Let's lift the load

We will insure and pack

Free visit for inspection

Very often, residents of large cities are faced with the problem of lifting and lowering oversized cargo. This is especially true for residents of high-rise buildings. What to do when the cargo simply does not fit through standard doorways? In this case, the best solution would be to seek help from professionals. They specialize in lifting a variety of loads in all conditions. Thanks to a carefully thought-out plan of action and the availability of professional equipment and equipment, you can be calm about the safety of your cargo. All work is carried out only if there are officially concluded contracts, which is a kind of insurance in case of any problems. Only specialists with extensive work experience who have been trained in extreme conditions are allowed to work. After all, only diligent preparation and well-planned work guarantee the integrity and safety of the delivered cargo.

Manual lifting of loads

There are two ways to lift loads - using manual lifting equipment and electric ones. Lifting mechanisms are special devices that are used both in industry and in everyday life to lift and move heavy loads, with the effort of only one person. The main purpose of these mechanisms is aimed at reducing the force that is applied to lift and move the load. These devices allow a person to work with a weight that is significantly higher than their own. The main advantage of such mechanisms is that most lifting devices do not require electricity. Therefore, they can be used both in large industries and small workshops, private garages and even in the field. Let's consider the types of devices and their features that can be used to lift and move loads manually.

How do we make lifting easier?

A cargo pulley is a system consisting of ropes and blocks, thanks to which you can gain effective strength while losing in length. The principle is quite simple. In length we lose exactly as many times as we win in strength. Thanks to this golden rule of mechanics, you can lift large loads without exerting much effort. Which, in principle, is not so critical. Let's give an example. Now you have won 8 times in strength, and you will have to stretch a rope 8 meters long to lift the object to a height of 1 meter.

The use of such devices will cost you less than renting a crane, and besides, you can control the gain in strength yourself. The pulley has two different sides: one of them is fixed, which is attached to the support, and the other is movable, which clings to the load itself. The gain in strength occurs thanks to the movable blocks, which are mounted on the movable side of the pulley. The fixed part serves only to change the trajectory of the rope itself.

Types of pulleys are distinguished by complexity, parity and multiplicity. In terms of complexity, there are simple and complex mechanisms, and the multiplicity means a multiplication of force, that is, if the multiplicity is 4, then theoretically you gain 4 times in strength. Also rarely, but still used, a high-speed pulley block is used; this type gives a gain in the speed of moving loads at a very low speed of the drive elements.

Types of hand winches

In fact, dividing models into home-made and factory-made, imported and domestic are classifications of winches. They can also be divided according to the type of fastening.

There are devices that are fixed on walls, on the ground, and combined ones. But, the main classification is related to the structure and type of winch mechanism:

No. 1 The lever mechanism can operate without fixation. Accordingly, there is no need to look for a base that, like a winch, can withstand a significant load.

Plus, the free mounting allows you to use the device both horizontally and vertically. The main lever in the design. He triggers a ratchet mechanism that rotates the shaft in only one direction.

The disadvantage of the design is the small winding of the cable on the drum. You won’t find more than 6 meters in models of this class. But the manual lever winch is a record holder for lifting capacity. It is among the devices with levers that there are 10-ton towing ones.

Such winches are large in size and are used in industry and construction sites. Most lever samples are miniature and purchased for household needs.

A subtype of a lever winch is considered to be an assembly-traction winch. It does not have a drum. This makes the models compact and removes restrictions on rope length. There are proposals with 20-25-meter cables.

They are clamped with cams on the body. The clamps are located opposite each other, ensuring an even load on the cable. Ultimately, it lasts longer. In addition, there is a function for locking the cams with a lever.

The latter is protected by a shear pin. The device is more advanced than other lever winches and is gaining popularity.

No. 2 The drum mechanism works only from the support. Designed for horizontal movement of cargo. If you need to move them at an angle of 45 degrees, the manual drum winch is mounted at a height of 15 centimeters from the ground.

It's minimum. If the load has to be moved at a large angle, the device is raised by 65 centimeters. In addition to the support, the handle, gearbox and drum work.

