When carrying out rigging, installation and construction work, there is often a need to fix and lengthen the steel ropes used, as well as create loops and eyes at their ends. For these purposes, rope clamps (cable clamps) are used.

A rope clamp is a device used to fix and secure a steel rope.

This type of rigging is not intended for work related to lifting, moving, holding and lowering loads. Its main purpose is to ensure strong tension on ropes and cables during the installation of structures and to secure objects in a stationary position, for example, on a vehicle platform during transportation.

Clips (rope clamps) are used in conjunction with a pear-shaped asymmetric thimble to secure the rope in a device for splicing the rope.

The size of the steel cable clamp is determined by the diameter of the rope used.

How to do it yourself

The type of fastener in question is easy to manufacture. To make it yourself, no special skills are required.

Materials:

- Bolt

- screw

- Rope

Tools:

- Bulgarian

- Vise

- Wrench

- File

After preparing all the necessary tools, start making. First of all, you need to know that during the creation of the cable fastening, the bolt thread will be damaged and cut off. To re-cut the ground surface, use a grinder or a sharpening machine. The grinder can be replaced with a simple hacksaw.

After restoring the thread, a cut is made along the bolt. A small rope is placed in the cut (it must be the right size). Then it is secured with a nut. How to use a cable clamp? They are usually needed to secure loops at the ends of ropes. This type is useful in everyday life, for example, for hanging various vessels and buckets.

Of course, this DIY device cannot be used for “more serious purposes.” That is, it will not be able to withstand a sufficient load in the form of any object that is suspended on a cable. Naturally, the rope is quite strong and, therefore, there is no point in using it to hang buckets.

There are many types of clamps. The article does not cover all of them, but only some of them.

Operating rules

Before starting work, you need to check the strength of the connections by applying a load to the cable once. If after several checks the cable and clamps continue to perform their functions, then it can be used. However, it is necessary to regularly check the condition of the clamps, since over time the connections can become loose, the nuts can become loose, and the metal can be destroyed.

The maximum service life of the clamps depends on the operating conditions. If this is a construction site with regular transportation of goods across floors by a construction crane, then replacement should be done every 4-6 months. In a domestic setting, you need to look at the state of wear to determine whether the clamp needs to be replaced or not.

In some cases, proper operation can save lives. This refers to the so-called lifeline. This is a tightly stretched cable with the ends attached to the sides of boats and ships. If a person accidentally falls out of a boat, it will be easier to save his life by grabbing onto it.

Safety requirements for cargo transportation determine the need to adhere to the technique of fastening steel cables and ropes. Before using the fastener, you need to check its load-bearing capacity. And if the connections are actively used, the degree of wear should be monitored.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.84%

No. More answers required. I'll ask in the comments now.

37.31%

Partially. There are still questions. I'll write in the comments now.

15.85%

Voted: 713

Crimping

The crimp cable clamp is made of aluminum alloy. It is a fairly durable and reliable type of fastener to use.

- It should be noted that clamps should not be used to secure products such as braids and ropes.

- Compared to ropes and cables, they are fragile to use.

- Such products are created from thinner material, and therefore are intended for other purposes.

- Depending on the type of clamp, you may need some tools to attach it.

Types of materials and coatings

Since working with cables and clamps involves significant loads, very durable materials must be used. The most common types are stainless steel, regular steel, copper and aluminum, but heavy-duty carbon steel clamps are also available. To work in harsh weather conditions, a clamp is used that is galvanized with zinc. The galvanized surface resists corrosion.

How to choose

In order to use an object, sometimes it is not enough to know only about its properties.

The following list will help you choose the right clamp:

- Determine the purpose of use.

- Determine the size correspondence, evaluate the capabilities of this fastener.

- Establish compliance of materials.

Some things made from different materials cannot be combined. This is known to everyone who understands even a little physics.

Thus, an aluminum cable clamp cannot be used for fastening trellis ropes, as well as ropes made of PVC. PVC (polyvinyl chloride) is a material commonly used for flooring. It also has similar properties to linoleum, but is more durable.

Once these criteria have been established, different species should be examined. To avoid safety violations, each must be used for its intended purpose.

The next thing you need to pay attention to is the quality of the retainer you choose. However, how do you understand how high quality a particular type of fastener is? The following points will help you determine this:

- The clamp does not have any defects (chips, cracks). Its surface is absolutely smooth.

- Marking. It should be clearly visible on the product, i.e. no special devices are required with which it can be seen.

- The fastener will be 100% high quality if it meets the characteristics of the cable that needs fastening.

Length, size - this is what all fasteners have. However, considering the purpose of each, they are all made for different purposes. Thus, a distinction is made between regular and reinforced products.

