Transporting most non-bulk cargo requires that it be securely secured in the back of the truck. Unsecured cargo poses a danger to road users, therefore, transportation without it being securely secured is prohibited and a fine is imposed for this. To quickly and reliably secure the cargo transported in the back of a truck, tie-down straps are used for fastening.

Purpose of tightening belts

Ties (tensioning straps for fastening) are designed for securing cargo during transportation. They are mainly used by truck drivers. But they are also used in air transportation when transporting relatively small cargo. Fastening with ties is quick and convenient, unlike fastening using conventional ropes or cables.

Screeds may not be used for their intended purpose. For example, car owners use tightening belts to pull out engines for repairs.

General requirements

To transport cargo on many types of semi-trailers, a standard set of belts or a loop lashing is used. Logs and metal pipes are additionally tied with steel cables or chains to eliminate the possibility of their loss during transportation. Particularly valuable goods are additionally packed in inflatable bags made of reinforced polypropylene film.

Some semi-trailers are additionally equipped with loops to which the load is secured. They are mounted into the structural elements of the platform.

Design features

Structurally, the screed consists of four main units:

- Durable, wear-resistant tape.

- Ratchet fastening.

- Fastening the tape.

- Ratchet mechanism.

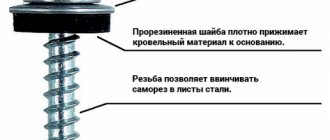

The fastening of the tape and ratchet is made of a steel rod with a diameter of at least 8 mm. The exact size of the rod depends on the power of the ratchet mechanism and the width of the belt used in a particular design. The rod is bent in such a way that it forms both a loop and a hook for fastening. A belt is inserted through the loops and stitched several times with strong threads. The hook is connected to the tape as firmly as possible. The wear of the belt during operation is prevented, because the surface of the rod does not have sharp edges.

The hook is attached to the ratchet using a piece of tape at a distance of no more than half a meter.

Structure of the ratchet mechanism

At first glance, it may seem that the ratchet device is complicated, but if you carefully study the diagram, everything becomes clear.

There is a slot in the central axis of the structure, the width of which is slightly larger than the width of the belt. The axis is rigidly connected to the ratchet sprockets, which are located along its edges. Sprockets are designed to transfer force from the lever to the central axis. The lever of the ratchet device reduces the clamping force and has a locking mechanism, with the help of which, at the moment of securing the load, force is transferred from it. The lever operates on the ratchet principle, i.e. It only pulls in one direction. After tensioning, the lever is installed in the transport position, the locking device begins to fulfill its intended purpose - to keep the tie from spontaneous unwinding. Special springs, which are located at the junction of the lever with the lock, help to hold the locking device in the transport position.

Structure of the ratchet mechanism

The tensioning strap with a ratchet consists of two parts: a short one, on which, in addition to fasteners, there is a belt clamp on the inner surface of the truck, and a long one, on which a ratchet is installed at its end. The structure of the mechanism itself includes the following elements:

- toothed ratchet with a pawl, it protects the belt from sudden unfastening;

- a lock that clasps the ratchet;

- a rotating bar with a spring, it is needed to adjust the length of the belt;

- steel base, it is necessary to connect the ratchet to the tension belt.

Types and designs

Ratchet straps are almost all built on the same principle. They can only differ in the width of the tape, the size of the ratchet and the shape of the hook. Ties can also be divided according to the quality of the steel from which they are made. The stronger the steel, the more load the locking device and ratchet can withstand.

The dimensions of the tape vary in the range of 25-100 mm, respectively, and the width of the ratchet device should be approximately the same, since the tape passes through its axis.

All manufacturers adhere to a standard design that has proven itself and is in demand among consumers.

Many people confuse ties with a ratcheting mechanism and devices for securing loads, in which the tensioning device is provided by the tape itself.

Such tapes are designed for light loads and are not suitable for securing large loads.

Truck loading diagram by axes

No matter how big the truck may seem, it still has restrictions on the permissible weight of the cargo, otherwise breakdowns and fines cannot be avoided. But even without exceeding the carrying capacity standards, you can damage the car if the goods being transported are not distributed correctly.

In order not to make a mistake, you need to know the number of axles, the type of trailer, and the correct location of the load.

Location of pallets in the truck

Features of choice

When choosing a screed, you need to decide for what purposes it is needed and what you plan to secure. If you need to fasten something that is not too heavy and bulky, then there is no need to overpay for a design with a wide belt. It is also worth deciding in advance on the required length and trying to buy a tie with a reserve.

It is recommended to buy a tie of maximum length. The design features of the tie and the principle by which it works make it possible to fasten small loads or structures with a tie with a long belt, and a supply will never hurt.

Determining the required width

When transporting cargo, lashing straps must have the required dimensions. The choice of the width of textile tapes is based on the dimensions of the horizontal plane, because it is through it that the device is directed. The modern market offers options with standard widths, defined in millimeters. They come in a range from 25mm to 100mm. The latter are the strongest, but sometimes their use is impractical; they are used when transporting heavy and large structures.

