Rolled metal with steel grade: 3PS/SP5—>3PS5/SP5

Reference Information:

When choosing rolled metal products, it is necessary to rely not only on its size and purpose, but also take into account the characteristics of the grade of steel from which it is made. The quality of the metal product and its performance characteristics depend on these parameters.

Decoding of steel grades is carried out thanks to generally accepted meanings, where each letter is assigned to one or another type of metal contained in the steel alloy, and letter combinations that indicate the condition of the steel. The chemical composition of any steel grade must comply with GOST to avoid defects and low quality of the product.

So, for example, steel of ordinary quality can be designated as st3sp (where sp is mild steel), St4ps (where ps is semi-mild steel), and high-quality carbon steel of any grade is 08kp, 10ps, 18K and practically does not contain alloying impurities.

For the manufacture of welded and hot-rolled products, it is preferable to use carbon and low-alloy steel grades. For pipes that are produced by welding steel sheets, 09g2s is most often used, where in addition to the amount of carbon contained in the alloy, the presence of manganese and silicon is indicated (letters g and c, respectively).

Source

Production Features

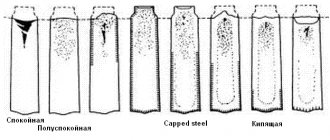

The properties of the finished material are determined by the substances that make up its composition and largely depend on what technologies were used in the production of a particular alloy.

The basis of the steel alloy is ferrite. It is a component of iron-carbon alloys. It is, in fact, a solid solution of carbon and alloying components. To increase its strength, the melt is saturated with carbon.

Impurities from which nothing but harm can be expected include phosphorus and sulfur, as well as their derivatives. Phosphorus, reacting with ferrite, reduces the ductility of the alloy when exposed to high temperatures and increases brittleness when exposed to cold. During the melting process, iron sulfide may be formed, which can lead to red brittleness. St3 steel contains no more than 0.05% sulfur and 0.04% phosphorus.

For the production of structural steels, two steelmaking technologies are used:

- open hearth;

- converter

The parameters of the St3 grade, obtained by one or another method, differ little from each other, but the converter technology is simpler and cheaper.

Application of St3sp steel, taking into account characteristics and properties

This type of steel is one of the most popular in construction and industry.

The absence of oxygen in the alloy and a homogeneous structure are factors that increase resistance to corrosion in aggressive environments. These qualities, as well as high ductility, make this steel indispensable in the production of structures and elements that have high rigidity requirements.

These are rolled products - sheet and shaped (channels, I-beams and T-beams, angles), blanks for fittings, pipeline elements (in particular, square pipes), etc.

The characteristics of steel make it possible to construct supporting load-bearing structures and frames from it, the operation of which is carried out in difficult conditions.

Elements and parts are made from St3sp steel without heat treatment, which makes it possible to preserve all the characteristics of the alloy - flanges, tees, transitions.

Steel is also used as a base layer in the production of hot-rolled 2-layer sheets that are resistant to corrosion.

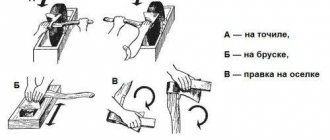

Mechanical restoration

Parts made from steel grade ST3PS are processed using pre-selected equipment and speed. This ensures that the required performance indicators are maintained, reduces local stresses, etc.

Sharpening and milling is carried out using a cutting tool made of VK8 or T5K10. Internal and external threads are created using taps and dies made of R18 and R6M5 steel. When processing on a machine, it is necessary to use cutting fluids, and when processing manually, castor oil.

The impact strength of ST3PS steel allows products to be processed on machine tools under constant vibration load. The speed depends on the properties of the alloy; other parameters are also selected:

- thickness 6-10 cm – tool holder 16*25 mm;

- cutting depth 3 mm – feed speed 0.7-1.2 mm/rev;

- rotation speed 700 rpm.

Steel grade st3sp5 decoding

The letters St

denote carbon steels of ordinary quality, the number

3

indicates the conventional number of the steel grade,

c

is the degree of deoxidation of the steel (calm).

