z | 0,222 | +9,0 | 222 | 4 504,5 |

| 8,0 | 0.50Z | 0.395 | -7,0 | Z95 | 2 5З1.6 |

| 10,0 | 0,787 | 0,617 | +5,0 -6,0 | 617 | 1 620,7 |

| 12,0 | 1.1З1 | 0,888 | 888 | 1 126,1 | |

| 14,0 | 1,544 | 1,210 | 1210 | 826,44 | |

| 16,0 | 2.01Z | 1,580 | +Z,0 -5,0 | 1580 | 6Z2.91 |

| 18,0 | 2,541 | 2,000 | 2000 | 500,00 | |

| 20,0 | Z,14Z | 2,470 | 2470 | 404,85 | |

| 22,0 | Z,805 | 2,980 | 2980 | ZZ5.57 | |

| 25,0 | 4,917 | Z,850 | Z850 | 259,74 | |

| 28,0 | 6,169 | 4.8З0 | 48З0 | 207.0Z | |

| Z2.0 | 8,040 | 6,З10 | +Z,0 -4,0 | 6З10 | 158,47 |

| Z6.0 | 10,186 | 7,990 | 7990 | 125,15 | |

| 40,0 | 12,575 | 9,870 | 9870 | 101,Z1 | |

| 45,0 | 15,004 | 12,480 | 12480 | 80,12 | |

| 50,0 | 19.6ZZ | 15,410 | +2,0 -4,0 | 15410 | 64,89 |

| 55,0 | 2Z,762 | 18,650 | 18650 | 5Z,61 | |

| 60,0 | 28.27Z | 22,190 | 22190 | 45,06 | |

| 70,0 | Z8,484 | Z0.210 | Z0210 | ZZ,10 | |

| 80,0 | 50,275 | Z9,460 | Z9460 | 25,Z4 |

When calculating the mass of a steel rod, the density of steel is taken into account, equal to 7.85 × 103 kg/m3. Maximum deviations in diameter size are regulated by GOCT 2590-2006. The ovality of rods with a smooth surface cannot be greater than the sum of + and - maximum deviations in thickness.

Figure 1. Corrugation shape of hot-rolled rods of conventional design.

Figure 2. Corrugation shape of hot-rolled special-purpose rods.

Rods AI (A-240) and A-II (A-Z00) with a thickness of less than 12.0 mm and A-III (A-400) with a thickness of up to 10.0 mm are supplied in coils or sections, for larger thicknesses - in sections. Rolled products of classes A-IV (A-600), AV (A-800) and A-VI (A-1000) of all thicknesses are supplied in the form of pieces. Steel for reinforcement with a thickness of 6.0 and 8.0 mm, at the customer’s request, is sold in coils.

The standard length of the segments is from 6.0 to 12.0 m. In one batch, the presence of rods with a length of 3.0 to 6.0 m is allowed, provided that their number does not exceed seven percent of the total volume of the batch.

Table 2. Dimensions of rods in Fig. 1 (drawings a and b).