The use of wide belts must be justified, because their cost is an order of magnitude higher than that of simpler analogues, and the fastening process is complicated by the increased weight and insufficient mobility of the belt.

Attention! The reliability of fastening the system depends on the thickness of the belt. For the most rational choice, the design features of the cargo should be determined. For example, to transport a large structure, you will need a belt with a minimum thickness of 50-70 mm.

Fastening principles

The main parameter that must be taken into account when securing loads using a ratcheting strap is the tension force. The load with which a ratchet can be tensioned has a limit. It will not be possible to break the tape, but it is easy to bend the tendrils of the locking mechanism, especially when the quality of the steel from which the part is made is low. This is the main problem that users encounter when using the screed.

The ratchet lever has certain dimensions, thanks to which the necessary tightening force of the tensioning belt is achieved. Do not tighten the mechanism by using foreign objects to strengthen the lever.

Drivers often break tie-down devices using a mounting spade from a car as a leverage booster. Because of this, the load on the antennae of the locking device sharply exceeds the permissible limit; they bend or immediately break if the material from which they are made is hardened.

To prevent damage to the tie mechanism, do not tighten the tie as much as possible during loading. You can tighten it by hand as far as you can, drive a couple of kilometers so that the load falls into place, and tighten it some more. This method is used by professionals who are accustomed to treating their belongings with care.

Video instructions for working with ties with ratchets:

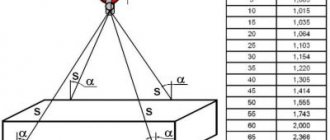

Axle load calculation

It is easier to determine the load on each axle using truck scales. But you can calculate it yourself using the formula:

Ma = Npo + Nzo

That is, vehicle weight = front axle load + rear axle load. For a three-axle vehicle, the formula is different: load on the front axle + load on the rear bogie. The trailer or rear axle is always loaded more.

Method for calculating axle load

The calculation of the load will depend on the quality of the roads, which are divided into two groups (A and B) and four categories. Seasonal restrictions also have an impact. All criteria for axle load distribution are specified in regulatory documents.

Rules for the safe use of tie-down straps for securing cargo

To ensure that securing a load using a tie is as safe as possible, you must adhere to the operating rules:

- It is forbidden to use tension belts that have abrasions or broken threads.

- Do not use tie rods with a faulty ratchet or locking mechanism.

- For fastening, it is necessary to use hinges specially provided for in the design of the motor vehicle. Manufacturers specifically install additional cargo racks in the back of a truck or in a car trailer.

- A moving load must be secured in all directions in which it can move.

- Tension control and inspection of fastening integrity must be carried out throughout the entire transportation route.

Truck loading methods

There are 3 types of downloads:

- Loading from above.

- Lateral.

- Rear.

Location of pallets in a truck. Side and top loading for multi-axle trucks are rarely used.

Rear loading is the most common. Pallets are loaded into the semi-trailer and transported into the body using a mechanical lift. Pallets are loaded packed.

In European warehouses this is the only convenient loading method. On ramps where the vehicle can be approached from the side, the driver only needs to open the doors and the rear awning.

Here's how the rear loading of a tilt Euro truck works:

It is easy to move stacked, well-palletized loads with a forklift The transport has forks that are inserted into the middle compartment of the pallet, lifted, and smoothly installed in the body of the semi-trailer. Convenient to load with a fork lift.

Manufacturers and cost of tension belts

There are not just many manufacturers of ratchet ties, but very many. It will not be possible to list everyone, but the products of the companies listed below are in demand and have a low price.

- KRAFT produces more than 10 models of ties of different lengths and loads.

- MEGAPOWER – the line includes inexpensive and high-quality models.

- Russian company AUTO-TROS. The cost of tie belts from this company starts from 300 rubles.

Reliable fastening of the load is possible without the use of belts with a tension mechanism. But this requires certain skills, for example, you need to be able to knit strong knots. Using a tie for fastening, you can save time, nerves and insure yourself against troubles associated with spontaneous movement of cargo during transportation.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.84%

No. More answers required. I'll ask in the comments now.

37.31%

Partially. There are still questions. I'll write in the comments now.

15.85%

Voted: 713

Withstand force

The maximum voltage depends on the specifications of each model. Options with a load capacity of up to 10 tons have become widespread, but for large objects, systems with a load of up to 20 tons are used. Durable materials and modern production methods are used to manufacture the latest belts and structural elements. When purchasing a tie-type ring tape, it is necessary to take into account the safety margin, the coefficient of which must be at least 2.

An important factor is the conditions of transportation. Frequent turns and drifts increase the shear force relative to the horizontal axis. High humidity provokes the movement of cargo. It is better to discard used clamps, since any deformation of the mechanism reduces the fixation force by almost half. The high quality of fastening is shown by the combination of rings, as well as fixing elements - hooks.

The use of high-quality models ensures excellent cargo securing during transportation. The choice of any system is based on the characteristics of the objects being transported (dimensions, shape, weight) and transportation conditions (presence of sharp turns, poor quality of the road surface, humidity, likelihood of skidding). To create a reliable system, you should prepare the necessary tools and materials.