The latter usually has tens of meters of cable. Therefore, the series models are also called cable models. Instead of a lever, the movement is set by a rotating handle.

Through the gearbox, it transmits the impulse to the drum, which sets the traction force. If it is excessive, the stopper is activated. This will protect you in moments of sudden drop of loads. They can weigh from 250 kilos to 5 tons.

The subclassifications of manual cable winch are due to different types of drive. The least reliable is considered:

-Worm. It has a helical gear and a main gear. The latter is mounted on a drum and rotates with a screw. The mechanism has an auto-stop and allows you to move the load in any direction; in other words, it works in reverse motion. The drive strength and the compactness of the mechanism are also pleasing. But the advantages are outweighed by rapid wear due to active friction in the worm pair. Reducing the load, you have to constantly lubricate it. Without lubrication, worm drives often jam.

-Single-speed gear drive consists of a large gear on the drum and a small transmission gear next to it. The design is also called gear. The gear ratio is calculated from the number of teeth on the gears. The leading one is monolithically fastened to the shaft, and the handle is fixed to it.

If her shoulder is long, the pull requires minimal effort. Short handles make you sweat. But the mechanism is reliable and durable, it pulls 2-3 tons horizontally, and several hundredweight vertically.

-Multi-speed gear drive. This one has several pairs of gears. Considering that each increases the force coefficient tens of times, the drive is the most powerful. But the rotation speed of the drum, characteristic of the first pair of gears, is lost.

An acceptable rhythm is gained with heavy loads weighing over a ton. If you plan to lift a bucket of gravel, the process will be protracted. The gear locking feature helps. You can stall certain pairs. Taking this into account, a manual chain winch with a multi-speed drive is the pinnacle of perfection in its class.

As you can see, the scope of its application depends on the nuances of the winch structure. There is even a separate classification based on the purpose of installations. We will consider it in a separate chapter.

How does a simple block design work?

Let's first consider a simple assembly pulley. It can be obtained by adding blocks to a support and a load. To get an odd mechanism, you need to secure the end of the rope to a moving point of the load, and to get an even one, we fasten the rope to a support. When adding a block, we get +2 to strength, and a moving point gives +1, respectively. For example, to get a pulley for a winch with a multiplicity of 2, you need to secure the end of the rope to a support and use one block that is attached to the load. And we will have an even type of device.

The operating principle of a chain hoist with a multiplicity of 3 looks different. Here the end of the rope is attached to the load, and two rollers are used, one of which we attach to the support, and the other to the load. This type of mechanism gives a gain in strength of 3 times, this is an odd option. To understand what the gain in strength will be, you can use a simple rule: how many ropes come from the load, this is our gain in strength. Typically, pulleys with a hook are used, on which, in fact, the load is attached; it is a mistake to think that it is just a block and a rope.

What is a refill, how is it made and what is it like?

Refilling is a change in the position of blocks and the distance between them. It is carried out to change the speed or height of lifting weights.

There are different types of refill schemes:

- Single-use: the hook is hung by 1 rope, which is then passed sequentially through each stationary block and wound onto a drum.

- Double. For beam cranes, 1 end of the rope is attached to the boom root, and the second end is passed through the bypass drum, all the blocks, and then attached to the winch. For cranes, the rope is attached to the winch and the stationary blocks are located on the boom head.

- Quadruple. A combination of the schemes listed above is used for each hook suspension unit.

- Variable. The movable rollers are complemented by 1 or 2 movable cages.

Complex block system - how to calculate the gain in strength?

Now we will find out how a complex type chain hoist works. This name refers to a mechanism where several simple versions of this cargo device are connected into one system; they pull each other. The gain in strength of such constructions is calculated by multiplying their multiplicities. For example, we pull one mechanism with a multiplicity of 4, and another with a multiplicity of 2, then the theoretical gain in force will be equal to 8. All of the above calculations take place only for ideal systems that have no friction force, but in practice things are different .

