Getting to know the element

Making a homemade knife is actually quite a labor-intensive process, but home craftsmen are not afraid of this. The main reason is to satisfy one's creative potential. Using available tools, you can make any type of knife.

And often, handicraft production is in no way inferior to factory production, and in some cases can even surpass it. Among other things, this is a good cost savings. Making a knife at home will require the master to strictly adhere to order and rules.

The most important stage in making a knife is the formation of slopes on the blade. These elements are made by milling flat blanks. They will greatly influence the piercing and cutting properties of the finished product.

What determines the sharpness of a knife?

Sharpness is the main characteristic of a cutting tool. The higher its degree, the easier the knife enters the material. What does this characteristic depend on?

- Properties of steel. The composition and grade of the metal directly affect the properties of the blade.

- Features of mechanical processing of the part.

- Temperature treatment during the hardening process.

- Features of the cross-section and dimensions of the blade.

- Sharpening quality. The main characteristic that affects sharpness.

We see that the effective quality of a knife depends on the coordinated work of several specialists. Fortunately, modern industry does all this work for us; all we have to do is maintain the tool in working condition, which involves its timely and correct sharpening.

A little theory

There is no one perfect solution for all types of knives. Descents are performed for blades with specific tasks.

You can try to find a middle ground, but the thickness of the blade and the thickness of the blade will not give the knife ideal parameters.

To understand the principle of cutting a knife, you should take a closer look at the process. First the cutting edge comes into play, and then the trigger comes into action. Thanks to its qualities, it pushes the material that is being cut apart. It turns out that the thinner the bevel, the faster the cut will be.

But due to this, the strength of the blade suffers. With a more massive descent, the strength of the blade increases, but the cutting speed decreases. When making a blade, you have to sacrifice something. The purpose of the knife plays a role here.

Blade descents.

Difficult to choose: a hiking companion or a folding knife for every day

When planning to purchase a knife, everyone sooner or later asks the question: “Is it possible to find a single model that will become universal, or will each type of task require a blade with a narrow specialization?” To get a comprehensive answer to this question, we will study the existing designs, types and features of modern knives. They will give you an idea of what to look for when looking for a suitable model. Let us immediately make a reservation that our study does not include kitchen knives, which also have their own classification.

Design

Choosing a suitable design assistant is extremely simple. It comes down to 2 options: an awkward knife (fixed) or a folding knife (folder). The differences between them are obvious: one has a blade that retracts into the handle, while the other does not.

| Folding (top) and non-folding (bottom) knife. |

The first type is based on the classical principle, when the blade and handle form a single whole. The peculiarity of such knives is that they are better suited for heavy loads and more difficult work. But the inability to hide the blade makes them quite long and does not allow them to be carried in a pocket. And in order not to get hurt on the cutting edge when carrying, they definitely need a belt cover.

In this sense, folding knives are more convenient, although the ease of removing the blade from the handle and the reliability of its fixation become more important for them. They fit easily into a pocket, backpack or on a belt, and their safety and ease of wearing make them preferable “companions”. There are mechanical, automatic and semi-automatic folding knives. Distinctive features of “folders” are different types of locking locks, as well as methods of opening with one or two hands.

The figure below shows a typical knife design, the elements of which will be often mentioned in our study.

| Structural elements of the knife: 1 - blade; 2 — handle; 3 - tip; 4 - blade, cutting edge; 5 — descent; 6 - butt; 7 — groove, dol (stiffening rib); 8 - heel; 9 - guard; 10 - back; 11 - abdomen; 12 - hole for lanyard. |

Types of folder locks

To ensure that the open blade of a folding knife forms a rigid, stationary structure with the handle, different types of locking clamps are used. There are quite a few of them, but most are variations of the most common types, which are most often found among leading manufacturers. Among them, the best locks stand out: Axis Lock, Back Lock, Button Lock, Liner Lock, Frame Lock and Virobloc, which have proven themselves to be reliable in fixing the blade and easy to use. Almost all the mechanics of the locks are hidden inside and do not pose any inconvenience to the user, which is why the design of the locks is not decisive when choosing a knife. Regardless of the type of lock, the main thing is that the blade is held firmly in the handle without play and does not fold under load.

- Axis Lock

is an invention of the famous company Benchmade, in which the lock is fixed using a movable pin. Despite the good locking of the blade in the closed and open positions, the lock is very demanding on cleanliness and can fail if the knife gets dirty.

- Back Lock

- the locking element of the lock is a spring-loaded plate, but this design is not suitable for one-handed opening.

- Button Lock

is another version of the pin lock, originally designed for automatic opening. Currently adapted for manual opening and often used in models with a peg.