| Profile number, dn | d | h | d1 | h1 | t | b | b1 | r | ||

| Nomin. | Max. off | Nomin. | Max. off | |||||||

| 6,0 | 5,75 | +0,Z -0,5 | 0,50 | ±0,25 | 6,75 | 0,50 | 5,00 | 0,50 | 1,00 | 0,75 |

| 8,0 | 7,50 | 0.7Z | 9,00 | 0,75 | 5,00 | 0,75 | 1,25 | 1,10 | ||

| 10,0 | 9,З0 | 1,00 | 11,З0 | 1,00 | 7,00 | 1,00 | 1,50 | 1,50 | ||

| 12,0 | 11,00 | 1,25 | 1Z.50 | 1,25 | 2,00 | 1,90 | ||||

| 14,0 | 1Z.00 | 15,50 | 1,90 | |||||||

| 16,0 | 15,00 | 1,50 | 18,00 | 1,50 | 8,00 | 1,50 | 2,20 | |||

| 18,0 | 17,00 | ±0,5 | 20,00 | |||||||

| 20,0 | 19,00 | 22,00 | ||||||||

| 22,0 | 21,00 | +0,4 | 24,00 | |||||||

| 25,0 | 24,00 | -0,5 | 27,00 | |||||||

| 28,0 | 26,50 | +0,4 -0,7 | 2,00 | Z0.50 | 2,00 | 9,00 | 2,50 | Z.00 | ||

| Z2.0 | Z0.50 | Z4.50 | 10,00 | 2,00 | Z.00 | |||||

| Z6.0 | Z4.50 | 2,50 | ±0,7 | Z9.50 | 2,50 | 12,00 | Z.50 | |||

| 40,0 | Z8.50 | 4Z.50 | ||||||||

| 45,0 | 4Z.00 | Z.00 | 49,00 | Z.00 | 15,00 | 2,50 | Z.50 | 4,50 | ||

| 50,0 | 48,00 | 54,00 | ||||||||

| 55,0 | 5Z.00 | +0,4 | 59,00 | 4,00 | ||||||

| 60,0 | 68,00 | 1,0 | ±1,0 | 64,00 | 5,00 | |||||

| 70,0 | +0,5 | 74,00 | 4,50 | 5,50 | ||||||

| 80,0 | 77,50 | -1,1 | 8Z.50 | 4,60 | ||||||

Table 3. Dimensions of reinforcing steel Fig. 2 (drawings a and b).

| Profile number, nominal diameter dн | d | h | d1 | h1 | hr | hB | t | b | b1 | r1 | a, hail | ||

| Nom. | Max. off | Nom. | Max. off | ||||||||||

| 10,0 | 8,7 | +0,Z -0,5 | 1,6 | ±0,5 | 11,9 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 1,5 | 11 | 50 |

| 12,0 | 10,6 | 1,6 | 1З,8 | 1,6 | 0,6 | 1,0 | 10 | 0,7 | 2,0 | 11 | |||

| 14,0 | 12,5 | 2,0 | 16,5 | 2,0 | 0,8 | 1,2 | 12 | 1,0 | 2,0 | 12 | |||

| 16,0 | 14,2 | 2,5 | 19,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | |||

| 18,0 | 10,2 | 2,5 | +0,65 -0,85 | 21,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 20,0 | 18,2 | 2,5 | 2Z,2 | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | |||

| 22,0 | 20, W | +0,4 -0,5 | 2,5 | 25, W | 2,5 | 1,0 | 1,5 | 12 | 1,0 | 2,0 | 12 | ||

| 25,0 | 2Z,Z | 2,5 | 28, W | 2,5 | 1,0 | 1,5 | 14 | 1,2 | 2,0 | 14 | |||

| 28,0 | 25.9 | Z.0 | Z1.9 | Z.0 | 1,2 | 1,8 | 14 | 1,2 | 2,5 | 14 | |||

| Z2.0 | 29,8 | +0,4 -0,7 | Z,2 | +1,0 -1,2 | Z6.2 | Z,2 | 1,2 | 2,0 | 16 | 1,5 | Z.0 | 14 | |

| Z6.0 | ZZ,7 | Z.5 | 40,7 | Z.5 | 1,5 | 2,0 | 18 | 1,5 | Z.0 | 19 | |||

| 40,0 | Z7.6 | Z.5 | 44,6 | Z.5 | 1,5 | 2,0 | 18 | 1,5 | Z.0 | 19 | |||

Table 4. Maximum length tolerances.

| L, m | Maximum length tolerances, mm | |

| normal cutting accuracy | increased cutting accuracy | |

| up to 6.0 m | +50,0 | +25,0 |

| from 6.0 to 12.0 m | +70,0 | +Z5.0 |

The maximum permissible curvature cannot exceed 0.6% of the total length.