When creating each, a different material is used from the other. For example, a galvanized cable clamp may be made, or maybe an aluminum one. The advantage of the first is its resistance to corrosion, so it is used at high humidity levels.

It is very important that the design is reliable and safe. Therefore, the question arises: how to obtain this guarantee? This needs to be sorted out.

If the cable used is without braid, then the fastener is selected according to the diameter of the cable. If there is a braid, things change somewhat. If you do not get rid of it, then the load limit will decrease by 30%. The fact is that the soft vinyl will be in contact with the body of the fastener. In this case, it is dangerous to use this design.

- Basically, fastening rope products are made of stainless steel, mild galvanized steel and hot-dip galvanizing.

- The last option is suitable for those who do not want to spend a lot of money on such devices.

- However, its corrosion resistance is less than that of stainless steel. Mild steel with zinc coating is perfect for everyday use.

Compared to stainless steel and hot-dip galvanizing, this material is the easiest to corrode. To justify this detail, the price does not rise too high.

Tips for choosing

Before choosing a specific product, you need to make sure of its quality. To do this, you should pay attention to the following points:

- the clamps must be legibly marked;

- there should be no visible burrs, cracks, grooves or other manufacturing defects on the surface;

- clamps must be selected in accordance with the characteristics of the cables used;

- The type of material/coating of the clamp must correspond to the external factors and conditions in which the work is performed.

All of these types of rope clamps are designed and manufactured to order by GPO-Snab. You can select and order them in our catalog of rigging products.

Price

There is no need to worry about the price of such devices. Not a single clamp (even the best quality) has a very high price, so purchasing the necessary one will not be difficult.

When using any fastening used to secure a steel rope, its original shape should not be changed. This is strictly prohibited. Not only will this damage the fastener, but it will also deteriorate the quality of the fastening.

Fastening the ends of the ropes to the axle

If it is necessary to secure the edges of the cable to the axle, thimbles are widely used. This is a forged, cast or stamped ring with a grooved section. The thimble protects against sharp bends and creases, reduces crushing stress and protects against abrasion on the axle. The cable is placed in the groove of the device and the free edge is connected to the main branch.

Fixation methods include:

- weaving;

- using shaped strips;

- using strips with trapezoidal grooves;

- fill;

- wedge

Weaving the wires of rope strands and then braiding them is considered a too labor-intensive method. Options with clamping devices are more common.

Installation

As mentioned earlier, clamps are most used in creating loops and fastening ropes. The following are technological standards that should be followed when installing fasteners:

- Be sure to check that the surface of the retainer is not damaged.

- Check that the size of the fastener matches the size of the rope.

Knowing these standards will help you install fasteners yourself.

Fastening the rope to the drum

The method of fixing the rope to the winch must be provided for by the design of the mechanism itself. It must provide a sufficient level of fastening reliability.

The cable is laid on drums with flanges (sides to prevent slipping) in one or several layers:

- single layer;

- multilayer winding.

The edges of the ropes are attached to the surface:

- Wedge clamps are a type of clamping element where the workpiece is secured by a simple wedge, they are used to increase or change the direction of the clamping force. They are used on lifting mechanisms when frequent replacement of cables is necessary.

- clamping bars - devices for fixing cables by pressing them to a surface, usually clamped using nuts, bolts or other threaded elements.

The most common method of fixation on winches is using clamping bars.

Photos of the best cable clamps

Laying cables on a cable to the house, garage, installation and installation

For various reasons, it is not always possible to lay an electrical cable underground to an object that needs to be provided with electricity. In such cases, the technology of laying cables or individual wires through the air on a cable is successfully used. In the article we will look at how to install and lay a cable on a cable to a house or garage, and what types of fastening are used.

Scope of technology

Such technologies are used only in electrical networks with a voltage not exceeding 1000 volts, the requirement of the PUE is Chapter 2.1. In most cases, the laying of cables on cables is used from buildings or power lines to individual structures over short distances. Where installation of power transmission line supports or digging trenches for cables is impossible due to technical production conditions during the operation of facilities, or unreasonably due to the volume of work performed, it is expensive from a financial point of view.

In production workshops, warehouses, buildings with large areas, high ceilings, the best option for lighting is to use these technologies. Cable cables are used for electrical networks of street lighting in certain areas.

For private home owners, this wiring method eliminates the time-consuming work of digging a trench. It’s easier to stretch a cable through the air from the distribution board in the house to outbuildings:

- workshop;

- summer kitchen;

- gazebo with barbecue;

- chicken coop;

- bathhouse and other possible structures in the courtyard of a private household.