- Liner Lock

is perhaps the most popular type of lock, distinguished by its simplicity and reliability. When opening the blade, the “liner” locking plate moves to the side and supports the blade.

- Frame Lock

is a modified version of the "liner" in which the spring is part of the handle rather than a metal plate. Thanks to this clamp, there are no unnecessary parts in the knife, and the design looks monolithic.

- Virobloc

- in this case, the lock is a metal rotary coupling with a longitudinal cut, which locks the blade in the closed and open position. This is Opinel know-how, which is used in all models of knives with wooden handles.

Separately, it is worth mentioning butterfly knives (balisong), which are unfolded by turning 2 parts of the handle relative to the blade. But in this case it is more of a method of inertial extraction and folding of the blade than a lock. We will talk about other ways to open knives below.

Opening methods

There are two main ways to manually remove the blade from the handle of a folding knife - with one or two hands. For one-handed opening, a pin, a finger hole in the blade or a tail fin (flipper) is used. Of course, easy one-handed opening provides certain convenience, but not everyone likes the presence of protruding elements. Therefore, knives with a hole in the blade are the most popular.

| Shpenek. |

| Shank (flipper). |

| Hole in the blade. |

In addition, there are models with an automatic blade ejection mechanism, which is carried out by pressing a button. However, their share among all products is very small.

And the classic way to remove the blade from the handle with both hands, by hooking your fingernail behind the notch on the blade, is the oldest and most well-tested. Traditional penknives, Swiss knives, and multitools implement just this method.

| Nail notch in the blade. |

Blade

The properties of the blade largely determine the purpose and functionality of the knife. The most important elements here are the length and thickness of the blade, shape (profile), cross-sectional geometry and sharpening of the cutting edge. A very long blade (15 - 20 cm) in some cases will help you work faster and more efficiently, but sometimes it will be an obstacle to performing tasks where a blade up to 10 cm will be much more convenient. In the vast majority of cases, a blade of this length will be the optimal balance between ease of wearing and working. The thicker the blade in the butt, the less flexible and more durable it is. But this is also not always necessary: for example, in fillet knives, a thin flexible blade is valued. Among the most popular profiles, we note the traditional universal normal blade (straight spine), drop-point and slip-point, used in everyday carry (EDC) and hiking knives, hunting bowie, tactical tanto, symmetrical spear-point and dagger, which are designed for piercing use, as well as antipodes of the classics with a straight line of sharpening: sheeps foot and wharncliffe, which are often used by rescue workers.

| Blade profiles. |

In addition to the blade profile, pay attention to the type of sharpening of the cutting edge, among which there are 3 main options: smooth, serrated and combined.

| Smooth sharpening. |

| Serrated sharpening. |

| Semi-serrated (combined) sharpening. |

The serrated type of sharpening was invented relatively recently, and knives with such blades are used for cutting parachute lines, cables, ropes, fishing gear, and are also used in combat conditions. Therefore, if you do not go fishing or do not belong to the military community, then you definitely do not need a knife with such a blade. Especially considering the difficulty of sharpening it. And mass-produced blades for various purposes traditionally have a smooth sharpening (Plain).

The cross sections of the blades are also varied, but we will focus only on the “very best”, which are found in 95% of knives.

| Blade sections. |

A straight double-edged trigger is used in most knives. It provides universal functionality of the tool, allowing you to chop, cut, and rip equally successfully. The lens-shaped section is characterized by uniform distribution of forces and high resistance to heavy work without damaging the cutting edge. As a rule, this is required in special-purpose knives, and sharpening is performed by professionals. The one-sided “chisel” escapement is good because it makes the blade stiffer, so the blade retains its edge better. This blade is convenient for removing wood shavings, but it has a significant drawback: it is a knife only for right-handed people. The narrow cross-section of the blade and the sharp sharpening angle of the cutting edge clearly determine the capabilities of the knife in performing delicate work. This blade does an excellent job of cutting food, peeling vegetables and fruits, processing skins, as well as filleting fish and meat. Therefore, the sharpest blades are used in fishing and hunting knives with a concave trigger. The sharpening angle of the blade is determined by the purpose of the blade, and the sharper the knife should be, the smaller the angle. So for a blade with a “razor” sharpening you need to bring the cutting edges at an angle of 10 - 15°, for a fillet knife - 25°, and for a hunting blade - 30 - 45°. Keep in mind that the resistance of an edge to dulling is inversely proportional to the sharpness of the sharpening. Therefore, in order for the knife to remain suitable for work longer, it is necessary to maintain an optimal balance.