An example of marking and its explanation:

● 20-A-II (AcЗ00) GOST 5781-82. This designates steel rods with a thickness of 20.0 mm of class A-II for special purposes.

Additionally, reinforcing steel can be designated by the following indices:

● C - easy to weld;

● T—heat-treated steel;

● K—corrosion-resistant steel (galvanized);

● CK - steel with high anti-corrosion properties, suitable for welding.

Carbon and material quality

Regulates from what raw materials construction fittings should be made, GOST 5781-82. In particular, the percentage of carbon has a fairly strong influence on the final parameters of the reinforced concrete product, its durability and reliability. The more carbon contained in the metal, the higher the hardness characteristic of the reinforcement will be, but at the same time the fragility increases. In addition, welding high-carbon steel is very difficult, often the result is not of sufficient quality, which affects the reliability of the entire structure as a whole.

The percentage of carbon allows the following classification:

- low-carbon steel reinforcement, where this compound is contained in an amount of no more than a quarter of a percent;

- with an average content level - from a quarter of a percent to 0.6;

- with a high content varying from 0.6 to 2%.

Technical requirements

2.1. Reinforcing steel is manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Reinforcing steel is made from carbon and low-alloy steel of the grades indicated in table. 5. The steel grade is indicated by the consumer in the order. If there is no indication, the steel grade is determined by the manufacturer. For class A-IV (A600) rods, steel grades are established by agreement between the manufacturer and the consumer.

Table 5

2.3. The chemical composition of reinforcing carbon steel must comply with GOST 380-88, low-alloy steel - with the standards given in table. 6

Table 6

In steel grade 32G2Rps, aluminum can be replaced with titanium or zirconium in equal units.

2.3.2. The mass fraction of nitrogen in steel grade 22Х2Г2АУ should be 0.015-0.030%, the mass fraction of residual nitrogen in steel grade 10GT should be no more than 0.008%.

2.3.3. The mass fraction of boron in steel grades 22Kh2G2R, 20Kh2G2SR and 32G2Rps should be 0.001-0.007%. In steel grade 22Х2Г2АУ, the addition of 0.001-0.008% boron is allowed.

2.3.4. It is allowed to add titanium to steel grades 18G2S, 25G2S, 35GS based on its mass fraction in finished rolled products of 0.01-0.03%, to steel grade 35GS based on its mass fraction in finished rolled products produced in coils of 0.01-0 .06%.

2.4. Deviations in the chemical composition in finished rolled products from carbon steels - according to GOST 380-88, from low-alloy steels, subject to compliance with the standards of mechanical properties - according to table. 7. Minus deviations in the content of elements (except for titanium and zirconium, and for the steel grade 20Kh2G2SR silicon) are not limited.

Table 7

2.5. Reinforcing steel of classes A-I (A240), A-II (A300), A-III (A400), A-IV (A600) is made hot-rolled, class A-V (A800) - with low-temperature tempering, class A-VI ( A1000) - with low-temperature tempering or thermomechanical treatment in the flow of a rolling mill.

It is allowed not to carry out low-temperature tempering of steel of classes A-V (A800) and A-VI (A1000) provided that a relative elongation of at least 9% and a uniform elongation of at least 2% are obtained when tested within 12 hours after rolling.

2.6. The mechanical properties of reinforcing steel must comply with the standards specified in table. 8.

For class A-II (A300) steel with a diameter over 40 mm, a reduction in elongation of 0.25% is allowed for each millimeter increase in diameter, but not more than 3%.

For steel class Ac-II (Ac300), a reduction in tensile strength to 426 MPa (43.5 kgf/mm) is allowed with a relative elongation of 30% or more.

For steel grade 25G2S class A-III (A400), it is allowed to reduce the tensile strength to 560 MPa (57 kgf/mm) with a yield strength of at least 405 MPa (41 kgf/mm), relative elongation of at least 20%.

Table 8

2.7. Statistical indicators of the mechanical properties of reinforcing steel bars of periodic profile must correspond to Appendix 1, with increased uniformity of mechanical properties - Appendix 1 and Table. 9.

