Load tie-down straps (also known as tie-down straps) are the most common means of securing transported objects on vehicles. They allow you to securely secure and properly transport cargo from point to point. They consist of an elastic textile tape, with the help of which the load is securely fastened, which eliminates the possibility of damage during transportation. The main consumers of such products are various cargo transportation companies on all types of transport. The production of these devices is based on weaving technology, which uses durable polyester textile tape. The width of the weaving tape can be 25, 35, 50 millimeters, which will depend on the intended load and scope of use. There are also options where a tape with a width of 75 to 100 millimeters is used for weaving - such devices are needed for extremely massive and dimensional transportation. Typically, the maximum possible load for each product is indicated on the label attached to it. This information must be taken into account under any circumstances, because otherwise, rupture during overload and damage to the cargo itself may occur.

Design features

Proper securing of cargo is one of the components of safe transportation. Tensioning tapes are manufactured in two varieties - in the form of elastic polypropylene belts with Velcro fasteners, as well as with a mechanical type clamp. The first one works on the principle of using tensile force, while the second one clamps over the entire girth due to a tension device. These systems interact well with other securing elements, one of which is the load securing rail. It is made of lightweight aluminum or durable steel.

The tensioning belt of mechanical fastening systems is made of rigid textiles that can withstand high mechanical loads. The first type is simpler from a design point of view, but has an obvious drawback - the material of the tape. It is not able to withstand high stress, and the strength of the anchorage depends on various factors, including the quality of the road surface.

Elastic band ties are divided into two types: textile and steel (chain ties). It is advisable to use them when:

- slight temperature fluctuations;

- no vibration impact;

- transportation of small-sized products.

Velcro fasteners lose their tightening force over time, so they are supplemented with a tension spring. At the same time, the reliability of fastening increases by only a few percent. The complete set of the tensioning device includes the following elements:

- A wear-resistant belt that does not change its properties and geometric dimensions under adverse conditions, including high mechanical load.

- Loop for securing cargo to the floor. It is an additional element that is permanently equipped with cargo vehicles.

- Fitting. It is a belt fastening unit in the form of a ring for securing a load or a hook made of steel.

- Ratchet (ratchet). This device creates and secures the necessary contraction force.

Attention! Cantaplus Ratchet hooks have proven themselves in operation, as evidenced by positive reviews from satisfied users.

Cargo fasteners must meet quality standards, so before purchasing, you need to ask the seller about the country of origin, system materials, and the availability of appropriate certificates. Pneumatic shells used for securing loads reduce vibrations and increase the reliability of fixation; they are inflatable bags.

Basics of safe operation of tie rods when securing loads

Before using the belt, it must be carefully inspected for any damage. A damaged unit must not be used under any circumstances!! Commonly occurring injuries include:

- Rust or deformation of metal parts of the belt (ratchets or hooks);

- Various cuts on the tape;

- All kinds of tears in the stitching on the connecting seam.

When transporting cargo with an uneven surface or sharp parts, you should use special pads, additional corners and other means to protect the canvas. Belt devices must be attached to special clamps in such a way that the main part of the load from the stretched belt can be distributed over the necks of the hooks.

When using tightening devices, it is strictly prohibited:

- Bend/twist the tape;

- Hook one hook after another or cling to the side of a vehicle if the latter does not have special eyes;

- Clean with chemically aggressive substances;

- Use a device with obvious signs of corrosion/deformation of the metal lock or hooks;

- Use tape damaged by exposure to high temperatures;

- Use a tape that is damaged along its length by more than 10% of its width;

- Use a ribbon tied in a knot;

- Use a tape that does not have an information label, or the information on which is not readable.

Structure of the ratchet mechanism

The tensioning strap with a ratchet consists of two parts: a short one, on which, in addition to fasteners, there is a belt clamp on the inner surface of the truck, and a long one, on which a ratchet is installed at its end. The structure of the mechanism itself includes the following elements:

- toothed ratchet with a pawl, it protects the belt from sudden unfastening;

- a lock that clasps the ratchet;

- a rotating bar with a spring, it is needed to adjust the length of the belt;

- steel base, it is necessary to connect the ratchet to the tension belt.

Features of selection and use

The choice of belt depends on the size and weight of the load, as well as its shape, transportation conditions and securing method. Tightening straps are often used to secure transported objects in wagons and containers. In this case, a special document is used that regulates the technical conditions for the correct placement and securing of cargo, which increases the safety and quality of transportation.

If the cargo occupies the area of a universal single car or a coupling of such cars, then it is considered oversized (clause 2.3 “Technical conditions for loading and reliable securing of cargo”). The dimensions are checked on a horizontal section; special devices are used for this. Before loading, it is necessary to perform a number of preparatory measures:

- The container floor, linings, and supporting elements of the cargo are cleaned of dirt, snow, ice and other types of contamination. During the winter, the shipper sprinkles a thin layer of purified sand on the floor and pads.