In each of the blocks there is a small loss in power due to friction, since it is still spent on overcoming the friction force. In order to reduce friction, it is necessary to remember: the larger the bend radius of the rope, the less frictional force will be. It is best to use rollers with a larger radius where possible. When using carabiners, you should make a block of identical options, but rollers are much more effective than carabiners, since the loss on them is 5-30%, but on carabiners it is up to 50%. It is also useful to know that the most effective block must be located closer to the load to obtain maximum effect.

Read also: Morse cones GOST sizes

How do we calculate the real gain in strength? To do this, we need to know the efficiency of the units used. Efficiency is expressed as numbers from 0 to 1, and if we use a rope with a large diameter or too stiff, then the efficiency of the blocks will be significantly lower than indicated by the manufacturer. This means that it is necessary to take this into account and adjust the efficiency of the blocks. To calculate the actual strength gain of a simple type of lifting mechanism, it is necessary to calculate the load on each branch of the rope and add them up. To calculate the gain in strength of complex types, it is necessary to multiply the real forces of the simple ones of which it consists.

How to make calculations for a chain hoist ↑

Despite the fact that theoretically the design of a pulley hoist is extremely simple, in practice it is not always clear how to lift a load using blocks. How to understand what multiplicity is needed, how to find out the efficiency of the lift and each block separately. In order to find answers to these questions, you need to perform calculations.

Calculation of a separate block ↑

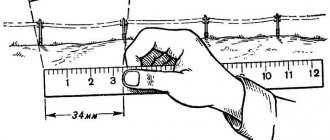

The calculation of the chain hoist must be performed due to the fact that the working conditions are far from ideal. The mechanism is subject to frictional forces as a result of the movement of the cable along the pulley, as a result of the rotation of the roller itself, no matter what bearings are used.

In addition, flexible and pliable rope is rarely used on a construction site or as part of construction equipment. Steel rope or chain has much greater rigidity. Since bending such a cable when running against a block requires additional force, it must also be taken into account.

For the calculation, the moment equation for the pulley relative to the axis is derived:

SrunR = SrunR + q SrunR + Nfr (1)

Formula 1 shows the moments of such forces:

To determine the moment, all forces are multiplied by the arm - the radius of the block R or the radius of the sleeve r.

The force of the approaching and escaping cable arises as a result of the interaction and friction of the rope threads. Since the force for bending/extension of the cable is significantly less than the others, when calculating the effect on the block axis, this value is often neglected:

Calculation of the useful action of the block ↑

As you know, efficiency is the efficiency factor, that is, how effective the work performed was. It is calculated as the ratio of work completed and work expended. In the case of a pulley block, the formula is applied:

ηb = Srun/ Srun = 1/(1 + q + 2fsinα×d/D) (3)

From this formula it can be seen that the efficiency is affected by the structure of the block (through the f coefficient), its size (through the d/D ratio) and the rope material (q coefficient). The maximum efficiency value can be achieved using bronze bushings and rolling bearings (up to 98%). Sliding bearings will provide up to 96% efficiency.

How to calculate the efficiency of the entire system ↑

The lifting mechanism consists of several blocks. The total efficiency of a pulley block is not equal to the arithmetic sum of all individual components. For the calculation, they use a much more complex formula, or rather, a system of equations, where all forces are expressed through the value of the primary S0 and the efficiency of the mechanism:

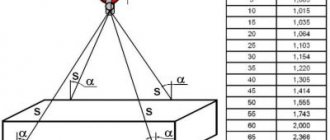

Since the efficiency value is always less than 1, with each new block and equation in the system, the value of Sn will rapidly decrease. The total efficiency of the pulley will depend not only on ηb, but also on the number of these blocks - the multiplicity of the system. Using the table, you can find ηp for systems with different numbers of blocks at different efficiency values of each.

Rope and its role in the operation of the pulley system

You should also not forget about the friction of the rope, since its branches can twist among themselves, and the rollers under heavy loads can converge and pinch the rope. To prevent this from happening, the blocks should be spaced relative to each other, for example, you can use a circuit board between them. You should also purchase only static ropes that do not stretch, since dynamic ones give a serious loss in strength. To assemble the mechanism, either a separate or a cargo rope can be used, attached to the load independently of the lifting device.