The probability of achieving the mechanical properties indicated in table. 8, must be at least 0.95.

2.8. On the surface of the profile, including the surface of the ribs and protrusions, there should be no rolled cracks, stress cracks, flaws, rolled films or sunsets.

Minor damage to the ribs and protrusions is allowed, in the amount of no more than three per 1 m of length, as well as minor rust, individual rolled out stains, prints, sagging, traces of rolled out bubbles, rippling and scaliness within the permissible deviations in size.

2.9. The weldability of reinforcing steel of all grades, except 80C, is ensured by the chemical composition and manufacturing technology.

2.10. The carbon equivalent for welded rod reinforcement made of low-alloy steel of class A-III (A400) should be no more than 0.62.

Table 9

How to improve?

In order for the reinforcing steel to have better quality, additional components can be added to the alloy. It is customary to use the following alloying components:

- tungsten;

- vanadium;

- chromium;

- nickel.

Some alloys add only one or two additional components, while others add a mixture of 5-6 metals. This allows you to obtain high-quality alloy steel with high performance:

- strength;

- hardness;

- corrosion resistance.

To obtain alloy steel, you can include silicon and manganese in the raw materials. Depending on how many additives are contained in a substance, it is customary to say that the material belongs to one of the following classes:

- low-alloy reinforcing steel containing no more than five percent inclusions;

- medium alloyed, in which the amount of additives varies between 5-10%;

- highly alloyed, one tenth or more consisting of additional components.

Acceptance rules

3.1. Reinforcing steel is accepted in batches consisting of profiles of the same diameter, one class of one melt-ladle and issued with one quality document. The batch weight should be up to 70 tons.

It is allowed to increase the mass of the batch to the mass of the melting ladle.

3. 2. Each batch is accompanied by a quality document in accordance with GOST 7566-81 with additional data:

- profile number;

- Class;

- minimum average value X and standard deviations S0 in a batch of values σT (σ0.2) and σB;

- results of cold bending tests;

- values of uniform elongation for steel class A - IV (A600), AV (800), A-VI (A1000).

3.3. To check the size and quality of the surface, select:

- in the manufacture of reinforcing steel in rods - at least 5% of the batch;

- when produced in skeins - two skeins from each batch.

3 4. To check the chemical composition, samples are taken according to GOST 7565-81.

The manufacturer determines the mass fraction of aluminum periodically, but at least once a quarter.

3.5. To test for tensile, bending and impact strength, two rods are selected from the batch

For a manufacturing enterprise, the interval for selecting rods must be at least half the time spent on rolling one profile size of one batch 3 6 If unsatisfactory test results are obtained for at least one of the indicators, repeated tests are carried out in accordance with GOST 7566-81.

"What's in a name?"

Reinforcing steel is not just steel, but also a large number of other chemical components. You can find out what inclusions are in the material from the name. Standards have been developed for designating certain additives in the name of the material. Examples:

- X – chrome.

- C – zirconium.

- T – titanium.

Numbers are written after the stamp. They reflect how much carbon a material contains. Hundredths are indicated. Next they write the letters. They designate a chemical element, after which it is indicated how much of it is contained in the reinforcement. If no figure is given, it can be concluded that the substance is included in a volume of less than one percent.

Example: “reinforcing steel 35GS” is deciphered as steel, which contains carbon in a concentration of 0.35%, and also contains silicon and manganese, but the percentage of both components is insignificant, so there is no specified data (they are present in a volume of less than a percent of the total amount of material).

Reinforcement depending on the metal used

Based on the component composition of the alloy used, two main groups of reinforcing bars are distinguished.

Carbon Steel Rebar

Reinforcement in this category is made from an alloy containing only two chemical elements in significant quantities: iron and carbon. When the relative proportion of carbon increases to a certain limit, the strength and hardness of the material increases, but brittleness to fracture appears and welding capabilities deteriorate.