Cable wiring allows you to conduct light three-wire wires for electrical consumers of low power and cables with large cross-section wires for power supply of powerful household appliances. Before proceeding with the installation of cable wiring, preliminary calculations are required.

Preliminary measures before installation

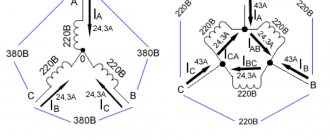

At the first stage, it is necessary to determine how much power will be consumed by electrical appliances in the structures that are planned to be provided with electricity. Based on the power consumption, the cross-section of the cable wires is calculated, its length and weight are taken into account. These parameters determine which fasteners to use, the diameter and material of the cable. To calculate power consumption and cable cross-section, a more detailed study of a separate topic is required. In simplified form it looks like this:

- The power of all electrical appliances that are supposed to be used in the calculated network is summed up. The power of each device is indicated in product passports or nameplates on the housing. The simplest example of a lighting lamp is always written 40 on them; 60; 75 or 100 or more watts.

∑Р = P1 + P2 +…Pn = 3.7 kW. (3700 W) – Total power.

- Determine the maximum possible current in the circuit

I = ∑Р/ U=3700 W/220 V = 16.8 A. – Maximum current.

U – network voltage.

- To determine the cross-section of wires in a cable, use the table

In our case, we choose a maximum current value slightly greater than 19A, taking into account that additional household appliances may be used in the future. According to the table, we obtain a power of 4.1 kW, which corresponds to a copper wire cross-section of 1.5 mm. You need to understand that the cross section is not the diameter, it is calculated using the formula:

Formula for calculating wire cross-section

Experienced electricians are well aware of the standards of cables and wires and determine the cross-section by eye. For ordinary consumers, there are tables for determining the cross-section by diameter ; it is enough to measure the diameter of the wire with a micrometer or caliper and determine its cross-section using the table.

Determining wire cross-section by diameter

- The next stage of preliminary work is measuring the length of the cable from the distribution board in the house to the switchgear (switchgear) on the building to which the cable structure is stretched. This can be done with a regular tape measure,

Tip #1. Be sure to take into account the cable reserve for cutting and connecting to the control panel; add approximately 30 cm at both ends.

Selecting the diameter and material of the cable

Determine the weight of the cable and other elements that will be attached to it. If the distance between the supporting fasteners is 5-6 m and the weight of the wire is not significant, you can stretch galvanized steel wire with a diameter of 2-3 mm.

When the distance is more than 10 m, the cable is heavy, especially if the cable structure is used with lighting elements, galvanized steel cable with Ø 4-6.5 mm is used.

Such a cable will withstand any cable with a wire cross-section of up to 10 mm/sq.m; larger cables are not used in private households due to limited power consumption. You can also hang up to 5 pieces on such a cable. lighting lanterns in a lightweight housing.

The cable can be wound and weighed on ordinary scales, or calculated by knowing its brand according to the characteristics table, which is included with the sale. The weight of the cable per 1 meter is indicated; you need to multiply the specified weight by the number of meters to get the total weight of the segment that is used for fastening to the steel cable.

For domestic conditions, in order not to waste money, you can hang the cable that was used for hidden wiring. In order for the insulation to last longer, lay it in a corrugated pipe; its weight is not significant. There are reference tables indicating the brand and weight of the cable. You can look it up on the Internet; some sites have calculators for calculating the length and weight of wires and cables.

Table indicating the cable brand and weight in kg. by 1 meter

For high current loads, it is better to use special cables for overhead cable structures:

- AVT, AVTS, APT already have a built-in supporting steel cable;

- AVRG, ANRG, APVG, AVVG are suspended from a supporting steel cable.

Supporting and tensioning elements of cable wiring

These products are installed on the walls of buildings, structures between which tension is stretched. Depending on the material and diameter of the cable, the fastening design is selected:

- Tension bolt, hook and tension anchor are used for flexible multi-core industrial cables carrying heavy loads; rolled wire with a diameter of up to 6 mm can be used.

- Anchors for tensioning strings with a small diameter are designed for light wires with a cross-section of up to 6 mm at a distance of up to 10 meters, without lighting elements.

- Anchors for industrial cables and wire rods are capable of supporting heavy cables and lighting elements at a distance of up to 12 m without additional supports.

- Fasteners for stringing parallel lines are often used for dual purposes, for power supply to structures and placement of lighting lanterns. A power cable with a wire cross-section of 10 -35 mm/sq. is laid along one cable; on the second, lighting outlets and distribution boxes with copper wire 2.5 - 4 mm are laid.