- The unloading hatches are closed. If during the loading process there is a need to use side boards, then the wedge locks can be opened, in other cases they are pushed all the way down.

- When the dimensions of the cargo are greater than the length of the platform floor, the end sides are folded onto special brackets.

- To prevent transported objects from resting on the end sides, they are placed on pads.

As fastening elements in cars, ties, straps, bars, stops, cassettes, lodgements, frames, tightening belts, and slings are used for reinforced cargo securing. They are divided into disposable and multi-turn. The party that sends the cargo is responsible for the quality and reliability of the latter. In the process of processing documents for transportation, the railway station requests from the shipper a certificate of regular inspection of reusable fastening devices, which confirms the suitability of the product for use.

The strength of the tensioning tapes is checked using a dynamometer together with a dimensional load attached to it. Transported objects must be prepared for transportation in such a way as to ensure maximum safety and security. To do this, the shipper must provide:

- high quality of all components into which fastening means are mounted;

- reliable fixation of cargo in the package;

- proper tightness when transporting small-fraction products.

The type of fastening devices has a great influence on the quality of transportation, therefore, when choosing, it is necessary to take into account the characteristics of the tightening belts, the manufacturing method, the reliability of the manufacturer, and the presence of additional fastening elements. Before preparatory work and actual loading, you should familiarize yourself with the code of safe practices for stowing and securely securing cargo.

The extension of the load beyond the boundaries of the end beam should not be more than 400 mm. In order to rationally use the capacity and carrying capacity of the cars, transported objects shorter than 17.2 meters with the same cross-section, uniformly distributed load, are transported on special platforms. On one side of the end the load may stick out. Placing and securing cargo on open rolling stock is carried out for objects that are not exposed to precipitation and other negative environmental conditions.

Middle price segment

"Gigant SR 1/3"

A good model with adjustable length. It is quite suitable for both domestic transportation and professional activities. Thanks to the ratcheting mechanism, the capabilities of the model are significantly expanded. The fabric is based on textile threads made using innovative technologies, which ensures a long service life. The maximum load is 1 ton, with a length of 3 meters and a dead weight of 200 grams. Country of origin - Russia, recommended market price - 310 rubles.

Advantages:

- Ability to independently adjust the length;

- New textile technologies;

- Sufficient quality.

Flaws:

- The handle for adjusting the length is a little inconvenient.

"TOPEX 97X183"

Despite its Asian origin and fairly low cost, this sample has proven itself well in practice. Objects inside the trunk are secured properly and with the required degree of reliability. Although metal buckles are not made of extremely strong steel, they perform their assigned task in full - the load does not wobble during installation, and no problems arise during transportation. The maximum load is 2.5 tons, with a length of 2.5 meters and a weight of 160 grams. The homeland of the brand is China. May be produced in Poland. The recommended price for the market is 350 rubles.

Advantages:

- The slings have excellent stitching;

- Reliability of fastening;

- A decent combination of price and quality.

Flaws:

- Not detected.

"MEGAPOWER 3500kg, tape 8m x 40mm M-73358"

An almost universal version of the screed, which can be used on almost all types of transport (carriage, van, river boat). This belt can be used to tighten not only objects that have a hard shape, but also those that have a certain amount of softness. For example, a belt can be used effectively to transport hay bales. The product itself is extremely light in weight. Withstands a clamping force of 3.5 tons, with a dead weight of 1 kilogram and a length of 8 meters. Produced exclusively in Germany. The recommended price for the market is 400 rubles.

Advantages:

- Can be applied to any cargo;

- Can be used on any type of transport;

- It has an increased length and a reliable ratcheting mechanism.

Flaws:

- Not detected.

Fastening principles

According to the instructions for lashing straps, several methods for securing the load are available to the user. Each of them has a number of distinctive features and nuances; let’s consider each of them in more detail:

- If the bottom part of the body or car has a flat shape, then the product is secured on one pallet; in this case, it is most rational to use the bottom method of securing cargo during transportation.

- The diagonal method shows high efficiency with non-standard dimensions of cargo with missing packaging.

- If it is not possible to secure the container on the sides, then they resort to a fixation system called “criss-cross”.

- Large structures are best secured by a combination of several methods, which increases reliability and reduces the likelihood of involuntary displacement of the load.

The last method is the safest, but to implement it you need to stock up on a large number of belts of different lengths. Its disadvantages include the long time required for preparatory activities and unloading work. In addition, the vehicle or container must have several securing elements not provided by the manufacturer. The ring belt for securing cargo shows high efficiency when transporting large items.

With the anchor method of fixation, at least 4 tightening straps should be used; with the cap method, at least 2 straps should be used. If the system includes more than 2 belts, then they must be made of the same material and have the same dimensions and properties.