Alloy steel fittings

Alloy steel contains small amounts of chromium, manganese, titanium, molybdenum, tungsten and other elements. A wide variety of combinations are possible, which have different effects on the performance characteristics of the resulting alloy. Manganese increases the strength and wear resistance of the material, and silicon makes it more elastic and fluid.

What to demand and expect?

According to current standards, reinforcing steel must be:

- easy to weld;

- plastic;

- durable.

Strength is usually understood as the ability of reinforcement to withstand destructive loads of the external environment. External influences can stretch and bend metal, twist and compress, and cut. For each type of load, separate strength indicators are identified. Reinforcement is more often used in conditions where tensile loads are high, so it is this value that you should pay attention to first. To assess how much reinforcement can resist tension, you need to evaluate:

- fluid limit;

- breaking resistance.

Plasticity is a parameter that reflects the adaptability of a material to external loads that try to change the shape of the product, its cross-section. If the reinforcement under such conditions retains its initial parameters, then after removing the load it can return to its original state or retain the changes obtained. Plasticity is expressed in elongation at break, bend angle, and the number of bends remaining after cooling of the metal.

Weldability is an indicator that reflects the ability to qualitatively connect with other materials when using a particular welding method. This parameter is defined:

- metal composition;

- smelting method;

- the size of the rods in section;

- connecting features;

- plasticity.

Mechanics and reliability

The above parameters allow us to talk about how good the mechanical parameters of steel are. It is on their basis that technical characteristics and indicators are distinguished.

An important feature of reinforcement is its temporary resistance. To determine it, as well as to determine how large the fluid limit is, how large the elongation of steel can be relative to the initial value, special tests are carried out in production: tensile testing machines designed for this task are used.

The work is carried out as follows: when starting the machine, the load on the placed sample gradually increases. In this case, the reinforcement is located in a rigid fastening system that does not allow the specimen to “slip away.” The mechanisms try to lengthen the rod longitudinally, deforming it. The indicators taken from the reinforcement make it possible to form a tension diagram (the scale is set arbitrarily).

Test methods

4.1. Chemical analysis of steel is carried out according to GOST 12344-88, GOST 12348-78, GOST 12350-78, GOST 12352-81, GOST 12355-78, GOST 12356-81, GOST 18895-81 or other methods that ensure the required accuracy.

4.2. The diameter and ovality of the profiles are measured at a distance of at least 150 mm from the end of the rod or at a distance of at least 1500 mm from the end of the skein with a skein weight of up to 250 kg and at least 3000 mm with a skein weight of more than 250 kg.

4.3. Dimensions are checked with a measuring tool of the required accuracy.

4.4. One sample is cut from each selected rod for tensile, bending and impact strength testing.

4.5. Sampling for tensile, bending and impact strength testing is carried out in accordance with GOST 7564-73.

4.6. The tensile test is carried out according to GOST 12004-81.

4.7. The bending test is carried out according to GOST 14019-80 on samples with a cross-section equal to the cross-section of the rod.

For rods with a diameter over 40 mm, it is allowed to test samples cut along the axis of the rod on a mandrel with a diameter reduced by half compared to that indicated in the table. 4, with bending force applied from the side of the cut.

4.8. Determination of impact strength is carried out according to GOST 9454-78 on samples with a concentrator type U type 3 for rods with a diameter of 12-14 mm and samples of type 1 for rods with a diameter of 16 mm or more. Samples are manufactured in accordance with the requirements of GOST 9454-78.

4.9. It is allowed to use statistical and non-destructive methods for monitoring the mechanical properties and mass of profiles.

4.10. The curvature of the rods is measured along the length of the supplied profile, but not shorter than 1 m.

4.11. Determination of statistical indicators of mechanical properties in accordance with mandatory Appendix 2.

4.12. The quality of the surface is checked without the use of magnifying devices.

4.13. The height of the transverse projections of a periodic profile should be measured along the vertical axis of the cross-section of the reinforcing bars.