Carbon steel of ordinary quality St3sp is used for load-bearing elements of welded and non-welded structures and parts.

| Mass fraction of basic chemical elements, % | ||

| C – carbon | Mn – manganese | Si – silicon |

| 0,14-0,22 | 0,40-0,65 | 0,15-0,30 |

| Temperature of critical points, °C | |||

| Ac1 | Ac3 | Ar1 | Ar3 |

| 735 | 850 | 680 | 835 |

| Technological properties | |

| Forging | Forging temperature, °C: beginning 1300, end 750. Cooling in air. |

| Weldability | Weldable without restrictions. Welding methods: manual arc welding, automatic arc welding, electroslag welding, resistance welding. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| Machinability | In the hot-rolled state at HB 124 and σв = 400 MPa: Kv carbide = 1.8 Kv high-speed steel = 1.6 |

| Flokensensibility. | Not sensitive |

| Tendency to temper brittleness | Not inclined |

Threaded holes

Table of drills for holes for cutting cylindrical pipe threads.

Wrench nut sizes

Basic spanner dimensions for hex bolt heads and hex nuts.

G and M codes

Examples, description and interpretation of L and M codes for creating control programs on CNC milling and lathes.

Thread types

Types and characteristics of metric, pipe, thrust, trapezoidal and round threads.

Drawing scales

Standard scales for images of parts on mechanical engineering and construction drawings.

Cutting modes

Online calculator for calculating cutting conditions during turning.

Threaded holes

Table of drills and holes for cutting metric threads with large (main) pitch.

CNC machines

Classification of CNC machines, CNC machines for metal for turning, milling, drilling, boring, threading, reaming, countersinking.

Cutting modes

Online calculator for calculating cutting conditions when milling.

Drawing formats

Table of side sizes of main and additional formats of drawing sheets.

CAD/CAM/CAE systems

CAD computer-aided design systems, 3D programs for design, modeling and creation of 3D models.

Reading blueprints

Technical drawing, rules for making drawings of parts and assembly drawings.

Carbon steel of ordinary quality, grade St3sp (St3sp5), is produced in accordance with GOST 380 “Carbon STEEL of ordinary quality. Stamps."

Steel St3sp (St3sp5) is used in the production of hot-rolled sections, shaped (angles, I-beams, channels), sheets, wide-band universal rolled products, cold-rolled thin-sheet rolled products and bent sections intended for building steel structures with welded and other connections, as well as ingots, blooms, slabs, strips, rolled and continuously cast billets, pipes, forgings and stampings, strips, wire, hardware, etc.

Where and how is it used?

The performance qualities allow the alloy to be used for the manufacture of elements of welded structures operating under load, machine parts and mechanisms. The operating temperature must be above 0 degrees. The fifth category of rolled elements can be used in conditions of negative temperatures -40/-425 C under the action of a variable load.

Complex products require subsequent heat treatment; annealing is most often used. It reduces residual stresses after welding. The scope of application of ST3PS includes the production of At-400S fittings.

The sheets are used to produce parts using cold stamping. The result is pallets for collecting cutting fluids in production, containers of various volumes and purposes, casings, etc.

Analogs

As already noted, the St3 grade is in demand in the production of various structures, and in fact, is the most popular structural steel. This is the reason why it is produced by metallurgical plants located in all parts of the world, for example:

- USA - A284Gr.D, A57036;

- Germany - 1.0038;

- Japan - SS330;

- European Union - Fe37-3FN;

- China - Q235.

Suppliers of steel produced outside our country must submit documents confirming the compliance of imported materials with domestic GOST and TU.

Similar foreign steels

The metal is one of the most common structural steels. Therefore, analogues of ST3PS include foreign products:

- Q235;

- S235J0;

- Fe235D;

- 1.0038;

- K01804 and D.

When purchasing foreign product ranges, you must ensure that they comply with GOST and TU requirements.

Sources

- https://nzmetallspb.ru/stanki/stal-st3-marki-harakteristiki-himicheskij-sostav.html

- https://molotok34.ru/spravochnik/st3ps-rasshifrovka-stali.html

- https://svarkaipayka.ru/material/stal/tehnicheskie-harakteristiki-uglerodistoy-stali-3.html

- https://promkrepez.ru/info/steel-grades/stal-marki-st3/

- https://metal.place/ru/wiki/st3sp/

- https://punktpriema.ru/articles/tehnicheskie-harakteristiki-konstruktsionnoy-stali-st3.html

- https://stanok.guru/stal/fiziko-himicheskie-harakteristiki-staley-st3.html