Conclusion

Unfortunately, in the Russian Federation it is the production (and not the operation!!!) of tie belts that is poorly regulated. This circumstance has led to the fact that the market is overflowing with low-quality and cheap goods. It is worth noting that brands that care about their image use the European standard 12195-2 “Fastening belts made of chemical fibers - fastening and safety” in the production of belts. However, this standard is not mandatory in the Russian Federation, and the current standards in relation to the product in question are very liberal.

Determining the required width

When transporting cargo, lashing straps must have the required dimensions. The choice of the width of textile tapes is based on the dimensions of the horizontal plane, because it is through it that the device is directed. The modern market offers options with standard widths, defined in millimeters. They come in a range from 25mm to 100mm. The latter are the strongest, but sometimes their use is impractical; they are used when transporting heavy and large structures.

The use of wide belts must be justified, because their cost is an order of magnitude higher than that of simpler analogues, and the fastening process is complicated by the increased weight and insufficient mobility of the belt.

Attention! The reliability of fastening the system depends on the thickness of the belt. For the most rational choice, the design features of the cargo should be determined. For example, to transport a large structure, you will need a belt with a minimum thickness of 50-70 mm.

Spring Lock Tapes

A belt with a spring lock is used to secure luggage weighing no more than 1 ton. To secure the load, the end of the tape is pulled through the buckle. This makes it possible to change the girth area depending on the size of the load. This belt can be safely used to secure light weight cargo.

Withstand force

The maximum voltage depends on the specifications of each model. Options with a load capacity of up to 10 tons have become widespread, but for large objects, systems with a load of up to 20 tons are used. Durable materials and modern production methods are used to manufacture the latest belts and structural elements. When purchasing a tie-type ring tape, it is necessary to take into account the safety margin, the coefficient of which must be at least 2.

An important factor is the conditions of transportation. Frequent turns and drifts increase the shear force relative to the horizontal axis. High humidity provokes the movement of cargo. It is better to discard used clamps, since any deformation of the mechanism reduces the fixation force by almost half. The high quality of fastening is shown by the combination of rings, as well as fixing elements - hooks.

The use of high-quality models ensures excellent cargo securing during transportation. The choice of any system is based on the characteristics of the objects being transported (dimensions, shape, weight) and transportation conditions (presence of sharp turns, poor quality of the road surface, humidity, likelihood of skidding). To create a reliable system, you should prepare the necessary tools and materials.

Premium class

"KantaPlus Ratchet 35 mm/5.0m"

An extremely high-quality sample, in which, in addition to its intended purpose, other aspects related to cargo transportation activities are implemented. The manufacturing material itself can easily be cleaned from almost any contaminants, and reliable locking locks will ensure real safety for operating personnel. At the same time, the belt has a fairly strong tightening force of 2.5 tons, with its own length of 5 meters and a weight of 1 kilogram. The manufacturer (Russia) claims an increased service life. Recommended market price – 750 rubles.

Advantages:

- The load is held firmly and does not slip out;

- The product has an extended service life;

- Reliable latches ensure worker safety

Flaws:

- Not detected.

"Argos UPY-5000-4.0m UT000007420"

The most durable and reliable belt from a domestic manufacturer. The fasteners feature a new alloy composition, which means they are able to withstand increased loads while ensuring maximum reliability of fixation. The most important quality is versatility - the belt can be used not only for transportation, but also for slinging heavy objects on construction sites. Recommended price – 870 rubles.

Advantages:

- Versatility;

- New alloy composition in locks;

- Maximum reliability.

Flaws:

- Not found.

"SKYWAY S03601005"

An excellent option, equipped with a ratcheting mechanism and a convenient length adjustment handle. Suitable for any work, the fabric is stitched securely and durable. Manufacturer – Russia, recommended price – 1000 rubles.

Advantages:

- Versatility;

- Affordable price;

- Good firmware.

Flaws:

- Reverse the order of tensioning the tape.

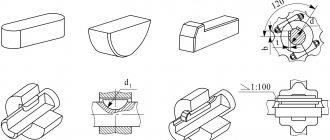

Photo of tightening belts

In the presented photos you can see the most common options for tensioning belts and fastening mechanisms. They differ not only in appearance, but also in basic characteristics, manufacturers, quality of materials, etc.

Tightening belts are characterized by a high level of reliability and convenience, which is why they are often used in the field of cargo transportation. This is an excellent device for securing transported objects in wagons and car bodies. Their choice must be approached as responsibly as possible, since quality, adhesion strength and service life depend on this. Coupling technology is regulated by the cargo transportation code and various regulations that the shipper must familiarize himself with before preparing and loading cargo.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.84%

No. More answers required. I'll ask in the comments now.

37.31%

Partially. There are still questions. I'll write in the comments now.

15.85%

Voted: 713