Technical features

The straight sections of the diagram reflect loads under which the sample does not deform. With increasing loads, you can see a proportional increase in length, which allows you to draw conclusions about the reliability of the steel and its ability to resist external influences. The limiting value of the load applied to the test specimen is preset. Upon reaching this value, the influence of mechanical force is also gradually reduced.

In the best case scenario, the rod, stretched under the influence of a large external force, returns to its original state when the load is removed. This ability is due to the elasticity of steel. It is worth understanding that the elastic zone for metal has certain limitations. If indicators exceed these limits, returning to the original values will become impossible. When such a limit indicator is identified, the elastic limit is reached.

If you test reinforcement made of ST3 steel manufactured in accordance with the current GOST, then you will be able to obtain parameters close to the following:

- yield strength - 2,460 kgf/cm2;

- relative elongation - 25;

- tensile strength in a given time period - 4,000 kgf/cm2.

Composite reinforcement

Composite reinforcement is a modern alternative to steel analogues, which have long been used in monolithic construction. Its development began back in the 60s of the last century. In Russia it is produced in accordance with the requirements of GOST 31938-2012. In other countries, the international standard ISO 10406-1:2008 is used as a basis.

Classification of composite reinforcement

The starting materials for the production of composite reinforcement are carbon, glass, and fibers based on natural minerals. They form a strong rod, which is given a ribbed shape in various ways. Parts acquire strength and hardness as a result of high-temperature treatment.

Based on material design, non-metallic fittings are divided into several categories:

1. Fiberglass composite reinforcement (FFR) is a product of a combination of fiberglass (glass roving) with special resins. The fibers are obtained by drawing a molten aluminoborsilicate mixture to a thickness of about 10-20 microns. They are used to form rods of larger diameter using adhesive impregnations and resins.

ASK fittings.

2. Basalt-composite reinforcement (BCR) is obtained from molten mountain mineral - basalt. It is brought to a molten state, stretched to the state of the finest fibers. They are woven in the presence of organic resins into fairly thick rods that, when hardened, can withstand extreme loads.

ABK fittings.

3. Combined composite reinforcement (AKK) consists of fiberglass rods coated on the outside with basalt-plastic winding. It is somewhat inferior in strength characteristics to basalt rods, although it is often passed off as them by unscrupulous suppliers.

ACC fittings.

4. Carbon composite reinforcement (ACF) is made from carbon fibers 3-15 microns thick, laid parallel to each other. This material has very high tensile strength, but is more expensive than other composite analogues.

5. Aramidocomposite rods (AAC) are durable and chemically resistant parts made from polyamide molecular chains. The hydrogen bonds that arise between them during the molding process give the products special reliability and durability.

Dimensions of composite reinforcement

Composite reinforcement, even with a small thickness, can take on enormous loads. The most popular diameters of such rods are presented in Table No. 4.

Table 4. Nominal diameters of composite reinforcement

| Nominal diameter according to GOST 31938-2012 Composite polymer reinforcement for reinforcing concrete structures. General technical conditions (as amended), mm | ||||||||||||

| 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 |

The standard allows the production of composite reinforcement with other sizes. The rods usually arrive from the manufacturer in a strictly defined cut. Their length ranges from 0.5 to 12.0 meters. Maximum deviations in the length of single copies cannot exceed the values specified in table No. 5.

Table 5. Requirements for the manufacturing accuracy of composite rods

| Rod length | Maximum deviations along the length, mm |

| up to 6 meters inclusive | +/- 25 |

| over 6 to 12 meters | +/- 35 |

| more than 12 meters | +/- 50 |

Some types of composite rebar come in the form of coils or wound on rigid drums.

Coil of composite reinforcement.

Parameters and scope

Reinforcement with high strength values is usually more expensive than low-quality material. At the same time, practice shows that the use of such material allows one to achieve significant savings, since the reinforcement of reinforced concrete structures requires more economical consumption of metal.