Handle

The handle is characterized by its shape, material (including linings), as well as the presence of a clip for wearing on a belt and the possibility of attaching a strap (lanyard). The shape is more about comfort for the hand and aesthetics, but such useful little things as a recess for the finger improve the grip of the knife. The handle itself and its lining are made of steel, titanium, aluminum, wood, plastic, rubber, fiberglass and other composite materials. These materials meet the criteria of durability, functionality and comfort of use, and also give the knife a stylish appearance.

Steel

Blade steel is characterized by its composition, hardness, ability to resist corrosion, wear and hold an edge for a long time. All steel for knife blades can be divided into 2 main categories: stainless and carbon. And if stainless steel definitely copes better with rust, then steel with a high carbon content (> 0.5%) is one way or another susceptible to oxidation. Stainless steels have less carbon, are softer and hold an edge less well. And tool steels, rich in carbon, are harder and stronger, they dull more slowly, but do not like dampness. The normal hardness for a knife is considered to be between 50 and 60 HRC (the higher the better). In this case, stainless steel is closer to the lower value, and high-carbon steel is closer to the upper value. A dull blade made of soft stainless steel can easily be sharpened in field conditions, even on a stone, but with a “toolbox” this trick will not work. The most popular brands of inexpensive steels in the mass knife industry:

- 420

— stainless steel, one of the most common among budget-class knives (hardness 52 - 56 HRC); - 440(A, B, C)

- carbon alloy steel with a high chromium content (hardness 55 - 60 HRC); - D2

- so-called “semi-stainless” tool steel, which, despite its high-carbon structure (> 1.5% C), has increased corrosion resistance (hardness 57 - 61 HRC); - Sandvic 12C27

- Swedish chromium steel with a high manganese content (hardness 54 - 60 HRC); - 8Cr13MoV, 8Cr14MoV, 5Cr15MoV

- Chinese chrome vanadium steels with the addition of molybdenum (hardness 56 - 58 HRC); - AUS-6 - AUS-10

- Japanese carbon steels with a high chromium content (analogs 440) and hardness 56 - 60 HRC.

As for Damascus or damask steel, it is worth dispelling the popular myth about their incredible properties and hardness. As a rule, such steel is not much different in quality from modern alloys, with the exception of the beautiful and intricate pattern that gives it an unusual appearance.

Types of knives by purpose

Knives, as such, do not have a strict classification according to their purpose and area of application. Therefore, even among experts, there are often discrepancies regarding which class to classify this or that model. However, most products have characteristic features that allow them to be classified into one of the following categories:

- Knife for hunting.

Depending on the specialization, it may have an emphasis on finishing and skinning an animal, using it in a camp site, for cooking, or for skinning. More often than not, the idea of a hunting knife as a cleaver with a wide 30-centimeter blade a la Crocodile Dundee is deceptive. And the most convenient is the “skinner” with a short and sharp blade, which better suits most purposes.

- Fishing knife.

This category can be divided into 2 main types: universal fisherman’s knives and models for fine filleting of catch. The first include short knives with a blade made of excellent stainless steel, which can be used to clean fish, chop firewood from dry pine needles, and cut a simple “brake” for dinner. And thin and long fillet knives are better suited for cutting large lake and sea fish.

- Knife for hiking (tourist).

Quite often, due to their use in nature, they are classified into the same group as hunting knives, but, nevertheless, it is better to separate such knives into a separate category. It can be either a folding or a fixed blade, which becomes the best assistant on a hike thanks to its balanced functionality.

- Everyday knife (EDC).

The most versatile tool with a single blade that can be carried with you at all times. It is often called a city knife, and the abbreviation EDC (Every Day Carry) that has become attached to it speaks for itself. Typically, these are compact folding models with a classic blade profile, which have a place of honor in your pocket.

- Swiss knife.

These are multi-purpose folding knives that, in addition to the main blade, have additional tools. The most famous and high-quality products of this class are produced by Victorinox. Despite the fact that most models are made in a portable keychain knife format, which cannot replace a full-size blade, the abundance of additional functions makes this device an excellent assistant. It can be safely recommended as an additional knife to the main target, and in some situations it can become an independent companion.

- Multitool

This group of products is closer to a folding portable tool set than to traditional knives. Yes, of course there is a blade here too, but it is not the dominant tool. The main thing in a multitool is pliers (pliers) and screwdrivers of different calibers and profiles. There may also be a file, an opener, a can opener, a sling cutter and many other elements, the total number of which can include up to a dozen functions. All this wealth is placed between 2 handles, which serve as holders for a folding tool.

- Tactical knife.

The actual purpose of this type of knife is combat. The characteristic shape of the blade, a rigid, awkward design with a guard and a reliable, comfortable handle for good grip on the surface of a tactical glove make these models suitable for security, special operations and combat watchkeeping. - Others (machete, balisong, for rescuers, for diving, etc.).