The advantage of using a separate rope is that you can quickly assemble or prepare a lifting structure in advance. You can also use its entire length, this also makes it easier to pass knots. One of the disadvantages is that there is no possibility of automatic fixation of the lifted load. The advantages of a cargo rope are that automatic fixation of the lifted object is possible, and there is no need for a separate rope. The important thing about the disadvantages is that it is difficult to pass through the knots during operation, and you also have to spend a cargo rope on the mechanism itself.

Let's talk about the reverse motion, which is inevitable, since it can occur when the rope is caught, or at the moment of removing the load, or when stopping to rest. To prevent backlash from occurring, it is necessary to use blocks that allow the rope to pass in only one direction. At the same time, we organize the structure so that the blocking roller is attached first from the object being lifted. Thanks to this, we not only avoid backtracking, but also allow us to secure the load while unloading or simply rearranging the blocks.

If you are using a separate rope, the locking roller is attached last from the load being lifted, and the locking roller should be highly effective.

Mounting and traction mechanisms "MTM"

They work by using manual human power. The operating principle of the MTM is to move the cable inside the clamping blocks. The main feature is the ability to work at a great distance from the load, no need to connect to electricity, and easy transportation. The mounting and traction mechanism will become an indispensable device on construction sites, where there is a need for unloading, loading and emergency work, as well as in warehouses. Unlike a manual hoist, a steel cable is used here. This mechanism can work at different angles; it is possible to attach it to different surfaces, such as a wall or ceiling. The MTM design is very light, but at the same time has good strength. A protective mechanism is provided. The mounting and traction mechanism provides many advantages that affect its quality work: increased wear resistance; relatively light weight and size; high strength steel cable; overload protection; long service life; the ability to select the required rope length; presence of a safe handle; resistance to temperature changes.

Methods for attaching a rope to a lifting mechanism

Now a little about attaching the lifting mechanism to the cargo rope. It’s rare that we have the right length of rope at hand to secure the moving part of the block. Here are several types of mechanism mounting. The first method is using grasping knots, which are knitted from cords with a diameter of 7-8 mm, in 3-5 turns. This method, as practice has shown, is the most effective, since a gripping knot made of 8 mm cord on a rope with a diameter of 11 mm begins to slide only under a load of 10-13 kN. At the same time, at first it does not deform the rope, but after some time, it melts the braid and sticks to it, beginning to play the role of a fuse.

Another way is to use a general purpose clamp. Time has shown that it can be used on icy and wet ropes. It begins to crawl only with a load of 6-7 kN and slightly injures the rope. Another method is to use a personal clamp, but it is not recommended, since it begins to creep with a force of 4 kN and at the same time tears the braid, or can even bite the rope. These are all industrial designs and their application, but we will try to create a homemade chain hoist.

We create a simple lifting mechanism with our own hands

But if you need a mechanism for cargo urgently or for a one-time use, but you don’t have time to buy it in stores and you’re sorry for the money, we’ll tell you how to make a chain hoist with your own hands. It’s good if you have threaded rods, bearings, a block, a cable, a hook, and a gear in your workshop. It will take a little time: you need to fit the bearings onto the stud. It is advisable to fix the nut from the stud so as not to waste some of the effort on turning the peculiar shaft. The end of the pin can be equipped with a gear, thus making a more convenient manual drive.

We throw a cable over the block and fasten it to a support, but at the other end we attach a hook on which we will hang the load. You can also fix a sling system at the end of the cable if the nature of the load does not allow it to be attached to the hook. In principle, the simplest version of the chain hoist is ready. All that remains is to get to work, observing safety precautions, which are the same for all mechanisms, both purchased and homemade. Carefully check all elements for integrity before work, and during work do not make sudden movements, lift the load smoothly, and, of course, do not stand under a suspended load.

Read also: Oil volume in a piston compressor

Good evening everyone!

Guys, share some advice, a link... in general, there is a hoist, there is a place for lifting, everything is no problem, but here’s how to lift a load in the field without using a truck crane.

max. load kg 500, height 3-4 meters depending on dimensions (loading will be needed in a car trailer)

Guys, the idea struck me to build something similar to a tripod... everything would be fine, but I couldn’t solve the problem of how to lift the load not under the tripod itself (at the place where three pipes intersect), but at a distance of half a meter, for example...) the whole structure should be make a collapsible one... I would look it up on YouTube, but how can I put what I need into the search, comrades, surely someone has done something similar, please share, please...