Pay attention to the plasticity of the reinforcement: there are certain limits beyond which it is extremely undesirable. When this parameter decreases below a certain level, it is impossible to use rolled products at full strength. A structure made using such consumable raw materials becomes fragile and can unpredictably collapse under the influence of external factors. There is another risk associated with a decrease in the ductility of the metal: the likelihood of brittle fracture increases already at the stage of reinforcing reinforced concrete structures.

Impact on steel samples

To improve the performance of reinforcement, they resort to various technologies of external influence. In particular, the practice of thermal hardening is widespread. At the same time, the strength of the material doubles, and sometimes even more. This is most applicable for low-alloy, carbon compounds. But the cost of the material increases by only 10-12%. Thermal hardening shows better performance compared to mechanical hardening, but to implement it you need to have serious modern equipment and a team of highly qualified specialists. Even minor errors in the technological process greatly affect the quality of the final product (and the reputation of its manufacturer).

Mechanical hardening is achieved using:

- winches;

- hydraulic jacks;

- profiled rolls.

The latter are needed to flatten steel. During hardening, it is possible to achieve plastic deformations, due to which the strength increases by 50% relative to the original value.

The most popular - what is it?

Traditionally, the most in demand in the metal market is reinforcement 8 mm in diameter. It belongs to the third class and is produced in coils, skeins, and rods. 8 mm is the parameter for the average diameter of the building material. The production of such fittings must comply with GOST 30136-95. The reinforcement produced in coils is called “wire rod” by specialists.

8mm reinforcement is made from low carbon steel. Brands ST0, ST3 are used. During the manufacturing process there are two (sometimes one) cooling stages, which makes it possible to achieve high reliability of the material. Wire rod in coils is wire.

A3 reinforcement is steel with a circular cross-section. It is necessary for the subsequent production of wire and springs. Raw materials are also indispensable in the production process of cold-drawn construction reinforcement.

Production and sales

8 mm reinforcement is usually made on wire-section machines from raw materials that comply with GOST 380. This is a standard technology that involves the presence of bar steel processed by a shaft system. On machines, the material is rolled and drawn, heated and cooled. Depending on the characteristics of a particular product, it will be cooled naturally or forcibly.

This product is available for sale both by linear meters and in large skeins (for wholesale buyers).

Why is this necessary?

8 mm reinforcement is indispensable in the construction of reinforced concrete and metal structures. The wire rod is quite thin, so it is used in the manufacture of meshes, frames, and ropes. The reinforcement is effective as a base for staples. It is used to strengthen building structures. A specific option is selected by analyzing the operating conditions of the building, on the basis of which a decision is made in favor of one brand or another.

Reinforcement is more often used as a raw material for the manufacture of other construction products, and not as an independent material. If wire rod is needed to produce nails or cables, then you need to control the evenness of the products: rough surfaces are unacceptable, this will significantly reduce the strength of the finished product. When manufacturing thick reinforcement and staples, the requirements for surface smoothness are not so significant. The reinforcement used to construct load-bearing walls cannot contain air-filled cavities or cracks. If 8 mm diameter reinforcement is purchased in rods, quality control involves tracking the identity of the products.

REQUIREMENTS FOR STATISTICAL INDICATORS OF MECHANICAL PROPERTIES

1. The manufacturer guarantees to the consumer the average values of tensile strength sв and yield strength (physical sт and conditional s0.2) in the general population - and the minimum average values of these same indicators in each heat batch, the values of which are established from the conditions:

³ Xi

bp +

t × S

;

> 0,9Xi

bp + 3

S

0;

³ Xi

bp,

where Hibr

— rejection values of values sв, s0.2 indicated in table. 8 of this standard;

t

— quantile value taken equal to 2 for classes A-II (A300) and A-III (A400) and 1.64 for classes A-IV (A600), AV (A800) and A-VI (A 1000).

2. Quality control of indicators of mechanical properties of products at the manufacturing plant