Other types of knives include highly specialized cutting tools that are used for certain types of work and are in demand by representatives of certain professional communities.

Recommendations for choosing a knife

If you are drawn to something “sharp” and your intention to purchase a knife has strengthened, then the first thing you should decide is for what purpose is it needed? The choice of a “companion” on a hike, fishing or just walking should be approached with an understanding of its purpose and scope of application. Most experts are convinced that there are no universal knives, and each type serves to solve specific problems. In fact, this is only a reflection of subjective opinions, and the truth is somewhere in the middle. Despite the fact that the capabilities of a cutting tool are determined by its design, there are many models that fully deserve the title of all-rounder.

For an outing into nature

A friendly company offers a wide range of products that will do an excellent job with most jobs. It can be either a “clamshell” or a knife in a sheath, but you shouldn’t get carried away with “long lengths” - a blade up to 12 cm is enough. In our climate there are no impenetrable jungles, so you definitely don’t need a machete to cut a clearing. And picking mushrooms, making stakes for a tent, preparing branches for a fire and chopping food for dinner is quite within the capabilities of an ordinary “small” person. Do not try to take a knife with high steel hardness outdoors, because there are unlikely to be conditions for sharpening a dull blade in field conditions. But stainless steel of medium hardness, which can be easily “corrected,” would be the best choice. Perhaps the tourist knife is the most affordable of all types, and you can choose from a wide range of tools, from the usual “pen-knife” to the Swiss knife, the best selection of which we presented in this material.

a hunting knife in much the same way.

, where size is not as important as convenience and functionality. Hunting involves a lot of movement and following the animal's tracks, so a large knife will interfere with walking and crouching. Often tactical models are used as a hunting knife, but in each case the feasibility of such a replacement must be taken into account. The main thing to remember is that the knife should have a comfortable handle, and a sharply sharpened blade should be strong and hard. And of course, don’t forget that a good sheath is very important when hunting.

Modern and advanced gear is the key to successful fishing, but choosing the right knife for the fisherman

. As a rule, these are multi-tasking models that are involved in cleaning and cutting fish, cooking and lighting a fire. And a separate type of fillet knives helps to process large catches. Regardless of the type of reservoir, fishing takes place in conditions of high humidity, which is why such a knife must meet the requirements for anti-corrosion resistance. To get acquainted with the current models of fishing blades, we suggest reading the following review.

Multifunctional Swiss Army Knife

It has long become a classic, without which it is impossible to imagine a campaign or forced march. As part of the all-in-one folding set, you will find everything you need to comfortably spend time in the field, in the forest and in the mountains. The Swiss makes a great camping knife, and tools like a can opener and a bottle opener are essential items. It’s amazing how organic and thoughtful everything is in this compact collection of disparate instruments. But when making a choice, you shouldn’t be greedy: take a model only with the necessary additions to the main blade. An excessive number of tools that you will not use will be an extra burden in your pocket, and a thick handle will not add comfort to your work.

Multitool

is the clear choice for those who love to tinker and repair things. By and large, this is not so much a bladed tool as a metalworking tool, which is a compact folding version of a full-fledged set from a box. When choosing a multitool, pay attention to the presence of pliers (they are not available everywhere), as well as Phillips and slotted screwdrivers. A multifunctional set will be convenient for working with full-size tools, so we strongly advise against purchasing models in mini format. And keep in mind that a good model can weigh up to 300 g, so you can’t put such a burden in your pocket: there is a case for it that is attached to the waist belt.

Tactical

models of piercing and cutting weapons are designed for combat use in paramilitary special forces. They are included in the equipment of security services, police, and the army, and a characteristic feature of the blades is a combined or serrated sharpening of the blade. Buying such a knife for fun or using it for another purpose is more expensive for yourself: no one has canceled the responsibility for storing and carrying edged weapons without the appropriate permission. After all, such knives have a very specific classification according to purpose, regardless of performance criteria. For this reason, military-style products are unlikely to become a universal knife.

No matter how much you need a set of knives for different purposes, the first purchase, especially when there is no clear understanding for what purpose it is being purchased, is always associated with a simple single-edge design. This is a universal blade

, which is suitable for multi-purpose use and must meet the following criteria:

- It would be better if it was a folding knife to be carried in your pocket;

- Small length of the main blade within 7 - 10 cm;

- Not bad, but not necessary if there are several additional tools in the folder;

- Medium-hard steel, easy to sharpen and edit in field conditions;

- You should not choose a product of complex shape with intricate blade geometry;

- Sharpening - only smooth;

- Select the locking mechanism and the method of opening the blade to suit your style of use.