Throughout the long history of its existence, man has more than once been faced with the task of lifting and moving heavy objects in space. For example, the familiar Egyptian pyramids consist of massive stone blocks that no one can lift. Therefore, one of the greatest achievements of mankind is the invention of the lifting crane, which made it possible to significantly simplify the task of moving heavy loads and speed up the construction of houses and other objects.

Machine structure

The operating principle of a crane is based on the physics of simple mechanisms. The simplest version of the crane is a stick placed on a fulcrum in such a way that the free ends have different lengths. Now if you hang a load on a short lever, it will take less effort to lift it. The most common design is one that uses, in addition to levers, a system of blocks.

A do-it-yourself crane is an indisputable assistant in small-scale construction. When constructing a private house, the use of bulky industrial cranes is not required. The height of the houses rarely exceeds 2 floors, and the weight of the lifted load is 200 kilograms.

Crane diagram

Although there are many variations of lifting mechanisms, a classic crane consists of the following parts:

- An arrow with a block attached to its end. Depending on its length, the height to which the load can be lifted is determined.

- Platform. The boom and counterweight are attached to it. It is the main part of the crane and is subject to significant loads. Therefore, when manufacturing a platform, it is important to pay special attention to its strength.

- Counterweight. Serves for crane stability. Defines the maximum load weight that the crane can lift. Stackable counterweight options are available to provide maximum stability.

- A guy wire connecting the boom and the counterweight. Allows you to adjust the tilt of the boom and move the load in both vertical and horizontal planes.

- Winch with cable. It is the lifting mechanism itself. The power of the winch determines how much weight the crane can lift.

- Stand with a rotating mechanism. It is necessary to turn the crane to the sides.

- The support cross, which is the base of the crane. Sets the stability of the entire structure. When manufacturing it, you should also pay attention to its strength.

Calculation of the chain hoist

Before manufacturing a chain hoist, it is necessary to calculate the main technical characteristics of the load-lifting structure. Calculations are required for drawing up drawings and are made according to the parameters of the working premises and the weight of the load.

To determine the loads affecting the block system during operation, it is necessary to calculate the parameters acting on individual blocks:

The equation used to find the moments of force is as follows: SM * R = SC*R + l*SC*R + N* g*d/2, where:

The efficiency of the pulley is determined by the following formula: η = SC/SM. This parameter is influenced by the quality of the blocks and the complexity of the circuit. There are the following efficiency levels of the block system:

When calculating, it is also recommended to determine the efficiency of the remaining bypass rollers, depending on the design features of the lifting mechanism.

terms of Use

To operate lifting mechanisms safely, certain rules must be followed.

Homemade Pioneer crane

These rules apply to any lifting device:

- The load capacity must not be exceeded. A load that is too heavy may damage the device.

- The base must be stable. Homemade lifting devices should be located on a previously prepared hard horizontal surface.

- In bad weather conditions, you should also refrain from working with the crane. Strong winds will throw the crane off balance, and poor visibility may make it difficult to see people under the boom.

- Before operating a crane or lifting device, it is necessary to conduct an external inspection to identify any malfunctions. If malfunctions are detected, operation of the crane is prohibited.

- It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load.

What characteristics should a garage lift have?

In garage conditions, two types of lifting mechanisms are used. The first type includes a lift that can lift the entire car, and the second type includes a goose-type lift that allows you to move loads around the garage.

Lifts of the first type are stationary devices and the main requirement for them is stability. The car weighs more than a ton and should not have the slightest chance of falling. In order to prevent any accidents, the garage lift must have a reliable stopper.

Homemade goose tap

The goose type lifts are most often used in auto repair shops. It is quite simple to make it from a profile pipe or channel. First, the base is welded on which the rotating mechanism needs to be installed. It is best to make an arrow with an adjustable reach. This will make it possible to move weights in any direction.