The best brands in the knife industry

Blades from the world's leading manufacturers are always high-quality steel, excellent assembly and hand-sharpened blades. Many companies do not reveal the technological secrets that have helped them achieve commercial success, and rightfully so. It happens that the same model of knife is produced with a blade made of different steel (budget and expensive), due to which the final product differs in price by several times.

There are dozens of well-known manufacturers of knife products in the world, which differ in the quality of materials, workmanship and price. Some companies produce premium knives, some are dispersed across different segments, and many are content with mass-produced products and releasing replicas.

Among the whales of the knife business, American companies Spyderco, Benchmade, Buck, Leatherman and Kershaw occupy a special place. No less famous are products from the brands Ontario, Gerber, SOG and Steel Will. European knife manufacturers with a long history include the Swiss company Victorinox, the Swedish concern Morakniv and the French company Opinel. And under the Ganzo brand, customers know inexpensive but high-quality products manufactured in China.

conclusions

We share the opinion of experienced users that each type of knife has its place. Therefore, we recommend using profile types of blades designed to perform specific tasks. Over time, you will understand that such a knife does its job much more conveniently and easier than any “multi-purpose knife.” But, despite such categorical judgments, there are many knives for everyday use that are worthy of taking a permanent place in your backpack, on your belt or in your pocket. Agree that it is difficult to foresee in advance what you might need on a hike or travel, and carrying several knives of different types with you at once is unreasonable and impractical. It is better to replace such a set with a universal blade that can cope with all challenges.

A good choice in this category can be considered the time-tested bestsellers of the EDC class Steel Will C22M-1 Cutjack, Ontario RAT-2, Spyderco Tenacious and Ganzo F704, as well as the solid “Swiss” Victorinox Spartan with a basic set of tools necessary for a hike.

Basic shapes and characteristics of descents

For a beginner, the task is often to choose the right trigger for the blade. The question may arise even when making an ordinary kitchen appliance. But don’t worry, let’s look at the most popular types of descents:

- The easiest to manufacture and most popular escapement is the wedge-shaped one. It is often used on kitchen knives.

- Also a wedge-shaped descent, with a transition to the cutting edge. But when sharpened, such a blade will automatically switch to type number 1. During sharpening, the cutting edge will be formed separately from the trigger. You can sharpen the entire trigger, but this is very problematic for the average person.

- The shape is typical for many knives. The descent begins from the middle or slightly higher to the butt, while the blade is flat. Easy to sharpen.

- A fairly commonly used option is wedge-shaped bevels and a cutting edge. Such blades have a good cut and sufficient strength. The slopes and the edge are in good harmony in the work.

- The double wedge forms the cutting edge. The material between the cutting edge and the bevels has been removed. The blade has an excellent cut, but is difficult to sharpen. Only professionals can handle it.

- Lenticular concave slopes. The cutting edge acts as a continuation of the edge between the blade and the bevel towards the tip. Such descents can start almost from the butt. This type of sharpening is called razor sharpening and is used for straight razors.

- Chisel one-sided sharpening of the blade. Sharpening a knife is not difficult. The bevel should be on the side of the working hand, and such a knife can be wielded with only one hand.

- Its shape resembles number 3, but there are practically no descents. Straight blade and straight cutting edge. This is how items for cutting are sharpened.

- Lens-shaped convex bevels smoothly transition into the cutting edge. This sharpening has a second name - bullet-shaped. It is difficult to cut with a knife; it gets stuck in the material, but has excellent chopping characteristics. This option is difficult to manufacture and is suitable for professionals.

The easiest to manufacture are options No. 1 and No. 3. They can be made for ordinary household knives. You should start making other options only after experiments with simple descents.

Basic forms of descents.

What does the blade profile consist of?

There are seven main types of blade profile, but there are many more combinations. Let's figure out what the concept of a profile consists of. To do this, let's look at the picture, which represents a cut of the blade:

- The butt is the blunt part of the blade, which is located opposite the blade;

- Slopes - the transition from the butt to the cutting edge, slightly tapering towards the tip of the knife;

- Blade - the part of the blade that directly forms the cutting edge;

- The cutting edge itself.

The blade profile has the following measurable characteristics:

- The thickness of the trigger is the width of the blade in the place where the smallest distance between the slopes is observed.

- The sharpening angle is the angle at which the blade is sharpened. The higher this indicator, the more durable the cutting edge we get in the end. The sharpening angle ranges from 7 to 20 degrees. For comparison, the sharpening angle of a straight razor is about 10 degrees, while for a kitchen knife it will be about 20 degrees.

- Bevel angle - the influence of this parameter on the characteristics of the product is determined by the general structure of the blade.

As we have already said, the profile of the blade determines the cutting properties of the product. Of course, the material from which the blade is made also affects this parameter, but it will largely determine how long the knife can hold an edge.

Trims with a grinding machine

The sharpening machine is a fairly simple design. This is an electric motor with an abrasive wheel mounted on a shaft. Surely many have seen him in workshops. But some points should be taken into account when making descents on such a device.

There are different circles, you should not take the first one you come across. To perform descents, we recommend a circle marked 25A, this indicates its composition of white electrocorundum. This wheel is inexpensive and works great on hardened steel.

It is advisable to have a tool rest on your sharpening machine. This is a small area in front of the circle; it will allow you to use various devices for proper work.

It is recommended to use the machine with good speed.

Otherwise you will have to suffer for a long time. If the machine is low-powered, the circle may stop when the blade is pressed hard against it. The process will thus slow down greatly. Choose a machine with a power of 450 W or more.

Examples of sharpening machines.

Features of knife sharpening. Angles

Knives are different. Some are intended for cutting carcasses, others for hunting or war, others for cutting wood, and so on. There are multifunctional or universal samples that can perform two or more tasks.

Exactly what qualities the cutting ability of an edge will differ in depends on the angle of its sharpening. The smaller the angle, the sharper the blade. In this case, the cutting edge will be thinner, which means its strength will decrease.

Finding the correct relationship between the angle between the cutting edges of an edge and its thickness, shape and strength is a difficult task. Each master gunsmith solves it in his own way. Over the thousands of years of blade development, standards for knife sharpening angles have been developed depending on their purpose:

- Razor blades and similar tools are 8 – 12˚.

- Knives for skinning and cutting meat – 10 – 15˚.

- An angle of 15 – 20˚ is suitable for the kitchen and everyday life.

- General purpose hunting knives - 20 – 25˚.

- Blades for cutting branches and wire, opening canned food and splitting wood are sharpened at an angle of 25 – 40˚.

Interestingly, the legendary Japanese katana is sharpened with an angle close to that of a kitchen knife. This sharpening, combined with the exceptional strength of the metal, gave the weapon incredible properties. There are known cases where such blades cut through gun barrels, bamboo stems and horse bodies.

In general, it must be said that military and especially long edged weapons often had different sharpening angles in different parts of the blade. For example, a Russian saber has a “strong” part sharpened at 40 degrees or more, while its “working” part is sharpened at 30˚.

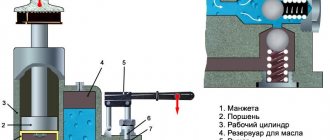

Main elements and parameters of the blade section (Fig. 1)

Figure 1 (comments)

- I - Blade - cutting edge

- II - Approach - cutting edges

- III - Descents

- IV - Butt

- 1 — Blade width

- 2 — Butt thickness

- 3 - Width of rectangular section

- 4 — Width of descents

- 5 — Width of cutting edges

- 6 — Thickness of cutting edges

- a - Angle of cutting edge (point angle or sharpening angle)

A number of Western manufacturers of hunting weapons consider the optimal sharpening angle to be 23˚. Others, such as the American Tidioute Cutlery Company, prefer to sharpen hunting and even combat knives of the KA-BAR brand at forty degrees. There is no consensus here, everything is very individual.

One way or another, the sharpening angle of the cutting edges of the blade is the most important characteristic of its sharpness, strength and, as a consequence, purpose. To put it simply, smaller angles are required for working with soft substances, and larger ones for working with hard ones (splitting firewood, chopping off branches). In addition, the sharpness and other properties of knives depend on the cross-section parameters of their blades.

Belt grinding machine for making bevels

In addition to the expensive grinder, you can find small grinders on the market that also use a belt. To make descents using such a device, you will need to additionally build the structure yourself.

It will allow you to firmly fix the machine in a vertical position, thus creating a miniature grinder. But these machines use a wood processing tape. You should find a suitable steel tape or tinker with the one you have available.

Belt grinder.

Characteristics and purpose of a cutting knife

A carving knife is a tool that is used for cutting and chopping meat and fish. They won’t be able to cut bones that are too large, but such a tool can handle small bones and, especially, non-tubular ones. A cutting knife is most convenient for deboning (separating pulp from bones) and working with tendons and cartilage.

| Characteristic | Short description |

| Cutting knife shape | Almost identical to a regular kitchen one, but there is a notch next to the handle (on the blade). It provides a reliable grip of the hand/fingers with the tool. |

| Blade | Always wide because it was specially designed to perform rough, aggressive work. |

| Cutting part | Always smooth, no teeth, serrated |

| Handle material | It can be metal, plastic, with rubber pads. The first option is not recommended for use - it will be inconvenient to work with a knife due to it slipping out of the palm. |

| Blade material | It must be very durable, so blades made of high-carbon steel are the best choice. |

How to make bevels on a knife using a grinder

How to make descents on a knife at home using an angle grinder? The question is quite sensitive and ambiguous. Experienced craftsmen, as one, argue that beginners should first try making descents by hand.