How a simple block design works

The pulley system or pulley system has been known to mankind since ancient times. The classic system design consists of pulleys and cable. One pulley is called a block. Depending on the method of fastening, the pulley can be movable or fixed:

- Fixed block. It is attached to the support and plays the role of changing the direction of movement of the rope. Does not provide any gain in strength.

- Movable block. It is located on the side of the load and gives a gain in strength.

Read also: How to make a car jack

The principle of operation of a pulley block is similar to the principle of operation of a lever in the physics of simple mechanisms. The role of the lever in this case is played by the cable itself. In the case of a simple block of two pulleys, the movable pulley divides the rope into 2 parts and in order to lift the load the same distance, a rope twice as long will be required. The work of lifting the load is performed in the same volume. And the effort, due to the fact that the length of the rope has become twice as long, becomes half as much.

If there are more than 2 pulleys in the system, the gain in strength is approximately equal to the number of blocks. In the case of 3 blocks, the effort will be 3 times less, and 4 blocks will require only a quarter of the original effort.

General information about pulley hoists

A pulley block consists of 2 or more pulleys (blocks) connected using rope ropes or chains:

Simple pulleys can consist of 1 pulley and rope. In them, the roller is located above the load: on the ceiling, beam or support. The first end of the rope is connected to the hook and goes down to the load being lifted. A man pulls on the other end of a rope, lifting a heavy object. Complex lifting devices include several simple pulleys and provide greater gains in strength.

The operating principle of pulley blocks is based on the rule of leverage. A rope is thrown over a stationary pulley. The load is raised to a height by applying forces commensurate with the weight of the object being lifted. The length of the rope or chain should be comparable to the height to which the load is lifted. To reduce the amount of effort required, it is necessary that the moving block moves parallel to the load.

There are the following types of pulleys:

Pull blocks are used for the following operations:

Various types of cranes, hydraulic and electric drives are equipped with pulleys. They were also used in older elevator prototypes.

Complex block system how to calculate power gain

If the system is designed in such a way that one simple pulley pulls another simple pulley, then this is already a complex system of blocks. To theoretically calculate the gain in strength, it is necessary to conditionally divide a complex chain hoist into simple ones and multiply the values of the gain from simple chain hoists.

For example, if the system consists of 4 blocks, and the first conditional simple pulley has a gain of 3. It pulls the second simple two-block pulley, also with a gain of 3. The total force that will need to be applied will be 9 times less. It is the 4-block complex chain hoist that is most often used by rescuers.

Methods for attaching a rope to a lifting mechanism

When creating complex pulley blocks, there are often situations when a cable of the required length for attaching the moving block is not at hand.

Crane for gas blocks

Methods for attaching a cable using general-purpose rigging:

- Using a cord. Using a self-tightening knot, the cord is tied to the main cable. As the load is lifted, the grappling knot moves along the main rope, thereby allowing the height of the load to be increased.

- Using clamps. In the case of using a steel cable, it is not possible to use a cord, so it is necessary to use special clamps.

Pulley hoists: from calculations to reeving

A chain hoist is a portable block system designed for lifting and moving loads of varying degrees of severity. This device is used in the construction industry, logistics, mountaineering and during rescue operations. To make a chain hoist with your own hands, you need to know the design features of this device, methods of attaching ropes to a forklift, and reeving technology.

We create a simple lifting mechanism with our own hands

Construction of a crane is not a quick task and is justified if it is required frequently or the volume of work is large enough. In cases where the load needs to be lifted urgently or this is a one-time operation, you can use improvised means.

To create a simple lifting device you will need a cord and two blocks. One block and the end of the rope are fixed motionless on the support. This will be the highest point to which the load can be lifted. We attach the second block to the load using slings or a hook. We first pull the rope along the block attached to the load, then pass it through the upper block. The gain in power will be 2 times. Using your own weight, you can easily lift a load weighing 100 kilograms to the required height.

DIY mini crane

If you add the ability to move the upper block along a guide, for example along a rail, you can get a do-it-yourself jib crane. It is useful in garage conditions for moving heavy machine parts.

It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load. The same rule applies to a crane - standing under the arrow is prohibited.