You can choose for yourself any homemade device that the Internet is replete with. There are plenty of tips on how to use such devices. But the manual method is recommended to learn to feel the metal.

Special devices will help save time. But for a beginner this will only be a hindrance. To achieve the best cut, it is necessary to achieve harmony between the bevels and the cutting edge. Let's try to consider the option for more or less experienced craftsmen to make bevels using an angle grinder.

Expert advice

Read this material so as not to make irreparable mistakes when working. They mainly concern the instrument. Cut the workpiece in accordance with the template from a sheet of metal using a circle with a thickness of no more than 7 mm.

When using a cutting wheel, the steel may overheat or break.

Small grooves may also appear. Grinding wheels are quite suitable for this job; those from well-known manufacturers perform especially well.

The cost of such circles is not high. Having learned how to use such material, you can move on to cut-off ones, but their thickness should be at least 2 mm. The disadvantage of such circles is vibration under lateral loads.

The entire instrument begins to shake. This can cause the disc to rupture and cause all sorts of injuries. Beginners who do not follow this advice still end up returning to the roughing circles.

Examples of Bulgarians.

Preparatory stage

In order not to run around the workshop and look for the right tool, you should collect the necessary things closer to you. Do not forget about safety precautions when working with an angle grinder. Under no circumstances is it recommended to remove the protective cover. In addition to the grinder you will need:

- the preparation of the future blade itself;

- cardboard template of the future knife;

- metal corner;

- not a bulky grinder, aka angle grinder;

- good and reliable vice;

- screw clamp;

- bucket with water.

The main tool for work is a grinder. Choose not large sizes, maximum 125 disc, otherwise you will be physically very tired. You won't need an overly powerful tool. 1000 W is enough. Work must be carried out with gloves and glasses.

Have you already tried making descents yourself?

Many times already! Not yet...

Cutting the workpiece

To cut the workpiece, follow these tips:

- Using a marker, the knife template should be transferred to the metal from which the blade will be cut.

- Cutting the workpiece should be done clearly, in accordance with the line of the template. Be very careful with the butt of the product; this part of the blade cannot be covered.

- Drawing the butt lines, this should not be done with a thick line, but clearly visible.

- The metal corner should be clamped in a vice and the already cut workpiece is pressed against it using clamps.

For high-quality clamping of the tip of the future knife, it is better to use two clamps. If you have one, then it should be gradually moved around the place where the blade is processed. The blade should adhere to the corner very tightly. The processing location should face the master.

Cut out the workpiece.

Chamfering

After the preparatory work, the chamfer should be cut. The purpose of this element will become clear later. The grinder should be positioned strictly perpendicular to the workpiece. If there are uneven surfaces, do not deviate from the original position.

It is not recommended to press the disk tightly against the workpiece; on the contrary, you need to try, slightly touching the metal. So you should remove a small chamfer along the cutting edge of the blade. This should be done carefully and it is necessary to maintain a distance of 0.2 mm from the line to the middle of the knife.

The process does not require speed; it requires patience and accuracy. During the process, it is necessary to cool the part, water it with water from a bucket. Overheating can have a significant negative impact on the finished product. You need to chamfer along the entire cutting edge; this will be a clear boundary that cannot be crossed.

Descent work

After completing the chamfering work, you should start working on the slopes. The direction of movement of the abrasive will be towards the butt to the marked line.

Carefully control the process; the descent will begin near the heel of the blade.

The grinder should be moved left and right with a small amplitude. It should be 15-20 mm, so the metal will be gradually removed. The abrasive must be strictly perpendicular to the cutting edge. Don't forget to cool the workpiece.

Do not deviate from the specified parameters, otherwise the disc may stand on its edge, which can lead to a big headache. The step-by-step process will not allow you to ruin all the work with one wrong move. You should not put pressure on the grinder; its weight is enough.

How to correctly set the overall cutting edge angle

This is important: if we are talking about a knife with symmetrical slopes, then the sharpening angle will be twice as large as the one under which we place the sharpening stone. For example, if we prefer to sharpen our hunting knife at 30 degrees, then there should be an angle of 15 degrees between the blade and the block.

From this we derive two concepts:

- full angle, which is the sharpening angle (in our example - 30 degrees);

- half angle is the one at which we place the blade in relation to the block (in our example - 15 degrees).

We determine the angle itself based on the purpose of the knife.

Special, particularly delicate cutting tools

By these we mean surgical instruments, shaving devices, blades, etc.

The sharpening angle for delicate instruments is 8–10 degrees.

The expression “razor sharp” arose for a reason - the angle of approach of the razor is one of the sharpest among all cutting tools

Knives for working on soft materials

These are mostly kitchen knives: fillet knives, vegetable chopping knives, etc.

The sharpening angle for fillet and vegetable knives is 10–20 degrees.

Fillet knives work with soft materials, so their approaches can be brought at a fairly sharp angle, up to 20 degrees

Universal kitchen knives

Chef's knives for various purposes can work on both soft and hard materials - cartilage, small bones, frozen fish or meat.

The sharpening angle of kitchen “universal” is 20–25 degrees.

“Universalists” have to work both with soft meat and bread, and with cartilage. We take the approach angle for them at a medium angle, up to 25 degrees

Knives for hunters, fishermen, survivalists. Tactical knives

Such tools are often found not only with soft camping products such as sandwiches, but are also designed to cut branches and fishing lines. Sometimes they are even used as sling cutters.

The sharpening angle of “street” knives is 22–25 degrees.

Hunting, tactical (pictured) and survivalist knives encounter hard materials and require a larger approach angle

Knives and other tools for working on hard materials

This includes kukris, machetes, garden knives, tourist and ordinary household axes.

The sharpening angle of knives for heavy work is 20–40 degrees, sometimes up to 50.

Machetes, kukri and other tools that work for striking and chopping need to be sharpened to 40–50 degrees

Making descents by hand

Manual sharpening was touched upon at the very beginning, it’s worth returning to this method. It is recommended for very beginners. The process will help you understand and feel the steel itself. It is very labor-intensive, and you will have to shed a hundred sweats to make the descents manually.

All work is done with files, only abrasive stones will be required at the end. To understand how much you need to grind off, you will answer for yourself when you make cuts more than once. You shouldn’t be lazy; in fact, it will be very cool to do descents manually.

How to choose a universal carving knife

When choosing a universal cutting knife, you need to take into account the following nuances:

- Material for making a blade . Since cutting meat and fish is considered a rather aggressive process, manufacturers can use high-carbon steel, metal with the addition of titanium and chromium, and specific ceramic alloys for the blade. All of them have high wear resistance and are not susceptible to the harmful effects of moisture, high and low temperatures.

- Ease of use . You can verify this only by taking the tool in your palm and paying attention to how comfortable the grip of your fingers is, whether the handle is slippery, whether there is a groove on the blade (closer to the handle), what the weight of the knife is.

- What kind of meat will be cut most often ? If we are talking about fillet pieces/pulp, then it is worth choosing a universal tool with a blade length of maximum 150 mm. If you frequently cut meat/fish into large portioned pieces, it is better to pay attention to knives with a blade length of 200-300 mm.

Experts recommend initially purchasing cutting knives in quantities of 2-3 pieces from different manufacturers. This will help you decide on your favorite and will make the choice easy for future purchases of more functionally oriented tools.

Knife care

All cutting knives are distinguished by high cutting/chopping characteristics, and in order to preserve them for a long time, you just need to follow the rules of caring for the tool:

- Store separately from other cutlery. Such knives should not lie next to forks/spoons; it is better to store them in plastic or wooden stands. You can use a magnetic wall tape holder - magnetic fields do not have a negative impact on the quality of steel.

- Wash the knife after each use. The procedure is performed with a soft sponge, detergent and warm water. It is strictly forbidden to use cleaning agents containing soda, chlorine and large abrasive particles to wash cutting knives. After washing, you should immediately wipe the blade dry - this will protect it from corrosion.

- Use only wooden and plastic cutting boards. Ceramics, glass, and stone surfaces spoil the knife blade and cause cracks and abrasions to appear on their surface.

Rules and subtleties of processing meat knives

Processing knives for meat and fish consists of periodically sharpening them. During the process, it is important to observe the angle parameters - they are “set” by the manufacturer and cannot be violated:

- boning – 25-30;

- for meat – 25-30;

- universal – 30-35;

- for fish – 20-25;

- cook's - 20-25.

If you change the sharpening angle yourself, this will lead to irreversible damage to the kitchen tool. If you only need to straighten a cutting knife, then you can use musats (pentagonal, convex, wedge-shaped and concave) for these purposes.

Watch the video about how to care for kitchen knives: